Why Understanding Isopropanol Safety Data Sheets Matters for Your Facility

An isopropanol safety data sheet provides critical information about handling this common solvent safely in your workplace. If you need quick answers about isopropanol hazards and safety measures, here are the key points:

Essential Isopropanol Safety Information:

- Classification: Flammable Liquid Category 2, Eye Irritant Category 2A

- Flash Point: 12°C (53.6°F) - extremely low ignition risk

- Exposure Limits: ACGIH 200 ppm TWA, 400 ppm STEL

- Key Hazards: H225 (flammable), H319 (eye irritation), H336 (drowsiness)

- Required PPE: Chemical-resistant gloves, safety goggles, flame-retardant clothing

- First Aid: Eyes - rinse 15+ minutes; Skin - wash thoroughly; Inhalation - fresh air

Isopropanol appears in many facilities as a cleaning agent, antiseptic, and solvent. The safety data sheet shows it's moderately toxic with an oral LD50 of 5,050 mg/kg in rats, but its low flash point makes fire prevention the top priority.

Storage requires cool, well-ventilated areas away from ignition sources, with containers grounded to prevent static discharge. The vapor density of 2.1 means isopropanol vapors sink and can travel to distant ignition sources.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes understand chemical safety requirements, including proper isopropanol safety data sheet interpretation for facility compliance. My background in mortuary equipment has shown me how critical proper chemical handling is for safe operations.

Isopropanol safety data sheet vocabulary:

Understanding Isopropanol: Composition, Uses & Key Properties

When you pick up an isopropanol safety data sheet, you're looking at information about one of the most versatile chemicals in your facility. Isopropanol goes by several names – 2-propanol, isopropyl alcohol, or simply IPA – but they all refer to the same three-carbon alcohol with CAS number 67-63-0.

This clear, colorless liquid has earned its place as a workplace essential for good reason. As a solvent, isopropanol cuts through oils, resins, and stubborn residues that plain water can't touch. Its antiseptic properties make it invaluable for disinfecting surfaces and equipment, especially in healthcare and mortuary environments where cleanliness isn't optional.

In colder climates, you'll find isopropanol working as a de-icing agent, preventing ice buildup on critical equipment. The chemical's rapid evaporation rate makes it perfect for cleaning electronic components without leaving behind any residue.

For mortuary facilities, isopropanol becomes particularly important for cleaning embalming instruments, disinfecting work surfaces, and maintaining refrigeration equipment. Its ability to evaporate quickly means less downtime and fewer complications with sensitive equipment.

The magic behind isopropanol's versatility lies in its molecular structure (C3H8O). With a molecular weight of 60.1 g/mol, it's lighter than many common solvents. What makes it especially useful – and potentially hazardous – is that it's completely miscible with water. This means it dissolves in any proportion, which helps with spill cleanup but also creates unique fire risks when mixed with water.

For a deeper dive into how temperature affects this chemical, check out our guide to the boiling point of isopropanol.

Typical Physical & Chemical Data

The numbers in your isopropanol safety data sheet aren't just technical details – they're the key to understanding how this chemical behaves in real-world situations.

The most critical number to remember is the flash point of 12 °C (53.6 °F). This extremely low temperature means isopropanol can ignite at normal room temperatures, making fire prevention your top priority. The boiling point of 82-83 °C (180 °F) explains why it evaporates so quickly, while the freezing point of −88 °C (−126 °F) means you won't have to worry about it solidifying in normal storage conditions.

The density of 0.785 g/cm3 tells you that isopropanol is lighter than water, which affects how spills behave and spread. The vapor pressure of 43 hPa at 20 °C indicates significant evaporation at room temperature, creating invisible vapor clouds that can travel far from the original source.

Here's where things get particularly important for safety: isopropanol has a vapor density of 2.1, meaning its vapors are more than twice as heavy as air. These heavier vapors sink into basements, pits, and other low-lying areas where standard ventilation might miss them.

