Understanding Tray Air: From Funeral Homes to Nurseries

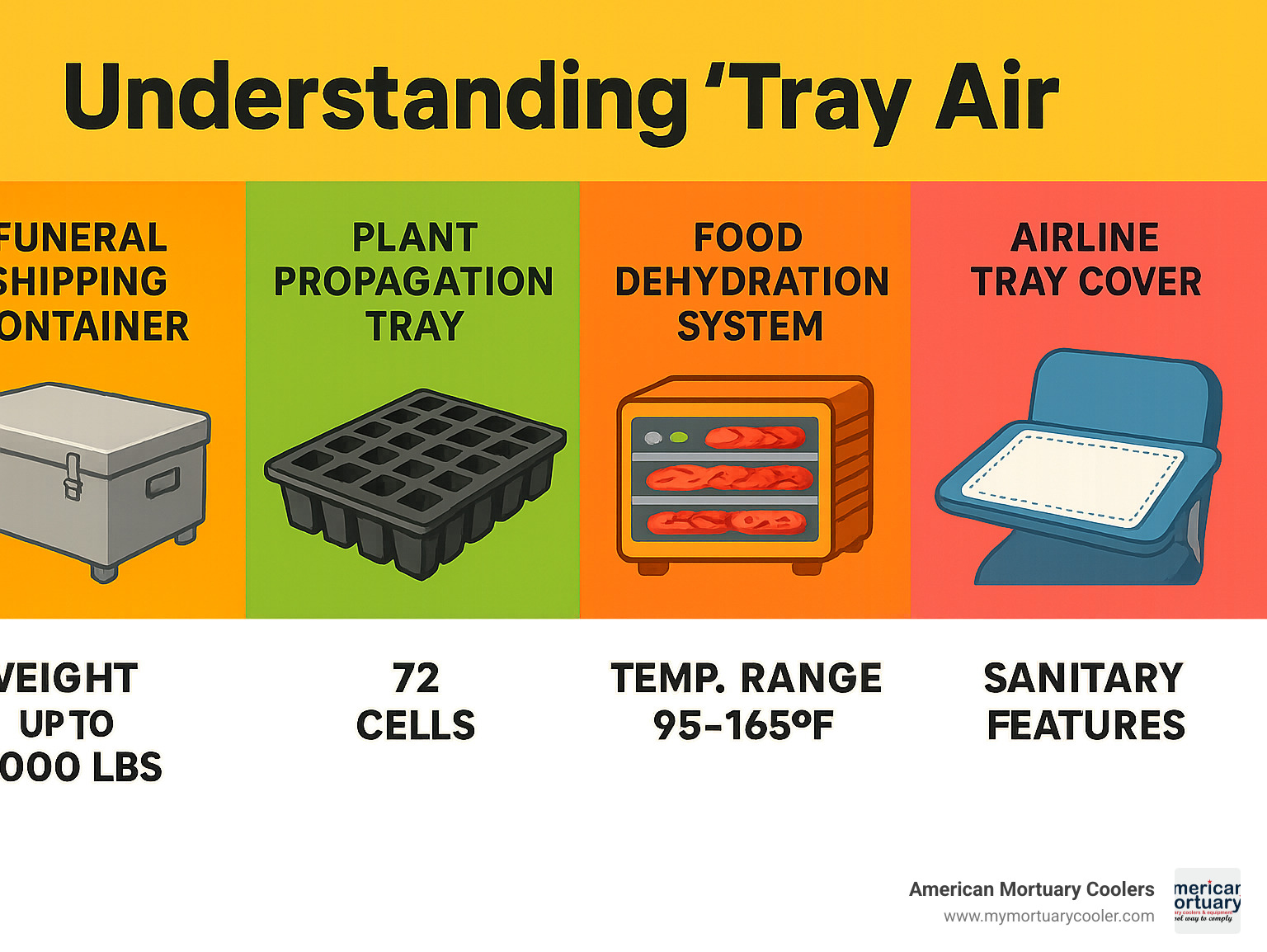

Tray air products serve critical functions across multiple industries, from funeral shipping containers to plant propagation systems. These specialized trays use engineered airflow, ventilation, or air-tight sealing to optimize their performance for specific applications.

