Why Pet Mortuary Coolers Are Essential for Animal Care Facilities

Pet mortuary coolers provide dignified, temperature-controlled storage for deceased animals while families make final arrangements or facilities prepare for cremation services. These specialized refrigeration units maintain optimal preservation conditions and support the emotional needs of grieving pet owners.

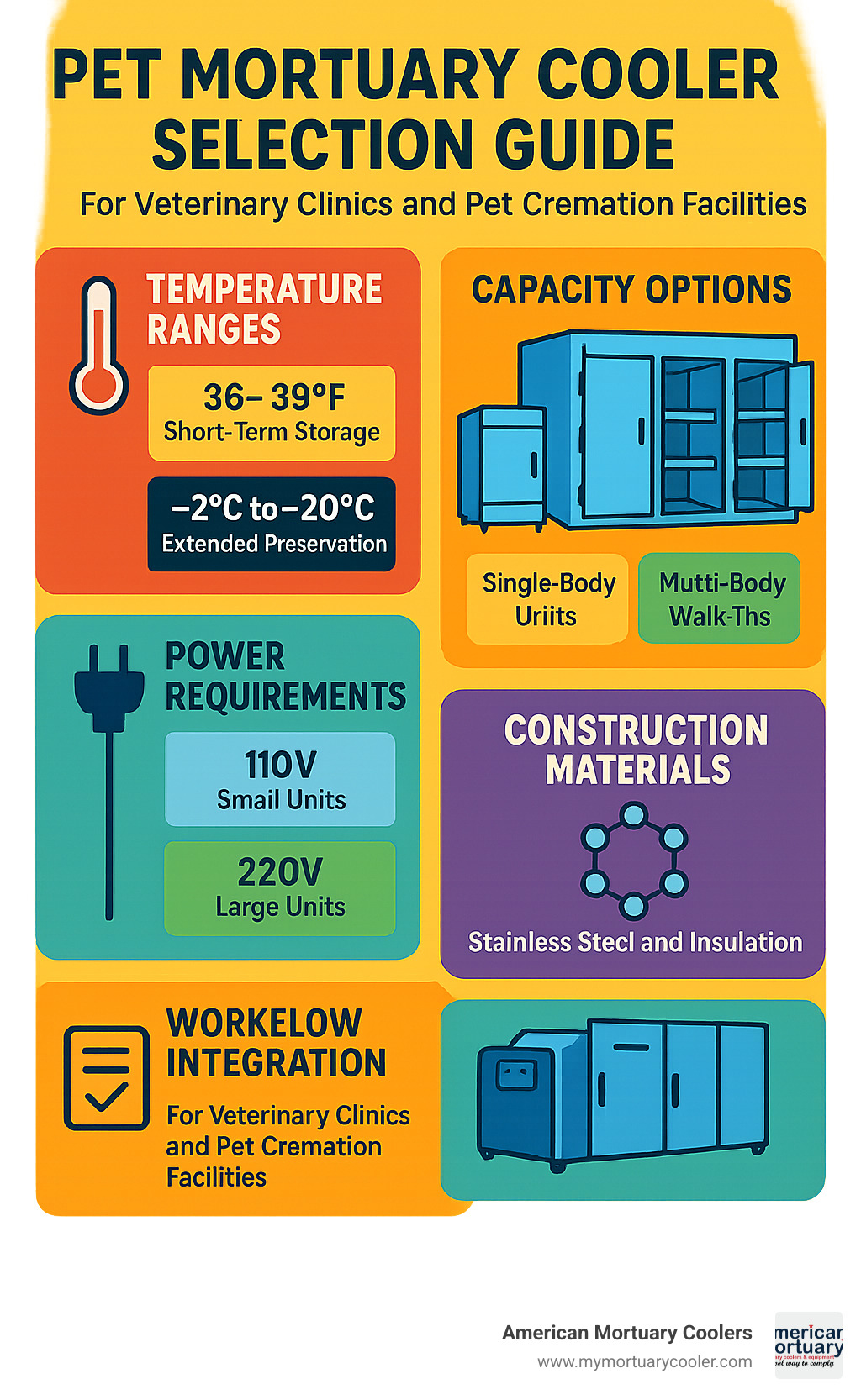

Key Features of Pet Mortuary Coolers:

