Why Walk-In Freezer Repair Matters for Your Business

Walk in freezer repair is critical for businesses that depend on frozen storage to protect valuable inventory and maintain food safety standards. When your walk-in freezer breaks down, you're facing potential losses of thousands of dollars in spoiled products, plus the risk of violating FDA temperature requirements.

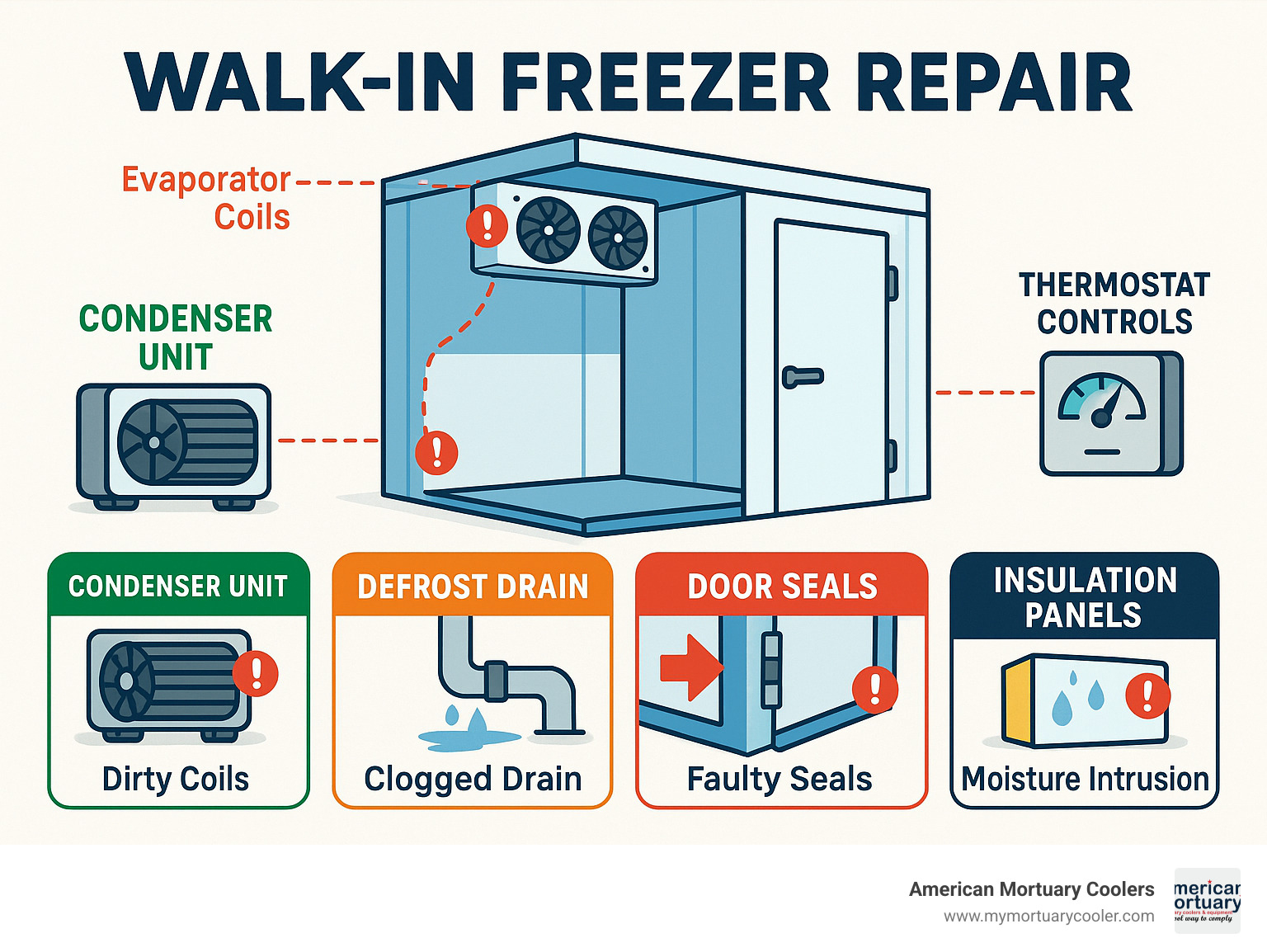

Common walk-in freezer problems and solutions:

- Ice buildup on walls/coils - Check door seals, clean drain lines, verify defrost cycles

- Not cooling properly - Inspect thermostat, clean condenser coils, check refrigerant levels

- Running constantly - Clean coils, check door seals, verify proper loading practices

- Strange noises - Examine fan belts, motor bearings, and unit leveling

- Water pooling - Clear defrost drain blockages, test drain heaters

As one industry expert notes: "Walk-in coolers and freezers represent a significant investment, typically ranging from $15,000 to $30,000, excluding installation costs." With proper maintenance, these units can last 10-15 years, but neglect often leads to costly emergency repairs and product loss.

Regular maintenance prevents most failures. Monthly coil cleaning, quarterly professional inspections, and daily temperature monitoring can catch problems before they become expensive disasters. The research shows that preventive maintenance can help catch minor issues before they become expensive problems.

I'm Mortuary Cooler, a national-level supplier of commercial refrigeration systems with experience in walk in freezer repair and maintenance. My background includes helping funeral homes and commercial facilities maintain reliable cold storage through proper equipment selection and preventive care strategies.

Find more about walk in freezer repair:

Most Common Problems & Early Warning Signs

When your walk in freezer repair needs start showing up, catching them early can save you thousands of dollars and keep you on the right side of food safety regulations. The FDA requires food to stay below 40°F, and your walk-in freezer should maintain around -10°F. Miss those targets, and you're facing spoiled inventory and potential regulatory issues.

The warning signs usually don't sneak up on you if you know what to watch for. Ice building up everywhere is often the first red flag, followed by thermostat issues that leave you guessing about actual temperatures. Refrigerant leaks can turn a small problem into an expensive emergency, while fan failures and defrost drain clogs create their own cascade of issues.

Don't ignore the door gasket wear either - those rubber seals work harder than you might think. When your unit starts running constantly, making strange noises, or you notice panel insulation starting to fail, it's time to take action. Compressor short-cycling is another biggie that can turn into a costly replacement if you wait too long.

Ice or Frost Everywhere

Nothing says "freezer trouble" quite like walking into what looks like an arctic wasteland. When ice buildup starts coating your evaporator coils, walls, and ceiling panels, your freezer is basically screaming for help. This happens when warm, humid air sneaks in through damaged door seals, worn gaskets, or compromised insulation panels.

Here's what one expert told us: "Ice on coils insulates the surface, reduces airflow, forces the compressor to work harder at higher differential pressure and longer runtimes." Translation? Your electric bill is about to get ugly, and your equipment is aging in dog years.

The ice patterns tell a story if you know how to read them. Ice extending to the compressor usually means refrigerant problems, while ice only on the top half of coils points to TXV issues. Ice on the lower coil section often reveals a broken defrost heater.

Most icing problems come from damaged door seals, malfunctioning defrost timers or heaters, clogged drain lines, overcrowding that blocks airflow, or aging insulation panels - especially if they're over 10 years old.

"Not Cold Enough" Alerts

When your freezer can't keep its cool, you've got problems brewing. Temperature fluctuations or failure to reach setpoint temperatures might start small, but they can escalate fast. Sensor errors, low refrigerant levels, and clogged condenser coils are usually the troublemakers.

Watch for digital displays showing temperatures above -10°F. You might notice frost melting and refreezing on product packaging or soft or partially thawed frozen goods. Your compressor running continuously without reaching setpoint temperature is another warning sign.

Walk-In Freezer Runs Constantly

A freezer that never takes a break is like an employee working 24/7 - something's going to burn out eventually. When your unit runs constantly, you're looking at sky-high energy bills and components that age way faster than they should. Our research on Walk In Cooler/Freezer runs constantly? shows this usually comes down to oversized inventory loads, dirty coils, high ambient temperatures, or undersized units.