When it comes to exposure limits, different organizations have different standards. ACGIH recommends 200 ppm TWA as the most conservative limit, while OSHA allows 400 ppm PEL for workplace exposure.

| Organization | TWA (8-hour) | STEL (15-minute) | Notes |

|---|---|---|---|

| ACGIH | 200 ppm (492 mg/m3) | 400 ppm (984 mg/m3) | Most conservative limits |

| OSHA | 400 ppm (980 mg/m3) | 500 ppm (1,225 mg/m3) | Federal regulatory standard |

| NIOSH | 400 ppm (980 mg/m3) | 500 ppm (1,225 mg/m3) | Recommended exposure limit |

The auto-ignition temperature of 425 °C provides some comfort – isopropanol won't spontaneously ignite from normal heat sources – but the low flash point means you still need to treat every container as a potential fire hazard.

Decoding the Isopropanol Safety Data Sheet

Every isopropanol safety data sheet follows the standardized 16-section format required by the Globally Harmonized System (GHS). This consistency means that once you understand how to read one SDS, you can steer any isopropanol product's safety information efficiently.

The GHS classification system assigns specific hazard categories and codes that appear on every isopropanol safety data sheet:

Primary Hazard Classifications:

- H225: Highly flammable liquid and vapor (Flammable Liquid Category 2)

- H319: Causes serious eye irritation (Eye Irritation Category 2A)

- H336: May cause drowsiness or dizziness (STOT SE Category 3)

The signal word "Danger" appears prominently on isopropanol labels, indicating serious hazards that require immediate attention. This signal word, combined with the diamond-shaped pictograms, provides instant visual recognition of the primary risks.

GHS Pictograms on Isopropanol Labels:

- Flame symbol: Indicates flammable liquid hazards

- Exclamation mark: Warns of eye irritation and drowsiness effects

NFPA (National Fire Protection Association) ratings provide another quick reference system. Isopropanol typically receives:

- Health: 1 (Slight hazard)

- Fire: 3 (Serious hazard)

- Reactivity: 1 (Slight hazard)

The fire rating of 3 confirms that flammability is isopropanol's most significant hazard. For comprehensive safety data sheet information, the Safety Data Sheet for 2-Propanol provides an excellent example of complete GHS-compliant documentation.

Health Hazards & First-Aid in the Isopropanol Safety Data Sheet

The health hazard information in an isopropanol safety data sheet reveals that while isopropanol isn't extremely toxic, it can cause significant problems if handled improperly.

Acute Toxicity Data:

- Oral LD50 (rat): 5,045-5,050 mg/kg - Moderate toxicity requiring substantial ingestion

- Dermal LD50 (rabbit): 12,800-15,800 mg/kg - Low skin absorption toxicity

- Inhalation LC50 (rat, 4h): 37.5-72.6 mg/L - Moderate inhalation hazard

Primary Health Effects:

- Eye contact: Serious irritation that can damage corneal tissue

- Skin contact: Defatting action leading to dermatitis with prolonged exposure

- Inhalation: Drowsiness, dizziness, and potential respiratory depression

- Ingestion: Central nervous system depression, potentially fatal in large amounts

Critical First-Aid Measures (GHS Precautionary Statements):

P305+P351+P338 (Eye Contact):

- Rinse cautiously with water for several minutes

- Remove contact lenses if present and easy to do

- Continue rinsing for at least 15 minutes

- Seek immediate medical attention if irritation persists

P304+P340 (Inhalation):

- Remove person to fresh air immediately

- Keep at rest in position comfortable for breathing

- Call poison control center if symptoms develop

- Provide artificial respiration if breathing stops

The 15-minute eye flush requirement isn't arbitrary - isopropanol can cause corneal damage that worsens without thorough irrigation.

Eye, Skin, Inhalation Guidance in the Isopropanol Safety Data Sheet

Eye Exposure Specifics: Isopropanol causes immediate stinging and tearing upon eye contact. The irritation results from the alcohol's dehydrating effect on sensitive eye tissues. Without prompt treatment, exposure can lead to corneal clouding and temporary vision impairment.

Dermal Contact Effects: Skin contact with isopropanol removes natural oils, leading to drying and potential dermatitis with repeated exposure. The defatting action can create pathways for other chemicals to penetrate more easily.

Inhalation Concerns: The STOT-SE-3 classification indicates that isopropanol affects the central nervous system. Symptoms progress from mild headache and dizziness to coordination problems and potential unconsciousness at high concentrations.