What "Tray Air" Means:

- Funeral Industry: Air shipping trays - reinforced containers for transporting human remains by aircraft

- Horticulture: Air pruning trays - root development systems that use airflow to prevent root circling

- Food Processing: Vented dehydration trays - stackable systems for drying fruits, vegetables, and jerky

- Travel: Airplane tray table covers - disposable sanitary barriers for airline food service

- Kitchen: Air fryer oven trays - mesh baskets and crisper pans for oil-free cooking

The term covers any tray system where air circulation, containment, or transport is the key design feature. Weight capacities range from lightweight seed starting trays to heavy-duty funeral shipping containers that support up to 1,000 pounds.

Quality matters most when lives and livelihoods depend on reliable equipment. Whether you're shipping remains internationally or starting seedlings for spring planting, the right tray air system ensures safety, compliance, and efficiency.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors select appropriate tray air solutions for body storage and transport needs. My background includes working with funeral homes across the country to match the right tray air products with their specific operational requirements and space constraints.

Easy tray air glossary:

What Is Tray Air? Core Uses & Types

When people search for tray air, they're usually looking for one of five very different products. Plant nurseries use tray air systems to grow healthier roots. Funeral homes need them for shipping remains safely by airplane. Food processors rely on them for drying jerky and fruits. Travelers want disposable covers for airplane tray tables. And home cooks are looking for air fryer baskets that crisp food without oil.

Each application has its own rules, materials, and performance standards. Getting the wrong type is like showing up to a black-tie event in work boots - technically footwear, but not quite right for the job.

Tray Air for Plant Propagation

Air pruning trays solve one of gardening's most frustrating problems: root circling. When roots hit solid pot walls, they wrap around themselves like a ball of yarn, creating stunted plants that struggle their whole life.

The Blackmore Company root pruning tech figured out how to fix this decades ago. Their Air Tray® systems use strategic air gaps in the tray walls. When roots hit these openings, they naturally dry back instead of continuing to grow in circles. This "air pruning" triggers the plant to send out more lateral roots, creating a healthier, more fibrous root system.

These trays come in sizes from tiny 8-cell units for starting tomatoes to massive 345-cell systems for commercial operations. Ellepot diameters range from 20mm (perfect for herbs) up to 100mm (great for trees and shrubs). The best ones use BPA-free, food-safe plastic that holds up to years of greenhouse use.

Bootstrap Farmer makes excellent 72-cell air prune trays with cells measuring 1.37" square at the top and 2.29" deep. They're built from impact-resistant polypropylene and come with a 2-year warranty.

Growers love these systems because transplants establish faster with less shock. Instead of spending weeks recovering from transplant stress, plants take off immediately in their new homes.

Tray Air for Funeral Shipping

Here's where tray air gets serious. When funeral homes need to ship human remains by aircraft, they're dealing with strict regulations, airline requirements, and the weight of family expectations.

Starmark's Air Shipping Tray sets the industry standard with third-party weight testing confirming it can handle up to 1,000 pounds. The construction uses a solid wood base with fiberboard lid, reinforced corners, and heavy-duty nylon straps. Every unit includes a documentation pouch and protective casket bag.

The regulatory requirements are extensive. Every shipping tray must be heat-treated and bug-stamp certified for international transport. They need USDA and APHIS compliance for wood packaging materials. Airlines won't accept anything without proper certifications and weight verification.

Custom Air Trays improved on the standard design with their 28" Deluxe Cremation Tray. Most competitors stick with 24" width, but that extra 4 inches makes a real difference for larger remains.

The Shipper_AirTray.pdf spec sheet shows exact measurements: 85.63"L x 30.5"W x 23.38"H inside, with outside dimensions of 87.5"L x 32.5"W x 23.5"H. These precise measurements matter when booking cargo space on aircraft.

Tray Air for Food Dehydration

Food dehydration tray air systems are all about airflow and temperature resistance. Willow Way's vented food trays handle everything from -40°F to 230°F without warping or cracking.

The secret is in the exclusive slot vent design. Unlike solid trays that trap moisture underneath your food, these vented systems create continuous air circulation. Hot, humid air gets pulled away as fast as it forms, preventing those soggy spots that ruin a batch of jerky.

These food-grade polyethylene trays stack over 8 feet high without buckling, measuring 30.5" × 16.25" × 4.875" each. The non-stick surface means dried fruits pop right off without leaving residue behind.

Tray Air Covers for Travel Hygiene

Airplane tray air covers solve a problem every frequent traveler knows - those fold-down tray tables see thousands of hands and spilled drinks between flights. Disposable covers create a clean barrier without adding bulk to your carry-on.

