Why Polar-King Leads Commercial Refrigeration

Polar-King has been manufacturing premium outdoor walk-in coolers and freezers for over 40 years, serving thousands of locations worldwide with their patented seamless fiberglass construction.

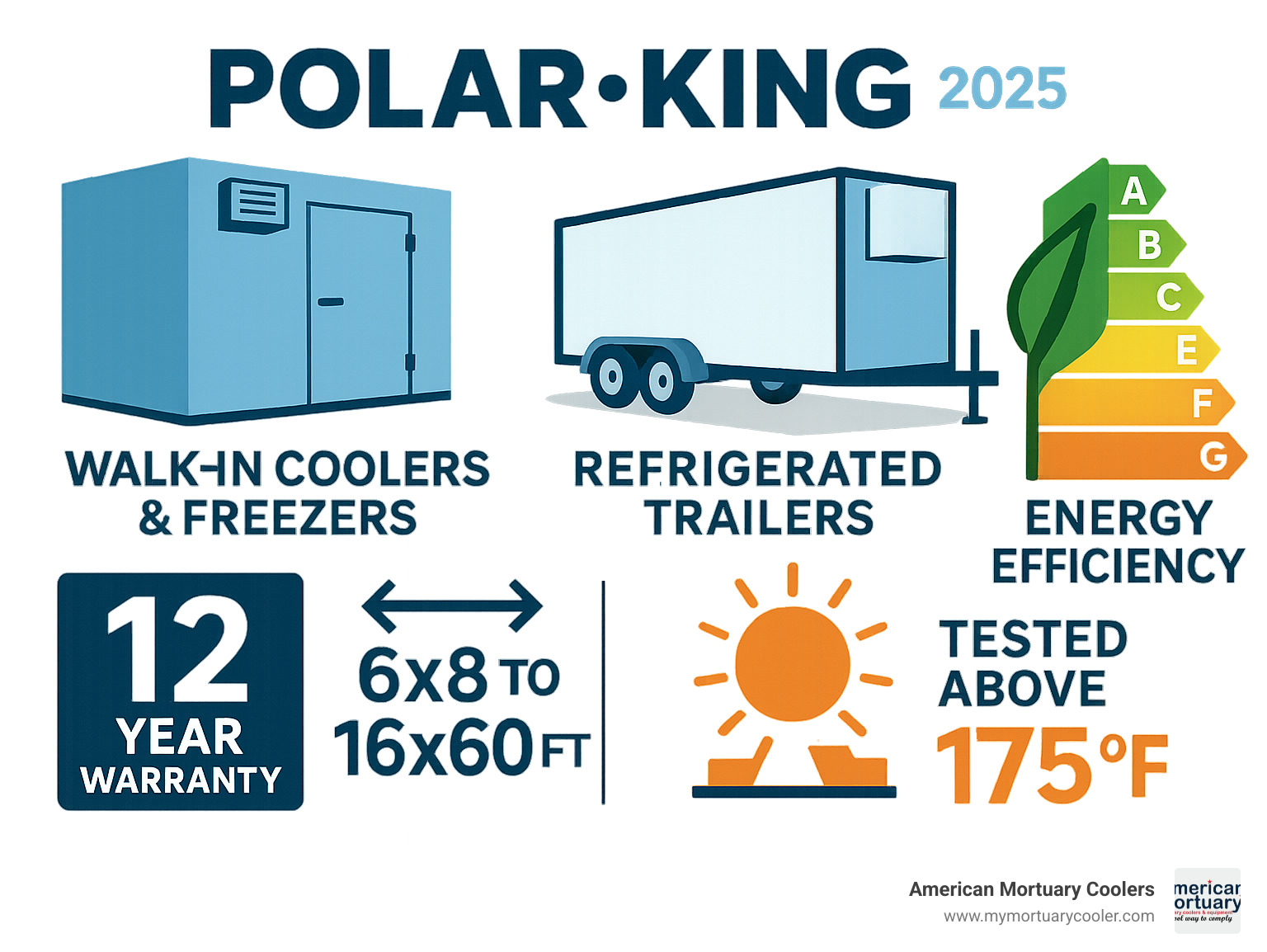

Key Polar-King Products & Benefits:

