Why Choosing the Right Morgue Equipment Suppliers is Critical for Your Facility

Morgue equipment suppliers provide the essential infrastructure that keeps funeral homes, hospitals, and pathology labs running safely and efficiently. From autopsy tables and cadaver lifts to walk-in coolers and storage racks, these specialized manufacturers serve facilities that handle everything from routine operations to mass fatality events.

Top morgue equipment suppliers include:

- Mopec - Comprehensive pathology and mortuary solutions with surge capacity systems

- Mortech Manufacturing - ISO 9001:2015 certified with 9,747+ completed projects since 1985

- CSI Jewett - American-made stainless steel equipment with seamless fabrication

- Mobimedical - US-manufactured mortuary coolers starting at $7,599 for 2-body units

- Mortuary Solutions - UK-based with 55+ years of bespoke manufacturing experience

- Shotton Parmed - Australian-owned with innovative One Tray System technology

The market spans from large-scale manufacturers offering standardized equipment to boutique suppliers creating fully customized solutions. Leading suppliers serve multiple sectors including funeral homes, NHS facilities, universities, and veterinary labs.

Key considerations when selecting suppliers:

- Certification standards (ISO 9001, NSF, CE marking)

- Geographic coverage and shipping capabilities

- Customization vs. standard product offerings

- Installation, maintenance, and after-sales support

- Financing options and warranty terms

We're American Mortuary Coolers, a national-level supplier specializing in American-made mortuary cooling solutions. With extensive experience working alongside major morgue equipment suppliers, we've seen how the right partnerships can transform facility operations.

Key terms for morgue equipment suppliers:

