Why Your Freezer Door is Critical for Energy Efficiency and Food Safety

A freezer door serves as the primary barrier between your controlled cold environment and the outside world, making it one of the most important components of any refrigeration system. Whether you're operating a mortuary cooler, commercial kitchen, or warehouse facility, understanding how to find and replace your freezer door can save you significant money and prevent costly temperature failures.

Key Freezer Door Functions:

- Airtight sealing - Prevents warm air infiltration and cold air loss

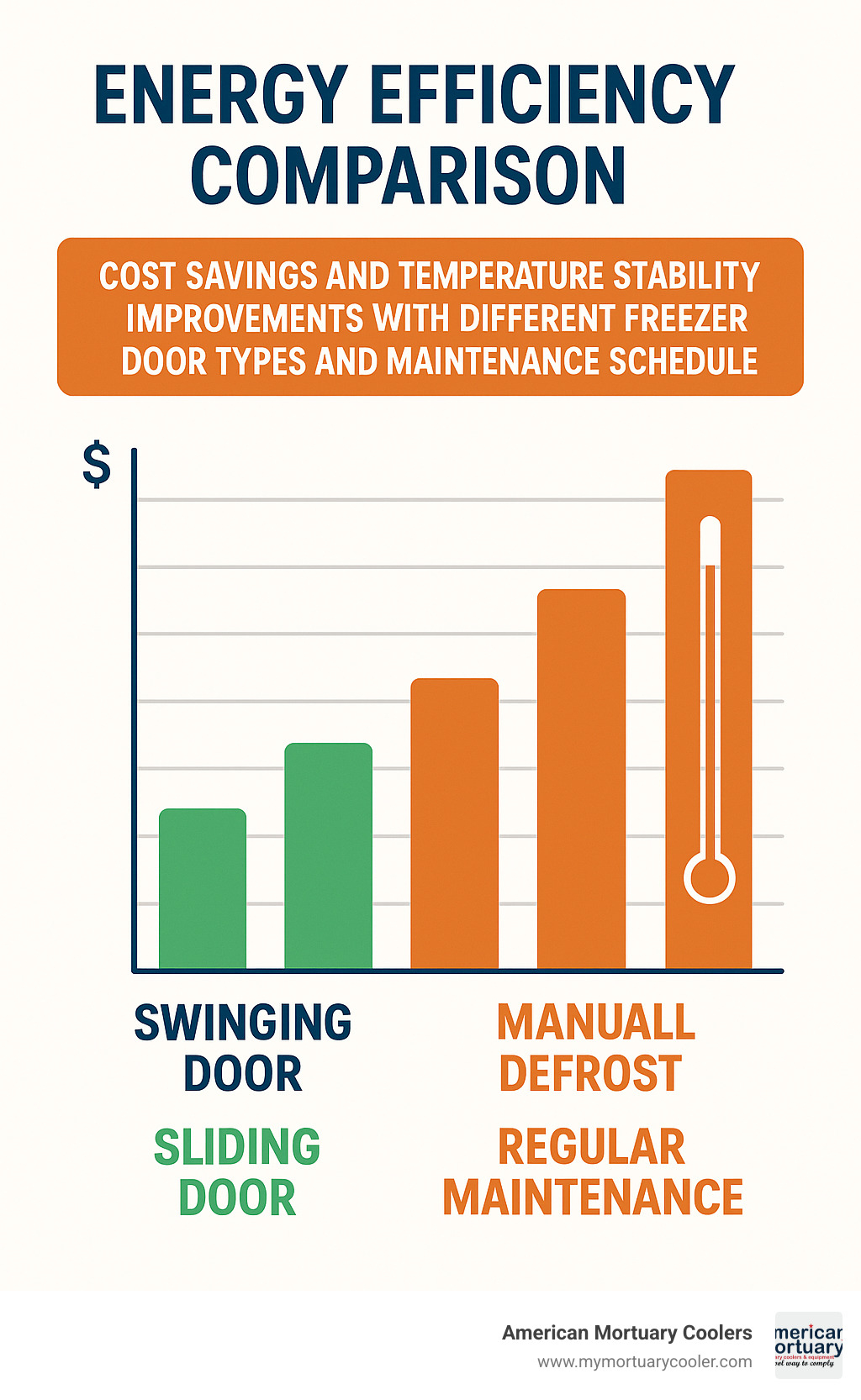

- Energy efficiency - A compromised gasket can increase energy consumption by up to 25%

- Temperature control - Maintains consistent internal temperatures for product preservation