- Walk-in Coolers & Freezers - Custom widths 6′-16′, lengths up to 60′

- Refrigerated Trailers - Electric-powered, 6×8 to 6×16 sizes

- Seamless Fiberglass Design - 0.04 BTUs thermal conductivity vs aluminum/steel

- Outdoor Durability - Tested above 175°F, snow load up to 100 lbs/sq ft

- Energy Efficiency - Reduces power bills and maintenance costs

- Quick Delivery - Some units ship in as little as 10 days

- Strong Warranties - 12-year structural, 25-year foam coverage

Polar-King's one-piece construction eliminates the panel joints found in traditional walk-ins. This means no rust, no leaks, and worry-free operation even in harsh weather conditions.

The company delivers units fully assembled and ready to operate - requiring only a simple electrical connection by a licensed electrician.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right polar-king refrigeration solutions for their specific needs.

Important polar-king terms:

Inside the World of Polar-King: Products and Heritage

Polar-King started in 1982 with a different approach: designing every component to thrive outdoors instead of just survive. Today, polar-king units operate in thousands of locations worldwide, from food trucks in Florida's heat to processing facilities in Alaska's winters.

The company focuses on four main products: walk-in coolers (35-38°F), walk-in freezers (0°F and below), refrigerated trailers for mobility, and refrigerated buildings for large storage.

Every unit comes with a 12-year complete structural warranty and 25-year coverage on the internal foam structure - far exceeding typical industry warranties of 1-5 years.

Core Polar-King Product Lines

Walk-in coolers maintain 35-38°F where fresh produce stays crisp and prepared foods maintain quality. The seamless fiberglass construction eliminates thermal bridges, cutting energy bills by up to 30%.

Walk-in freezers handle 0°F or below using the same seamless technology. The temperature difference creates massive energy challenges - exactly where seamless construction shines brightest.

Refrigerated trailers come in three sizes: 6'×8' (336 cubic feet), 6'×12' (500 cubic feet), and 6'×16' (600 cubic feet). They run on regular 110V power instead of noisy diesel generators.

Combination units provide both fresh and frozen storage in one footprint for businesses without space for separate units.

Why Businesses Choose Polar-King

The patented seamless design eliminates thermal bridges, moisture entry points, and maintenance headaches. Polar-King eliminated all panel joints in one stroke.

The outdoor rating means these units perform better than indoor units forced to work outside. Units run perfectly in desert heat above 120°F and arctic conditions below -40°F. The fiberglass shell handles snow loads up to 100 pounds per square foot.

NSF and UL approvals ensure compliance with food safety and electrical safety standards. The worldwide service network means qualified help is always available.

The Science Behind Seamless Fiberglass Construction

Polar-King molds the entire shell as one continuous piece of fiberglass. No joints. No seams. No weak spots.

Traditional walk-ins use metal panels that conduct 50-100 times more heat than Polar-King's fiberglass exterior that absorbs only 0.04 BTUs. It's like wearing wool versus metal - fiberglass acts like insulation itself.

The rust-proof fiberglass never corrodes. 20-year-old polar-king units still look almost new with basic cleaning, while metal walk-ins show rust spots within years.

Snow load capacity of 100 lbs/ft² handles serious weather without additional steel framing. Testing above 175°F proves these coolers handle extreme heat while metal panels struggle around 100°F.

The moisture barrier keeps insulation dry for decades. Panel systems have hundreds of potential water entry points, while polar-king units have virtually none.

Rounded corners make cleaning easier and more sanitary than sharp corners in panel systems that harbor bacteria.

For technical details, this Scientific research on thermal conductivity explains the science behind thermal performance.