Ingestion Response: Accidental ingestion requires immediate medical attention. Unlike ethanol, isopropanol metabolizes to acetone rather than acetaldehyde, creating different toxicity patterns. Induced vomiting is contraindicated due to aspiration risks.

Safe Handling, Storage & Personal Protection

When you're working with isopropanol, the right protective gear and handling procedures can mean the difference between a safe workday and a trip to the emergency room. Every isopropanol safety data sheet makes this crystal clear - prevention beats cleanup every single time.

Nitrile gloves are your first line of defense - look for gloves tested to EN 374 standards with breakthrough times over 480 minutes. Latex gloves simply can't handle isopropanol exposure, and PVC gloves break down almost immediately.

Safety goggles with side shields aren't optional when handling isopropanol. That GHS Category 2A eye irritation rating means even a small splash can cause real damage. For large transfers or situations where splashing is likely, add a face shield.

Respiratory protection becomes critical when ventilation can't keep vapor levels below 200 ppm. Type A respirators with organic vapor cartridges work for most situations. For confined spaces or major spill cleanup, supplied-air respirators are the only safe choice.

Isopropanol's Category 2 flammable classification means you need flame-retardant clothing. Synthetic fabrics that melt when heated can turn a flash fire into a devastating burn injury.

Engineering controls work around the clock to keep you safe. Local exhaust ventilation at your work area prevents vapor buildup before it becomes dangerous. General ventilation should provide at least 6 air changes per hour. That vapor density of 2.1 means you need floor-level exhaust points to catch vapors that sink and accumulate.

Static discharge prevention through proper bonding and grounding is essential. With isopropanol's flash point at just 12°C, even tiny static sparks can trigger ignition.

Storage temperatures between 15-25°C hit the sweet spot for safety and product stability. Oxidizing agents are isopropanol's worst enemies - keep at least 20 feet between isopropanol storage and any oxidizing chemicals.

Approved flammable liquid containers with tight-fitting lids prevent vapor escape and contamination. Metal containers generally provide better fire resistance than plastic.

For more insights on chemical safety in healthcare environments, check out our complete guide to disinfectant SDS sheets for additional safety strategies.

Workplace hygiene prevents many accidents. Wash your hands thoroughly before breaks and after work. Keep isopropanol away from food, drinks, and smoking materials. Change contaminated clothing immediately, and shower after significant exposure. Never eat, drink, or smoke in areas where isopropanol is handled.

Fire, Explosion & Spill Response Essentials

When it comes to fire safety, every isopropanol safety data sheet tells the same sobering story – this chemical can ignite at surprisingly low temperatures and create explosive atmospheres faster than most people realize.

With a Lower Explosive Limit (LEL) of just 2 %, it doesn't take much vapor in the air to create a dangerous situation. The Upper Explosive Limit (UEL) reaches 12.7 %, giving isopropanol one of the widest flammable ranges we encounter. The auto-ignition temperature of 425 °C provides some comfort – isopropanol won't spontaneously burst into flames under normal conditions. But with that flash point of 12 °C, we're dealing with vapors that can ignite at typical room temperatures.

When fires do happen, choosing the right extinguishing agent makes all the difference. Alcohol-resistant foam works best for large liquid fires because regular foam simply dissolves when it hits the alcohol. Carbon dioxide (CO2) is our go-to choice around electrical equipment, while water spray helps cool containers and dilute spills without spreading the fire. Dry chemical powder handles smaller fires effectively.

Never use direct water streams on an isopropanol fire – you'll just spread burning liquid everywhere. Regular foam won't work either, since the alcohol breaks it down immediately.

Fire codes treat isopropanol storage areas as Class I, Division 1 hazardous locations. This classification requires explosion-proof electrical equipment, specialized ventilation, and strict controls on ignition sources.