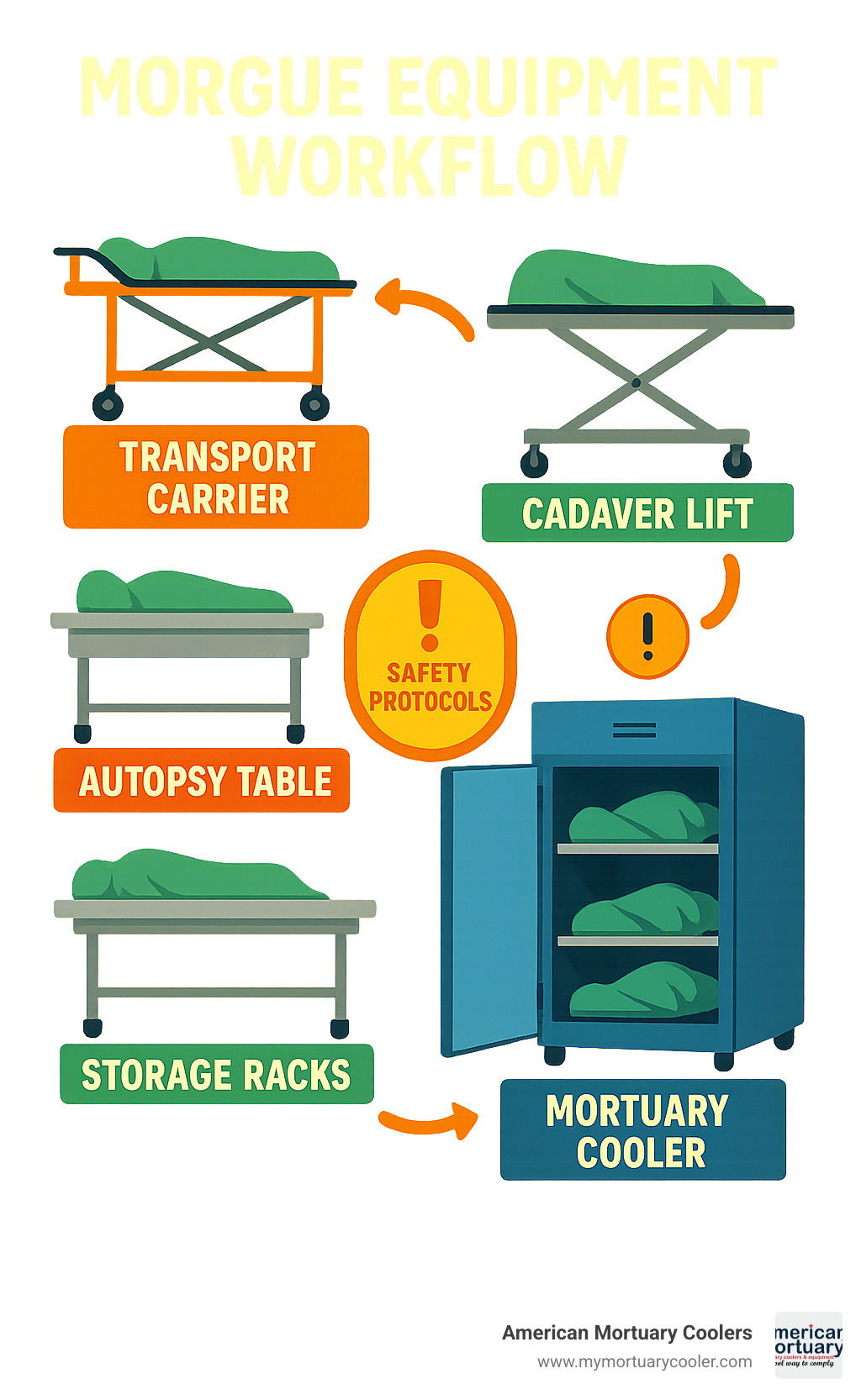

Essential Morgue Equipment at a Glance

When setting up or upgrading a morgue facility, most operations rely on the same core pieces of equipment, each designed to handle specific parts of the body handling and examination process.

Autopsy tables are the heart of any pathology facility. Morgue equipment suppliers like Mopec build their autopsy tables from heavy-duty 14-gauge stainless steel with built-in large integral sinks and GFCI electrical receptacles for proper drainage and safe electrical access during examinations.

Cadaver lifts are essential for staff safety. Manual lifting injuries are one of the biggest workplace hazards in morgue operations. ARES Scientific makes cadaver lifts that handle up to 1,000 lbs for bariatric covered cadaver carriers, protecting staff and ensuring OSHA compliance.

Mortuary coolers maintain proper preservation temperatures. Mobimedical offers solid options, with their 4-body upright mortuary cooler running $9,199 and a 2-body roll-in style at $7,599. Temperature control is non-negotiable for preservation and dignity.

When space gets tight, storage racks become essential. Mopec's Guardian Rack Quick Deploy Morgue Rack & Body Tray System supports up to 1,500 lbs and assembles with just 8 bolts, perfect for emergency surge capacity.

Grossing stations provide pathologists a safe, controlled environment for tissue sample examination with down-draft ventilation systems and chemical-resistant surfaces.

Embalming sinks need specialized fixtures including hot and cold water supplies with hydro-aspirators and perimeter rinse systems to prevent fluid accumulation during preparation procedures.

Modern facilities accept imaging systems like Mopec's PathCam, which integrates digital documentation into examination workflows, improving accuracy and creating permanent records.

Personal protective equipment (PPE) includes specialized disposable overalls, gloves, and respiratory protection designed specifically for mortuary environments.

Ergonomic design ensures staff can work without physical strain. Adjustable height tables, proper lighting, and intuitive controls reduce fatigue and improve examination quality.

Bariatric capacity equipment addresses growing needs with specialized lifts, wider tables, and reinforced storage systems accommodating weights up to 1,000 lbs or more.

Why the Right Gear Matters for Morgue Equipment Suppliers

Infection control drives modern morgue equipment design. Seamless stainless steel construction eliminates bacteria-harboring crevices, while proper ventilation systems contain hazardous materials. CSI Jewett emphasizes seamless fabrication for improved infection control and operational efficiency.

OSHA compliance keeps facilities operational and staff safe. Equipment must minimize manual lifting, provide adequate ventilation, and include proper electrical safety measures.

ISO 9001 certification demonstrates quality management commitment. When morgue equipment suppliers like Mortech Manufacturing earn ISO 9001:2015 certification alongside NSF and CE certifications, they prove consistent quality and safety standards.

Stainless steel construction remains the gold standard, resisting corrosion, simplifying cleaning, and maintaining appearance over decades of heavy use.

Market-Specific Sets From Morgue Equipment Suppliers

Funeral homes need compact, efficient equipment for preparation rooms, including reliable embalming tables, preparation sinks, and modest cooling capacity.

Hospitals require high-capacity systems with large walk-in coolers, multiple autopsy stations, and surge capacity equipment for varying caseloads.

Public mortuaries need forensic-grade equipment with evidence handling capabilities, specialized imaging systems, secure storage, and chain-of-custody features.

Universities require equipment serving both medical education and research, including anatomy dissection tables and teaching-friendly designs.