Polar-King Energy Efficiency Edge

Lower power bills are usually first noticed - many report 20-40% energy savings. Over 15 years, savings often pay for the entire unit.

Thicker insulation with no thermal bridges creates the most efficient cooling envelope possible. Reduced maintenance comes naturally when you eliminate most failure points.

Climate resilience lets units operate reliably in conditions that destroy conventional walk-ins, from salt spray to extreme temperature swings.

Sizes, Configurations & Customization Options

Polar-King builds units in widths from 6′ to 16′ and lengths up to 60′ - no wasted space, no settling for "close enough."

Thru-wall and freestanding configurations offer different benefits. Thru-wall units save interior space while providing convenient inside access. Freestanding units offer complete flexibility.

Quick Ship program delivers popular sizes like 8'×8', 8'×12', and 8'×20' in just 10 days.

Custom colors transform utilitarian appliances into attractive additions. Options include standard colors or custom matches to existing buildings.

| Feature | Standard Units | Custom Units |

|---|---|---|

| Size Options | 8×8, 8×12, 8×20 | 6′-16′ wide, up to 60′ long |

| Lead Time | 10-30 days | 4-8 weeks |

| Color Options | White, Tan | Any color, custom patterns |

| Door Locations | Standard positions | Anywhere needed |

Industries and Applications

Restaurants move cold storage outside to free up kitchen space. Breweries use dual-temperature units for ingredients and finished products. Pharmaceutical applications demand absolute reliability for temperature-sensitive medications.

Catering operations benefit from quiet electric trailers versus loud diesel generators. Agricultural businesses use units for farm-to-market transport and on-site processing.

Morgues and funeral homes represent our specialty at American Mortuary Coolers. The seamless, sanitary interior meets health requirements while maintaining precise temperature control.

Comparing Polar-King Trailers to Traditional Reefers

Traditional refrigerated trucks cost $100,000-$300,000 and require CDL licenses. Polar-King trailers operate on simple 110V/15A power - no diesel costs, maintenance, emissions, or noise.

Compact sizes fit spaces where full-size reefers can't go. NATM compliance ensures federal safety standards. Cost savings are substantial - purchase prices start around $30,000-$50,000 versus six-figure diesel units.

For more detailed information, check our guide on cooler units.

Delivery, Installation, Warranty & Support

Your Polar-King unit arrives factory-assembled and ready to operate. The simple electrical hookup needs just a licensed electrician for the final power connection.

Nationwide delivery uses Polar-King's own trucks and trained drivers with crane or forklift equipment to position units exactly where needed.

Quick Ship programs deliver standard sizes in 10-30 days. Warranty coverage includes 12 years on structure, 25 years on foam insulation, 5 years on compressors, and 1 year on parts.

Maintaining Your Polar-King Walk-In

Coil cleaning keeps systems efficient - monthly in dusty environments, quarterly in normal conditions. Door gasket checks prevent air leaks. Temperature logs satisfy inspectors and catch problems early.

Door discipline training makes real differences in operating costs - keep door-open time short and maintain clear traffic paths.

Troubleshooting Common Issues

Not cooling properly usually has simple causes - check thermostat settings, circuit breakers, and remember defrost cycles temporarily raise temperatures.

Freeze-up issues happen when humid air gets inside. Check door seals and avoid propping doors open. The bump start feature cycles the compressor 3-5 times normally.

Leaking problems are rare with seamless construction. Most "leaks" are spills from inside that need cleaning.

For broader context, our guide to American cooler options covers selection criteria and comparisons.

