Understanding Walk-In Freezer Investment: What Every Funeral Director Needs to Know

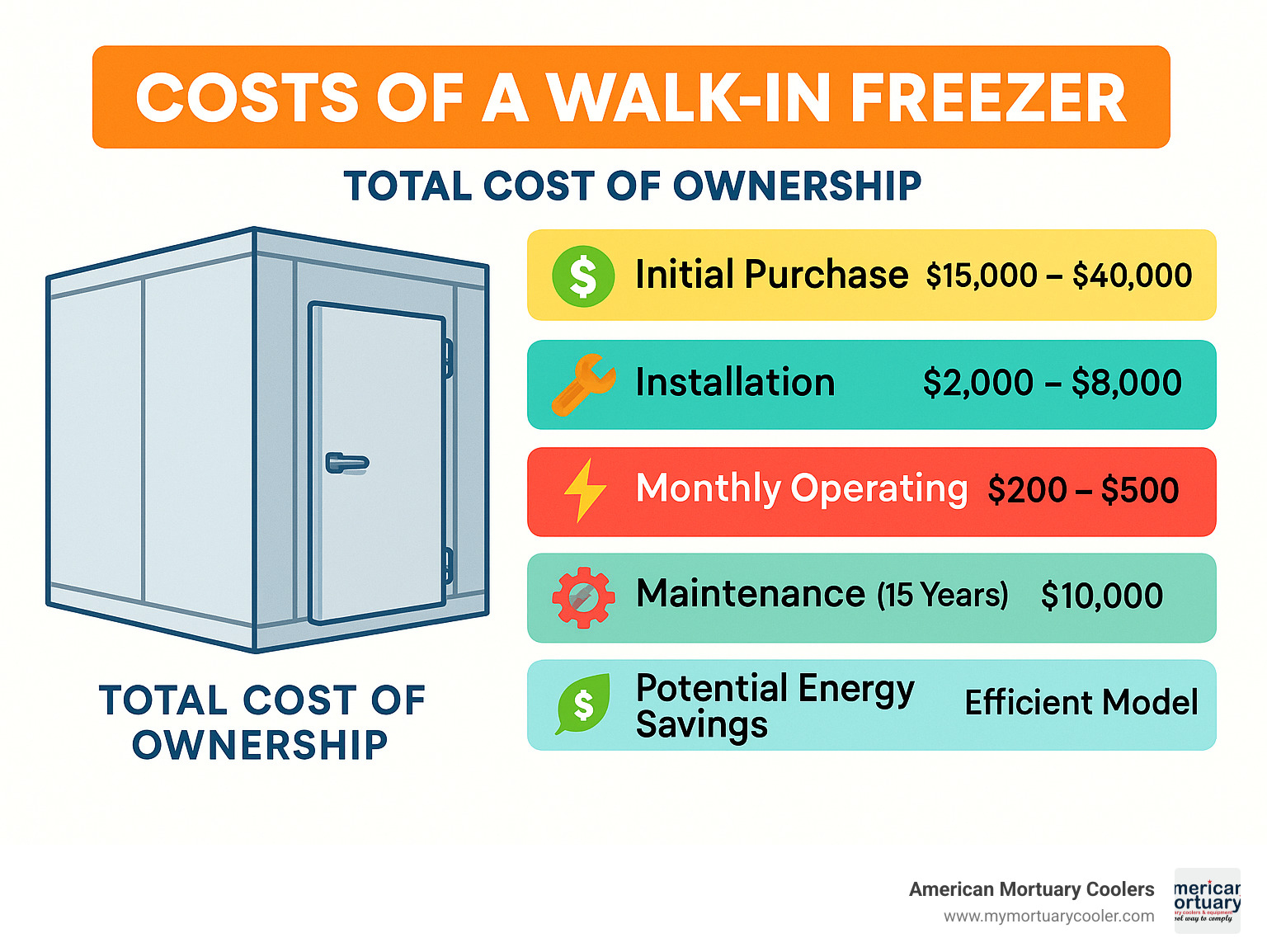

The cost of walk in freezer units varies significantly based on size, features, and installation requirements, but most funeral homes can expect to invest between $15,000 to $40,000 for a complete system. Here's what you need to budget for:

Quick Cost Breakdown:

- Standard Units: $10,000 - $30,000 (quick-ship models)

- Custom Units: $20,000 - $100,000+ (specialized configurations)

- Monthly Operating: $200 - $500 (electricity costs)

- Installation: $2,000 - $8,000 (site prep, electrical, startup)

Walk-in freezers represent a significant investment for any funeral home, but understanding the true cost goes far beyond the sticker price. The refrigeration unit alone accounts for 30-40% of the overall system cost, making it crucial to choose wisely from the start.