Dirty condenser coils are probably the biggest culprit - they can't transfer heat efficiently when clogged with dust and debris. Faulty door seals create constant battles against warm air infiltration, while thermostat malfunctions prevent proper cycling.

Strange Noises & Vibrations

Your walk-in freezer should be the strong, silent type. When it starts making a racket, it's trying to tell you something important. For complete troubleshooting guidance, check out My Walk-In Cooler/Freezer Is Making Loud Noise?

Grinding or squealing sounds usually mean worn motor bearings needing replacement. Loud humming often points to dirty condenser coils or blocked ventilation. Rattling noises typically come from loose fan belts or mounting hardware.

Vibration issues often trace back to improper unit leveling or worn isolation pads. But if you hear hissing sounds, that's potentially a refrigerant leak requiring immediate attention.

Walk In Freezer Repair: DIY Troubleshooting & Preventative Maintenance

Proactive maintenance is your best defense against costly walk in freezer repair emergencies. A systematic approach combining daily checks, weekly monitoring, monthly inspections, and quarterly professional service can extend equipment life from the typical 10-15 years to over 30 years in some cases.

The key is establishing a maintenance schedule that addresses all critical components before problems develop. Regular cleaning of condenser coils every 60-90 days, proper door management training for staff, defrost drain maintenance, and accurate temperature logging create a foundation for reliable operation.

Step-by-Step Cooling Failure Checklist

When your walk-in freezer isn't cooling properly, follow this systematic diagnostic approach before calling for professional service. Many cooling issues stem from simple problems that can be resolved quickly with basic troubleshooting.

Power and Electrical Check:

- Verify power supply to the unit

- Check circuit breakers and reset if tripped

- Inspect electrical connections for corrosion or looseness

- Test voltage at the disconnect switch

Thermostat and Controls:

- Verify thermostat settings (-10°F for freezers)

- Test thermostat calibration with separate thermometer

- Check for damaged temperature sensors

- Inspect control board for error codes

Airflow and Mechanical:

- Ensure evaporator fan is spinning freely

- Check for ice buildup blocking airflow

- Verify condenser fan operation

- Inspect coil condition for dirt or damage

For detailed guidance on resolving iced evaporator issues, see our comprehensive guide: How to Fix an Iced Evaporator with These 5 Easy Changes

Defrost Drain Problems & Quick Fixes

Clogged defrost drains cause water pooling, increased humidity, and ice buildup throughout the freezer. These problems are particularly common in high-usage environments where food debris can accumulate in drain lines. For comprehensive troubleshooting, refer to Walk In Freezer defrost drain problems?

Signs of drain problems:

- Water pooling on freezer floor

- Excessive frost on walls and ceiling

- Strange odors from standing water

- Reduced cooling efficiency

Quick fix procedures:

- Locate the defrost drain (typically behind access panel)

- Remove visible debris with small brush or pipe cleaner

- Flush with hot water using plumbing snake

- For mineral buildup, use hot water and vinegar solution

- Test drain heater cable for proper operation

- Verify proper drainage flow after cleaning

Cleaning Condenser & Evaporator Coils

Dirty coils are the leading cause of refrigeration inefficiency and premature component failure. Condenser coils should be cleaned quarterly, while evaporator coils need monthly attention in high-use environments.

Condenser coil cleaning steps:

- Turn off power to the unit

- Remove protective covers and panels

- Use soft-bristle brush to remove loose debris

- Apply food-safe coil cleaner following manufacturer instructions

- Rinse thoroughly with water

- Allow complete drying before reassembly

Evaporator coil maintenance:

- Check for ice buildup during defrost cycles

- Brush away dust and debris monthly

- Ensure adequate airflow clearance around coils

- Monitor for acidic food residue that can corrode coils

Professional coil cleaning services like KE2therm offer specialized equipment and cleaning solutions for heavily soiled or hard-to-reach coils.

