Understanding Walk-In Refrigerator Pricing for Your Business

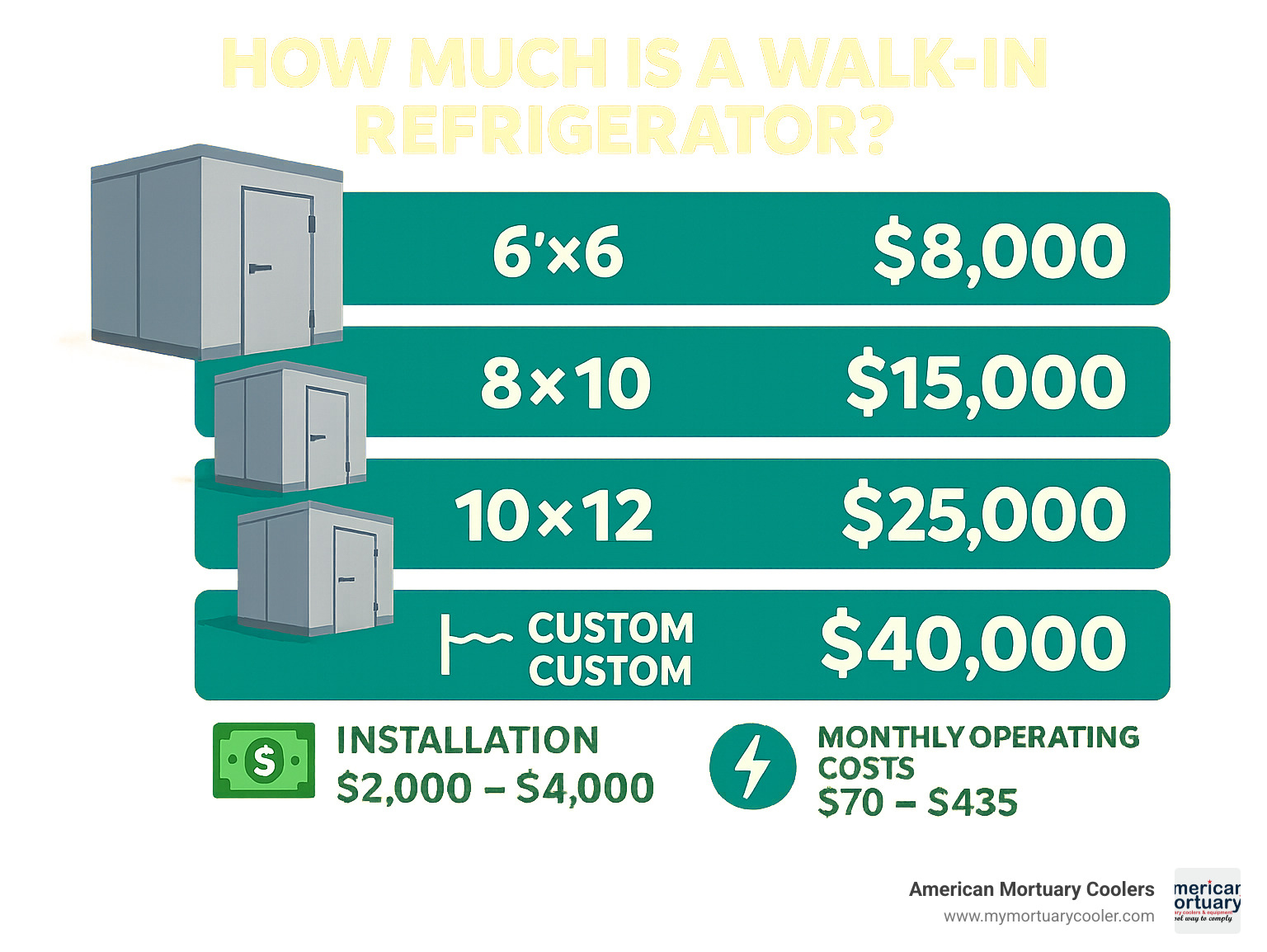

How much is a walk in refrigerator depends on several key factors, but here's what you can expect to pay:

- Average Cost: $15,000 for a standard unit

- Quick-Ship Models: $8,000 - $30,000 (delivery in 1-6 weeks)

- Custom Units: $10,000 - $40,000 (delivery in 10-12 weeks)

- Installation: Additional $2,000 - $4,000 for labor

- Operating Costs: $70 - $435 per month depending on size

Walk-in refrigerators are essential for businesses needing large-scale cold storage. Whether you're running a restaurant, funeral home, or medical facility, these units provide the space and temperature control needed to keep products safe and fresh.