Veterinary labs need scaled equipment designed for animal necropsy, including specialized tables, smaller cooling units, and animal-specific handling equipment.

Mapping the World's Leading Morgue Equipment Suppliers

When looking for reliable morgue equipment suppliers, you'll find industry veterans and innovative newcomers scattered globally, each bringing unique strengths to the market.

Mopec stands as the heavyweight champion of North American morgue equipment, built on comprehensive pathology and mortuary solutions. Their patented MERCSystem for rapid mortuary cooling and mass fatality disaster response capabilities set them apart.

Mortech Manufacturing has perfected their craft since 1985 with 9,747 completed projects and ISO 9001:2015 certification. Their wall-mounted autopsy stations feature configurable designs with large removable instrument drawers for improved workflow.

CSI Jewett takes pride in American-made stainless steel equipment with seamless fabrication focused on infection control and decades-long durability.

Mobimedical offers American-made durability with transparent pricing - 2-body roll-in coolers start at $7,599, while 4-body upright units run $9,199, with financing options available.

Shotton Parmed in Australia innovates with their One Tray System technology, allowing seamless body movement between racks, trolleys, examination stations, and viewing rooms using one tray, reducing handling and contamination risk.

Mortuary Solutions brings over 55 years of UK manufacturing experience since 1969, creating standard and custom solutions for funeral homes, NHS facilities, public mortuaries, and educational institutions with direct-from-manufacturer pricing.

Morquip Industries serves as New Zealand's morgue equipment specialist with relationships across multiple global manufacturers, offering comprehensive product portfolios for funeral homes, hospitals, universities, and veterinary facilities.

WJ Kenyon operates across Europe and the UK, specializing in bespoke autopsy and mortuary equipment with price-matching guarantees and full customization services.

The industry includes regional hubs across the US, UK, Australia, and New Zealand, plus global distributors connecting smaller facilities with appropriate equipment. Many suppliers now hold ISO-certified status, ensuring consistent quality standards.

