Why R404A P-T Charts Are Critical for Refrigeration Professionals

The r404a p-t chart is your most important tool for properly charging and diagnosing commercial refrigeration systems. This chart shows the exact relationship between pressure and temperature for R404A refrigerant, helping you determine if your system is running correctly.

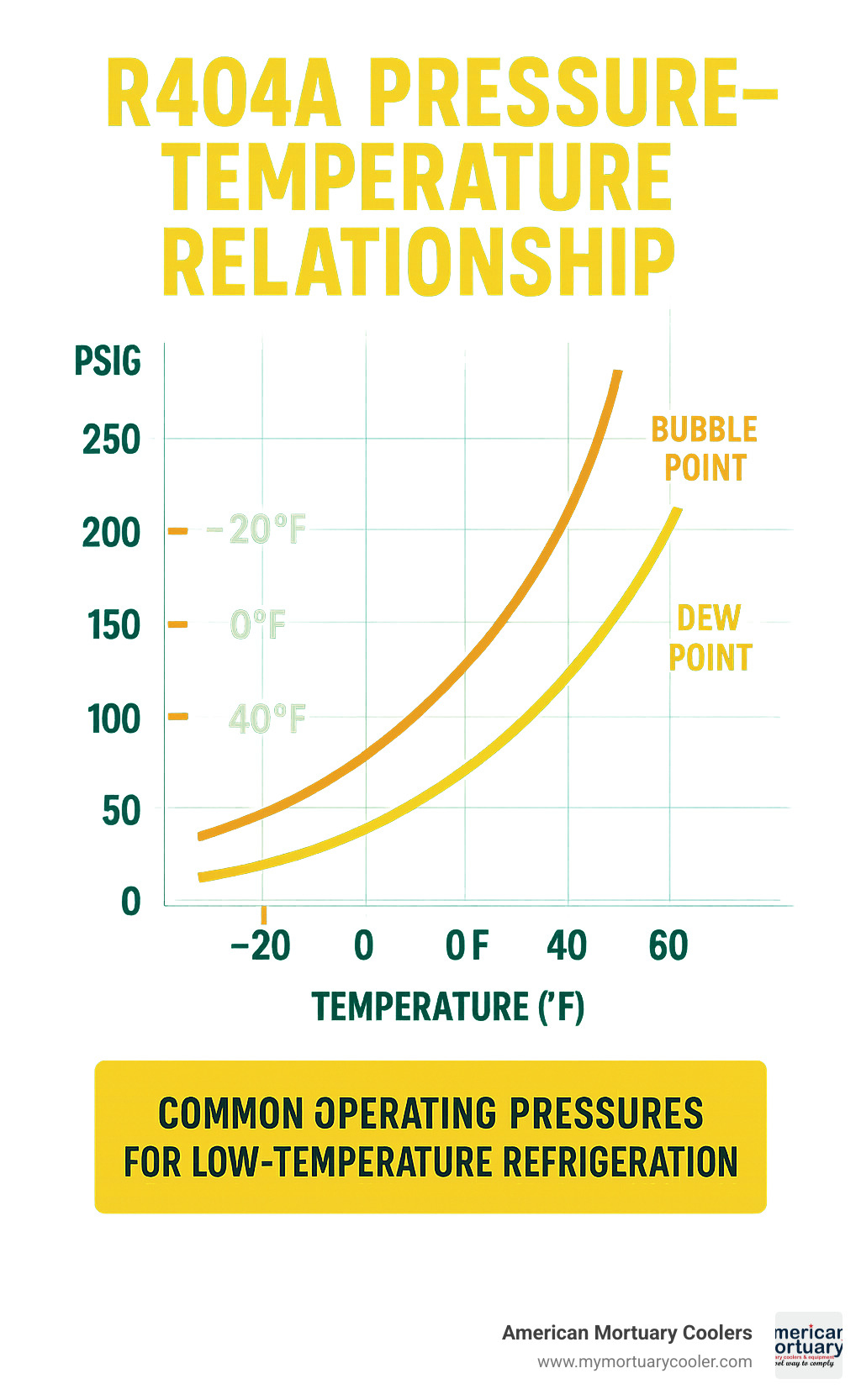

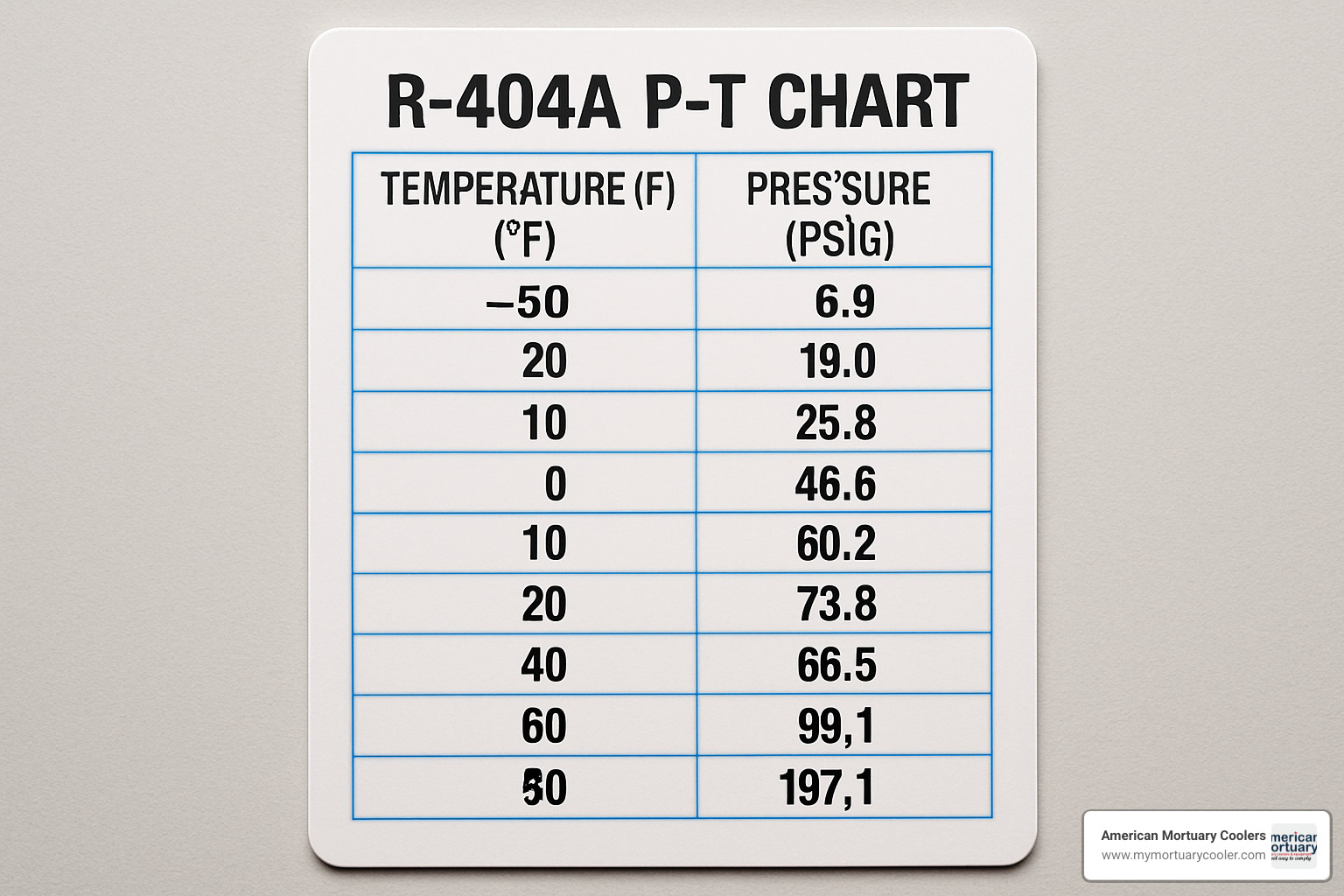

Quick Reference: Key R404A Pressure Values

- -20°F: 4.3 psig

- 0°F: 32.6 psig

- 40°F: 85.4 psig

- 100°F: 234.6 psig

- Critical Temperature: 161.7°F at 540.8 psi

R404A is a zeotropic blend of three HFC refrigerants (44% R125, 4% R134a, 52% R143a) commonly used in low and medium-temperature commercial refrigeration. Despite its high Global Warming Potential of 3922, it remains widely used in supermarket display cases, walk-in coolers, transport refrigeration, and mortuary cooling systems.