Cost varies widely based on size, features, and customization. A basic 6×6 unit might cost $8,000, while a large custom unit can reach $40,000 or more. The refrigeration system alone accounts for 30-40% of the total cost.

Beyond purchase price, budget for installation, permits, and ongoing electricity costs. A standard 8×8×8 walk-in cooler uses about 8,000 kWh per year, costing roughly $1,200 annually to operate.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses understand walk-in refrigerator costs and find the right solution for their needs.

Walk-In Refrigerators 101: Definition, Uses & Temperature Basics

A walk-in refrigerator (also called a walk-in cooler) is a large, insulated storage room cold enough to walk into. These commercial units are assembled on-site, giving you enough space to literally walk inside and organize inventory on shelves or mobile racks.

These versatile units serve businesses across many industries. Commercial kitchens rely on them for storing fresh produce, meats, and prepared foods in bulk. Medical and scientific labs depend on them for precise temperature control of sensitive materials. Funeral homes benefit from specialized mortuary cooling needs, while convenience stores and flower shops use them to maintain product freshness.

The ideal temperature for most walk-in coolers is around 38°F. The FDA mandates that refrigerated products must stay at 41°F or lower for food safety. Most commercial walk-in coolers are NSF listed for sanitation compliance.

Construction features insulated panels, typically 4 inches thick, that provide excellent thermal performance. The panels connect using cam-action locking mechanisms that create tight seals while allowing for easy assembly.

For detailed information about safe food storage temperatures, the Food safety temperature chart is an excellent resource.

Walk-In Cooler vs Walk-In Freezer

Walk-in coolers operate between 28°F to 55°F, typically set around 35-38°F. They're perfect for fresh produce, dairy, and prepared foods with manageable energy consumption.

Walk-in freezers operate between -20°F to 0°F, typically set at -10°F. They handle frozen foods and long-term storage but consume about three times more energy than coolers.

The difference in operating costs is significant. An 8×8 walk-in cooler might cost $70-150 monthly to run, while the same-sized freezer could hit $240-435 per month.

| Feature | Walk-In Cooler | Walk-In Freezer |

|---|---|---|

| Temperature Range | 28°F to 55°F | -20°F to 0°F |

| Typical Setting | 35-38°F | -10°F |

| Monthly Energy Cost (8×8) | $70-150 | $240-435 |

| Annual kWh Usage | 660-1,410 | 2,280-4,070 |

| Insulation Requirements | Standard R-29 | Improved R-32 |

| Defrost Cycles | Minimal | Regular cycles needed |

Freezers also need improved insulation and require regular defrost cycles to prevent ice buildup.

How Much Is a Walk in Refrigerator? Average Prices & Cost Breakdown

When business owners ask "how much is a walk in refrigerator," the average cost is around $15,000, though this varies widely based on your specific requirements.

Quick-ship models run between $8,000 and $30,000 and ship in 1-6 weeks. Custom units range from $10,000 to $40,000 but take 10-12 weeks since they're made specifically for your space and needs.

A standard 10′ × 10′ × 8′ walk-in cooler starts at $7,956.87, including shipping to the lower 48 states. The refrigeration system alone accounts for 30-40% of your total cost.

"How Much Is a Walk in Refrigerator" for Standard vs. Custom Models

Standard quick-ship models with lead times of 1-6 weeks and costs of $8,000 to $30,000 work perfectly for most restaurants and commercial applications. You'll have limited size options but get speed and value.

Custom models take 10-12 weeks and cost $10,000 to $40,000, but they're worth the wait for unique space constraints or special requirements. Protective finish upgrades can add 10-40% to your base cost, while outdoor packages typically add another 10-15%.

For detailed pricing comparisons, check out our Walk-In Cooler Pricing 101: Compare Walk-In Cooler Prices guide.

Installation & Site Preparation Costs

Professional installation typically runs $2,000 to $4,000 for labor alone, bringing total installation costs to $3,000 to $9,000 for a standard 10 square foot unit.

