Why Understanding Blade 12 Variants Matters

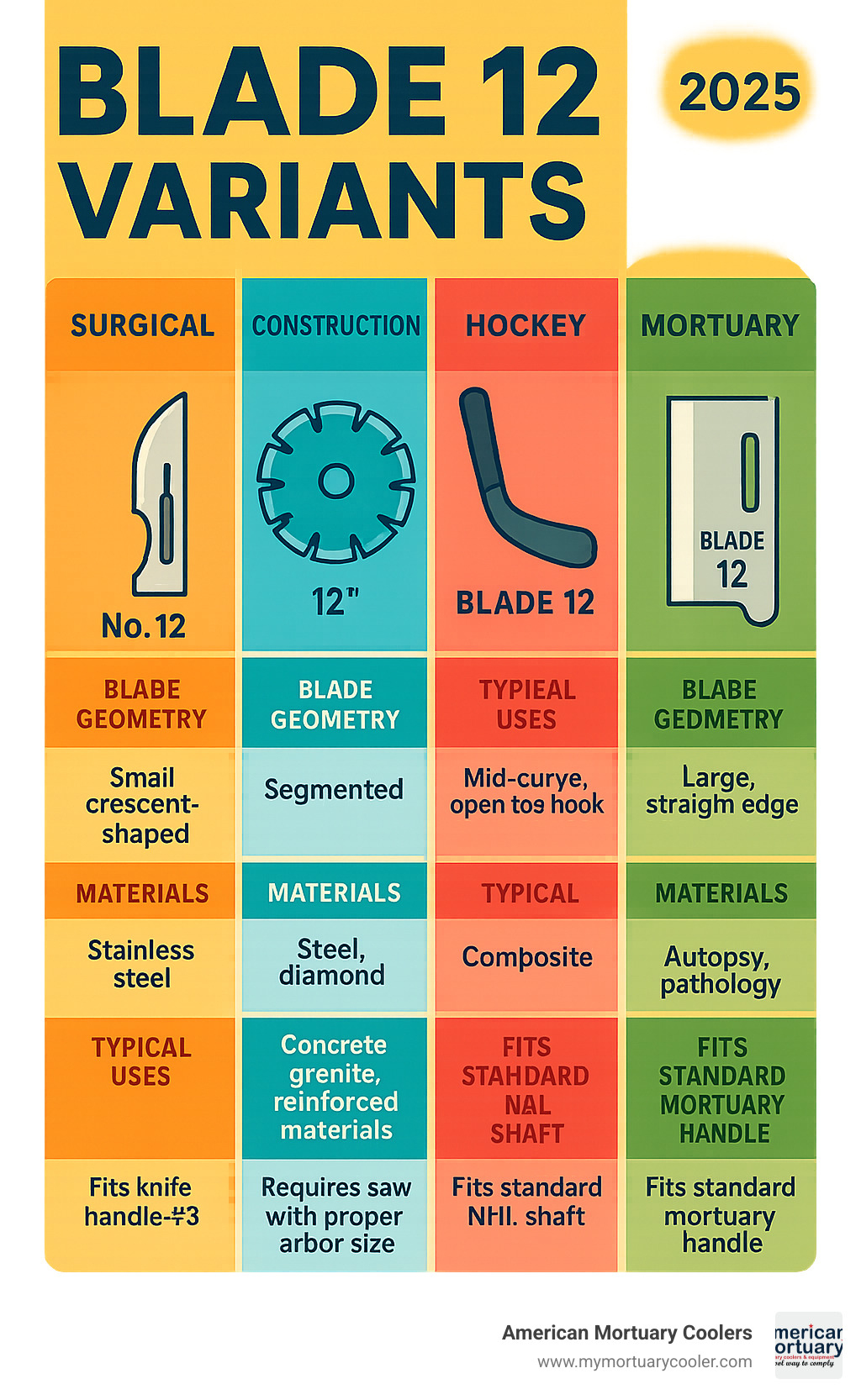

Blade 12 refers to multiple specialized cutting tools across different industries, each engineered for specific tasks and performance requirements. Whether you're looking at the surgical No. 12 scalpel blade, a 12-inch diamond saw blade, or the hockey Blade 12 curve pattern, understanding the key differences is crucial for making the right choice.

