Why Mortuary Cold Room Doors are Critical for Your Facility

Mortuary cold room doors manufacture involves specialized engineering to create doors that maintain precise temperature control, ensure hygiene standards, and provide reliable access for funeral home operations. These doors serve as the critical barrier between your temperature-controlled storage environment and the outside world.

Key aspects of mortuary cold room doors manufacture include:

- Materials: 304 stainless steel or polyester-coated galvanized steel (0.5mm thickness)

- Insulation: High-density polyurethane foam at 42±2 kg/m³ density, typically 100mm thick

- Temperature Control: Maintains 2°C to 6°C (35.6°F to 42.8°F) with ±1°C variation

- Safety Features: OSHA-compliant interior release handles and anti-panic hardware

- Door Types: Hinged, sliding, bi-parting, and electric options for different facility layouts

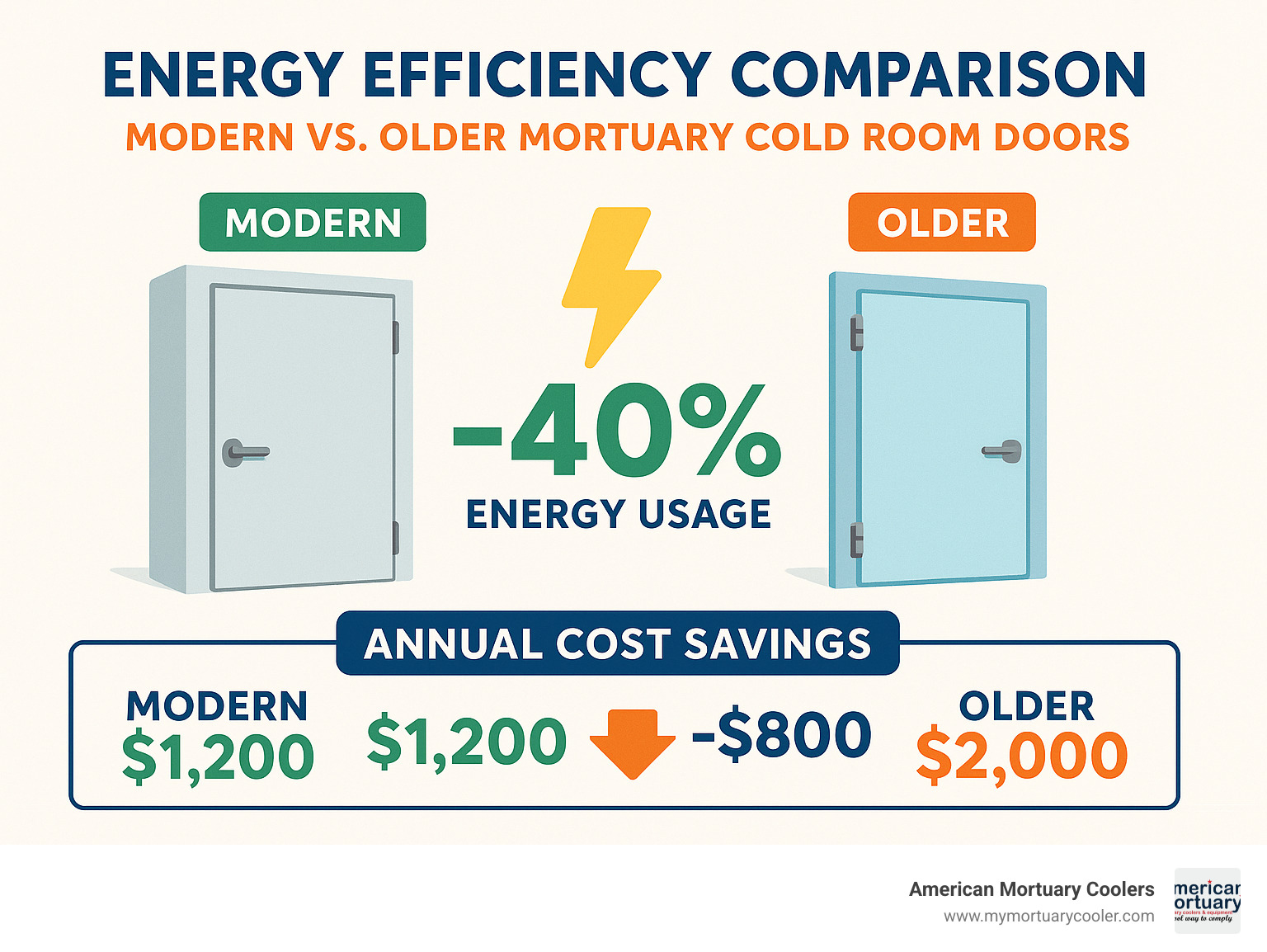

- Energy Efficiency: Modern doors reduce energy consumption by up to 25%

The manufacturing process involves precision panel cutting, foam injection, lamination, curing, and rigorous quality testing. Quality doors typically pay for themselves within 3-5 years through energy savings and reduced maintenance costs.

As funeral directors face increasing pressure to maintain dignified storage conditions while managing operational costs, choosing the right door manufacturer becomes crucial. Poor-quality doors can lead to temperature fluctuations, increased energy bills, and potential compliance issues.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in mortuary cold room doors manufacture and installation across the United States. My background includes working with funeral homes nationwide to specify, install, and maintain temperature-controlled storage solutions that meet both regulatory requirements and operational needs.

Mortuary cold room doors manufacture terms you need:

Understanding Mortuary Cold Room Doors Manufacture

Building quality mortuary doors isn't like making your typical walk-in cooler door. Mortuary cold room doors manufacture requires a whole different level of precision and care. These doors need to handle the unique demands of funeral homes - from maintaining exact temperatures to providing easy access for staff and equipment.

The magic starts with the right materials. Most quality manufacturers use 304 stainless steel for its durability and easy cleaning properties. Some opt for polyester-coated galvanized steel instead, but both need to be at least 0.5mm thick to handle daily use.

What really sets these doors apart is the insulation. We're talking about high-density polyurethane foam at 42±2 kg/m³ density, typically packed into 100mm thick panels. This isn't your average foam - it's engineered to maintain those critical temperatures day after day.

The R-value (thermal resistance) tells the real story. Quality mortuary doors achieve R-values greater than 28, which is significantly higher than standard commercial refrigeration doors. This superior insulation performance directly translates to energy savings of up to 25% compared to older equipment.

Modern doors also feature thermal-break technology in the frames. This prevents condensation and mold formation - something you definitely don't want in a mortuary environment. The airtight magnetic gaskets complete the thermal envelope, keeping temperature variations to a minimum within your storage chambers.