Site preparation includes building and health department permits, preparing concrete slabs for outdoor units, and often upgrading electrical systems. Regional costs vary significantly: $9,638 in New York, $6,800 in Chicago, $5,577 in Denver, and $6,200 in Atlanta.

Never attempt DIY installation. The complexity of HVAC, electrical, and plumbing work requires professional expertise, and DIY installation usually voids your warranty.

Our Walk-In Cooler Installation Cost resource covers everything about professional installation.

Operating Expenses, Electricity & Maintenance—How Much Is a Walk in Refrigerator to Run Monthly?

Monthly electricity costs depend heavily on whether you're running a cooler or freezer. A 6×6 cooler costs about $70.74 per month, while a 8×8 cooler runs $119.30 monthly, and a 10×10 cooler costs $151.07 per month. Freezers cost roughly three times more.

These numbers are based on the national average commercial electricity rate of $0.1071 per kWh. A typical 8×8×8 walk-in cooler uses about 8,000 kWh per year, costing roughly $1,200 annually.

Maintenance costs are predictable with proper care. Budget about $200-$400 annually for regular coil cleaning, $100-$300 for gasket replacement, and $500-$1,000 for professional maintenance visits.

For current commercial electricity rates, check the Energy Information Administration commercial kWh data.

Sizing, Features & Options That Impact Your Budget

Getting the right size is crucial—too small and you'll be cramped, too big and you're wasting money. Use this simple rule: one cubic foot of space holds about 28 pounds of food. For 1,000 pounds of inventory, you'll need roughly 36 cubic feet plus room for aisles—at least 40 inches of width for cart access.

Smart business owners plan for growth. Size your unit for 20-30% more capacity than you need today. It's cheaper to buy slightly larger now than replace in three years.

Walk-in prices increase with size, but larger units often provide better value per cubic foot. Features dramatically impact your budget: self-contained vs. remote refrigeration systems, floor vs. no-floor construction (saves 10-20%), and panel materials and finishes (can add 10-40% to total cost).

Calculating the Right Size & Refrigeration Capacity

Your refrigeration system needs to handle BTUH load (British Thermal Units per Hour)—the cooling power needed to maintain proper temperature.

A 10×10 walk-in cooler typically needs about 9,072 BTUH for normal use, but heavy-duty applications might need 10,790 BTUH. A 6×6×8 unit needs about 4,986 BTUH, while a 12×12×8 unit requires 12,150 BTUH.

Factors that increase BTUH requirements include room temperature, door opening frequency, product loading volume, and foot traffic. Getting the calculation wrong is expensive—too little refrigeration means 24/7 operation and shortened equipment life.

For detailed sizing help, check our guide on Selecting the Best Walk-In Cooler System.

Construction Choices: Floor, Panels, and Door Configurations

Panel insulation is your first choice. Most units use 4-inch thick panels with R-29 insulation for coolers or R-32 for freezers. Extruded polystyrene holds insulation value better over time than polyurethane.

The floor question: Units with floors cost more but provide complete insulation and easier cleaning. No-floor units save 10-20% but require perfectly level concrete pads.

Door choices range from basic swing doors to glass doors (add 15-25% cost) and automatic closers ($200-$500). Smart add-ons include vinyl strip curtains, LED lighting, and digital temperature monitoring ($300-$1,500).

If you need floor replacement later, our How to Replace a Walk-In Cooler Floor in 5 Simple Steps guide helps.

Warranty, Lifespan & Service Expectations

Most quality units last about 15 years with proper maintenance. Panels typically come with 20-year warranties, doors get 5-year coverage, and compressors have 5-year parts warranties with 1-year labor.

Maintenance habits directly impact lifespan. Units receiving monthly door gasket inspections, quarterly coil cleaning, and annual professional check-ups consistently outlast neglected ones.

Build quality matters—cheap units use thinner panels and lower-grade compressors. Quality units cost more initially but save money through lower energy bills, fewer repairs, and longer lifespan.

Saving Money Over the Life of Your Walk-In: Energy Tips, New vs Used, Financing

Smart purchasing decisions can save thousands over your walk-in's lifetime. Immediate savings opportunities include utility rebates, Section 179 tax deductions, and timing purchases during slow seasons.

The biggest long-term savings come from choosing energy-efficient components upfront. A high-efficiency unit might cost $2,000 more but save $50-100 monthly on electricity—paying for itself within two years.