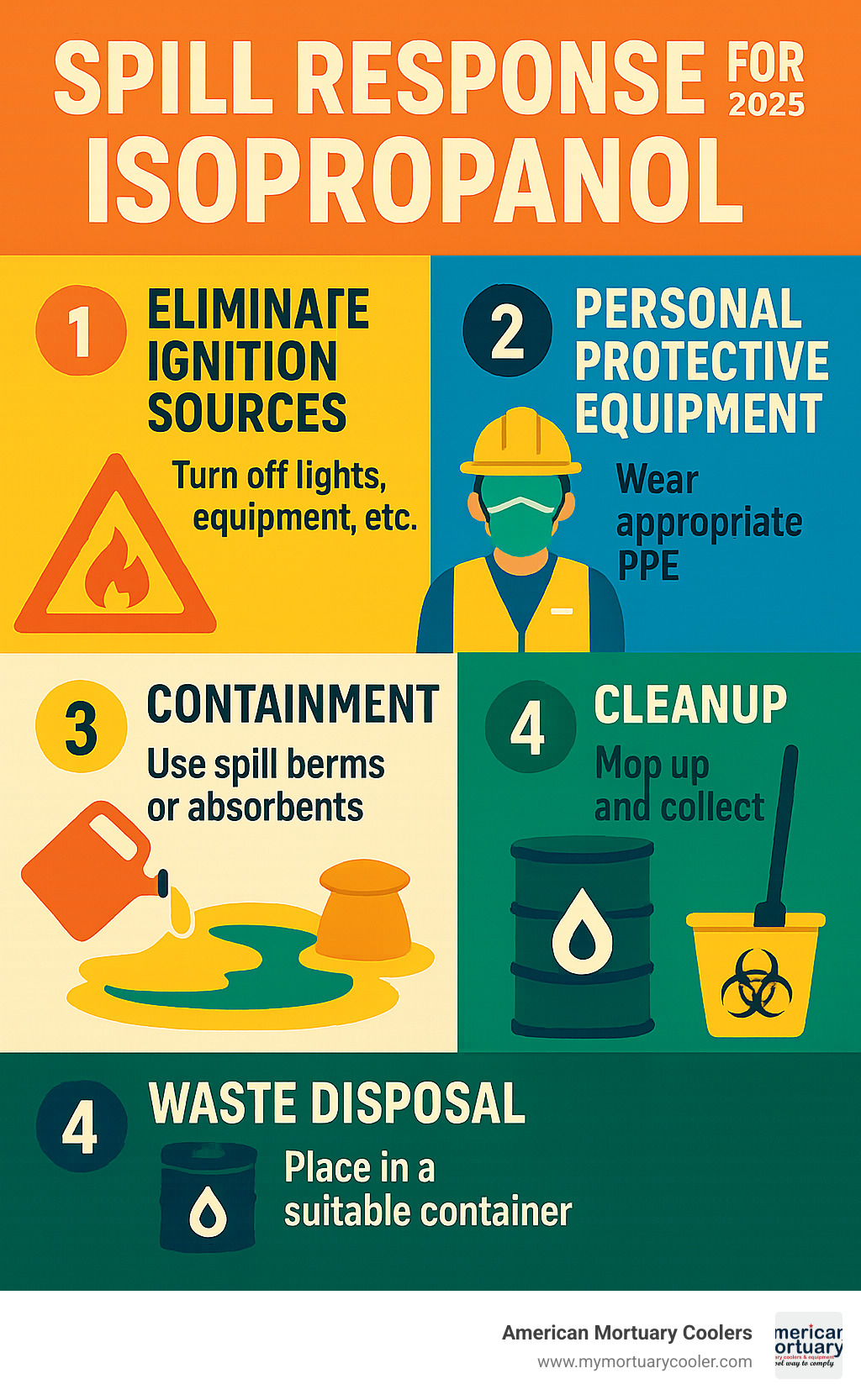

Spill response starts with eliminating all ignition sources within 50 feet – no exceptions. Evacuate non-essential personnel immediately, then don appropriate PPE before anyone gets close to the spill.

Containment requires non-sparking tools exclusively. We absorb spills with sand, vermiculite, or commercial absorbents, never sawdust or other organic materials that increase fire risk. For large spills, diking prevents spreading while we work on cleanup.

The cleanup process demands patience and thoroughness. Collect absorbed material in sealed, labeled containers for proper hazardous waste disposal. Ventilate the area thoroughly and test the atmosphere with calibrated gas monitors before declaring it safe.

Every facility should maintain readily accessible emergency contacts including the local fire department, Poison Control at 1-800-222-1222, and CHEMTREC at 1-800-424-9300 for 24-hour chemical emergency response.

For additional technical specifications, the ISOPROPYL resource provides comprehensive safety data.