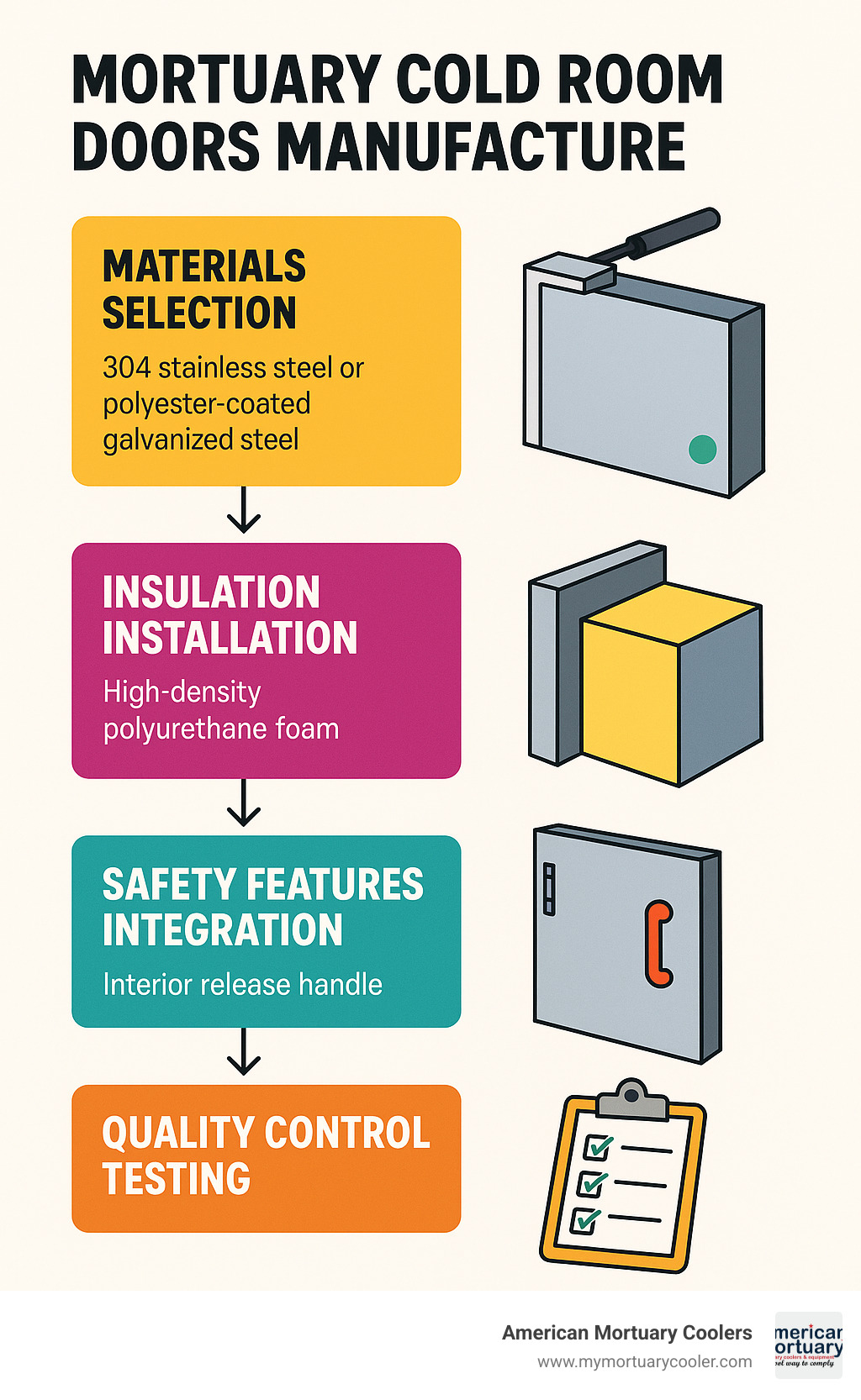

Key Stages in Mortuary Cold Room Doors Manufacture Process

The mortuary cold room doors manufacture process follows strict quality protocols that ensure every door performs consistently. Each stage matters, and cutting corners anywhere can compromise the final product.

Panel cutting kicks things off with computer-controlled precision. Clean, exact cuts determine both structural integrity and thermal performance down the road. There's no room for "close enough" here.

Foaming is where the science really shows. Injecting that high-density polyurethane foam requires precise temperature and pressure control. The foam must hit that specific 42±2 kg/m³ density target for optimal insulation properties. Too light, and you lose efficiency. Too heavy, and you're wasting materials.

Lamination bonds the steel facings to the foam core under controlled pressure. This creates what engineers call a "monolithic structure" - basically, everything works together as one solid unit. This prevents thermal bridging and keeps the door structurally sound for years.

The curing process can't be rushed. The foam needs time to reach full strength and develop its thermal properties. Manufacturers who try to speed this up often end up with doors that fail prematurely.

Frame assembly incorporates those crucial thermal breaks and precision-machined components. This stage determines how smoothly your door operates and how well it seals over time.

Finally, hinge fitting involves heavy-duty hinges with reinforcement plates. These doors are heavy due to all that insulation, so the hardware needs to handle the weight while maintaining proper alignment through thousands of open-close cycles.

Quality Control & Testing in Mortuary Cold Room Doors Manufacture

Quality control in mortuary cold room doors manufacture goes way beyond someone just looking at the finished product. Modern manufacturers use thermal imaging to detect potential thermal bridges or insulation voids that could compromise performance later.

Leak testing ensures those airtight seals actually work. Meanwhile, OSHA safety-release mechanisms undergo rigorous testing to meet 1910.145 standards - because safety can't be an afterthought.