- Temperature Range: 36-39°F for short-term storage, -2°C to -20°C for extended preservation

- Capacity Options: Single-body units to 12-body walk-in configurations

- Power Requirements: Standard 110V plug-and-play or 220V for larger units

- Construction: Stainless steel interiors with PUF insulation for hygiene and efficiency

- Storage Types: Upright cabinets, roll-in racks, or walk-in chambers with adjustable shelving

Whether you're a veterinary clinic handling 2-3 pets weekly or a pet crematory processing dozens daily, the right cooler ensures proper preservation while providing families the time they need to say goodbye. As one funeral director noted, "The right equipment not only creates operational efficiency but also extends compassion to clients."

Modern pet mortuary coolers range from compact 2-body units starting around $6,900 to large walk-in systems accommodating 25+ animals. Energy-efficient models consume just 4-6 kWh daily while maintaining consistent temperatures that prevent decomposition and control odors.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in pet mortuary coolers for veterinary clinics, animal hospitals, and pet cremation facilities across the United States. With years of experience helping facilities choose the right cooling solutions, I've seen how proper equipment selection impacts both operational efficiency and the quality of care provided to grieving families.

Pet mortuary coolers terms to know:

Understanding Pet Mortuary Coolers

When a beloved pet passes away, families need time to grieve and make final arrangements. That's where pet mortuary coolers become absolutely essential. These specialized refrigeration units do far more than just keep things cold - they preserve dignity during one of life's most difficult moments.

Pet mortuary coolers maintain precise temperatures between 36-39°F for standard preservation needs. For longer-term storage, these units can reach much colder temperatures from -2°C to -20°C. This careful temperature control slows decomposition and prevents odors, giving families the precious time they need to say goodbye properly.

But here's what makes these coolers truly special: they're designed specifically for the unique challenges of animal care facilities. Unlike throwing a blanket over a regular refrigerator and hoping for the best, these units feature improved insulation, precise digital controls, and construction materials that meet strict hygiene standards for biological remains.

The emotional aspect can't be overlooked either. Proper preservation maintains the appearance of deceased pets, which is crucial when families want to have final visits or open-casket viewings. As many veterinarians will tell you, having the right equipment helps extend compassion to grieving clients during their most vulnerable moments.

What Is a Pet Mortuary Cooler?

A pet mortuary cooler is essentially a specialized refrigeration unit built from the ground up for short-term storage of deceased animals. Think of it as the difference between a regular car and an ambulance - both have wheels and engines, but one is purpose-built for a critical job.

These units serve veterinary hospitals, animal control facilities, humane societies, pet cemeteries, and cremation services. Basically, any facility that handles deceased animals needs reliable preservation equipment while arrangements are made or before cremation services can be performed.

The engineering behind these coolers is quite impressive. Take the MG Animal Mortuary Chamber, for example - it preserves animal bodies at temperatures ranging from -2°C to -20°C, with each chamber capable of holding up to 250 kg. Despite this heavy-duty performance, these units consume just 4-6 units of power per day, making them surprisingly energy-efficient for continuous operation.

What really sets these apart from standard commercial refrigerators is the attention to detail. The insulation is thicker, the temperature controls are more precise, and every material is chosen to meet hygiene standards for handling biological remains safely and respectfully.

How Pet Mortuary Coolers Differ from Human Units

Here's where things get interesting - pet mortuary coolers actually offer several advantages over their human counterparts. The biggest difference? Size range and flexibility. While human units are pretty standardized, pet coolers range from compact single-body units perfect for small veterinary clinics to massive 12-body systems for high-volume facilities.

Multi-chamber privacy is another game-changer. These systems allow simultaneous storage of multiple pets while maintaining complete separation of remains. This is absolutely critical for facilities offering private cremation services, where families need rock-solid assurance that their pet's remains won't be mixed with others.