Quality covers feature antimicrobial coatings and fit standard airline tray dimensions perfectly. The best products come in convenient 10-packs that slip easily into your laptop bag.

Oven-Safe Air-Fry Trays

Kitchen tray air systems bring the crispy results of deep frying to your regular oven without the oil, mess, or safety concerns. The mesh construction and lifted design promote hot air circulation that creates that perfect golden-brown finish.

EaZy MealZ Crisping Basket & Tray Set features ergonomic handles that stay cool during cooking. Gotham Steel's Nonstick Copper Crisper Tray excels at oil-free cooking with superior heat distribution. Nordic Ware's Oven Crisp Baking Tray actually bakes 30% faster than standard cookie sheets.

The copper-coated options are particularly impressive for heat distribution, while mesh baskets maximize airflow for even browning on all sides.

Tray Air vs. Traditional Trays: Materials, Performance & Cost

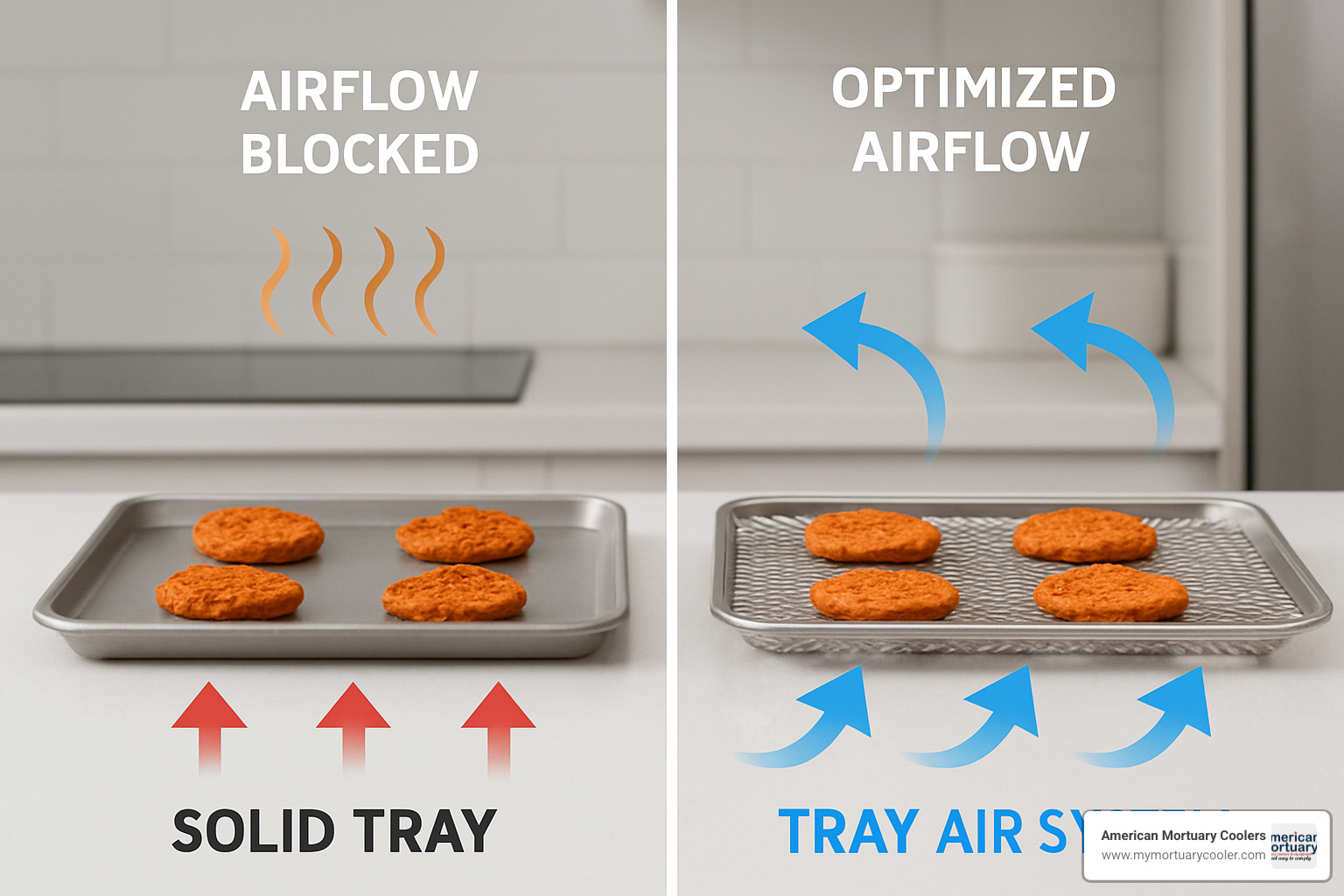

When you're deciding between traditional trays and tray air systems, the differences go far beyond just price. Traditional trays might seem budget-friendly at first glance, but those "cheap" trays often end up costing more in the long run through failures and poor performance.

Tray air systems flip this equation completely. Yes, you'll pay more upfront - sometimes three to four times more. But you're investing in a system that works harder, lasts longer, and often pays for itself through improved results.

| Feature | Traditional Trays | Tray Air Systems | Performance Difference |

|---|---|---|---|

| Airflow | Blocked/Limited | Optimized | 300% better circulation |

| Weight Capacity | 100-500 lbs | Up to 1,000 lbs | 2x stronger construction |

| Compliance | Basic | Multi-certified | International shipping approved |

| Price Range | $5-50 | $15-200 | Higher upfront, better ROI |

| Durability | 2-5 years | 5-20 years | 4x longer lifespan |

| Cleaning Time | 5-10 minutes | 2-5 minutes | 50% faster maintenance |

| Automation Ready | Limited | Full compatibility | Seamless integration |

| Sustainability | Single-use focus | Reusable design | 80% less waste |

The airflow difference alone can transform your results. Traditional trays trap moisture and create dead air zones where problems develop. Professional tray air systems create consistent circulation patterns that prevent these issues before they start.