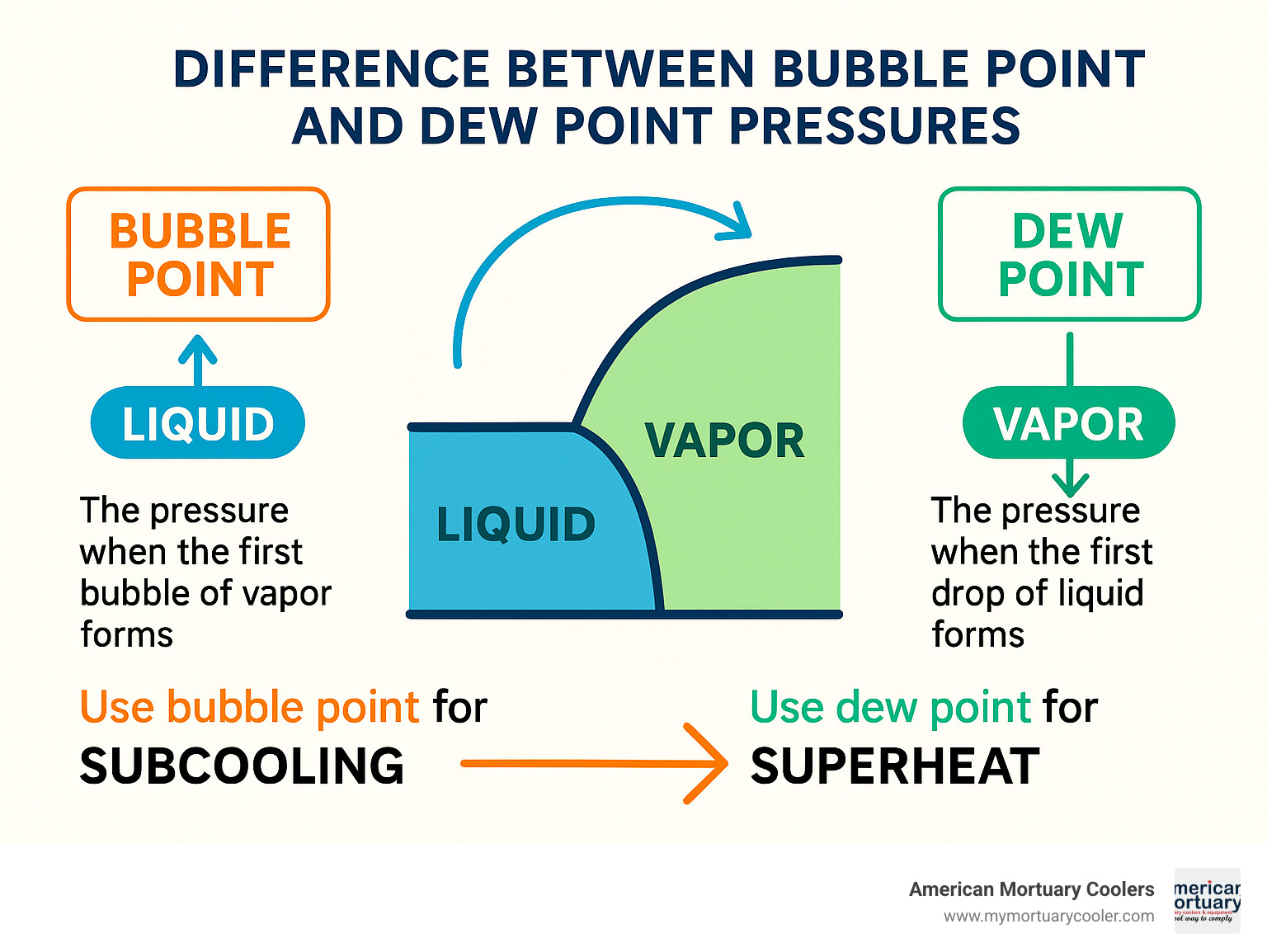

The pressure-temperature relationship is crucial because R404A has a small temperature glide - meaning the liquid and vapor phases exist at slightly different temperatures at the same pressure. This is why you'll see both "bubble point" and "dew point" columns on professional P-T charts.

As one experienced technician noted: "Rookie techs calling seasoned pros - whether in Miami or Fargo - are always first asked their subcool and superheat values." Without an accurate P-T chart, you can't calculate these critical measurements.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes maintain precise temperature control using refrigerants like R404A. Understanding the r404a p-t chart has been essential in my work ensuring reliable cooling systems for sensitive mortuary applications.

R404a p-t chart terms at a glance:

What Is R404A and Why Technicians Still Use It

R404A has been the go-to refrigerant for commercial cooling systems for good reason. This synthetic blend combines 44% R125, 4% R134a, and 52% R143a to create a powerhouse that keeps our food frozen and our businesses running smoothly.

What makes R404A special? Its boiling point of -51.8°F means it can handle the coldest applications without breaking a sweat. Whether you're dealing with ice cream freezers that need to stay rock-solid or walk-in coolers storing fresh produce, this refrigerant delivers consistent performance.

The numbers tell the story of R404A's capability. With a critical temperature of 161.7°F and operating pressures that work well with standard equipment, it's no wonder technicians have relied on it for decades. When you're looking at your r404a p-t chart, you're seeing the reliable pressure-temperature relationship that has made countless installations successful.

We see R404A dominating several key areas. Supermarket refrigeration systems depend on it for everything from the deli counter to frozen food aisles. Transport refrigeration trucks use it to keep food fresh during cross-country hauls. Walk-in coolers and freezers in restaurants and food service operations rely on its steady performance.