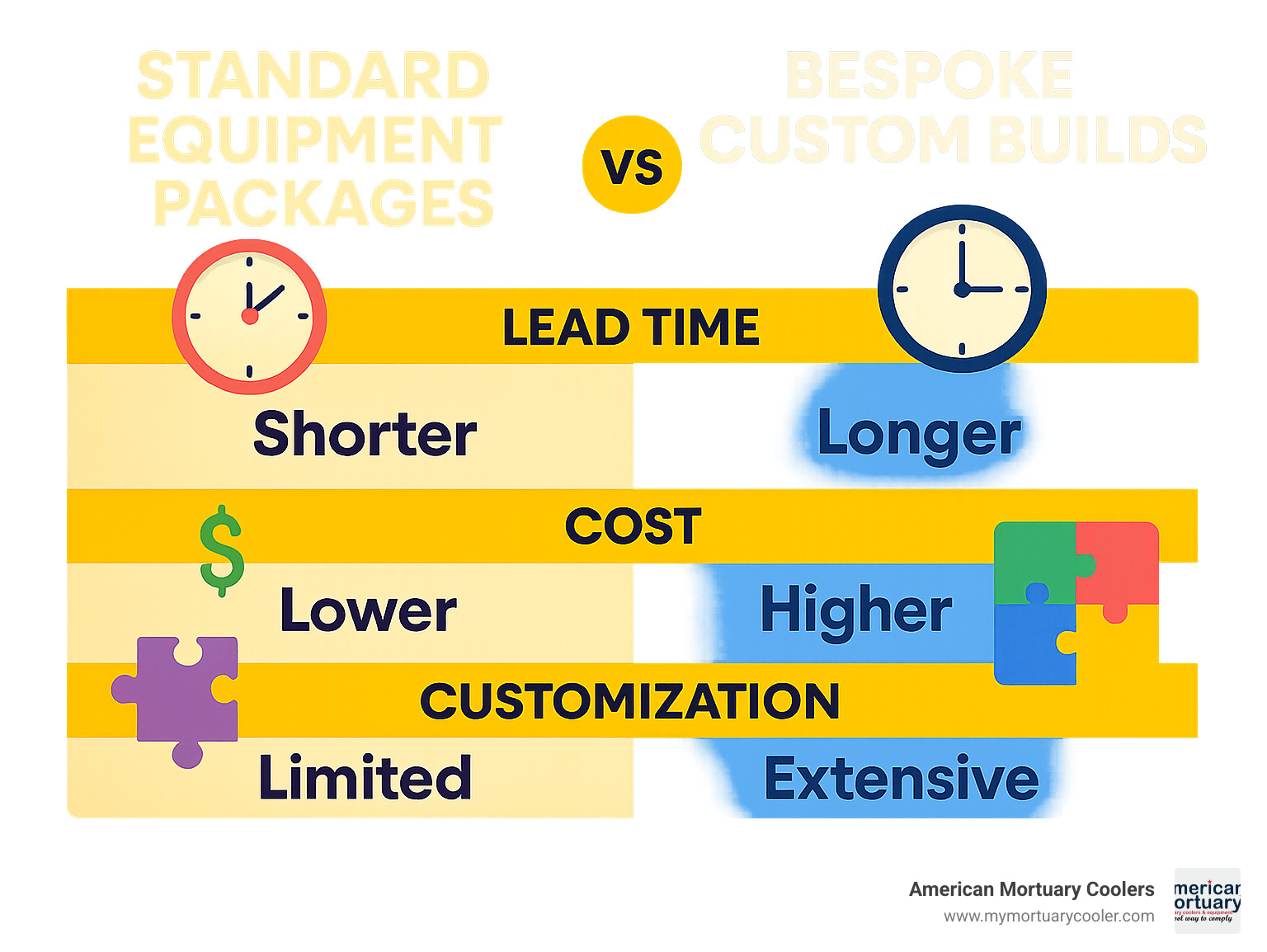

The choice between standard versus bespoke builds depends on specific needs and timeline. Standard equipment ships faster and costs less, while custom builds take longer but fit spaces perfectly.

Regional Standouts: Morgue Equipment Suppliers in North America & Europe

US giants like Mopec and Mortech combine scale with customization, offering competitive pricing on standard equipment while handling complex custom projects. "Made in USA" often means faster shipping, easier warranty service, and domestic manufacturing support.

Direct-to-buyer models change how facilities purchase equipment. Companies like MortuaryMall.com, run by the Bergin family with 151 years of funeral service experience, eliminate distributor markups while providing genuine industry expertise.

UK bespoke manufacturers like Mortuary Solutions and WJ Kenyon serve NHS facilities and educational institutions with custom approaches requiring longer lead times but delivering equipment designed specifically for unique workflows and space constraints.

Rising Stars: Morgue Equipment Suppliers in Australia & New Zealand

One-Tray systems represent significant workflow innovation. Shotton Parmed's approach eliminates multiple transfers that slow operations and increase contamination risks - a "why didn't we think of this sooner?" innovation.

Local service becomes valuable for specialized equipment in remote locations, with suppliers understanding local regulations, providing faster response times, and eliminating international shipping headaches.

Export assistance programs help regional suppliers compete globally, with innovations in workflow efficiency and ergonomic design attracting worldwide attention from facilities seeking alternatives to traditional approaches.

Innovations & Technology Shaping the Sector

The morgue equipment industry has experienced remarkable technological advances, especially since COVID-19 revealed critical gaps in traditional body handling systems. Modern morgue equipment suppliers now develop solutions blending reliability with innovation.

Quick-deploy racks emerged as game-changers during unprecedented capacity challenges. Mopec's Guardian Rack system assembles with just 8 bolts while supporting up to 1,500 lbs, changing surge capacity from weeks of construction into hours of assembly.

The MERC System (Mortuary Improved Remains Cooling) represents breakthrough disaster response thinking. This patented rapid cooling technology provides temporary relief when permanent facilities become overwhelmed, bridging the gap between crisis and recovery.

Surge containers offer mobile capacity as self-contained units arriving ready to deploy with cooling systems and proper ventilation - essentially morgues-on-wheels positioned wherever needed most.

PathCam imaging technology revolutionizes documentation practices by integrating digital documentation directly into examination workflows. Pathologists capture images, record observations, and create permanent records without interrupting examinations.

Down-draft stations address persistent challenges in containing airborne contaminants safely. These engineered systems can function without external ducting when properly designed, simplifying installation in existing facilities.

The one-tray transfer concept eliminates multiple handling steps that increase contamination risks and staff strain. Bodies remain on the same tray from initial transport through final disposition.

Reverse-flow aspirators solve suction blockage problems during procedures. Mortech's deluxe aspirator includes this feature to quickly clear obstructions using water pressure.

Antimicrobial coatings provide extra protection between cleaning cycles, actively inhibiting bacterial growth on equipment surfaces while proper cleaning protocols remain essential.