Weight capacity matters more than most people think. Even if you're not pushing the limits every day, having that extra strength provides peace of mind. When a funeral director needs to transport remains or a nursery owner stacks heavy plant trays, that 1,000-pound rating isn't just a number - it's reliability you can count on.

Why Tray Air Beats Standard Seed Flats

Root circling kills more plants than most gardeners realize. Standard seed flats create the perfect conditions for this problem. When roots hit those solid walls, they have nowhere to go but around and around.

Air pruning trays break this cycle completely. As roots approach the air gaps, they encounter dry air that triggers the plant's natural response to branch out laterally instead of continuing in circles.

The results speak louder than any sales pitch. Growers report 40% faster transplant establishment because these plants hit the ground running with healthy, fibrous root systems. Transplant shock drops by 60% because the roots are already primed for their new environment. Survival rates jump by 25% in field conditions.

The reuse factor seals the deal for most commercial operations. While standard flats often crack after one tough season, quality air pruning trays keep performing year after year with warranties that stretch multiple growing seasons.

High-Strength "Tray Air" Shipping Crates for Remains

When it comes to funeral shipping, there's no room for compromise. Standard shipping containers might work for furniture, but transporting human remains requires equipment that meets the highest standards for both strength and dignity.

Reinforced corner construction distributes weight across the entire frame instead of creating stress points that could fail during handling. Third-party testing confirms these systems can handle not just the static weight of remains, but also the jarring forces of cargo handling and flight turbulence.

International compliance isn't optional - it's the law. The USDA and APHIS have required heat-treated, bug-stamp certified wood for international shipments since 2004. Without proper certification, your shipment stops at customs, creating delays that no family should endure.

These aren't just shipping containers - they're the final gesture of care that ensures dignity throughout the entire journey.