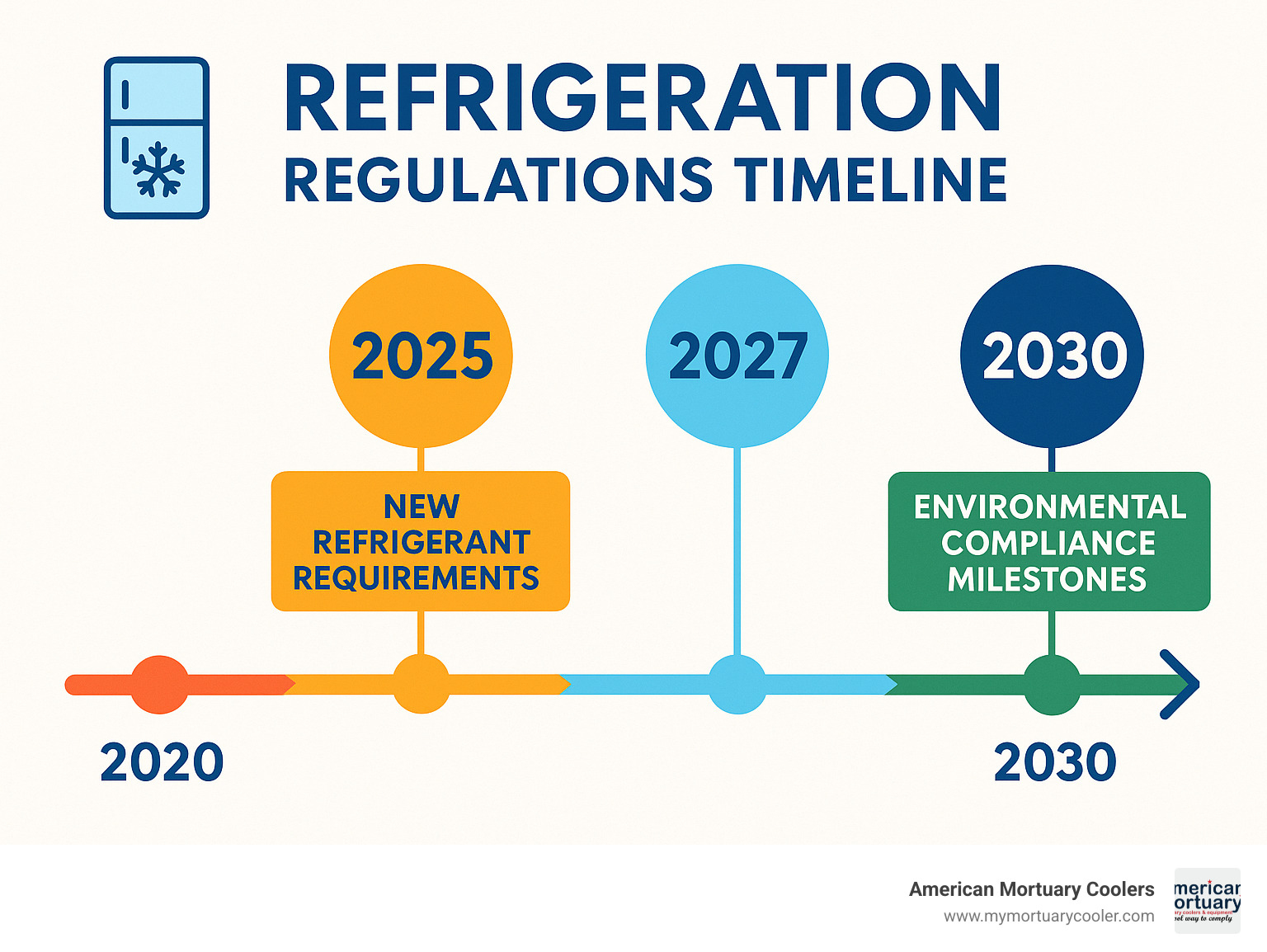

Compliance, Innovations & Future-Proofing

NSF certification meets NSF Standard #7 for walk-in refrigerators. UL listing covers electrical safety with UL approval for burning characteristics. NATM compliance ensures refrigerated trailers meet federal motor vehicle safety standards.

2025 refrigerant regulations will require high-efficiency motors and eco-friendly refrigerants. Polar-King is already ahead of these requirements with energy-efficient components and preparation for next-generation refrigerants like R-290 (propane) and R-744 (CO2).