- Safety features - Includes pressure relief and emergency release mechanisms

Common Freezer Door Types:

- Swinging doors - Most common, require floor clearance

- Sliding doors - Space-saving for tight areas

- Vertical-lift doors - Maximize space under high ceilings

- High-speed roll-up - Commercial applications with frequent access

The research shows that regular inspection and maintenance of freezer door gaskets can extend appliance lifespan and prevent up to 20% of food spoilage incidents caused by temperature fluctuations. Signs you need a replacement include visible cracks in the gasket, difficulty closing the door, increased energy bills, or frost buildup around the seal.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in freezer door solutions for funeral homes and specialized facilities. With years of experience helping facilities maintain proper temperature control, I understand the critical role that quality freezer doors play in preserving sensitive materials and controlling operational costs.

Explore more about freezer door:

Understanding the Freezer Door and Its Functions

When you really look at a freezer door, you're seeing an impressive piece of engineering disguised as something simple. Think of it as the unsung hero of your refrigeration system – working 24/7 to keep everything at the perfect temperature while making it easy for you to access what you need.

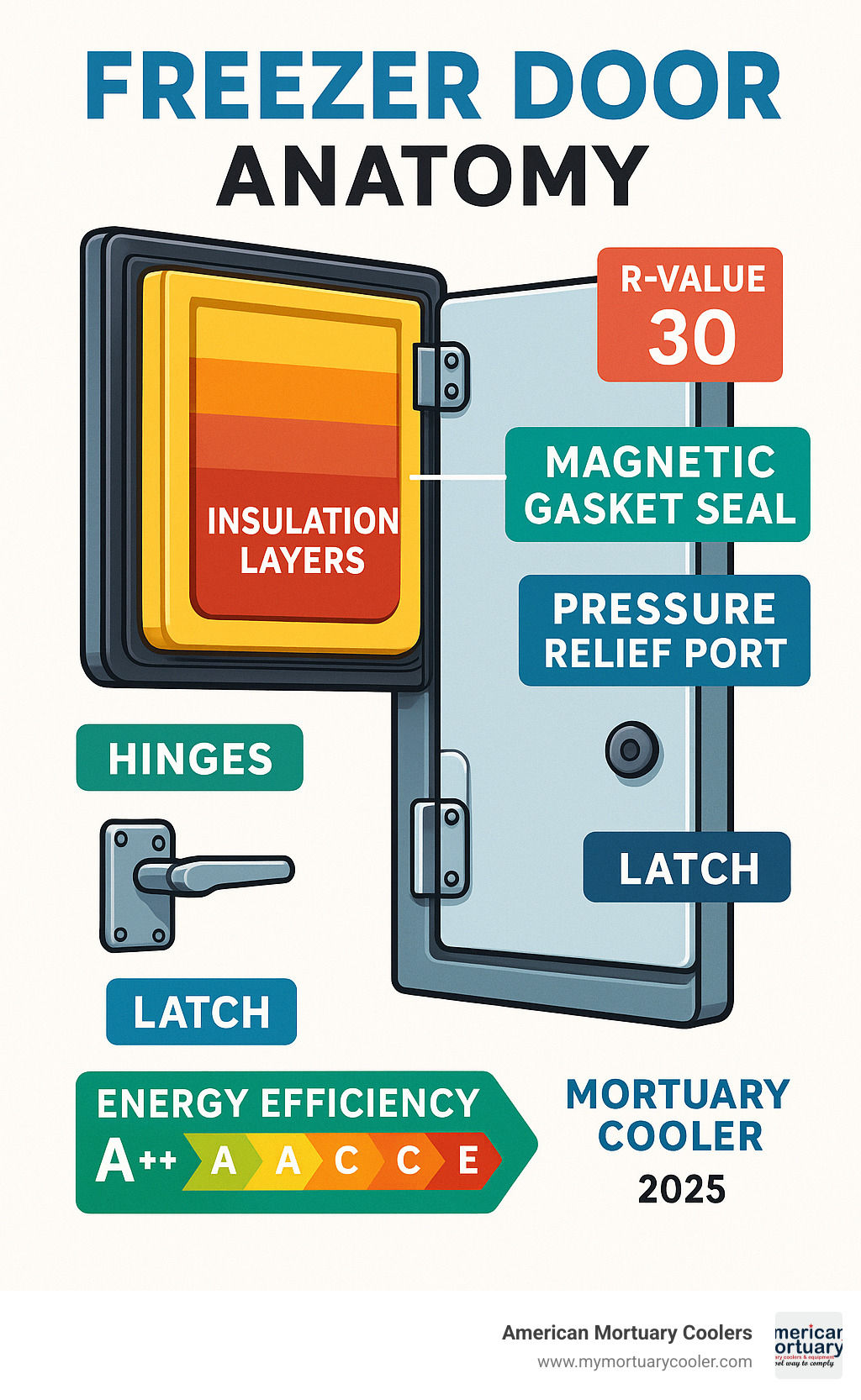

The magic happens in the layers you can't see. Inside that door panel, multiple layers of insulation work together like a thermal fortress. Engineers measure this protection using something called an R-value – basically, how well the door resists heat transfer. Commercial freezer doors can achieve R-values up to R-40 for extreme temperature requirements, especially crucial for specialized applications like mortuary coolers and pharmaceutical storage.

The magnetic seal system is where the real science happens. When you close the door, the gasket compresses against the frame, creating what's essentially a vacuum seal. Most modern gaskets have embedded magnetic strips that pull the door tight against the frame, ensuring that airtight barrier stays strong even in busy environments.

For more detailed information about temperature control systems, check out this Scientific research on temperature loss.

Main Functions of a Freezer Door

The airtight seal is your door's most important job. Even tiny gaps can cause big problems – we're talking about a compromised gasket increasing energy consumption by up to 25%. That's not just bad for your utility bills; it's terrible for whatever you're trying to preserve.

Cold air retention is where your door really earns its keep. Warm air wants to get in, and cold air wants to escape – it's just physics. Your door has to win that battle constantly, preventing the temperature swings that cause frost buildup and ice formation.

Safety latches might seem like an afterthought, but they're lifesavers – literally. Every commercial freezer door should have emergency release handles that let someone exit safely if they get trapped inside. Pressure relief ports prevent those scary vacuum lock situations where pressure differences make doors impossible to open.

Common Types of Freezer Doors