In mortuary facilities, confined spaces where isopropanol vapors can accumulate require modified response procedures. The tight quarters common around mortuary coolers mean vapors concentrate quickly, making vapor monitoring and forced ventilation essential before anyone enters the space.

Regulatory & Environmental Considerations

Understanding the rules around isopropanol isn't just about checking boxes - it's about protecting your facility, your workers, and the environment. Every isopropanol safety data sheet includes detailed regulatory information that affects everything from daily operations to waste disposal.

Workplace Exposure Rules:

ACGIH recommends keeping worker exposure below 200 ppm over an 8-hour shift, while OSHA still allows up to 400 ppm. This reflects new research showing that isopropanol affects people at lower concentrations than we once thought. Following the stricter ACGIH limits of 200 ppm TWA means better ventilation systems and more frequent air monitoring.

The 400 ppm STEL (short-term exposure limit) from ACGIH gives you some flexibility for brief, high-exposure tasks.

Transportation Requirements:

Shipping isopropanol involves specific transportation rules. The key identifier is UN 1219, which tells everyone in the shipping chain exactly what they're dealing with. This classification as a DOT Class 3 flammable liquid in Packing Group II means moderate danger that requires specific handling.

If you're ordering more than 119 gallons at once, expect additional paperwork and special truck placarding. The same UN 1219 classification works internationally.

Disposal Requirements:

When it's time to dispose of used isopropanol, the RCRA waste code D001 applies because of its flammable nature. This means you can't just pour it down the drain or toss it in regular trash. Many waste management companies can process spent isopropanol for fuel blending or solvent recovery, which costs less than incineration.

Environmental Impact:

Here's good news from the environmental data: isopropanol breaks down quickly in the environment. With 53% biodegradation within 5 days, isopropanol doesn't stick around to cause long-term problems. The aquatic toxicity numbers show moderate impact - it takes about 9,640 mg/L to harm fish in lab tests.

Chemical Inventory Compliance:

Isopropanol appears on every major international chemical inventory - TSCA in the United States, DSL in Canada, and EINECS in Europe. The main reporting requirement kicks in at 25,000 pounds annually under SARA Title III Section 313. Most funeral homes use nowhere near this amount.

While federal rules provide the baseline, some states add their own requirements. California's chemical reporting tends to be the strictest, but isopropanol currently doesn't trigger Proposition 65 warnings.

At American Mortuary Coolers, we've helped funeral homes across 48 states understand these requirements as part of our equipment installations. The regulatory landscape varies, but the basic safety principles remain consistent.

Frequently Asked Questions about the Isopropanol Safety Data Sheet

What PPE does the isopropanol safety data sheet require for routine handling?

When you're working with isopropanol regularly, the isopropanol safety data sheet makes it clear that proper protective equipment is essential for keeping your team safe.

Chemical-resistant nitrile gloves form your first line of defense. These need to meet EN 374 standards with breakthrough times exceeding 480 minutes. Latex gloves simply don't cut it with isopropanol, and PVC gloves can actually degrade when exposed to this solvent.

Your eyes need safety goggles with side shields every single time you handle isopropanol. The GHS Category 2A eye irritation classification means even a tiny splash can cause serious damage.

Respiratory protection becomes crucial when your ventilation can't keep vapor concentrations below 200 ppm. For routine work, organic vapor respirators with Type A cartridges usually do the job. In confined spaces like cooler maintenance areas, supplied-air respirators are often required because vapors build up quickly.

Flame-retardant clothing is necessary because isopropanol is a Category 2 flammable liquid. Synthetic fabrics that melt under heat can actually make burn injuries worse, so natural fibers or specially treated materials are your safest bet.

How do I interpret the flammability data on an isopropanol safety data sheet?

The flammability numbers in an isopropanol safety data sheet tell a story that could save your facility from disaster.

That flash point of 12°C (53.6°F) is the number that should grab your attention first. It means isopropanol can ignite at normal room temperature, making it one of the more dangerous common solvents you'll encounter.

The explosive limits from 2% to 12.7% create the "danger zone." Below 2% concentration, there's not enough fuel to ignite. Above 12.7%, there's not enough oxygen. But anywhere between these numbers, any spark or flame can cause an explosion. What makes this particularly tricky is how wide that range is.