Smart controls enable remote monitoring, automated defrost scheduling, and predictive maintenance alerts. Humidity modules provide precise environmental control for specialized applications.

Recent Technological Advances

Smart monitoring systems connect units to cloud platforms for real-time status updates and energy usage reports. Dual-temperature combination units maintain different temperatures in separate compartments within one footprint.

E-Track ready trailers accommodate modern cargo management with built-in tie-down points. Improved foam core insulation uses advanced polyisocyanurate for better moisture resistance and consistent R-values.

Quick Ship expansion covers more sizes and configurations for faster delivery of popular models.

Frequently Asked Questions about Polar-King Walk-Ins

What sizes can I order?

Here's where Polar-King really shines - they don't force you into standard panel dimensions like other manufacturers. You can order widths from 6′ to 16′ and lengths up to 60′, which means you get exactly the storage space you need without paying for wasted square footage.

Need something fast? Their Quick Ship program covers popular sizes like 8×8, 8×12, and 8×20 feet with delivery in just 10-30 days. These are the workhorses that most businesses rely on, so Polar-King keeps them in inventory for immediate shipment.

Custom sizes take a bit longer - usually 4-8 weeks - but that's where the magic happens. You can position doors anywhere you need them, not just where panel joints allow. This flexibility makes all the difference when you're trying to integrate a walk-in with your existing workflow.

How energy efficient are Polar-King units?

The numbers tell the story here. Polar-King's seamless fiberglass has a thermal conductivity of only 0.04 BTUs compared to the aluminum and steel used in panel systems. That's not a small difference - it's the difference between a refrigeration system that cycles normally and one that runs constantly trying to keep up.

Real customers report energy savings of 20-40% compared to their old panel-based walk-ins. On larger units, that translates to thousands of dollars saved annually on power bills. The superior insulation combined with zero thermal bridges means your compressor actually gets to rest between cycles.

What really matters for long-term efficiency is the 25-year foam warranty. While panel systems gradually lose efficiency as gaskets fail and joints develop gaps, Polar-King units maintain consistent performance for decades. The seamless construction keeps moisture out of the insulation, so R-values stay stable year after year.

How does outdoor weather affect performance?

This is where Polar-King separates itself from the competition. These units are specifically engineered for outdoor operation - not indoor units adapted for outside use. The fiberglass shell has been tested above 175°F ambient temperature and can handle snow loads up to 100 pounds per square foot without requiring additional steel framing.

We've seen these units operating flawlessly from Arizona's brutal desert heat to Alaska's bitter cold. The seamless construction prevents the moisture infiltration that destroys panel-based systems in harsh climates. No joints means no entry points for rain, humidity, or temperature cycling damage.

Rain, salt spray, and extreme temperature swings don't faze the fiberglass construction like they do metal panels. The non-corrosive material maintains both appearance and performance even in coastal environments where salt air quickly destroys steel and aluminum systems. After 20 years of exposure, a well-maintained Polar-King unit still looks professional and operates efficiently.

Conclusion

After four decades, Polar-King has proven seamless fiberglass construction delivers superior performance. At American Mortuary Coolers, we've witnessed how these units outperform traditional systems with lower lifetime costs from reduced energy bills and minimal maintenance.

The seamless fiberglass construction eliminates every joint and potential failure point. Whether you need a compact 6×8 trailer or massive 16×60 walk-in, polar-king delivers custom solutions that fit your exact needs.

For funeral homes requiring absolute reliability, the professional appearance and precise temperature control meet the highest standards while outdoor durability handles any weather. The 25-year foam warranty and 12-year structural coverage provide best peace of mind.

Ready to explore options? Our guide A Comprehensive Guide to Finding the Best Polar Cooler walks through the selection process.

At American Mortuary Coolers, we deliver these innovative solutions nationwide, backed by our funeral industry expertise. Contact us to find how Polar-King products provide the reliability, efficiency, and durability your business deserves.