Quick Reference for Blade 12 Types:

- Surgical No. 12: Small crescent-shaped blade for arteriotomies, parotid surgery, and mucosal cuts

- 12-inch Diamond Blade: Construction blade for concrete, granite, and reinforced materials

- Hockey Blade 12: P90T curve pattern combining mid-curve with open toe hook

- Autopsy/Pathology Blade 12: Specialized cutting tool for mortuary and forensic applications

The challenge isn't just knowing what blade 12 is - it's understanding which variant fits your specific needs. Each blade 12 variant has unique design features, material compositions, and performance characteristics that directly impact cutting performance, safety requirements, and cost considerations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right equipment, including specialized cutting tools like blade 12 variants used in autopsy and preparation procedures.

Relevant articles related to blade 12:

What Is Blade 12? Origins and Cross-Industry Variants

Blade 12 isn't just one tool - it's a family of cutting instruments that evolved across different industries, each solving unique problems.

The surgical No. 12 became part of the standardized scalpel system in the 1950s. Surgeons needed something more precise than straight blades for delicate work, leading to this distinctive crescent shape with inside-edge sharpening.

Construction crews needed bigger, more aggressive blades for tougher materials like reinforced concrete and granite. The 12-inch diamond blade emerged as the solution for heavy-duty cutting jobs.

Hockey's Blade 12 pattern (P90T) was created when Jamie Benn requested a curve combining features from two existing patterns, delivering both shooting accuracy and puck control.

Surgical No. 12 Basics

The surgical No. 12's crescent shape with inside-edge sharpening allows surgeons to follow natural tissue contours with precision. Arteriotomies represent the blade's primary use - the curve allows clean incisions into arteries without awkward hand positioning.

The blade excels during mucosal cuts in septoplasty procedures and parotid surgeries, following natural curves around facial structures. Dental professionals use the No. 12 for raising skin flaps and cleaning excess composite resin.

Compatibility includes Handles 3, 3L, 3 Graduated, 5B, 7, 9, B3, and B3L, allowing surgical teams to use preferred handle styles.

Industrial & Construction 12-inch Blades

Construction blade 12 variants feature diamond segmented construction with anti-crack gullets that prevent stress fractures when cutting reinforced concrete or steel rebar.

The Unicon Premium Diamond Blade at 12" x 0.125" x 20mm bore handles wet and dry cutting up to 6,300 RPM. Depth-of-cut indicators provide precise visual feedback, while stabilizer vents and anti-vibration slots ensure smooth operation.

At 1.44 pounds, these blades balance stability with comfortable handling during extended use.

Sports & Recreation "Blade 12" Patterns

Hockey's Blade 12 pattern combines the best features of Blade 1 and Blade 6 patterns. The P90T curve features a moderate mid-curve with an open toe hook that excels at multiple skills.

Shooting accuracy benefits from the curve's geometry, while the toe hook design provides excellent puck control. Professional players like Evander Kane and Andrew Ladd adopted this pattern alongside Jamie Benn.

The trade-off is reduced backhand performance due to the deeper mid-section curve, requiring technique adjustments.