Swinging doors are the workhorses of the freezer world. They're reliable, straightforward, and get the job done day after day. The only catch? They need floor space to swing open, which can be a problem in tight quarters.

Sliding doors solve the space problem beautifully. They glide horizontally along tracks instead of swinging out, making them perfect for narrow aisles or cramped areas where every square foot matters.

Vertical-lift doors are the smart choice when you have high ceilings but limited floor space. These doors lift straight up rather than swinging out, making them excellent for warehouses and facilities where floor area is precious.

High-speed roll-up doors like the Dynaco M2 represent the cutting edge of freezer door technology. These speed demons can operate at up to 96 inches per second, dramatically reducing cold air loss in high-traffic areas.

Vinyl strip curtains offer flexibility when you need frequent forklift or cart access but still want some thermal protection. They're not as effective as solid doors, but they're better than nothing when you need that middle ground.

| Door Type | Best For | Clearance Needed | Key Benefit |

|---|---|---|---|

| Swinging | General use | Full door width | Reliable, cost-effective |

| Sliding | Tight spaces | Minimal floor space | Space-saving |

| Vertical-lift | High ceilings | Overhead clearance | Maximum floor space |

| High-speed roll-up | High traffic | Minimal | Energy efficient |

| Strip curtains | Frequent access | None | Flexible access |

Choosing, Finding, and Replacing a Freezer Door

Selecting the right freezer door replacement doesn't have to feel overwhelming. After helping facilities from Tennessee to California steer this process, I've learned that success comes down to three key factors: accurate measurements, understanding your options, and knowing when to call in the professionals.

The first step is getting precise measurements of your existing door opening. You'll need the width, height, and depth of the frame, plus any special considerations like nearby walls or equipment that might affect installation. Don't forget to measure the swing radius if you're staying with a traditional swinging door - nothing's more frustrating than finding your new door won't open properly because of a nearby wall.

Retrofit frames have become a game-changer in the replacement world. These clever systems fit right over your existing opening, eliminating the need for major construction work. Think of them as a custom-fitted adapter that makes your new door work perfectly with your old setup. The installation cost is typically much lower than a complete rebuild, and the process is significantly faster.

When searching for replacement parts, part numbers are your best friend. Every door manufacturer uses specific model numbers and part codes that ensure you get exactly what you need. Write down everything you can find on your existing door - model numbers, serial numbers, and any specification plates. This information prevents costly ordering mistakes and ensures compatibility.

Professional installation becomes especially important for larger commercial applications or specialized environments like mortuary coolers where temperature precision is critical. The installation cost might seem significant upfront, but it's often worth it for the warranty protection and peace of mind that comes with proper installation.