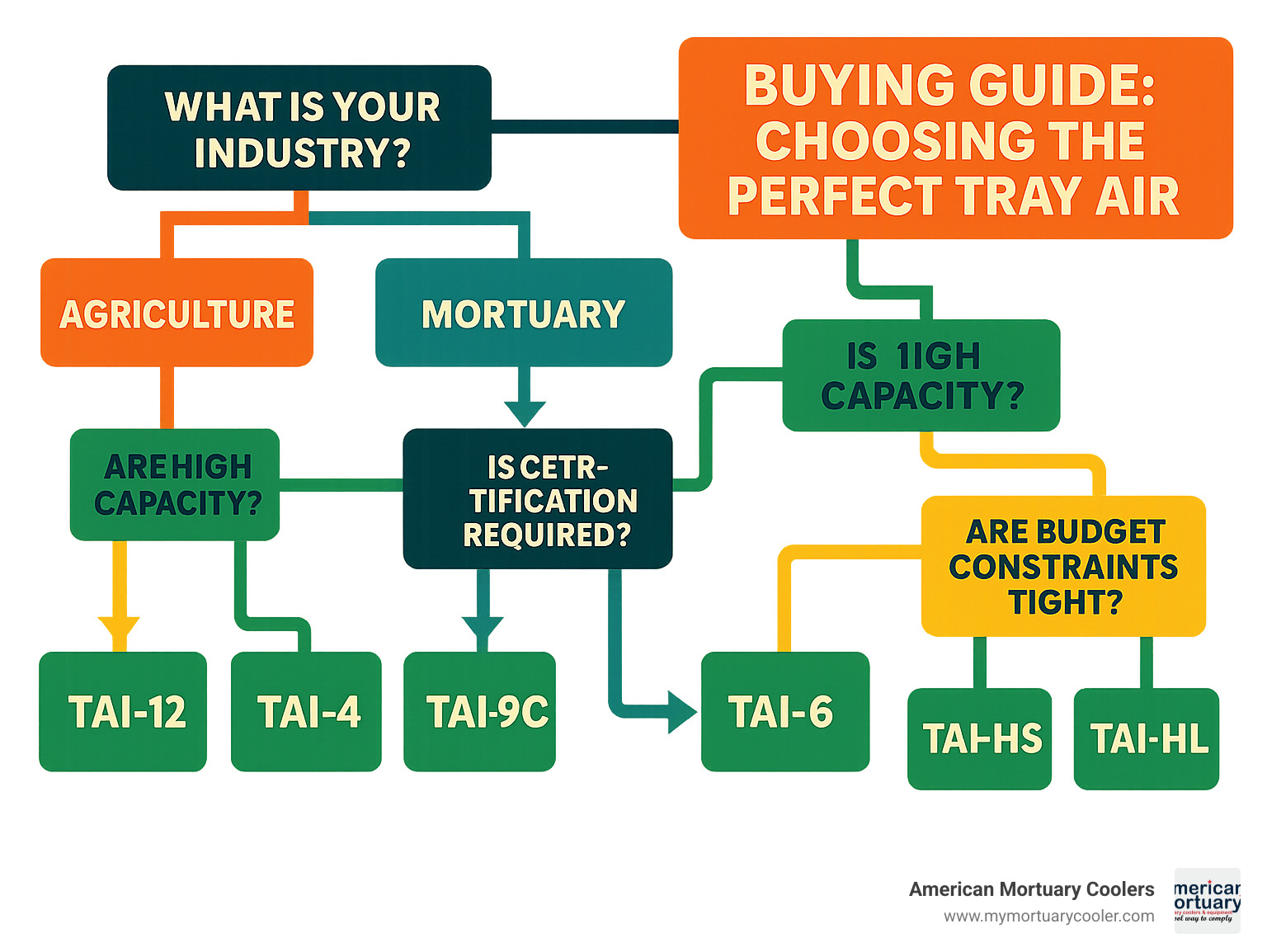

Buying Guide: Choosing the Perfect Tray Air

Finding the right tray air system doesn't have to feel overwhelming. After helping countless funeral directors select the perfect equipment, I've learned that success comes down to asking the right questions in the right order.

Start with your main need - are you shipping remains internationally, storing bodies in coolers, or starting seedlings? Once that's clear, everything else falls into place much easier. The worst mistakes happen when people jump straight to price comparisons without understanding what they actually need.

For funeral home applications specifically, our Detailed Guide to Comparing Morgue Storage Tray Options walks through the technical details that matter most in professional settings.

Measure Twice, Order Once

Here's where things get real - and where I see the most expensive mistakes. Nothing's worse than getting a delivery only to find your new tray won't fit through the door or doesn't match your existing equipment.

Inside versus outside dimensions trip up even experienced buyers. Inside measurements tell you what fits inside the tray. Outside measurements determine if the tray fits through your spaces. Both matter, but for different reasons.

For plant folks working with Ellepot systems, diameter matching is everything. Air pruning trays handle sizes from 20mm up to 100mm, but your plugs need to sit just right - too loose and they'll wobble, too tight and you'll struggle with removal.