The load capacities tell an interesting story too. Human mortuary coolers are designed for fairly predictable adult weights, but pet coolers need to handle everything from tiny hamsters under one pound to Great Danes exceeding 150 pounds. Some systems can accommodate up to 250 kg per tray - that's serious versatility.

From a regulatory standpoint, pet mortuary equipment generally faces more flexible requirements compared to human systems. Don't get me wrong - facilities still need to meet local health department standards and EPA guidelines for biological waste handling. But the approval process is typically more straightforward.

The bottom line? Pet mortuary coolers are purpose-built for the unique needs of animal care facilities, offering the flexibility, capacity range, and specialized features that human units simply weren't designed to provide.

Types, Sizes & Configurations of Pet Mortuary Coolers

Choosing the right pet mortuary coolers depends on your facility's unique needs and space constraints. From compact single-body units perfect for small veterinary practices to expansive walk-in systems that can handle dozens of animals, there's a configuration for every situation.

The beauty of modern pet mortuary equipment lies in its flexibility. Whether you're a small animal clinic seeing just a few cases monthly or a busy pet crematory processing hundreds of animals, the right cooler design can transform your workflow and improve the care you provide to grieving families.

Single vs. Multi-Body Options

Single-body coolers work beautifully for smaller veterinary clinics that handle one or two deceased pets per week. These compact units typically measure around 7'3" wide by 3'¾" long by 5'2" high and can accommodate pets up to 150-200 pounds. They're perfect when space is tight but you still need professional-grade preservation.

Multi-body systems serve higher-volume facilities with grace and efficiency. A 2-body cooler might be just right for small to medium practices, while 4-body, 6-body, and even 12-body configurations support busy animal hospitals and pet cremation services. The largest systems can process 60+ pets per day according to industry data - that's serious capacity.

Here's something smart to consider: when planning capacity, think about both your current needs and future growth. One Texas facility doubled their capacity using separation trays without doubling operating costs, demonstrating how thoughtful equipment choices can scale beautifully with business growth.

Upright, Roll-In & Walk-In Layouts

Upright cabinets offer the smallest footprint and work wonderfully in cramped prep rooms. These units typically feature front-opening doors and can accommodate 2-4 pets depending on size. They're like the Swiss Army knife of pet mortuary coolers - compact but surprisingly capable.

Roll-in configurations allow staff to slide stretchers or gurneys directly into the cooling chamber, which is a real back-saver. No more awkward lifting or maneuvering - just roll right in. These systems work particularly well for larger animals or facilities where staff mobility is a concern.

Walk-in coolers provide maximum capacity and flexibility. The slim-style 3-tier rolling rack models measure 57½" wide by 8' deep by 8' high and can accommodate numerous animals on adjustable shelving. Larger walk-in systems with oversized entrance doors can store 25+ animals while providing easy access for staff - it's like having a whole room dedicated to dignified preservation.

Budget-Friendly DIY Coolers (CoolBot)

For facilities working with tighter budgets, CoolBot systems offer an innovative alternative that's honestly pretty clever. By pairing a CoolBot controller with a standard air conditioning unit, facilities can build walk-in coolers at a fraction of traditional costs.

One mortuary director built an 8'×12' CoolBot walk-in cooler for approximately $5,000, providing capacity for twenty-five bodies. The system maintains stable temperatures of 37-38°F using a standard 12,000 BTU air conditioner - that's impressive efficiency for the price point.

CoolBot systems can also retrofit existing walk-in coolers after compressor failures, allowing facilities to restore functionality without major capital investment. The CoolBot Pro model includes WiFi connectivity for remote temperature monitoring and emergency alerts, so you can keep an eye on things even when you're not on site.

These DIY cooler solutions prove that quality preservation doesn't always require the biggest budget - sometimes it just requires the smartest approach.

Critical Features & Technical Specifications

When shopping for pet mortuary coolers, understanding the technical details can mean the difference between equipment that serves you well for years and a unit that becomes a constant headache. Let's break down what really matters – and why these features directly impact your daily operations.