In our work at American Mortuary Coolers, we've installed R404A systems across Tennessee, Georgia, Illinois, and throughout our service regions. These mortuary cooling systems require absolute reliability, and R404A has delivered that dependability when families need it most.

The environmental story of R404A is a mixed bag. The good news? It has zero Ozone Depletion Potential (ODP), meaning it won't harm the ozone layer like the old CFC and HCFC refrigerants that came before it. The challenging news? Its Global Warming Potential of 3922 has caught the attention of environmental regulators.

Many technicians still choose R404A because they know how it behaves. The retrofit history shows successful conversions from older refrigerants, and the existing infrastructure supports it well. But the phase-down timelines are changing that equation.

Environmental Footprint & Future Alternatives

The writing is on the wall for R404A, and it's written in regulation. The AIM Act is pushing the industry toward a future with just 15% of baseline HFC levels by 2036. That's a dramatic reduction that will reshape how we think about refrigeration.

The EPA's SNAP program isn't just suggesting alternatives - it's actively restricting R404A use. The timeline is tight and getting tighter. New self-contained equipment using R404A hits a manufacturing wall on December 31, 2024. You'll have a three-year grace period to sell and install existing inventory, but that window closes on December 31, 2027.

Scientific research on HFC phasedown shows the regulatory pressure will only increase. Larger commercial applications face system restrictions starting in 2026-2027, making the transition unavoidable.

The industry isn't standing still. R452A (Opteon XP44) offers a GWP of 2141 - about 45% lower than R404A. Better yet, it uses the same POE oil, making retrofits much simpler than you might expect.