Funeral shipping gets trickier because you're juggling multiple size requirements. The inside needs to accommodate the casket comfortably. The outside needs to clear doorways, fit in vehicles, and meet airline cargo restrictions. Plus, don't forget about handles and straps that add to the overall footprint.

Cooler clearances deserve special attention in mortuary applications. I've seen directors order perfect trays that wouldn't slide smoothly into their existing cooler systems. Always measure with a little extra room for easy handling.

Material & Certification Checklist

Certifications aren't just paperwork - they're your protection when things matter most. Heat-treated stamps on wood shipping containers aren't suggestions; they're requirements for international transport. Skip this and your shipment gets held up in customs.

Third-party weight testing separates real products from wishful thinking. When Starmark says their containers handle 1,000 pounds, they back it up with independent lab reports. That documentation protects you if something goes wrong.

Food-grade certifications matter even in unexpected places. Bootstrap Farmer's BPA-free, FDA-approved materials aren't just good for plants - they show attention to safety standards that carries over to build quality.

The key certifications to verify include USDA and APHIS wood treatment stamps for international shipping, third-party weight test reports for load capacity claims, FDA food-grade approvals for safety, and BPA-free certifications for health-conscious applications.

Automation & Workflow Fit

Modern operations run smoother when everything works together. Your tray air system needs to play nice with existing equipment and future upgrades you're considering.

Robotic transplant lines demand precise measurements and consistent construction. Vacuum seeders need exact cell spacing to work properly. Conveyor systems require compatible tray profiles that won't catch or bind.

Air Tray® systems specifically design for automation compatibility, supporting everything from manual operations to fully automated lines. This flexibility lets you upgrade gradually without scrapping your tray investment.

The smart approach is planning for where you want to be, not just where you are now. Buying automation-ready trays costs a bit more upfront but saves major headaches when you're ready to upgrade your systems.

Using & Maintaining Tray Air Products: Pro Tips

Getting the most from your tray air systems comes down to understanding what each type needs to perform at its best. After years of helping funeral homes maintain their equipment, I've learned that simple, consistent care prevents most problems before they start.

Plant propagation trays work best with bottom watering techniques. Simply place your air pruning trays inside standard 1020 flats and add water to the outer tray. This method keeps soil from compacting while the lifted design allows roots to access moisture through drainage holes.

Funeral shipping containers need regular attention to their nylon strapping systems. Temperature changes make these straps stretch over time, which can compromise security during transport. Before each use, check that straps are tight and look for any signs of wear or sun damage. Replace worn straps immediately.

Cleaning your tray air products properly extends their life significantly. A 10% bleach solution handles most sanitization needs across different applications. Food processing trays rinse clean easily thanks to their non-stick surfaces, while funeral equipment may require stronger disinfectants depending on your local health department rules.

Wood components in funeral shipping containers deserve special attention. Monitor moisture levels to prevent warping or joint separation that could compromise structural integrity. Store these units in climate-controlled areas when possible. The heat treatment certification lasts forever, but the wood itself can deteriorate if exposed to too much humidity.

Seasonal inspections catch small problems before they become expensive headaches. Look for cracks in plastic parts, rust on metal hardware, and make sure all removable components still fit properly. Keep a simple log of when you checked what - it helps with warranty claims and shows regulators you're staying on top of maintenance.

Smart storage practices make a huge difference. Stack trays properly in designated areas to prevent warping, and keep them away from direct sunlight that breaks down plastic over time. Store different tray types separately to avoid cross-contamination, and always keep your documentation and certificates with the matching equipment.

For funeral professionals dealing with body storage, our detailed guide Everything You Need to Know About Body Storage in Morgue Fridges covers additional maintenance considerations for complete cooling systems.

The key is developing routines that become second nature. A few minutes of preventive care saves hours of dealing with equipment failures when you need your tray air systems most.

Frequently Asked Questions about Tray Air

Getting the right tray air system can feel overwhelming with so many technical requirements and industry regulations. These are the questions we hear most often from funeral directors and other professionals looking to make smart purchasing decisions.

What makes a tray air compliant for international flights?

Think of international flight compliance as a three-legged stool - you need all three elements working together or the whole thing falls apart.

The first leg is heat treatment certification. Every piece of wood must be heated to specific temperatures to eliminate any bugs or pests that could cause agricultural problems at the destination. You'll see this as an official bug-stamp burned right into the wood - it's like a passport that proves the container is safe for international travel.