The heart of any quality pet mortuary cooler lies in its ability to maintain precise temperatures. Most facilities need temperatures between 36-39°F for standard preservation, though some situations call for much colder storage at -2°C to -20°C for extended preservation needs. This isn't just about keeping things cold – it's about giving families the time they need to process their grief.

Modern units consume surprisingly little energy when properly designed. You're looking at 4-6 kWh per day for most well-built coolers, which translates to reasonable monthly electric bills even with continuous operation. The MG Animal Mortuary Chamber, for example, achieves this efficiency while maintaining consistent temperatures across multiple storage chambers.

Construction quality separates the reliable units from the ones that'll have you calling for repairs. PUF (polyurethane foam) insulation provides superior thermal performance compared to cheaper alternatives, while stainless steel 304 interiors resist corrosion and make cleaning between uses much easier. These materials cost more upfront but pay dividends in durability and hygiene.

| Feature | Stainless Steel Interior | Aluminum Interior |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Cleaning Ease | Superior | Moderate |

| Initial Cost | Higher | Lower |

| Longevity | 15+ years | 8-12 years |

| Hygiene Standards | Medical grade | Commercial grade |

For facilities interested in alternative preservation methods, scientific research on alkaline hydrolysis shows how proper temperature control integrates with newer technologies in pet aftercare.

Temperature Range & Why It Matters for Pet Mortuary Coolers

Getting the temperature right isn't just about preservation – it's about rapid cooling that immediately slows bacterial growth and maintains the animal's appearance for family viewings. When a grieving family wants to say goodbye, proper temperature control ensures their pet looks peaceful and dignified.

The 36-39°F range works perfectly for short-term storage of up to several days. This temperature slows decomposition without freezing tissues, which can damage the animal's appearance. Many veterinary clinics find this range ideal for their typical workflow.

Extended storage at -2°C to -20°C becomes essential when cremation services are delayed or when facilities need to hold remains for postmortem examinations. Veterinary diagnostic labs particularly benefit from these lower temperatures, which can preserve samples for weeks without degradation.

Odor control represents another critical benefit of proper temperature management. Families visiting to say goodbye shouldn't encounter unpleasant smells – proper cooling prevents this entirely. Disease mitigation also improves with consistent temperature control, protecting both staff and other animals in the facility.

Modern digital controls with alarm systems provide peace of mind through continuous monitoring. When temperatures drift outside acceptable ranges, audible and visual alarms alert staff immediately. Some units even include smartphone connectivity, letting you monitor conditions remotely.

Materials, Construction & Hygiene Standards

Quality construction starts with the insulation, and PUF panels provide superior thermal efficiency compared to standard foam alternatives. This advanced insulation system reduces energy consumption while maintaining rock-solid internal temperatures, even when doors open frequently during busy periods.

Seamless welds eliminate crevices where bacteria could hide and multiply. This attention to detail matters when you're cleaning between uses – smooth surfaces wipe down easily and thoroughly. NSF-approved gaskets ensure tight seals around doors and access panels, preventing temperature loss and contamination.

The difference between quality materials and cheaper alternatives becomes obvious over time. Stainless steel 304 construction resists corrosion even with frequent cleaning and disinfection. Some facilities prefer copper construction for its natural antimicrobial properties, though stainless steel remains the industry standard for good reason.

External construction varies based on installation location and budget. Marine-grade aluminum offers excellent durability for outdoor installations, while indoor units may use painted steel exteriors to keep costs reasonable without sacrificing functionality.