Preventive Maintenance Calendar

A structured maintenance schedule prevents most walk-in freezer failures and extends equipment life significantly. Here's a comprehensive maintenance calendar:

Daily Tasks:

- Check door closure and seal condition

- Verify temperature readings and record in log

- Inspect for unusual noises or vibrations

- Ensure proper product loading and airflow

Weekly Tasks:

- Review temperature logs for trends

- Check defrost drain for standing water

- Inspect door hinges and hardware

- Verify adequate clearance around condenser

Monthly Tasks:

- Clean evaporator coils and fan blades

- Inspect door gaskets for cracks or tears

- Test door heaters and pressure relief ports

- Check refrigerant lines for damage

Quarterly Tasks:

- Professional condenser coil cleaning

- Comprehensive electrical connection inspection

- Calibrate thermostats and sensors

- Inspect insulation panels for damage

Bi-Annual Professional Service:

- Complete refrigeration system analysis

- Refrigerant level and leak testing

- Compressor performance evaluation

- Preventive part replacement as needed

Professional Walk-In Freezer Repair Services & Replacement Decisions

Sometimes your freezer throws you a curveball that's way beyond basic maintenance. When you're dealing with complex walk in freezer repair issues like compressor failures or refrigerant leaks, it's time to call in the professionals. These aren't the kind of problems you want to tackle with a YouTube tutorial.

The investment in commercial refrigeration is substantial – we're talking $15,000 to $30,000 for most walk-in freezer installations. With that kind of money on the line, you need technicians who know what they're doing. Look for service providers with CFESA (Commercial Food Equipment Service Association) membership.

Here's something that might surprise you: commercial freezer compressors typically last about 10 years, while walk-in cooler compressors can push 15 years with proper care. Knowing these lifespans helps you make smarter decisions about repair versus replacement when major components start failing.

The reality is that refrigeration emergencies don't care about your business hours. That's why 24/7 emergency service isn't just a nice-to-have feature – it's essential when you've got thousands of dollars worth of product at risk.

When to Call a Pro for Walk In Freezer Repair

Some problems are clear signals to step back and let the experts handle things. Compressor failure tops this list – these units are expensive, complex, and dangerous to work on without proper training.

Refrigerant leaks are another hands-off situation. Beyond the environmental concerns, handling refrigerants requires EPA certification. Plus, finding and fixing leaks requires specialized equipment that most businesses don't have.

Electrical shorts or control board failures can be tricky and potentially dangerous. Modern walk-in freezers use sophisticated control systems that need proper diagnostic tools to troubleshoot effectively.

When your insulation panels become saturated with moisture, you're looking at structural issues that affect the entire unit's performance. This kind of damage often indicates deeper problems that need professional assessment.

For detailed guidance on finding qualified technicians, check out this helpful resource: Walk-In Cooler Service 101: Find Reliable Repair Providers.

Safety considerations make professional service even more important. OSHA lockout-tagout procedures prevent serious accidents during repairs. Proper ventilation during refrigerant work prevents dangerous exposure, and electrical work must meet local code requirements.

Choosing the Right Service Partner

Finding the right repair partner can make the difference between a quick fix and days of downtime. Start by verifying their EPA refrigerant handling certification – this isn't optional for anyone working with refrigeration systems. State and local licensing requirements vary, so make sure they're properly credentialed.

Insurance coverage protects you if something goes wrong during repairs. Look for both liability and workers' compensation coverage. You don't want to be on the hook if a technician gets hurt on your property.

Emergency response time becomes critical when your freezer goes down on a Friday night. The best service partners offer genuine 24/7 availability, not just an answering service. Ask about their typical response times and what constitutes an emergency call.

OEM parts inventory can dramatically reduce repair time. Companies that stock common replacement parts can often complete repairs in one visit instead of making you wait for special orders. Warranty terms on both labor and parts show confidence in their work quality.

For more detailed guidance on selecting the right specialist, this article covers all the bases: Expert Help for Your Walk-In Cooler: Choosing the Right Specialist.