For detailed guidance on replacement options and specifications, check out our comprehensive resource on Replacement Walk-In Cooler Doors.

Signs Your Freezer Door Needs Replacement

Knowing when your freezer door has reached the end of its useful life can save you from emergency situations and costly energy waste. The signs aren't always obvious at first, but they tend to get progressively worse over time.

A worn gasket is usually the first red flag. Look for cracks, tears, or areas where the rubber has become hard and brittle. Sometimes the gasket looks fine but has lost its flexibility - it won't compress properly against the frame anymore. This creates gaps that let warm air sneak in and cold air escape.

Warped door panels are another clear indicator that replacement time has arrived. Temperature stress, age, and normal wear can cause metal panels to bend or warp over time. Even a slight warp prevents the door from sealing properly, creating energy-wasting gaps that get worse over time.

Keep an eye on your energy bills too. If your electricity costs have been creeping up without explanation, a failing freezer door could be the culprit. Research shows that a compromised door seal can increase energy consumption by up to 25% - that's money literally escaping through the cracks.

Frost buildup around the door frame or inside the freezer compartment is nature's way of telling you that warm, humid air is getting where it shouldn't. This not only wastes energy but can also damage your stored products and create maintenance headaches down the road.

Step-by-Step Freezer Door Gasket Replacement

Sometimes you don't need to replace the entire freezer door - just the gasket. This is often the most cost-effective solution, especially when the door itself is still in good structural condition.

Start with the dollar-bill test - it's simple but surprisingly effective. Place a dollar bill between the gasket and the door frame, close the door, and try to pull the bill out. If it slides out easily without resistance, your seal is compromised and needs attention.

DIY gasket replacement is definitely doable for most people, but you'll need the right supplies and a bit of patience. The essential items include a replacement gasket (always go with OEM when possible), basic screwdrivers, a utility knife for trimming, cleaning supplies, and a hair dryer to make the new gasket more flexible during installation.

Required Supplies:

- Replacement gasket (OEM recommended)

- Screwdriver set

- Utility knife

- Cleaning supplies (mild detergent, warm water)

- Hair dryer (for gasket flexibility)

- Measuring tape

The actual replacement process starts with carefully removing the old gasket. Pay attention to how it's attached - some use screws, others use clips or adhesive strips. Clean the mounting surface thoroughly with mild detergent and warm water. Any dirt or residue will prevent the new gasket from sealing properly.

When installing the new gasket, start at one corner and work your way around systematically. The hair dryer helps make the rubber more pliable and easier to position. Make sure the gasket is properly seated in its channel and aligned correctly before securing it in place.

For complex door systems or when warranty coverage is important, professional installation is often the smarter choice. We provide professional installation services throughout our coverage area, ensuring your new gasket performs optimally from day one.

Maintenance, Cleaning, and Troubleshooting

Taking care of your freezer door doesn't have to be complicated, but it does need to be consistent. After years of helping facilities across the country, I've seen how proper maintenance can make the difference between a door that lasts decades and one that fails within a few years.

The gasket is your door's hardest-working part, creating that crucial seal every time you close the door. Monthly gasket cleaning should become as routine as checking your oil. Use warm water and mild detergent to gently clean away grease, food particles, and any mold that might be starting to form.

Pressure relief ports are small but mighty components that prevent your door from becoming impossible to open. When they get blocked by ice or debris, you might find yourself struggling to open a door that just closed easily. A quick visual check during cleaning can save you from this frustrating situation.

Hinge maintenance is straightforward but often skipped. Loose hinges throw off door alignment, which compromises your seal and makes the door harder to close properly. A few minutes with a screwdriver can often solve problems that might otherwise require professional service.

For more detailed technical information about how gaskets wear over time, check out this Scientific research on gasket wear.

Preventive Maintenance Checklist

Creating a simple maintenance routine prevents most freezer door problems before they start. Most of these tasks take just a few minutes and don't require special tools or expertise.

Monthly cleaning goes beyond just wiping down surfaces. Start with the gasket, using that mild detergent solution we mentioned. Pay attention to the corners and folds where debris likes to hide. Clean the door surfaces inside and out, and don't forget the hardware – hinges, handles, and latches all benefit from regular cleaning.

Visual inspection becomes second nature once you know what to look for. Check for cracks in the gasket, especially at the corners where stress concentrates. Look for loose screws, ice buildup around the seal, and any signs that the door isn't closing flush with the frame.