Energy Efficiency & Running Costs

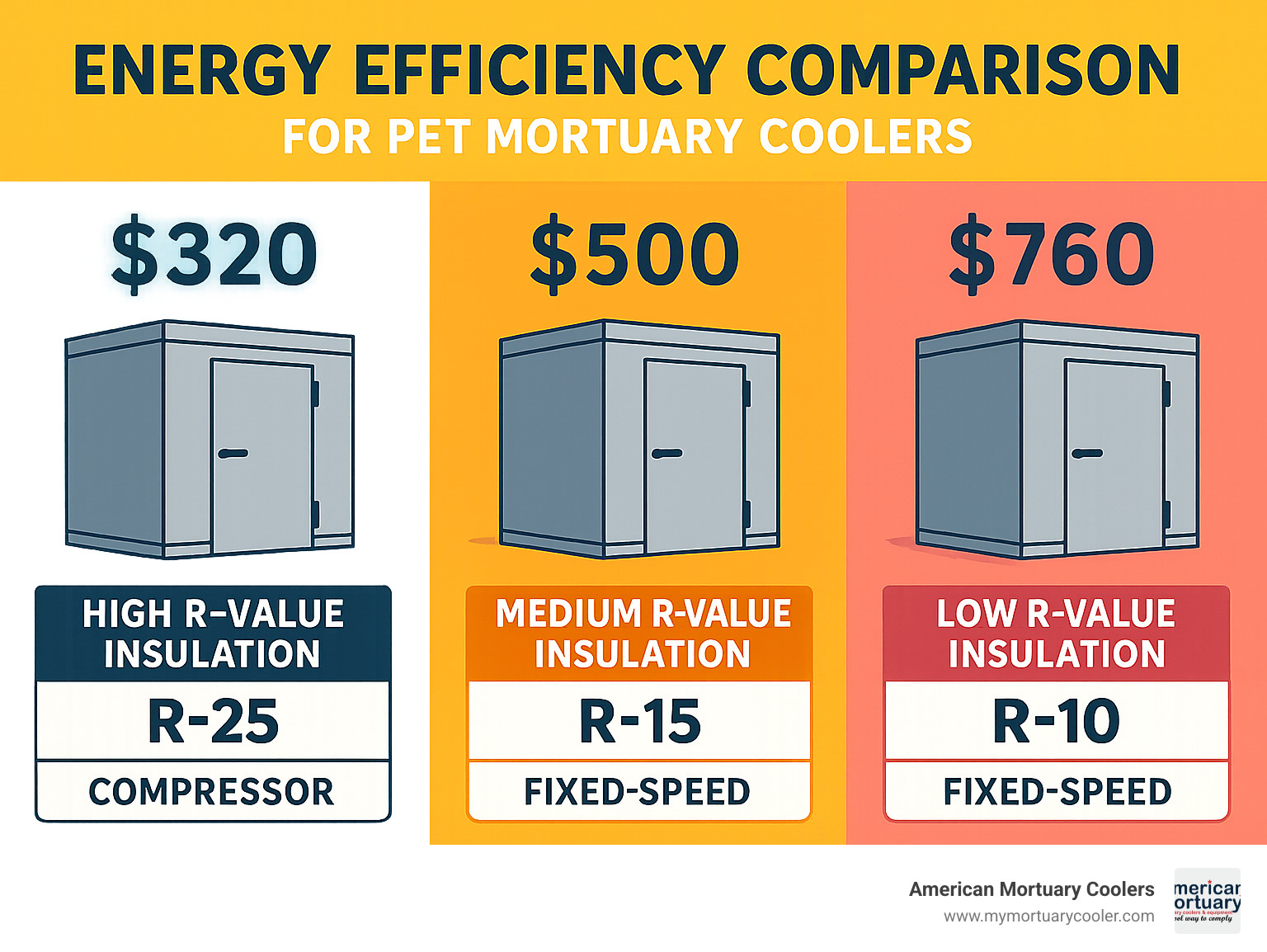

Nobody wants surprise electric bills, especially when operating cooling equipment continuously. Units with high R-value insulation cost more initially but deliver significant savings over their typical 15-year lifespan. Think of it as an investment that pays you back every month.

DOE/EISA compliance ensures units meet federal energy standards, specifically the Federal Energy Independence & Security Act of 2007 requirements for walk-in panel insulation. This isn't just regulatory compliance – it's your assurance that the unit won't waste energy through poor insulation.

Properly sized compressors operate more efficiently than oversized units that cycle on and off constantly. Inverter technology allows variable speed operation based on actual cooling demand, much like a car that gets better mileage at steady speeds than in stop-and-go traffic.

Some facilities explore solar assistance for remote locations or to reduce dependence on grid power. Battery backup systems ensure continued operation during power outages, protecting valuable remains from temperature fluctuations when the lights go out.