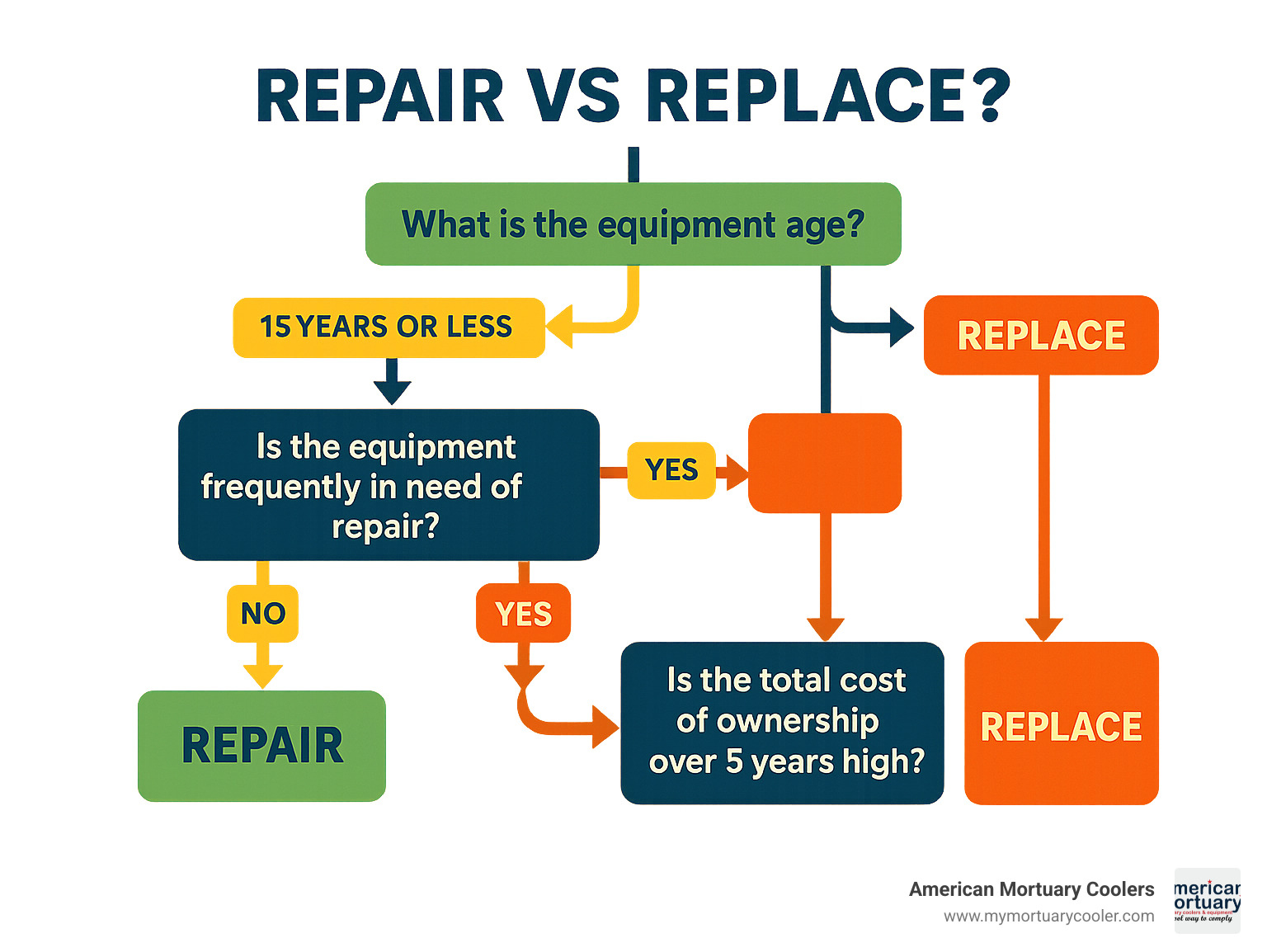

Repair vs Replace: Decision Matrix

The hardest decision in walk in freezer repair is often whether to fix what you have or start fresh with new equipment. Units over 15 years old with repeated failures usually make better candidates for replacement than continued repairs.

Age is a major factor in this decision. Equipment under 10 years old with a single component failure and good maintenance history usually makes sense to repair, especially if the repair cost stays under 50% of replacement value.

On the flip side, energy bills that keep climbing often signal it's time for an upgrade. Older units simply can't match the efficiency of modern equipment. When your freezer starts failing to meet current DOE efficiency standards, the monthly energy savings from a new unit can offset the purchase price over time.