Anatomy & Design Features That Make Blade 12 Unique

What makes blade 12 special is the thoughtful engineering behind each variant. Different industries have tackled similar cutting challenges with completely different approaches.

| Blade Type | Blade 10 | Blade 11 | Blade 12 | Blade 15 |

|---|---|---|---|---|

| Surgical Shape | Large curved | Pointed straight | Small crescent | Small curved |

| Primary Use | General incisions | Stab incisions | Arteriotomy/mucosal | Detail work |

| Edge Type | Outside curve | Straight point | Inside curve | Outside curve |

| Saw Blade Size | 10-inch | 12-inch | 14-inch | 16-inch |

|---|---|---|---|---|

| Max RPM | 7,200 | 6,300 | 5,500 | 4,800 |

| Weight | 1.1 lbs | 1.44 lbs | 1.8 lbs | 2.3 lbs |

| Cutting Depth | 3.5" | 4.5" | 5.5" | 6.5" |

The curved tip geometry in surgical blades follows your body's natural curves better than straight edges. Industrial blades pack 60 teeth for smooth cuts, with diamond segments that handle concrete and granite.

Surgical Precision Factors in Blade 12

The surgical No. 12's edge geometry concentrates cutting force along a tiny contact area, delivering clean cuts with minimal tissue damage. This minimal trauma profile means faster healing and less scarring.

Suture cutting becomes effortless with the curved design, allowing precise positioning without nicking healthy tissue. For detailed safety information, check our scalpel safety guide. Additional technical specs are available in scientific research on No. 12 scalpels.

Wood & Metal Cutting Geometry

Industrial blade 12 variants feature carbide tips formulated for high-impact cutting. The 5-degree hook angle optimizes cutting for non-ferrous metals like aluminum and brass.

The burr-free finish results from combining high tooth count with the calculated hook angle. Lubrication with WD-40 every 4-5 cuts prevents heat buildup and extends blade life.

Hockey Curve Dynamics

The hockey Blade 12 pattern balances shooting power and puck control. The mid-curve provides excellent stickhandling without sacrificing shooting accuracy.

The open face design enables quick releases, though windy conditions can affect stick handling. Professional adoption by elite players validates the pattern's effectiveness, despite backhand trade-offs requiring practice adjustments.

Materials, Manufacturing & Performance Metrics

When it comes to blade 12 variants, the materials used can make or break your cutting experience. Each material brings its own personality to the table, and understanding these differences helps you pick the right tool for your specific needs.

Carbon steel blades are like that friend who's incredibly sharp but needs a bit of babying. In surgical applications, carbon steel delivers best sharpness and holds its edge beautifully. The downside? These blades can corrode if you're not careful with storage and cleaning. For precision surgical work, though, nothing beats that razor-sharp edge.

Stainless steel takes a more practical approach. While it might not get quite as sharp as carbon steel, it makes up for it with serious staying power. These blades resist corrosion and sterilize easily, making them perfect for both surgical and mortuary applications where cleanliness is non-negotiable.

High-carbon steel splits the difference nicely. You get improved sharpness compared to regular stainless, plus better durability than pure carbon steel. It's like getting the best of both worlds, which explains why many surgical professionals gravitate toward this middle ground.

Construction applications tell a completely different story. Diamond segments embedded in metal create blades that laugh at concrete and granite. These aren't your typical cutting edges - they're engineered to handle the toughest materials construction workers encounter daily.

Hockey players get their own special treatment with DLC (Diamond-Like Carbon) coating. This space-age technology adds serious hardness while reducing friction, giving players that slick surface they crave for better puck handling. The coating also extends blade life, which any hockey parent's wallet will appreciate.

Premium hockey blades often use tool steel construction with Swiss-army-knife quality materials. These blades get heat-treated to 54-58 HRC for that sweet spot between hardness and durability. When you're competing at high levels, this kind of precision manufacturing makes a real difference.

Performance numbers matter, especially when safety's on the line. 12-inch diamond blades max out at 6,300 RPM - and that's not a suggestion. Push beyond these limits and you're asking for trouble. Blade failure at high speeds isn't just expensive; it's dangerous.

The 1.44-pound weight of a typical 12-inch diamond blade strikes a smart balance. Heavy enough to stay stable during cutting, but light enough that your arms won't give out during longer projects. After spending a day cutting concrete, you'll appreciate every ounce of thoughtful engineering.