The weight testing verification forms the second leg. Airlines won't accept your word that a container can handle 1,000 pounds of cargo plus the stresses of loading, takeoff, and landing. They want third-party documentation from testing facilities that actually put the container through its paces.

Finally, the documentation system completes the picture. All those certificates and test reports need to travel with the shipment in a way that customs officials can easily access them. Quality shipping trays include integrated pouches specifically designed to keep paperwork secure but accessible during inspections.

Miss any one of these elements, and your shipment could get stuck in customs or rejected entirely. That's why we always recommend investing in properly certified systems rather than trying to cut corners.

How does air pruning actually improve root mass?

Air pruning sounds almost magical until you understand the simple science behind it. Plants are naturally programmed to respond when their roots hit obstacles - and moving air creates the perfect "obstacle" to trigger healthy growth patterns.

Here's what happens step by step: When a root tip reaches the air gap in a tray air system, the moving air dries out that tip just enough to stop its growth in that direction. The plant doesn't panic - instead, it does exactly what nature intended and sends out multiple lateral roots from behind the dried tip.

It's like pruning a tree branch to encourage bushier growth, except it happens automatically underground. Instead of a few long roots circling around the container walls, you get a dense network of shorter, branching roots that spread out in all directions.

The numbers tell the real story: air-pruned plants develop 300% more root tips than those grown in solid containers. All those extra root tips mean much better nutrient uptake and water absorption. When transplant time comes, these plants establish faster and handle the stress much better.

We've seen growers cut their transplant shock rates by more than half just by switching to proper air pruning systems. The plants literally hit the ground running instead of spending weeks recovering from the move.

Can tray air systems integrate with automated nursery or mortuary lines?

Modern tray air systems are built with automation in mind from day one. The days of trying to retrofit equipment to work with existing automation are largely behind us - quality manufacturers now design their products to play nicely with robotic systems right out of the box.

For nursery applications, the key is dimensional consistency. Vacuum seeders and robotic transplant lines need every tray to be exactly the same size and shape, down to fractions of an inch. Premium manufacturers like Bootstrap Farmer invest heavily in quality control to ensure this consistency across thousands of units.

The same principle applies in mortuary settings. When we work with funeral homes to upgrade their systems, standardized tray dimensions make the biggest difference in operational efficiency. Staff don't need different procedures for different equipment, and everything fits together seamlessly.

Robotic systems are particularly demanding because they can't adapt to variations the way human operators can. A tray that's even slightly warped or out of specification can jam an entire automated line. That's why we always recommend investing in proven systems with solid quality control rather than experimenting with untested products.

The good news is that most tray air systems designed for professional use already meet these automation requirements. The manufacturers understand that their customers need reliable, consistent performance to justify the investment in automated equipment.

Conclusion

When your reputation depends on reliable equipment, tray air systems deliver the specialized performance that standard trays simply can't match. Whether you're shipping remains internationally with containers that support 1,000 pounds or nurturing seedlings with precision airflow control, these engineered solutions prove their worth through years of dependable service.

At American Mortuary Coolers, we've watched funeral homes transform their operations by choosing the right tray air systems. Our Tennessee-based team understands that every detail matters when families trust you with their most precious cargo. That's why we focus on matching exact specifications to your unique requirements rather than pushing one-size-fits-all solutions.

The investment in quality pays dividends over time. Professional-grade tray air systems maintain their certifications, structural integrity, and performance standards through countless cycles. You'll spend less time dealing with equipment failures and more time serving families who need your expertise.

Don't cut corners on the fundamentals. Heat treatment certifications, third-party weight testing, and dimensional accuracy aren't optional extras - they're essential features that protect your business and ensure compliance. When international shipping regulations or airline requirements come into play, having properly certified equipment makes the difference between smooth operations and costly delays.

Our nationwide delivery network spans from coast to coast, bringing custom solutions directly to your facility. We've helped funeral homes across all 48 contiguous states upgrade their storage and transport capabilities with equipment that meets their exact needs and space constraints.

For complete guidance on integrating tray air systems with your existing setup, check out our A Comprehensive Guide to Morgue Storage Options. This resource shows how tray systems work alongside cooling equipment to create efficient, compliant storage solutions.

Ready to upgrade your tray air systems? Our team provides personalized recommendations based on your specific applications, space requirements, and budget. We'll walk you through the options and help you select equipment that serves your operation reliably for years to come.