Parts availability becomes an issue with older equipment. Manufacturers eventually discontinue support for older models, making repairs expensive and time-consuming. When you start hearing "we'll have to special order that part," it's often a sign that replacement makes more financial sense.

Modern replacement options offer significant advantages. Norlake panel retrofit systems can upgrade your structure while keeping the existing footprint. Capsule Pak ECO™ systems use efficient R-290 refrigerant that meets current environmental standards. Split-Pak™ remote systems offer flexible installation options that can solve space or noise issues.

The key is looking at total cost of ownership over the next five years, not just the immediate repair bill. Sometimes spending more upfront saves significant money in the long run through improved efficiency and reduced maintenance needs.

Energy Efficiency, Safety & Compliance

When it comes to walk in freezer repair and maintenance, staying compliant with modern regulations isn't just about avoiding fines—it's about protecting your business and your customers. The landscape of commercial refrigeration has changed dramatically in recent years, with new DOE AWEF (Average Walk-in Energy Factor) standards pushing manufacturers to create more efficient systems.

These regulations work hand-in-hand with NSF/ANSI Standard 7 for food service equipment and various state energy codes. The result? Walk-in freezers that use less energy while maintaining the precise temperatures your business depends on.

One of the most exciting developments is the shift to R-290 (propane) refrigerant in systems like the Capsule Pak ECO™. This isn't just about being environmentally friendly—these systems often run more efficiently than older refrigerants, which means lower energy bills for you.

Here's something that might surprise you: installing air curtains can reduce your compressor runtime by up to 27%. That's significant savings, and the scientific research on air curtains backs up these impressive numbers.

Your compliance checklist includes: maintaining FDA-required temperatures below 0°F for frozen foods, following OSHA lockout-tagout procedures during maintenance, properly handling EPA refrigerant regulations, and meeting local building codes for electrical and mechanical work.

Organizing & Loading Best Practices

You might not realize it, but how you load your walk-in freezer can make or break its efficiency. I've seen units work twice as hard simply because someone stacked boxes too close to the evaporator fan. It's like trying to breathe through a straw—the system struggles to move air where it needs to go.

Smart loading starts with the six-inch rule. Keep at least six inches of clearance around evaporator fans. This simple step can prevent countless headaches and expensive repairs down the road. When you use pallets, stack them so air can flow freely between products. Your freezer's circulation system was designed with specific airflow patterns in mind.

FIFO rotation (First In, First Out) isn't just good for inventory management—it helps you spot temperature problems early. When you're regularly moving products, you'll notice if something feels softer than it should or if ice crystals are forming where they shouldn't be.

Here's a tip that can save your evaporator coils: keep acidic foods covered. Items like tomato sauce or citrus products can corrode coils over time if their vapors aren't contained. Installing dehumidifiers near entrances also helps manage humidity levels, especially in high-traffic areas.

Door management training for your staff pays dividends. Time-based door alarms help, but nothing beats teaching your team why keeping doors closed matters. Every second that door stays open, warm humid air rushes in, forcing your system to work harder.

Walk-In Freezer vs Walk-In Cooler: Key Differences

Understanding the difference between walk-in freezers and coolers helps you maintain each system properly. While they might look similar from the outside, they're built for completely different jobs.

Temperature is the obvious difference—freezers maintain -10°F to 0°F while coolers stay between 34°F and 40°F. But that temperature gap creates a cascade of other differences that affect maintenance and repair needs.

Insulation thickness reflects these different demands. Freezers need R-32 insulation minimum, while coolers can get by with R-29. That extra insulation isn't just about keeping cold in—it's about preventing condensation and moisture problems that can destroy panels over time.

Defrost systems work much harder in freezers. While walk-in coolers rarely need defrost cycles, freezers run them regularly to prevent ice buildup. This means more wear on defrost heaters, timers, and drain systems.

Component sizing also differs significantly. Freezer compressors, fans, and coils are all larger to handle the greater temperature differential. This affects everything from repair costs to energy consumption.