Energy costs deserve special attention. A typical 10×10 walk-in freezer consumes approximately 3,476 kilowatt hours per month, translating to roughly $372 in monthly electricity bills at national average rates. Over a 15-year lifespan, operating costs can easily exceed the initial purchase price.

I'm Mortuary Cooler, and as a national-level mortuary cooler supplier, I've helped hundreds of funeral homes steer the cost of walk in freezer decisions while ensuring they get reliable, American-made equipment that fits their specific space and budget constraints.

Walk-In Freezer Basics & Alternatives

When you're considering the cost of walk in freezer units, it helps to understand exactly what you're buying. A walk-in freezer is essentially a room-sized refrigeration unit that maintains temperatures below freezing - typically between -10°F to 0°F. This is quite different from walk-in coolers, which operate in the much warmer 28°F to 55°F range.

For funeral homes, these units serve a critical purpose in the cold-chain process. When embalming isn't immediately possible or when you need extended storage, a walk-in freezer becomes essential equipment.

The storage volume advantage is where walk-in freezers really shine. A typical 8×10 walk-in freezer provides approximately 640 cubic feet of storage space. To put that in perspective, you'd need roughly 16 standard reach-in chest freezers to match that capacity.

Walk-in freezers aren't your only option. Reach-in freezers work well for limited storage needs. Blast freezers are specialized units for rapid cooling. Some facilities consider combination cooler/freezer units that provide both temperature zones in one system.

Key Differences That Influence Cost

Several design factors can dramatically affect your cost of walk in freezer investment.

Insulation thickness is probably the most important factor affecting both initial cost and long-term operating expenses. Most standard units come with 4-inch polyurethane panels, but polyurethane's R-value degrades over time. It starts with an R-value of 32, but after five years, it drops to approximately R-8. Extruded polystyrene maintains better performance, retaining about R-24 after five years.

The compressor size directly impacts upfront costs since the refrigeration unit accounts for 30-40% of your total system cost.

Floor versus no-floor options can reduce initial costs by 10-20%. If your existing concrete floor meets certain criteria, you can skip the floor panels entirely.

Indoor versus outdoor placement affects pricing by 10-15%. Outdoor units require additional weatherproofing but free up valuable indoor space.

Finally, you'll choose between package versus remote system configurations. Package units mount the refrigeration directly on the freezer - simple and cost-effective. Remote systems place the condensing unit elsewhere, reducing noise but increasing installation complexity.