Energy-Saving Upgrades & Best Practices

LED lighting uses 50-70% less energy than fluorescent bulbs. ECM fan motors with variable speed control use 30-50% less energy than standard motors. Hot-gas defrost systems are far more efficient than electric defrost for freezers.

Smart operational practices matter equally. Set temperature at 38°F instead of 32°F—those six degrees significantly impact energy consumption while maintaining food safety. Strip curtains dramatically reduce heat infiltration, and automatic door closers prevent accidentally leaving doors open.

Regular maintenance keeps efficiency high. Clean condenser coils monthly, check door gaskets, and watch for light leaks. A well-maintained unit runs 20-30% more efficiently.

For detailed analysis, check Operating Costs for Walk-In Coolers and Freezers.

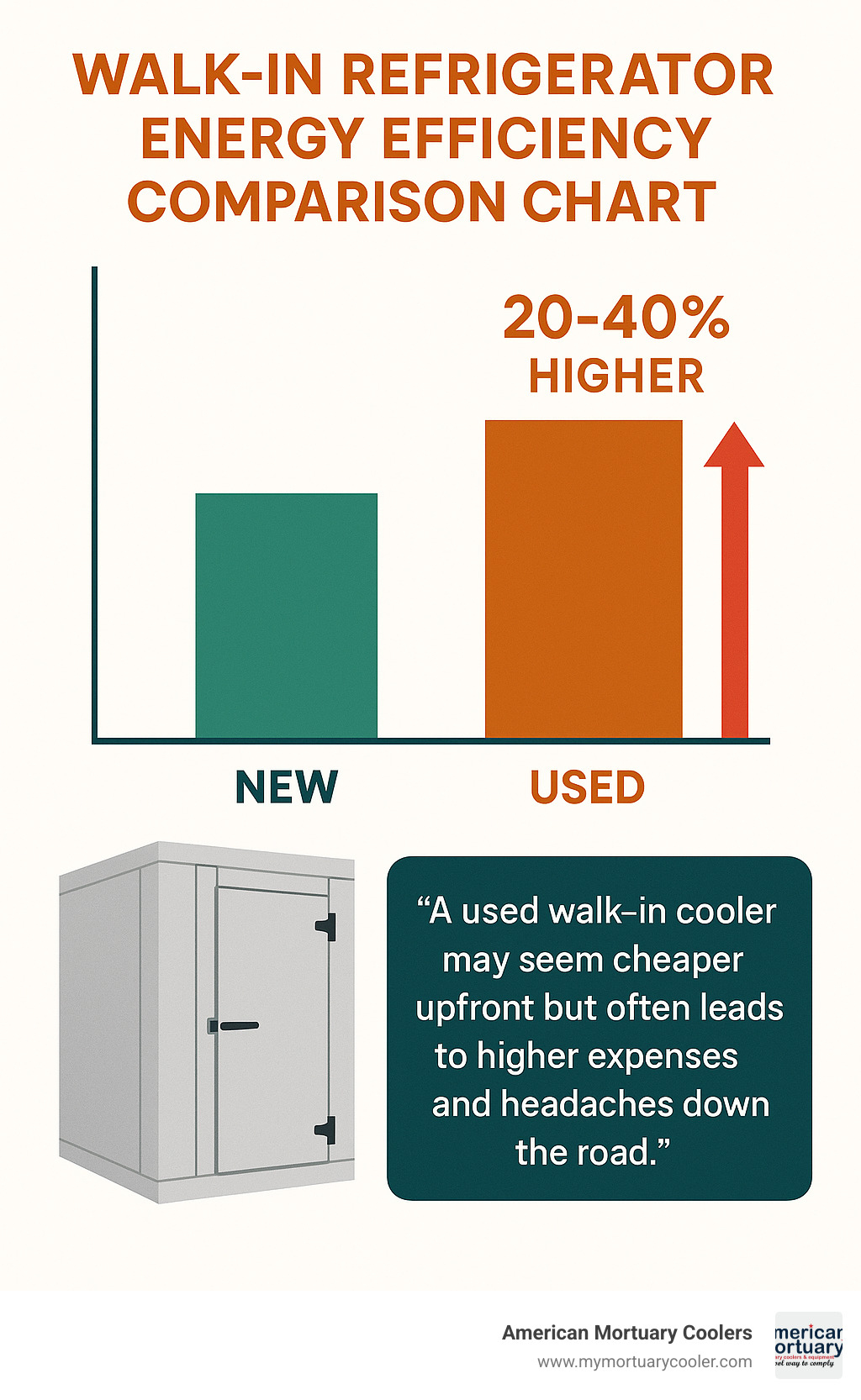

Pros & Cons of Buying Used Walk-In Refrigerators

Used walk-in refrigerators cost 30-60% less and are usually available immediately, but they're often expensive mistakes disguised as bargains.