AI-ready tracking systems prepare facilities for next-generation inventory and case management. Barcode readers and RFID systems integrate with facility management software for comprehensive tracking, reducing human error while creating detailed audit trails.

Scientific research on ergonomic lifting validates that mechanical assistance dramatically reduces workplace injuries. Modern equipment design prioritizes staff safety alongside functional requirements.

Future-Proofing With Morgue Equipment Suppliers

Smart technology integration changes how facilities monitor and manage operations. IoT monitoring systems provide real-time oversight of critical equipment functions with temperature sensors, door alarms, and system status monitors providing early failure warnings.

These connected systems prevent equipment failures that compromise entire facility operations, like receiving 2 AM text alerts about cooling system problems for immediate response.

Barcode tracking systems like SPOT Imaging's PathTracker automate specimen management throughout examination processes, reducing documentation errors while creating comprehensive tracking records essential for large caseloads.

Energy-efficient refrigeration technology addresses environmental concerns and operational costs with advanced compressors and improved insulation minimizing energy consumption without compromising temperature control.

Forward-thinking morgue equipment suppliers design systems with built-in upgrade pathways, accepting modular improvements rather than requiring complete replacement when technology advances.

How to Choose, Buy & Finance Your Equipment

Buying morgue equipment requires breaking down the process into manageable steps with careful consideration of multiple factors.

Needs assessment starts with honest conversations about daily facility operations. Examine current caseload and those busy weeks that test limits, considering physical space constraints and potential service expansion. The pandemic taught us that emergency surge requirements are essential planning considerations, not theoretical concerns.

Capacity planning balances routine operations with emergency scenarios. COVID-19 showed how quickly normal operations become inadequate, making smart facilities plan for both regular workflow and situations where capacity might triple overnight.

The customization vs. standard equipment decision depends on budget and timeline. Some morgue equipment suppliers excel at modifications, building exactly what you envision, while others focus on proven standard configurations that ship quickly and cost less.

Leasing versus purchasing depends on financial situation and long-term plans. Mortuary Solutions offers financing from £1,000 + VAT, and many suppliers provide similar options. Leasing preserves cash flow and often includes maintenance, while purchasing builds equity and eliminates ongoing payments.

Warranties vary dramatically between suppliers. Some offer comprehensive coverage including parts, labor, and loaner equipment during repairs, while others provide basic coverage. Read fine print carefully - higher upfront costs often pay for themselves through better warranty terms.

Maintenance contracts keep equipment running when needed most. Response times matter enormously with broken coolers. Ask about parts availability, technician qualifications, and holiday/weekend coverage.

Installation logistics require coordination for large equipment needing proper site preparation, utility connections, and sometimes structural modifications. Coordinate delivery timing carefully.

For deeper insights into selecting manufacturers, check our detailed guide on mortuary equipment manufacturers.

Ordering Workflow With Morgue Equipment Suppliers

Accurate quotes require detailed upfront information including specifications, quantities, realistic delivery timelines, facility drawings, and utility information for accurate proposals instead of rough estimates.

3D design services offered by companies like Mopec help visualize equipment fit within space and workflow, preventing costly mistakes and helping staff understand changes before installation.

Production lead-times vary enormously between standard and custom equipment. Standard items might ship within weeks, while custom builds can take several months. Factor these timelines into project planning.

White-glove delivery services handle installation, training, and startup support. This comprehensive approach costs more than basic delivery but ensures equipment works properly from day one.

After-Sales Essentials From Morgue Equipment Suppliers

Training makes the difference between equipment that works well and equipment that works perfectly. Comprehensive programs cover operation, maintenance, and basic troubleshooting, helping staff catch problems early.

Spare parts availability affects long-term costs and operational reliability. Understand which parts fail most often, their costs, and delivery speed. Some suppliers stock common parts locally while others ship from distant warehouses.

Remote diagnostics capabilities are becoming standard, letting technicians troubleshoot problems without site visits, often resolving issues faster and cheaper than traditional service calls.

Service level agreements prevent misunderstandings about response times and coverage, specifying what's included, extra costs, and help arrival times - details that matter most during equipment failures in busy periods.

Frequently Asked Questions about Morgue Equipment Procurement

When you're investing in morgue equipment, it's natural to have questions. After years of working with facilities across the country, we've heard the same concerns come up again and again. Let's tackle the big ones that keep facility managers up at night.

What certifications should I demand from a supplier?