Cost of Walk-In Freezer: Upfront Price Breakdown

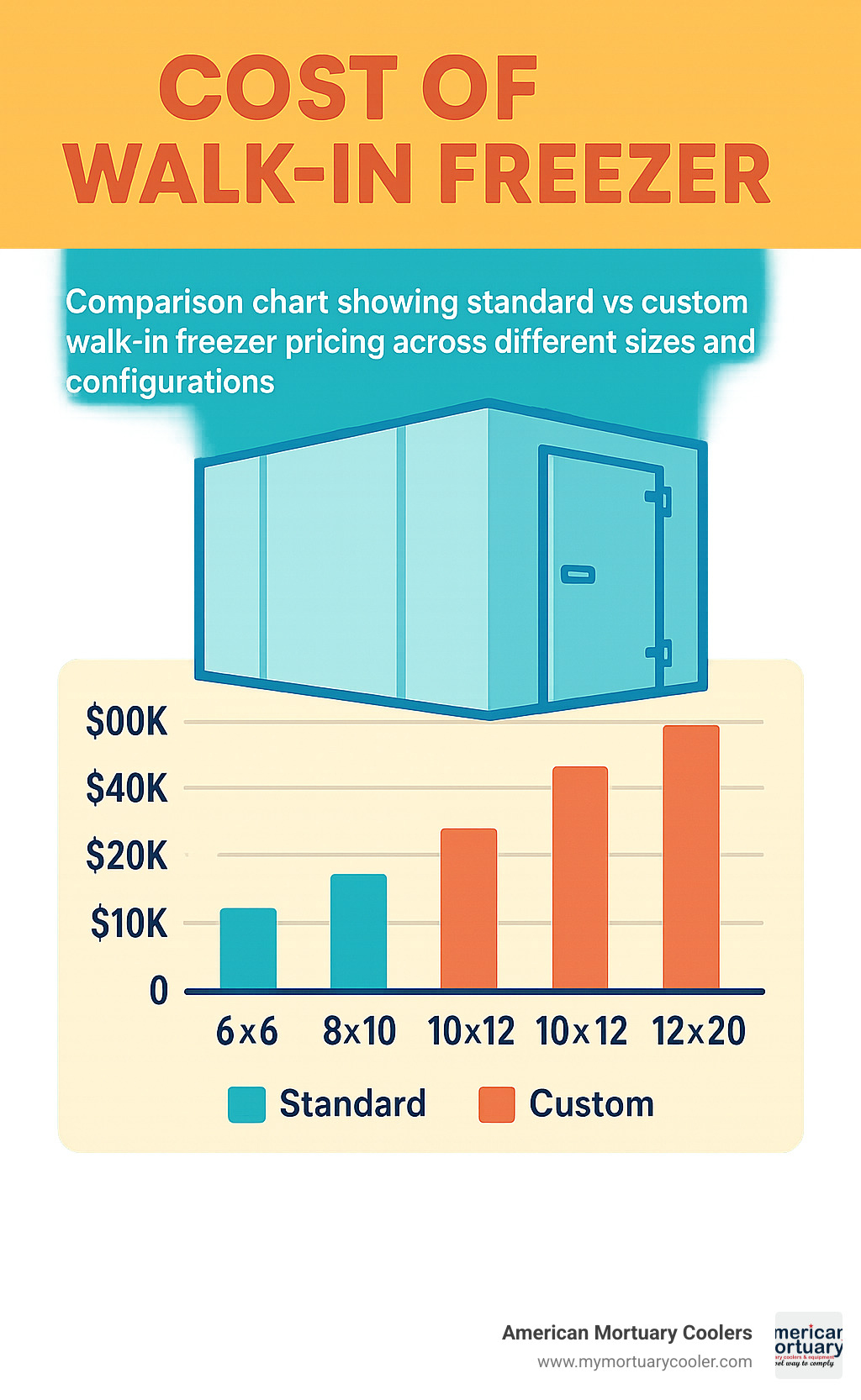

When it comes to the cost of walk in freezer units, you're looking at a wide range depending on what your funeral home needs. Standard quick-ship models typically run between $10,000 and $30,000, while custom configurations can stretch from $20,000 to $100,000+ for specialized setups.

Size plays a huge role in pricing. A compact 6×6 freezer might start around $15,000, while stepping up to a spacious 12×20 unit can push you past $50,000. The refrigeration system alone accounts for 30-40% of your total cost.

Standard Cost of Walk In Freezer Units

For most funeral homes, standard quick-ship units hit that sweet spot between quality and value. These pre-designed configurations average around $15,000 for a typical 8×10 unit, including basic refrigeration equipment.

The beauty of going with a standard unit is straightforward. You'll get faster delivery - 1-6 weeks instead of the 10-12 weeks for custom work. These designs have been tested in the real world, so you know they'll perform reliably. Plus, you're not paying extra for engineering time.

Standard warranty coverage is solid - typically 10 years on panels and 1 year on the refrigeration system. About 70% of funeral homes can meet their storage needs with standard configurations.

More info about Walk-In Cooler Pricing 101

Custom Cost of Walk In Freezer Configurations

Sometimes standard won't cut it, and that's where custom units come in. These start around $20,000 but can climb to $100,000+ for complex installations. The higher price reflects engineering time, specialized components, and unique manufacturing requirements.