For detailed information about cooler specifications and features, check out The Complete Guide to Walk-In Cooler Features and Prices. Understanding these differences helps you make better decisions about maintenance schedules and walk in freezer repair priorities.

Frequently Asked Questions About Walk-In Freezer Repair

When it comes to walk in freezer repair, we hear the same questions over and over again. That's totally understandable - these units are expensive investments, and nobody wants to make the wrong decision about maintenance or repairs.

Let me share the most common concerns we encounter and give you straight answers based on real-world experience.

How often should a walk-in freezer be serviced?

Here's the honest truth: most walk-in freezers need professional attention at least twice a year, but that's just the baseline. If you're running a busy restaurant or processing facility, you'll want to bump that up to quarterly service calls.

The sweet spot for most businesses is monthly coil cleaning (which you can often handle yourself), quarterly professional inspections, and immediate attention whenever something sounds or feels off. Don't wait for complete failure - that's when repair bills get scary.

Think of it like your car. You wouldn't skip oil changes for two years and then wonder why the engine seized up. Same principle applies to your freezer's compressor and refrigeration system.

What causes a walk-in freezer to run non-stop?

A freezer that never takes a break is crying for help. Dirty condenser coils are usually the biggest culprit - they're like trying to breathe through a dirty air filter. The system works overtime but can't get the job done efficiently.

Faulty door seals are another major cause. When warm air keeps sneaking in, your freezer becomes like a bucket with holes - it can't maintain temperature no matter how hard it tries. Thermostat problems can also trick the system into thinking it never reaches the right temperature.

Sometimes the issue is simpler than you'd expect. Overloading the unit or placing it in a hot, poorly ventilated area forces constant operation. We've seen freezers return to normal cycling just by cleaning coils and fixing a torn door gasket.

When is replacement more economical than repair?

This is the million-dollar question, isn't it? The general rule is when repair costs hit 50% of replacement value, it's time to seriously consider a new unit. But age matters too - units over 15 years old with recurring problems usually make better candidates for replacement.

Here's what really makes the decision clear: if you're calling for walk in freezer repair every few months, those bills add up fast. A $2,000 compressor repair might seem reasonable until you realize you'll need a new evaporator next month and new controls the month after that.

Energy efficiency is the hidden factor most people miss. Newer models meeting current DOE standards can cut your electric bill significantly. Sometimes the energy savings alone justify replacement, even when the old unit is technically repairable.

We always tell our customers at American Mortuary Coolers: if you're spending more time worrying about your freezer than using it, replacement probably makes sense. Peace of mind has real value in business operations.

Conclusion & Next Steps

Your walk in freezer repair strategy can make or break your business operations. When you combine regular preventive maintenance with quick responses to warning signs and professional service when needed, you're not just fixing problems – you're protecting thousands of dollars in inventory and keeping your customers safe.

Here at American Mortuary Coolers, we've seen what happens when refrigeration fails. Based in Tennessee, we craft custom mortuary coolers and related equipment for funeral homes across the contiguous 48 states. While our specialty is mortuary equipment, the principles of reliable refrigeration apply everywhere. A single breakdown can cost more than years of proper maintenance.

The most successful businesses we work with follow a simple approach: establish your maintenance schedule early, train your staff properly, build relationships with qualified service providers before you need them, and make smart repair-versus-replacement decisions based on real numbers, not emotions.

Think of your walk-in freezer like a car. You wouldn't skip oil changes and expect it to run forever, right? The same logic applies here. Monthly coil cleaning, quarterly professional check-ups, and daily temperature monitoring aren't just suggestions – they're insurance policies against disaster.

Don't wait until you're standing in front of a broken freezer with thousands of dollars of spoiled product. Schedule that preventive maintenance call today. Implement the monitoring procedures we've outlined. Find your service provider now, while you have time to research and compare options.

Your frozen inventory depends on it. More importantly, your peace of mind depends on it.

Ready to dive deeper into commercial refrigeration best practices? Check out our comprehensive resource: The Complete Guide to Commercial Refrigeration Repair Near You. It's packed with practical advice that can save you time, money, and headaches down the road.