ISO 9001:2015 quality management certification should be at the top of your list. This isn't just paperwork - it means the supplier has proven systems for consistent quality control. Mortech Manufacturing holds this certification along with several others, showing their commitment to reliable processes.

NSF certification matters because it applies food service equipment standards to mortuary equipment. While it might seem odd, these standards ensure materials and construction methods meet health and safety requirements that protect both staff and the public.

CE marking becomes essential if you're dealing with European suppliers or equipment that might be used internationally. This certification shows compliance with European safety standards.

Don't forget about electrical codes and healthcare facility requirements. All electrical components need to meet your local electrical codes, and materials should comply with healthcare facility standards. LEED Green standards compliance is becoming more important as facilities focus on environmental responsibility.

When evaluating morgue equipment suppliers, ask to see these certifications upfront. Reputable suppliers will gladly share their credentials because they're proud of the work they've put into earning them.

How do I scale storage for pandemic surges?

The COVID-19 pandemic taught us all a hard lesson about surge capacity. Nobody wants to be caught unprepared again, and thankfully, equipment manufacturers have responded with smart solutions.

Quick-deploy systems like Mopec's Guardian Rack offer the fastest path to emergency expansion. These systems support up to 1,500 lbs while assembling with just basic tools - no complex installation required. When disaster strikes, you don't have time for complicated setup procedures.

Portable racks with casters give you the flexibility to reconfigure space as needs change. During surge events, you might need to repurpose areas that normally serve other functions. Mobile equipment makes this possible without major renovations.

The MERC System provides temporary cooling solutions when your permanent capacity gets overwhelmed. This patented technology can bridge the gap while you arrange for additional permanent cooling or wait for caseloads to return to normal levels.

Plan for 2-3x your normal capacity based on what we learned during the pandemic. This might seem excessive during normal times, but when you really need it, you'll be grateful for the extra space.

Can equipment be retro-fitted into an existing cooler room?

Most equipment can be adapted to fit existing spaces, but success depends on the details. Morgue equipment suppliers have gotten very good at working with existing facilities because complete renovations aren't always possible or practical.

Provide detailed facility drawings including exact dimensions, door sizes, utility locations, and structural information. The more information you can share upfront, the better solutions suppliers can recommend. Don't forget to measure doorways and hallways - we've seen beautiful equipment designs that couldn't actually get into the room.

Electrical upgrades often become necessary when adding modern equipment to older facilities. New equipment typically requires more power and better grounding than what was standard years ago. Factor this into your budget and timeline.

Ventilation improvements might be needed depending on what equipment you're adding. Down-draft stations and certain imaging systems have specific airflow requirements that existing HVAC systems might not handle.

Structural reinforcement becomes important for heavy equipment like large autopsy tables or high-capacity storage racks. Have your facility engineer review weight requirements before finalizing equipment selections.

The good news is that experienced suppliers can usually find solutions that work within existing constraints. They've seen every type of facility challenge and have developed creative approaches to make equipment fit where it needs to go.

Conclusion

Finding the right morgue equipment suppliers comes down to matching your facility's unique needs with suppliers who understand your challenges.

The market offers comprehensive solutions for everyone. Large manufacturers like Mopec and Mortech bring decades of experience and complete product lines, while specialized suppliers like Mortuary Solutions and Shotton Parmed prove innovation often comes from companies willing to rethink traditional approaches.

Technology keeps pushing the industry forward with IoT monitoring systems for checking cooler temperatures remotely, automated tracking eliminating paperwork headaches, and energy-efficient designs reducing operational costs while improving performance.

The pandemic taught valuable lessons about surge capacity and emergency preparedness. Suppliers responded with quick-deploy systems and mobile solutions expanding capacity when needed most - adaptability that will serve facilities well ahead.

At American Mortuary Coolers, we've spent years working alongside the industry's best morgue equipment suppliers. Based in Tennessee, we focus on custom walk-in coolers and mortuary cooling solutions that fit your space and workflow.

We deliver across all 48 contiguous states because every facility deserves equipment that works reliably for decades. Our American-made coolers come with support from a company that understands funeral service isn't just business - it's a calling.

Whether planning complete facility upgrades or replacing temperamental coolers, we're here to help. Our financing options and custom design services make it easier to get exactly what you need without breaking budgets.

The funeral industry deserves suppliers who care about your success. That's our standard and what you should expect from any morgue equipment suppliers you choose.

For detailed guidance on making the right choice, check our comprehensive guide on choosing a walk-in cooler supplier.