Special finishes like stainless steel or custom colors bump up costs. Combination cooler/freezer sections add complexity and price. Unusual dimensions or unique door configurations require custom engineering.

Even with custom units, you can save money. Skipping floor panels can save 10-20% when your existing concrete floor meets requirements. Choosing indoor placement over outdoor installation typically reduces costs by 10-15%.

At American Mortuary Coolers, we've built our reputation on creating custom solutions that balance functionality with budget reality. Operating out of Tennessee, we deliver directly across all 48 contiguous states.

More info about Commercial Walk-In Freezer Cost

Installation & Operating Costs: Electricity, Insulation, Location

Beyond the initial purchase price, the true cost of walk in freezer ownership includes installation expenses and ongoing operating costs. Installation typically runs $2,000 to $8,000, but these expenses often catch buyers off guard.

The electricity bill deserves serious attention. A standard 10×10 walk-in freezer consumes approximately 3,476 kilowatt hours each month, translating to roughly $372 in monthly electricity costs at the national average rate. Over a 15-year lifespan, you're looking at more than $67,000 in electricity costs alone.

This is where energy efficiency becomes crucial. EISA compliance ensures your unit meets minimum efficiency standards, but investing in higher-efficiency models can slash operating costs by 20-30%.

Location matters more than you might think. Proper placement with adequate ventilation can reduce operating costs by 15-25%.

Installation Expense Checklist

Getting your freezer installed properly protects your investment and ensures reliable operation. Site preparation starts with a proper concrete slab that's level within 1/4 inch tolerance. If you're skipping floor panels, you'll need a vapor barrier to prevent condensation issues.

The electrical work requires a dedicated circuit sized for your equipment load, plus a proper disconnect switch. You'll need a licensed electrician for final connections.

Professional startup services include refrigeration system commissioning, temperature calibration, and staff training. This documentation is often required for warranty coverage.

More info about Walk-In Cooler Installation Cost

Operating Cost of Walk In Freezer Per Month

Understanding monthly operating costs helps you budget accurately. The cost of walk in freezer operation depends on several factors beyond local electricity rates.

Runtime patterns show most freezers operate about 18 hours daily. Frequent door openings increase energy consumption as warm air enters. Product load temperature matters too - placing warm items inside forces the system to work harder.

Here's what you can expect for average monthly costs by size: A 6×6 freezer typically costs $244 monthly to operate, while an 8×8 runs about $298. That 10×10 unit hits $372, and a 12×12 freezer reaches $458 per month.

Preventive maintenance directly impacts your electric bill. Regular coil cleaning, gasket inspection, and system tune-ups can reduce energy consumption by 10-15%. We recommend quarterly professional inspections to maintain peak efficiency.

Extra Features, Customization & Long-Term ROI

When you're already investing in a walk-in freezer, the right upgrades can actually save you money over time while making operations smoother.

LED lighting systems might add $500-800 to your upfront cost of walk in freezer, but they use 75% less energy than traditional lighting and last 10 times longer.

Digital temperature monitoring with alarms has saved countless funeral directors from weekend disasters. These systems typically add $1,200-2,000 to your initial investment but provide invaluable peace of mind.

Energy-efficient motors and controls represent smart investments. Variable-speed compressors adjust their output based on actual cooling needs rather than running full-blast constantly.

Most energy efficiency upgrades deliver solid ROI within 3-5 years. After that, it's pure savings flowing to your bottom line. We've had customers document $200-400 monthly savings on electricity bills with the right combination of efficient components.

Many utility companies offer rebates for energy-efficient commercial refrigeration. Some customers have received rebates covering 15-30% of upgrade costs. Return on investment (ROI) calculations become much more attractive when someone else helps pay for improvements.

How Insulation & Energy Upgrades Pay Off

Standard polyurethane insulation starts strong with an R-value around 32 but degrades significantly over time. After five years, you're looking at roughly R-8 performance.

Extruded polystyrene insulation costs more upfront but maintains about R-24 even after five years. It also handles moisture better and won't develop thermal bridging issues.

We've tracked actual performance data from funeral homes using both types. Facilities with extruded polystyrene consistently show 25-35% lower operating costs after the five-year mark. That translates to $100-150 monthly savings on a typical 10×10 freezer.