Selecting, Installing & Maintaining the Right Cooler

Choosing the right pet mortuary cooler doesn't have to feel overwhelming. After helping hundreds of facilities make this decision, I've learned that success comes down to honest assessment of your needs and planning for the future.

Start with your current volume, then add a healthy buffer. If you're handling five 30-pound pets daily, that's about 150 pounds of storage needed. But don't cut it close - aim for at least 200-pound capacity to handle busy weeks and unexpected situations. Trust me, running out of space during a difficult time creates stress nobody needs.

The key question isn't just "what do I need today?" but "where will my practice be in three years?" A small clinic adding cremation services or extending weekend hours will need different capacity than one maintaining current operations.

Capacity & Growth Planning

Smart planning means thinking modular from day one. Modular panel systems let you expand walk-in coolers by adding sections rather than starting over completely. It's like adding rooms to your house instead of moving to a bigger one.

Consider the variety of animals you serve. A practice treating everything from guinea pigs to German Shepherds needs flexible shelving systems that adapt to different body sizes. Separation trays work beautifully here - they let multiple small animals share space while keeping each one properly identified and separate.

One Colorado crematory I worked with started small but planned smart. When they tripled their volume, they simply expanded their multi-door system instead of buying all new equipment. The result? They could guarantee private cremations for every family without breaking their budget.

Future expansion should influence your initial choice. Adding cremation services, extending hours, or serving larger animals all impact storage needs. Plan for 25-50% excess capacity to handle seasonal fluctuations and growth spurts.

Installation Checklist & Site Prep

Installation requirements vary dramatically depending on what you choose. Compact upright coolers are plug-and-play simple - just adequate floor space and a standard 110V outlet. Walk-in systems need more planning: concrete pads, three-phase power, and room for assembly.

Floor load calculations become critical with larger units. A fully loaded 12-body cooler can weigh over 5,000 pounds. If you're on an upper floor, consult a structural engineer first. It's much cheaper than dealing with floor damage later.

Doorway clearance affects your delivery options. Pre-assembled units arrive ready to go but need adequate access for the delivery truck. Knocked-down units squeeze through tighter spaces but require 1-2 hours of assembly time with basic tools.

Utility requirements include electrical service (110V for smaller units, 220V for larger ones), potential drainage for condensate, and adequate ventilation. Self-contained units eliminate most drainage needs, while proper ventilation prevents moisture buildup and keeps compressors running smoothly.

Maintenance, Hygiene & Regulatory Compliance

Daily care is straightforward: check temperatures visually and wipe down interior surfaces. Weekly tasks include cleaning door seals and ensuring proper closure. Monthly inspections cover compressor operation and overall system performance.

Quarterly maintenance involves thorough coil cleaning and electrical connection checks. Annual service should include comprehensive refrigerant system evaluation and any required emissions testing based on local regulations.

Hygiene protocols must address both routine cleaning and deep sanitization. EPA-approved disinfectants eliminate pathogens while protecting your equipment materials. Some facilities add UV sanitization systems for extra protection.

Regulatory compliance varies by location but typically includes health department approvals, EPA biological waste guidelines, and OSHA worker safety requirements. State veterinary regulations may add specific requirements for facilities handling animal remains.

The good news? Most modern pet mortuary coolers are designed with maintenance in mind. Quality units from manufacturers like American Mortuary Coolers come with clear maintenance schedules and responsive support when you need help.

More info about pet cremation equipment provides comprehensive guidance on integrating cooling systems with cremation workflows, helping you create a seamless operation that serves families with dignity and efficiency.

Frequently Asked Questions about Pet Mortuary Coolers

When helping facilities choose the right pet mortuary coolers, we hear the same questions repeatedly. Here are the answers to the most common concerns we encounter from veterinary clinics and pet cremation facilities.

How cold should a pet mortuary cooler be set?

Most pet mortuary coolers work best at 36-39°F for short-term storage lasting 1-7 days. This temperature range does exactly what you need - it slows down decomposition without freezing the tissues. Think of it like a controlled pause button that preserves your pet patients with dignity.