Hidden costs add up fast. Insulation degradation means higher energy costs—you might save $10,000 upfront but spend an extra $200 monthly on electricity. Warranty coverage is void, leaving you responsible for all repairs.

Code compliance issues are common with older units. Health departments often require upgrades to meet current standards, adding thousands in unexpected costs. Refrigeration system replacement alone can cost $3,000-$8,000.

As one industry veteran told me: "A used walk-in cooler may seem cheaper upfront but often leads to higher expenses and headaches down the road."

For more insights, visit Now that you have a better idea…used walk in cooler.

Financing & Leasing Options

Traditional bank loans offer competitive rates (3-7% for qualified buyers). Equipment financing uses the walk-in as collateral, often resulting in better rates. Leasing options provide flexibility and lower monthly payments.

Section 179 deductions allow you to write off up to $1,160,000 in equipment purchases immediately (2023 limits). Bonus depreciation provides additional first-year deductions, and financing interest is tax-deductible.

Some manufacturers offer seasonal payment plans for businesses with cyclical revenue, allowing higher payments during busy months and lower payments during slow periods.

Frequently Asked Questions about Walk-In Refrigerator Costs

What size walk-in do I need for my business?

Most people underestimate their needs. Start with the 28 pounds per cubic foot rule—if you store 2,000 pounds of product, you need about 72 cubic feet plus room to move around.

For restaurants, small operations work well with 6×6 or 8×8 coolers. Larger establishments usually need 10×10 or 12×12 units. Don't forget to plan for growth—budget for 20-30% more capacity than you need today and ensure 40-inch aisle width for cart access.

What temperature should I set my walk-in refrigerator for food safety?

Set your walk-in cooler at 38°F for optimal performance. This stays well within the FDA's 41°F maximum while accounting for temperature fluctuations from door openings and product additions.

Don't go below 36°F unless specifically needed—you risk freezing delicate produce and waste energy. The 38°F setting works efficiently for most applications.

How can I reduce monthly electricity costs?

Smart choices can cut electricity costs by 15-30%. LED lighting uses 50-70% less energy, ECM motors provide 30-50% savings, and strip curtains reduce heat infiltration.

Daily habits matter: Keep condenser coils clean, check door gaskets monthly, set temperature at 38°F not 35°F, and avoid placing hot items directly in the cooler. Schedule regular professional maintenance—a well-tuned system runs more efficiently and lasts longer.

Conclusion

Figuring out how much is a walk in refrigerator requires seeing the complete picture. Prices range from $8,000 for basic quick-ship models to over $40,000 for large custom units, plus installation costs of $2,000-$4,000 and monthly operating expenses of $70-$435.

Smart decisions focus on understanding what drives costs: size and capacity needs, standard vs. custom construction, installation complexity, energy efficiency, and warranty coverage.

Here at American Mortuary Coolers, we've been helping businesses steer these decisions from Tennessee. We deliver custom solutions across all 48 contiguous states because cookie-cutter approaches don't work for specialized needs. Whether you're running a funeral home, medical facility, or another operation requiring precise temperature control, we understand your requirements.

Our durable, custom-built units provide peace of mind. We cut out middleman costs by delivering directly to you, meaning better value without sacrificing quality construction and reliable service.

Whether you need a compact 6×6 unit or a large custom installation, we're here to help you find the sweet spot where your needs meet your budget. No pressure, no confusing jargon—just honest guidance from people who understand this business.

Ready to stop wondering how much is a walk in refrigerator and start getting real answers? Contact us today for a custom quote custom to exactly what you need. We'll walk you through sizing, features, and financing options so you can make a decision you'll feel good about for years to come.

For more detailed information, check out our Best Walk-In Cooler Options Available guide.