Variable-speed compressors are game-changers for efficiency. Traditional compressors run at full capacity whenever they're on. Variable-speed units can match their output to actual cooling needs, reducing energy waste by 20-40%.

Premium insulation and efficient components typically add $3,000-6,000 to your initial investment but can reduce operating costs by $1,500-2,500 annually. You're looking at payback within 3-4 years, followed by decades of continued savings.

Location, Layout & Workflow Savings

Smart placement decisions save money both upfront and long-term while making staff lives easier.

Thru-wall installations offer compelling advantages. The refrigeration equipment mounts outside while the freezer space stays inside. You save valuable indoor square footage and get easier service access.

Outdoor prefab units cost about 10-15% more initially but solve space problems neatly. They come with weather protection and can be relocated if facility needs change.

Think about workflow efficiency too. Placing your freezer close to preparation areas reduces transport time and effort.

Door placement and swing direction matter more than you might think. A door that swings into a hallway creates daily frustration. We always review facility layouts to optimize door locations during planning.

PolarLeasing.com offers financing options that can help you afford optimal placement and premium features without straining cash flow.

Buying Decisions: New vs Used, Warranty & Maintenance

When it comes to the cost of walk in freezer equipment, the new versus used decision can make or break your long-term budget.

New equipment gives you peace of mind that's hard to price. You'll get comprehensive warranty coverage - typically 10-12 years on panels and 1-5 years on refrigeration components. Plus, you're guaranteed the latest energy efficiency standards, translating to lower monthly operating costs from day one.

Used equipment might seem like a bargain initially, but hidden problems lurk beneath the surface. Refrigerant leaks, panel delamination, and insulation degradation aren't always visible during inspection.

The refrigerant phase-out issue particularly affects older units. If your used freezer runs on R-22 or other phased-out refrigerants, repair costs skyrocket when you need service.

Here's the reality about maintenance costs: newer units typically require $500-$1,000 annually for professional service, while older equipment often doubles or triples that expense. When you factor in higher energy consumption from less efficient components, the "savings" from buying used quickly evaporate.

More info about The Complete Guide to Choosing a Walk-In Freezer

Maintenance Costs & Schedules

Smart maintenance prevents expensive emergencies and keeps operating costs predictable. Budget between $500-$1,500 annually for professional maintenance, depending on your system's complexity and age.

Quarterly maintenance keeps things running smoothly. Coil cleaning tops the priority list - dirty coils force your compressor to work harder, driving up electricity costs. Temperature calibration ensures accurate readings, while gasket inspection prevents warm air infiltration.

Annual comprehensive inspections catch problems before they become costly repairs. A qualified technician will check refrigerant levels, test safety controls, and evaluate overall system performance.

Professional maintenance typically pays for itself through improved efficiency and avoided emergency repairs. Well-maintained freezers run 15-20% more efficiently than neglected units, translating to significant monthly savings.

Pros and Cons of Buying Used

The lower upfront investment tempts many buyers - used equipment typically costs 30-50% less than new. You'll also find immediate availability, since you're not waiting for manufacturing and shipping.

But the downsides often outweigh the savings. Higher operating costs from reduced efficiency eat into your monthly budget. Increased maintenance requirements mean more service calls and higher annual expenses. Limited warranty coverage leaves you vulnerable to major repair costs.

ROI uncertainty makes used equipment particularly risky for funeral homes. Unlike restaurants that might tolerate occasional equipment downtime, funeral homes face serious consequences when refrigeration fails.

We've calculated that most used units actually cost more over five years when you factor in repairs, higher energy consumption, and reduced reliability. For funeral homes where equipment failure creates serious problems, the reliability and efficiency of new equipment usually justifies the higher initial investment.

Frequently Asked Questions about the Cost of Walk-In Freezer

What impacts the total cost of walk in freezer most?

The biggest factor affecting your cost of walk in freezer investment is surprisingly straightforward - it's the size and refrigeration power you need. Think about it this way: the refrigeration system alone eats up 30-40% of your total budget, so getting the sizing right from the start makes a huge difference in your wallet.