For longer storage periods beyond a week, you'll want colder temperatures between -2°C to -20°C. The MG Animal Mortuary Chamber demonstrates this perfectly, offering this extended temperature range for facilities that need more flexibility.

Here's what really matters though - temperature consistency beats absolute temperature every time. Modern units use digital controls with ±1°F accuracy, so you won't get those temperature swings that can compromise preservation quality. Nobody wants to explain to a grieving family why their pet's condition deteriorated due to equipment failure.

What size cooler does a small animal clinic need?

This depends entirely on your patient volume, but we can give you some solid guidelines. A typical small animal clinic seeing 2-3 deceased pets weekly usually does well with a 2-body cooler. These units measure around 7'3" W × 3'¾" L × 5'2" H externally and can handle pets up to 150-200 pounds per compartment.

If you're handling 5+ pets weekly, consider stepping up to a 3-4 body system. Trust us on this - having extra capacity during busy periods saves you stress and gives families the time they need for decisions.

Size matters with pets. A single Great Dane might take up an entire compartment that was designed for two beagles. When we help clinics plan capacity, we always factor in the mix of animal sizes they typically see. It's better to have slightly more space than to find yourself scrambling during a difficult week.

How often should filters and gaskets be replaced?

Door gaskets typically last 3-5 years with proper care, but you should check them monthly for tears or compression problems. If a gasket isn't sealing properly, replace it immediately. Temperature fluctuations from bad seals can compromise preservation - and that's not a risk worth taking.

Air filters need attention every 3-6 months, though this varies based on your environment. Facilities in dusty areas or those with high traffic might need more frequent changes. It's one of those maintenance items that's easy to forget but makes a real difference in performance.

For the bigger components like compressor driers and filters, stick to manufacturer schedules. These typically get attention during annual service visits by qualified technicians. Think of it like getting your car serviced - regular maintenance prevents expensive breakdowns when you need your equipment most.

The key is staying ahead of problems rather than reacting to them. A simple monthly inspection routine catches most issues before they become expensive repairs.

Conclusion

Finding the right pet mortuary cooler for your facility doesn't have to be overwhelming. Whether you're a small veterinary clinic handling a few pets each month or a busy crematory processing dozens weekly, the perfect solution exists to meet your specific needs.

At American Mortuary Coolers, we've spent years helping facilities across the country make these important decisions. Based in Tennessee, we understand that every facility faces unique challenges - from tight budgets to space constraints to varying volume demands. That's why we specialize in custom solutions rather than one-size-fits-all approaches.

The facilities that succeed long-term are those that plan thoughtfully from the start. Accurate capacity planning with room for growth prevents costly upgrades down the road. Energy-efficient construction keeps operating costs manageable year after year. Proper temperature controls with reliable alarm systems protect both your reputation and the families you serve.

We've seen too many facilities struggle with equipment that seemed adequate initially but couldn't handle growth or seasonal fluctuations. Our approach focuses on understanding your current needs while building in the flexibility for future expansion. Whether that means modular walk-in systems that can grow with your business or compact upright units that maximize efficiency in tight spaces, we craft solutions that work.

The hygienic materials and construction we use aren't just about meeting regulations - they're about making your daily operations smoother. Easy-to-clean surfaces and seamless construction reduce maintenance time while ensuring the dignified care that grieving families deserve.

Our direct delivery service reaches facilities across the contiguous 48 states, and we handle everything from site preparation guidance to professional installation support. Many of our clients tell us that our ongoing maintenance expertise has been just as valuable as the initial equipment purchase.

The investment in quality pet mortuary coolers pays for itself through reliable operation and reduced energy costs. More importantly, it provides the peace of mind that comes from knowing you can offer proper care during families' most difficult moments. As one veterinarian recently told us, "The right equipment doesn't just improve our operations - it helps us extend genuine compassion when it matters most."

For facilities looking to maximize their investment, our More info about used equipment deals guide explores cost-effective options that don't compromise on quality or reliability.

Ready to discuss your specific needs? Contact us today for a custom quote on pet mortuary coolers designed to serve both your facility and the families who trust you with their beloved companions.