Hockey performance gets trickier to measure since so much depends on individual player style. The Blade 12 pattern consistently delivers improved puck control and shooting accuracy, though your mileage may vary based on technique and personal preferences.

For those interested in diving deeper into diamond blade technology, check out the latest research on diamond blades for detailed technical specifications and performance data.

Safe Handling, Maintenance & Environmental Considerations

Working safely with blade 12 variants requires understanding each type's specific safety challenges and following proper handling practices.

Surgical blade safety starts with never recapping used blades by hand. Use single-use blade removers for safe detachment. Sharps disposal is non-negotiable - every used blade goes straight into approved sharps containers.

Sterilization procedures for reusable surgical blades require following manufacturer guidelines. Steam sterilization works for most applications, but specifications vary by blade type.

PPE requirements include safety glasses and cut-resistant gloves regardless of application. Construction work with diamond blades requires hearing protection and dust masks.

Industrial blade maintenance follows different protocols. Diamond blades need redressing rather than sharpening, while carbide-tipped blades can be professionally sharpened multiple times. Track sharpening intervals based on usage and materials.

Lubrication schedules prevent heat buildup and extend blade life. Spray liquid lubricant every 4-5 cuts for metal cutting, avoiding wax-based lubricants for non-ferrous metals.

The cost versus longevity equation favors premium blades that last longer and need less maintenance. Smart buyers consider total ownership costs, not just purchase price.

Environmental considerations include recycling steel blades through scrap dealers, though surgical blades require special biohazard handling. Consider the eco-impact of disposable versus reusable options, factoring in sterilization energy costs.

For mortuary professionals, proper blade handling is critical given the sensitive work environment. Our guides on dissection tools and equipment and mortuary tool safety provide detailed safety protocols.

Good safety habits develop through consistent practice and attention to detail, keeping everyone safer and more productive.

How to Choose the Right Blade 12 for Your Task

Choosing the right blade 12 means matching your specific needs to the blade's design strengths. Start by identifying your primary application.

Surgical procedures like arteriotomies demand precision. The curved No. 12 blade's inside-edge sharpening provides delicate control for mucosal cuts and tissue work. Ensure compatibility with your existing handles.

For construction work, material hardness drives decisions. Cutting concrete or granite requires diamond-segmented blades with anti-crack gullets. Softer materials work with carbide-tipped options. Always verify your saw's RPM rating matches the blade - 12-inch blades typically max at 6,300 RPM.

Hockey players need honest assessment of skill level and playing style. The Blade 12 pattern excels at stickhandling and shooting but challenges backhand performance. Advanced players adapt quickly, but beginners may struggle.

Mortuary applications require consideration of performance, safety protocols, and institutional policies. For comprehensive guidance, check our complete guide to mortician tools.

Budget considerations extend beyond purchase price. Premium blades lasting twice as long often provide better value than frequent replacements.

Compatibility factors are crucial. Surgical blades must fit handles properly. Saw blades need matching power and speed specifications. Hockey blades should complement stick flex and kick point.

Personal preference significantly impacts performance. Comfortable surgeons perform better procedures. Confident contractors work more efficiently. Players trusting their equipment focus on the game.

Warranty coverage indicates manufacturer confidence. Longer warranties typically mean better construction, though they may include specific usage requirements.

When uncertain, start with versatile options: surgical No. 12 for multiple procedures, wet/dry diamond blades for various construction materials, or Blade 12 hockey pattern for all-around performance.

Blade selection involves trade-offs. Evaluate needs honestly, considering skill level, usage frequency, and performance priorities. Thoughtful selection saves frustration and money.

Frequently Asked Questions about Blade 12

Why pick blade 12 over blade 11 for delicate surgical work?

The choice between blade 12 and blade 11 comes down to the specific cutting motion your procedure requires. While blade 11 excels at straight, precise punctures with its pointed design, blade 12 shines when you need to follow curved tissue contours.