Here's something that might surprise you - a 10×10 freezer costs roughly double what you'd pay for a 6×6 unit, but you get nearly triple the storage space. That's actually pretty good math when you break it down per square foot.

Energy efficiency features deserve serious consideration because they impact your costs for years to come. Yes, premium insulation and high-efficiency components cost more upfront, but they typically slash your operating costs by 25-35%. Most funeral directors find these upgrades pay for themselves within 4-6 years just through lower electricity bills.

The location choice also plays a bigger role than most people expect. Choosing indoor placement over outdoor installation can save you 10-15% right off the bat, while skipping floor panels (when your existing floor works) can cut another 10-20% from your total investment.

How long does a walk-in freezer last?

Most walk-in freezers serve funeral homes reliably for 15-20 years with proper care. The interesting thing is that the insulated panels often outlast the refrigeration equipment by several years. You might need to replace or overhaul the compressor and cooling components after 10-15 years, but the box itself keeps going strong.

I've seen well-maintained units still running smoothly after 25 years, while others that were ignored needed major repairs within 5-10 years. The difference usually comes down to consistent professional maintenance and catching small problems before they turn into expensive headaches.

Your freezer's lifespan depends heavily on how well it was installed initially, whether you stick to a regular maintenance schedule, the environment it operates in, how often staff open the doors, and frankly, the quality of components you chose at the beginning. It's like buying a car - take care of it, and it'll take care of you for decades.

Are there cost-saving tips when ordering?

Absolutely, and some of these strategies can save you thousands without cutting any corners on quality. The smartest approach is design optimization - making choices that reduce costs while still getting exactly what you need.

Skipping floor panels saves 10-20% if your existing concrete floor meets the requirements and you install proper thermal breaks. Many funeral homes can make this work, and it's one of the biggest single cost reductions available.

Timing your purchase can also impact your bottom line. Manufacturers often offer better pricing during slower seasons, and quick-ship models typically cost less than custom builds. If you can be flexible with your timeline, standard sizes almost always cost less than custom dimensions.

Consider combination units if you need both freezer and cooler space. A single combo unit usually costs 10-15% less than buying separate freezer and cooler units, plus you save on installation complexity.

At American Mortuary Coolers, we've helped hundreds of funeral homes find these cost-saving opportunities while ensuring they get equipment that perfectly fits their specific needs. Energy efficiency investments often qualify for utility rebates and tax incentives that can offset a significant portion of upgrade costs - we help identify these programs during the planning process.

The key is balancing upfront savings with long-term value. Sometimes spending a bit more initially saves thousands over the equipment's lifetime.

Conclusion

Making sense of the true cost of walk in freezer systems means looking at the whole picture, not just that initial price tag. A basic unit might seem reasonable at $15,000, but when you factor in installation, those monthly electric bills, and maintenance over 15 years, you're really looking at $75,000 to $125,000 in total costs.

The cheapest option upfront usually isn't the smartest choice. Investing in premium insulation and energy-efficient components might bump up your initial costs by 15-25%, but it typically saves you money in the long run through lower operating expenses and fewer emergency calls.

At American Mortuary Coolers, we've built our reputation on understanding exactly what funeral homes need. Based in Tennessee, we deliver custom, durable solutions across all 48 contiguous states. We're not just selling you equipment - we're partnering with you to find the right solution that fits both your space and your budget.

Every funeral home is different. Maybe you need a standard quick-ship unit that'll be running in three weeks, or perhaps your space requires a custom configuration with special features. Either way, we're ready to sit down with you, understand your specific needs, and provide detailed quotes that make sense.

Our experience installing hundreds of units in funeral homes gives us insights you won't find elsewhere. We know which shortcuts to avoid, which upgrades actually pay for themselves, and how to steer the tricky balance between features and budget.

More info about A Quick Start Guide to Comparing Walk-In Cooler Quotes & Prices

The lowest initial price rarely represents the best value. Focus on what that freezer will cost you over its entire 15-20 year lifespan. Think about reliability, energy efficiency, and working with a manufacturer who actually understands the funeral industry. When you get it right, your walk-in freezer becomes one of those pieces of equipment you barely think about - it just works, year after year, exactly when you need it most.