Many leading manufacturers maintain ISO 9001 certification for quality management. This means their processes consistently meet international quality standards. The best companies also hold ISO 14001:2015 for environmental management, showing they care about both quality and sustainability.

Scientific research on insulation performance continues driving improvements in thermal efficiency and energy savings. These ongoing developments help funeral homes reduce operating costs while maintaining the precise environmental control their operations require.

Door Mechanisms, Safety & Hygiene Essentials

When it comes to mortuary cold room doors manufacture, choosing the right mechanism can make or break your daily operations. I've seen funeral directors struggle with poor door choices that create bottlenecks during their busiest moments.

Hinged doors remain the gold standard for most facilities. They're reliable, easy to maintain, and cost-effective. The main drawback? They need full swing clearance, which can be a real challenge in tight spaces.

Sliding doors are perfect when you're working with limited space. They only need wall space equal to the door width - no swing clearance required. This makes them ideal for those narrow hallways that seem to plague older funeral homes.

For facilities handling bariatric cases, bi-parting doors provide the wider openings you need. These double-sliding doors split in the middle, giving you maximum access without requiring enormous wall space.

Electric doors with motion sensors offer hands-free operation that's genuinely helpful when you're maneuvering gurneys. As one funeral director recently told me, "The electric doors are a genuine blessing when guiding a gurney through the doorway during busy days."

The hygiene aspect of mortuary cold room doors manufacture focuses heavily on magnetic gaskets and surface treatments. These gaskets create the airtight seal that keeps your temperatures stable. Plan to inspect them monthly and replace them every 2-3 years under normal use.

Anti-microbial coatings on door surfaces actively fight bacterial growth - a crucial feature for infection control. Heated frames prevent frost and ice buildup, especially important in high-humidity environments where condensation becomes a real problem.

Safety compliance isn't optional. OSHA 1910.145 requires interior release mechanisms so no one gets trapped inside. NSF-7 standards guide cleanability requirements, while ADA compliance ensures accessibility for all staff members.

Comparative Matrix of Door Types & Use-Cases

| Door Type | Space Required | Initial Cost | Maintenance | Best Use Case |

|---|---|---|---|---|

| Hinged | Full swing clearance | Lowest | Minimal | Standard installations |

| Sliding | Wall width only | Medium | Moderate | Limited space facilities |

| Bi-parting | Half wall width each | Highest | Higher | Bariatric access needs |

| Electric | Varies by type | Premium | Highest | High-volume operations |

Smart Features & Energy Innovations

Modern IoT monitoring capabilities let you track temperature and door status remotely through your building management system. Cloud-based temperature alerts have become what facility managers call "a game-changer" - giving you 24/7 oversight without requiring staff on-site around the clock.

Auto-close sensors prevent those costly accidents where doors get left open. We've all been there - someone gets distracted and suddenly your cooler's been running with the door ajar for hours.

Thermal-bridge breakers built into the door construction eliminate those sneaky heat transfer paths that can compromise efficiency. Combined with improved insulation and better sealing technologies, these innovations deliver energy savings of up to 25%.

That 25% reduction in energy consumption isn't just good for your bottom line - it supports sustainability goals while keeping your operational costs manageable. When you consider that quality doors typically pay for themselves within 3-5 years through energy savings alone, these smart features become genuine investments rather than expenses.

Customization, Integration & Selection Guide

Your facility's unique layout tells the story of what door type will work best. We've learned that facility layout considerations matter more than anything else when choosing doors. The way your staff moves gurneys through hallways, how tight your spaces are, and where your storage racks sit all shape the perfect door solution.

Bariatric access has become increasingly important in our work. Standard 36-inch doors simply won't accommodate larger individuals with dignity. We often recommend 48-inch openings or bi-parting doors that provide the width needed while maintaining temperature control.

The racking interface needs careful planning too. Your cantilever storage systems or body box configurations must work seamlessly with door swing patterns. We've seen too many installations where doors interfere with rack access, creating daily frustration for staff.

Modular panel construction gives you flexibility for the future. Facilities change, expand, and reorganize. Smart door design accommodates these changes without requiring complete replacement. Side-loading configurations can maximize every square foot in compact facilities where space costs money.