Lubricant application keeps moving parts working smoothly. Use only the lubricants recommended by your door manufacturer. A light application to hinges and moving parts every few months keeps everything operating like new.

Temperature logging helps you monitor your freezer's performance. If you notice temperature fluctuations, your door seal might be the culprit.

Troubleshooting Common Freezer Door Problems

Freezer door leaks are the most common issue we see, and they're often easier to fix than people think. The dollar-bill test is your first diagnostic tool. If the bill slides out easily from any part of the door seal, you've found your leak location.

Ice buildup around your door frame is like a warning light – it's telling you something needs attention. This usually means warm, humid air is getting inside where it doesn't belong. The ice itself isn't the problem; it's a symptom of a seal issue or blocked pressure relief.

Hard-to-close doors can be frustrating. Before assuming you need a new door, check the pressure relief system first. Sometimes a door that closes fine but becomes difficult to reopen immediately has a simple pressure equalization issue. Misaligned hinges are another common culprit that's usually fixable with basic tools.

Vacuum lock situations are more serious, especially in walk-in freezers where someone could get trapped. If your door becomes impossible to open right after closing, this indicates a pressure relief problem that needs immediate attention.

Most of these problems have straightforward solutions when caught early. A well-maintained freezer door not only saves energy and preserves your products – it also keeps your facility running smoothly day after day.

Industry-Specific Considerations: Mortuary Coolers & Beyond

Different industries have unique requirements for freezer door systems. Mortuary coolers, our specialty at American Mortuary Coolers, require precise temperature control and specialized features for handling sensitive materials. Our custom solutions are designed specifically for funeral industry needs, with direct delivery available across the contiguous 48 states.

Pharmaceutical facilities require doors that meet strict regulatory standards and maintain precise temperature control for sensitive medications and biological materials. Food service operations need doors that can withstand frequent use while maintaining sanitary conditions. High-speed doors are often preferred in these environments to minimize temperature fluctuations during busy periods.

Warehouses handling frozen goods often require ASRS (Automated Storage and Retrieval System) compatible doors that can integrate with robotic systems. These doors must operate reliably in automated environments while maintaining thermal efficiency.

For specialized mortuary applications, explore our comprehensive guide to Mortuary Cold Room Doors.

High-Performance & High-Speed Door Benefits

The Dynaco M2 high-speed freezer door represents the pinnacle of freezer door technology. With opening speeds up to 96 inches per second and closing speeds up to 70 inches per second, these doors minimize cold air loss while maintaining high traffic flow efficiency.

Rapid cycle times reduce energy costs by minimizing the time the door remains open. Energy savings from high-speed doors can be substantial by reducing air exchange between spaces, helping maintain consistent temperatures while reducing the workload on refrigeration systems.

Workflow efficiency improves dramatically with high-speed doors, as staff can move quickly through openings without waiting for slow door cycles. This is especially important in commercial kitchens and distribution centers where time is critical.

Selecting the Right Freezer Door for Specialized Spaces

Clearance limitations often dictate door type selection. Measure available floor space and ceiling height carefully before choosing between swinging, sliding, or vertical-lift options. Swinging doors require the most floor clearance, while sliding doors need adequate wall space for the door panel.

Hygiene standards in medical and food service applications may require specific materials, finishes, and cleaning procedures. Stainless steel surfaces and specialized gasket materials may be necessary to meet regulatory requirements.

Regulatory compliance varies by industry and application. Mortuary facilities, pharmaceutical storage, and food service operations each have specific requirements that must be met. We help ensure compliance across all our installations.

Frequently Asked Questions about Freezer Doors

Let's tackle the most common questions we hear from our customers across the country. After years of helping funeral homes and commercial facilities with their freezer door needs, these are the issues that come up time and again.

What is a freezer door gasket and why does it fail?

Think of a freezer door gasket as the unsung hero of your cooling system. This flexible rubber or silicone seal wraps around your door's perimeter, creating that crucial airtight barrier that keeps your cold air where it belongs. Most modern gaskets have magnetic strips embedded inside them, which gives you that satisfying "thunk" when the door closes properly.

But here's the thing about gaskets - they're working hard every single day. Every time someone opens and closes that door, the gasket flexes and compresses. Add in the constant temperature changes from cold to warm and back again, plus exposure to cleaning chemicals, and you've got a component that's under serious stress.

The typical gasket lives about 5-7 years, but that depends heavily on how often your door gets used and how well you maintain it. We've seen gaskets in busy facilities fail in just 2-3 years, while well-maintained ones in low-traffic areas can last a decade.