The auto-ignition temperature of 399-425°C brings some good news. Isopropanol won't spontaneously burst into flames under normal conditions. However, hot equipment surfaces, electrical faults, or even a cigarette can easily reach these temperatures.

Vapor density of 2.1 means isopropanol vapors are more than twice as heavy as air. They don't just float away - they sink to floor level and can travel surprising distances to find an ignition source. This behavior explains why floor-level ventilation is so important.

What are the recommended first-aid measures according to the isopropanol safety data sheet?

When accidents happen with isopropanol, the isopropanol safety data sheet provides life-saving guidance through standardized first-aid procedures.

Eye contact requires immediate action following the P305+P351+P338 protocol. That 15-minute flush time isn't a suggestion - isopropanol can cause serious corneal damage that gets worse without thorough irrigation. Remove contact lenses only if you can do it easily, then keep flushing. If irritation continues or vision seems affected, get medical help immediately.

Skin contact follows the P303+P361+P353 guidance. Get contaminated clothing off right away and rinse the affected skin thoroughly with water. Isopropanol strips away your skin's natural oils, which can make it easier for other chemicals to penetrate later.

Inhalation emergencies use the P304+P340 protocol. Move the person to fresh air immediately and help them find a comfortable position for breathing. Call poison control at 1-800-222-1222 if any symptoms develop. Be ready to provide artificial respiration if their breathing becomes inadequate.

Ingestion requires special care because the standard "induce vomiting" response can actually make things worse. Never try to make someone vomit after isopropanol ingestion due to aspiration risks. Just rinse their mouth with water and get medical help immediately. Unlike drinking alcohol, isopropanol breaks down into acetone in your body, creating different and potentially more serious toxic effects that need professional evaluation.

Conclusion

Working with isopropanol safely comes down to understanding what makes it dangerous and taking the right precautions. Every isopropanol safety data sheet tells the same story - this is a useful chemical that demands respect, especially when it comes to fire safety.

The numbers don't lie: with a flash point of just 12°C, isopropanol can ignite at room temperature. That extremely low ignition point, combined with explosive limits spanning from 2% to 12.7%, means vapors can turn dangerous fast. We've seen too many close calls in facilities where someone thought "just a little bit" wouldn't matter.

Fire prevention isn't just about keeping flames away - it's about understanding how isopropanol behaves. Those vapors are more than twice as heavy as air, so they sink and travel. They'll find ignition sources you didn't even think about. Proper grounding, bonding, and explosion-proof equipment aren't suggestions - they're necessities.

Personal protection makes the difference between a safe workday and a trip to the emergency room. Chemical-resistant nitrile gloves protect your hands from the defatting action that leaves skin cracked and vulnerable. Safety goggles prevent the serious eye irritation that can damage your corneas. When ventilation can't keep vapor levels below 200 ppm, respiratory protection becomes your lifeline.

Emergency preparedness isn't about expecting the worst - it's about being ready when things go sideways. Keep those emergency contacts handy: poison control at 1-800-222-1222, CHEMTREC at 1-800-424-9300, and your local fire department. Make sure your team knows how to use that eyewash station and where you keep the alcohol-resistant foam.

The environmental side matters too. While isopropanol breaks down relatively quickly in nature, spills can still harm aquatic life. Proper storage, handling, and disposal through licensed hazardous waste facilities protect both your community and the environment.

Compliance isn't just about avoiding fines - though the RCRA D001 classification for waste disposal and DOT UN 1219 requirements for transport do carry real penalties. It's about creating a workplace where everyone goes home safe.

For more insights on maintaining healthy workplace environments, check out our essential guide to staying healthy in healthcare facilities.

At American Mortuary Coolers, we've spent years helping funeral homes across the country handle chemicals safely while maintaining efficient operations. Our custom refrigeration solutions support proper chemical storage and help facilities meet safety requirements from Tennessee to California, from New York to Texas.

We understand that every facility has unique needs. That's why we deliver durable, custom mortuary equipment directly to funeral homes throughout all 48 contiguous states. Whether you need specialized storage for cleaning chemicals or custom cooling solutions that support your safety protocols, we're here to help.

Contact us today to discuss how our custom mortuary cooler solutions can support your facility's safety and operational needs. Our experience across diverse markets means we understand both local regulations and real-world safety challenges.