Think of it this way: blade 11 is like a precise dart, perfect for stab incisions and direct punctures. Blade 12, with its crescent shape and inside-edge sharpening, works more like a tiny scythe that can gracefully follow natural tissue curves.

This curved geometry makes blade 12 particularly valuable for arteriotomies where you need to make precise incisions into arteries, or during septoplasty procedures where following the natural contours of nasal tissues reduces trauma. The inside-edge sharpening concentrates cutting force along the concave surface, giving you much better control than trying to curve a straight blade.

Another practical advantage is blade 12's compatibility with more handle types - including handles 3, 3L, 7, and 9. This flexibility means you can stick with your preferred handle while getting the specialized cutting geometry you need for delicate work.

How often should a 12-inch diamond blade be re-dressed or replaced?

Here's the honest answer: it depends on how hard you're working that blade. Under typical construction conditions cutting concrete and masonry, a quality 12-inch diamond blade needs re-dressing every 10-15 hours of actual cutting time.

You'll know it's time for maintenance when the blade starts cutting slower, creating more vibration, or leaving rough surfaces. The diamond segments might look glazed over - that's your cue that fresh diamond particles need to be exposed through re-dressing.

The good news is that a quality blade like the Unicon Premium can typically be re-dressed 3-4 times before you need complete replacement. This makes premium blades more economical in the long run, even with their higher upfront cost.

Wet cutting extends blade life by 25-50% compared to dry cutting because water reduces heat buildup and washes away debris. If you're doing a lot of cutting, investing in a wet saw setup pays for itself through extended blade life.

Complete replacement becomes necessary when segment height drops too low or when you see warping or cracking in the steel core. At that point, safety becomes the priority - a damaged blade isn't worth the risk.

Does the hockey Blade 12 curve hurt my backhand?

Let's be honest - the Blade 12 curve does make backhand shots more challenging. The moderate mid-curve and open toe hook that make this pattern so great for forehand shooting and stickhandling create a different puck contact angle on backhands.

But here's the thing: professional players like Jamie Benn and Evander Kane have proven you can still maintain excellent backhand performance with proper technique adjustments. The key is adapting your hand position and follow-through to work with the curve geometry rather than fighting against it.

Many players find the trade-off worthwhile because Blade 12's hybrid design - combining elements from Blade 1 and Blade 6 patterns - provides overall versatility that's more valuable than optimized backhand performance. You get excellent puck control, accurate forehand shooting, and effective stickhandling all in one pattern.

If backhand performance is absolutely critical to your game, you might consider the Blade 6 pattern instead. It offers similar stickhandling benefits with less impact on your backhand shots. But for most players, the learning curve for adapting backhand technique proves manageable compared to the overall benefits of the Blade 12 pattern.

Conclusion

Choosing the right blade 12 becomes clearer once you understand what makes each variant unique. The surgical No. 12's crescent shape provides incredible control during delicate arteriotomies, while 12-inch diamond blades tackle concrete with durability that keeps projects moving.

Performance and safety go hand in hand with every blade 12 variant. Hockey players need to understand backhand impacts, surgeons must follow disposal protocols, and contractors can't ignore RPM limits without risking accidents.

Blade 12 technology keeps evolving with improved materials, better coatings, and refined designs based on professional feedback. At American Mortuary Coolers, we've seen how the right cutting tools make all the difference in mortuary work, helping funeral homes across the country with reliable, properly selected equipment.

Your perfect blade 12 choice comes down to matching blade capabilities with your actual needs. Consider specific procedures, materials, budget, and safety requirements.

Technical specs matter, but so does real-world performance. Take time to understand trade-offs, ask questions, and start with basic options if unsure.

For more insights about mortuary tools and equipment selection, check our comprehensive guides at morgue tools and equipment guides. We're always here to help you make informed decisions about the tools that matter most to your work.