You'll know your gasket is crying for help when you see visible cracks or tears, notice the rubber getting stiff and inflexible, or find yourself fighting to get the door to close properly. Rising energy bills and frost buildup around the seal are also dead giveaways that your gasket isn't doing its job anymore.

How do I measure for a replacement freezer door?

Getting accurate measurements for your freezer door replacement is absolutely critical - and honestly, it's where a lot of people trip up. Here's the approach that works every time.

Start by measuring your door opening at multiple points - width at the top, middle, and bottom, then height on both sides. Why? Because buildings settle over time, and what looks square to your eye might be off by half an inch or more. Always use the largest measurements you get to ensure your new door will fit properly.

Don't forget about the door thickness and note which way your door swings. Is it right-hand or left-hand? Where's the handle positioned? Are there any special features like windows or access ports? Take plenty of photos of your existing setup - trust me, you'll reference these later when you're placing your order.

For retrofit installations, you'll also need to measure any existing frame components that might affect the new door's fit. If all this measuring feels overwhelming, we offer professional measurement services. Sometimes it's worth having an expert handle this step to avoid costly mistakes.

Are high-speed freezer doors worth the investment?

This is where the numbers really tell the story. High-speed freezer doors like the Dynaco M2 aren't cheap upfront, but they can pay for themselves surprisingly quickly in the right situation.

If you're running a busy facility where people are constantly going in and out of your freezer space, traditional doors become energy vampires. They stay open longer, let more cold air escape, and force your refrigeration system to work overtime. High-speed doors solve this by opening and closing in seconds rather than the leisurely pace of conventional doors.

We typically see facilities with frequent door cycles - think busy commercial kitchens, distribution centers, or high-traffic storage areas - recoup their investment within 2-3 years through energy savings alone. But the benefits go beyond just lower utility bills. Your products maintain better temperature consistency, you get less frost buildup to deal with, and your staff can move through the space more efficiently.

Now, if you're operating a low-traffic mortuary cooler that gets opened maybe a few times a day, a high-speed door probably isn't necessary. Traditional doors work just fine for those applications. But for facilities where that door is opening dozens of times daily? The investment usually makes perfect sense.

The key is honestly evaluating your usage patterns and calculating the potential energy savings based on your specific situation. We're always happy to help you run those numbers and determine if high-speed doors make sense for your facility.

Conclusion

Your freezer door is more than just an entry point - it's the guardian of your entire refrigeration system. From the simple gasket that creates an airtight seal to the complex high-speed doors that maximize efficiency, understanding these systems helps you make smart decisions that save money and protect your valuable inventory.

We've covered everything from basic maintenance like the dollar-bill test to advanced solutions like the Dynaco M2 high-speed doors. The key takeaway? Don't wait until problems become emergencies. A small gasket replacement today can prevent thousands in energy waste and product loss tomorrow.

At American Mortuary Coolers, we've seen how the right freezer door solution transforms facility operations. Whether it's a funeral home in Johnson City needing precise temperature control or a commercial facility in Los Angeles requiring high-traffic durability, we understand that every situation is unique.

Our Tennessee-based team brings decades of specialized experience to every project. We don't just sell doors - we partner with facilities across all 48 contiguous states to ensure optimal performance. From Atlanta to Chicago, Dallas to Los Angeles, our regional presence means you get both local understanding and national expertise.

What sets us apart is our focus on custom solutions that actually work. While others offer one-size-fits-all approaches, we take time to understand your specific needs. Need a mortuary cooler door with specialized gaskets? We've got you covered. Require high-speed doors for a busy commercial kitchen? We can help with that too.

The funeral industry has unique requirements that general refrigeration companies often miss. That's why we specialize exclusively in mortuary applications, bringing deep industry knowledge to every installation. Our direct delivery model eliminates middleman delays and ensures you get exactly what you ordered, when you need it.

For comprehensive guidance on specialized applications, explore our detailed resource on morgue refrigeration door manufacturers. This guide covers everything from regulatory compliance to energy efficiency optimization.

A properly maintained freezer door is an investment that pays dividends for years. Regular cleaning, timely gasket replacement, and professional installation when needed will keep your system running efficiently while minimizing operational costs.

Whether you're dealing with a simple gasket issue or planning a complete system upgrade, we're here to help. Your facility's temperature control is too important to leave to chance - partner with specialists who understand both the technical requirements and the human impact of reliable refrigeration systems.