Workflow optimization considers how your team actually works. Emergency access paths, maintenance accessibility, and daily movement patterns all influence door placement and type. More info about comprehensive solutions shows how thinking about the whole system delivers better results than picking doors in isolation.

Checklist for Choosing the Right Manufacturer

Finding the right partner for mortuary cold room doors manufacture requires asking the tough questions upfront. Lead times vary dramatically between manufacturers. Standard doors typically ship within 2-4 weeks, but custom configurations often need 6-8 weeks. Plan accordingly, especially during busy seasons.

ISO certification matters more than marketing brochures. Look for ISO 9001:2015 quality management systems and relevant safety certifications. NSF certification isn't required for mortuary work, but it shows a manufacturer takes hygiene seriously.

Warranty coverage separates serious manufacturers from the rest. Quality companies offer 10-year warranties on panels and solid coverage on mechanical components. Some extend compressor coverage to 4 years with exchange warranties that minimize downtime.

The 3-5 year ROI through energy savings and reduced maintenance costs should be clearly documented. If a manufacturer can't show you the math, keep looking. A service network with nationwide coverage protects your investment, especially if you operate multiple locations.

References from similar facilities tell the real story. Follow up on performance and service experiences. One funeral director's headache is worth avoiding with your own facility.

Common Installation & Retrofit Challenges

Door squareness and floor level issues cause more problems than any other installation challenge. We've found that careful site preparation prevents most headaches down the road. Uneven floors create gaps that compromise temperature control and waste energy.

Condensation control requires proper vapor barriers and thermal breaks built into the door frame design. Poor installation here leads to mold, ice buildup, and structural damage over time. It's worth doing right the first time.

Limited hallway space often forces creative solutions. In one recent project, we installed bi-parting doors to handle both tight quarters and bariatric access needs. The extra cost paid for itself in improved workflow and staff satisfaction.

Our mitigation approach starts with thorough site surveys and detailed installation drawings. Coordination with other trades prevents conflicts and delays. Temporary cold storage arrangements ensure your operations continue smoothly during installation or retrofit work. Nobody wants to explain to a family why their loved one couldn't be properly cared for because of a door installation.

Care, Maintenance & Lifespan Optimization

Taking care of your mortuary cold room doors isn't complicated, but it makes all the difference in getting those 15-20 years of reliable service that quality doors are designed to provide. Think of it like maintaining a car - a little regular attention prevents big expensive problems down the road.

Daily maintenance really just means keeping things clean and paying attention. A quick wipe-down with approved disinfectants keeps surfaces sanitary and prevents bacterial buildup that could become a health concern. While you're at it, take a moment to check that the door closes properly and the gaskets look good.

Monthly gasket checks are where you'll catch most problems before they become headaches. Look for small cracks, tears, or areas where the magnetic seal isn't holding tight. One funeral director told us, "I wish I'd caught that tiny gasket tear earlier - it cost me a weekend of temperature problems."

Quarterly hinge lubrication with food-grade lubricants keeps everything moving smoothly. This is especially important for heavy insulated doors that put more stress on hardware than regular doors. Don't skip this step - seized hinges are expensive to replace.

The annual thermal scan using infrared cameras might sound high-tech, but it's become standard practice for facilities that want to stay ahead of problems. These scans detect hidden insulation failures or thermal bridges that your eye can't see but your energy bill definitely feels.

A comprehensive spare-parts plan is like insurance for your doors. We always recommend keeping gaskets, basic hardware, and other wear items on hand. When something fails at 2 AM on a weekend, you'll be glad you planned ahead.

Preventive Maintenance Schedule at a Glance

Here's your maintenance roadmap broken down by frequency:

Daily: Visual check of gaskets and hardware, clean and disinfect surfaces, verify proper closure

Weekly: Test interior safety release, inspect door tracks for sliding doors, confirm temperature stability

Monthly: Detailed gasket inspection for damage, clean and adjust hardware, check magnetic seal strength

Quarterly: Lubricate hinges and moving parts, clean condensate drains, test automatic controls

Annual: Professional thermal imaging inspection, comprehensive alignment check, replace worn components

Troubleshooting Quick Reference

When problems pop up (and they will), most issues have straightforward solutions if you know what to look for.

Fogging issues almost always point to gasket problems or thermal bridge failures. Start by checking gasket condition and door alignment - that solves about 80% of fogging complaints we see.

Ice buildup is common in high-humidity environments and usually means you need heated door frames or better ventilation. It's not just annoying - ice buildup forces your cooling system to work harder and wastes energy.

Gasket tears need immediate attention to prevent temperature fluctuations and energy waste. More info about gasket replacement walks you through the replacement process step by step.

Sensor faults on automatic doors usually clear up with basic cleaning. Clean the sensor lenses and check wiring connections before calling for service - you might save yourself a service call.

The bottom line? Mortuary cold room doors manufacture creates equipment built to last, but even the best doors need regular care to deliver their full potential. A little attention now prevents big problems later.

Frequently Asked Questions about Mortuary Cold Room Doors

What temperature range should quality doors maintain?

When we talk about mortuary cold room doors manufacture, temperature control is absolutely critical. Quality doors should help maintain interior temperatures between 2°C and 6°C (35.6°F to 42.8°F) with minimal variation of just ±1°C.

This specific range isn't arbitrary - it's the sweet spot that slows decomposition effectively without freezing tissues. Think of it as finding that perfect balance where preservation works optimally without causing damage.

The door's insulation and sealing performance directly impacts how stable these temperatures stay. We've seen facilities with poor-quality doors struggle with temperature swings that not only compromise preservation but also drive up energy costs significantly. It's like trying to keep your house cool with the front door slightly open - you're fighting a losing battle.

Which is better for tight spaces: hinged or sliding doors?

This is one of our most common questions, and the answer usually comes down to your facility's layout. Sliding doors are generally the winner for limited-space facilities because they operate parallel to the wall and only need wall space equal to the door width.

Hinged doors, on the other hand, need full swing clearance. Imagine trying to open a traditional door in a narrow hallway while maneuvering a gurney - it becomes a real challenge quickly.

However, there's a trade-off to consider. Sliding doors typically have higher maintenance requirements due to their track systems and cost more initially. But here's the thing - the space savings often justify that additional investment, especially in urban facilities where every square foot counts.

One funeral director recently told us, "The sliding doors transformed our workflow. We went from constantly juggling space to smooth, efficient operations."

How often should magnetic gaskets be replaced?

Magnetic gaskets are the unsung heroes of mortuary cold room doors manufacture - they're what keep that critical seal intact. You should inspect them monthly and plan on replacement every 2-3 years under normal usage.

But don't just go by the calendar. Watch for these warning signs that mean immediate replacement is needed: visible cracks, tears, reduced magnetic adhesion, or permanent deformation. If the gasket isn't hugging the door frame snugly, it's time for a change.

High-use facilities or those dealing with challenging environments might need more frequent replacements. We've worked with busy urban funeral homes that replace gaskets annually due to heavy traffic.

The good news? Proper cleaning and maintenance can extend gasket life significantly. A simple monthly wipe-down and inspection routine can save you money and prevent those middle-of-the-night temperature alarm calls that no one wants to receive.

Conclusion

Mortuary cold room doors manufacture requires specialized expertise, quality materials, and rigorous testing to deliver doors that maintain dignity while controlling costs. The investment in quality doors pays dividends through energy savings, reduced maintenance, and reliable performance over 15-20 year lifecycles.

At American Mortuary Coolers, we understand that every facility has unique requirements. Our custom U.S.-built solutions, delivered nationwide from our Tennessee headquarters and regional locations, ensure you get doors engineered for your specific needs. Whether you're in Johnson City TN, Atlanta GA, Chicago IL, or anywhere across our service regions, we deliver energy-efficient, compliant solutions that honor the dignity of those in your care.

The 25% energy savings, 3-5 year ROI, and decades of reliable service make quality mortuary cold room doors a smart investment. Don't compromise on the critical barrier that protects your facility's most important function.

More info about mortuary coolers and our comprehensive range of temperature-controlled storage solutions designed specifically for the funeral industry.