R448A takes the environmental benefits further with a GWP of 1274. It maintains similar performance characteristics while cutting the environmental impact significantly.

For those ready to make a bigger leap, natural CO₂ refrigerants offer zero GWP. The trade-off? You'll need completely different system designs and equipment rated for higher operating pressures.

At American Mortuary Coolers, we're helping funeral homes prepare for this transition. Our custom mortuary cooling systems are designed to work with both current R404A systems and the low-GWP alternatives coming down the pipeline. We understand that when you're serving families in their time of need, your cooling system can't be an afterthought.

Understanding the r404a p-t chart

When you pick up an r404a p-t chart, you're holding what's essentially the "Rosetta Stone" of R404A refrigeration. This chart translates the language between pressure and temperature, telling you exactly what pressure R404A should be at any given temperature.

But here's where R404A gets interesting - and where many technicians trip up. Unlike simple refrigerants that have one clear boiling point, R404A is a blend of three different refrigerants, each with its own personality. Think of it like a team where everyone doesn't quite march to the same beat.

This creates what we call temperature glide - about 0.7°F difference between when the liquid starts to bubble and when the last drop finally becomes vapor. It's not a huge difference, but it matters enough that professional P-T charts show two columns instead of one.

The bubble point column shows the pressure when liquid R404A just starts to get excited and turn into vapor. The dew point column shows when vapor R404A decides it's time to settle down and become liquid again.

Most charts present this information in dual units - temperature in both Fahrenheit and Celsius, with pressure in psig (pounds per square inch gauge). When you're dealing with really cold applications below -26.1°F, you'll see pressures listed in inches of mercury because the system is actually running below atmospheric pressure.

How to Read the R404A P-T Chart

Reading an r404a p-t chart isn't rocket science, but doing it wrong can make your diagnosis completely off base. Here's how we approach it in the field:

Start by identifying exactly what temperature you're working with - evaporator temperature, condenser temperature, or ambient temperature. Each serves a different purpose in your calculations.

Next, choose your column wisely. Use the bubble point (liquid column) when you're calculating subcooling or taking measurements on the liquid line. Switch to the dew point (vapor column) for superheat calculations and suction line work.

Once you've found your temperature in the left column, read straight across to find the corresponding pressure. If your exact temperature isn't listed (and it usually isn't), you'll need to interpolate between the closest values. Don't worry - with R404A's small glide, you don't need to be perfect to the decimal point.

Here's a real-world example: You're checking a suction line that's reading 10°F on your thermometer and 45 psig on your gauge. Look up 10°F on the dew point side - it should be around 49 psig. That 4 psig difference tells you something about your superheat situation.

Typical Values on the R404A P-T Chart

Every technician worth their salt has certain values from the r404a p-t chart burned into memory. These are the numbers that'll save you time when you're troubleshooting at 2 AM in a walk-in freezer.

For freezer applications, -20°F sits right around 16 psig and 0°F hits about 33 psig. These are your bread-and-butter low-temperature readings that we see constantly in mortuary cooling applications.

Medium-temperature cooler work centers around 20°F at 65 psig and 40°F at 86 psig. These values come up all the time in walk-in coolers and display cases.

On the high side, your condenser pressures will typically run 80°F at 200 psig and 100°F at 235 psig. When ambient temperatures climb, you'll see 120°F pushing 337 psig and 150°F reaching 456 psig.

The critical point sits at 161.7°F and 540.8 psi - beyond this temperature, physics gets weird and there's no real difference between liquid and vapor anymore. Thankfully, most of us never see pressures that high in normal operation.

These values are based on NIST standards, so you can trust them when you're commissioning systems or troubleshooting problems. We rely on these exact numbers when we're setting up mortuary cooling systems across Tennessee and our other service states.

Using the Chart in the Field: Charging, Diagnostics & Altitude Corrections

Real-world application of the r404a p-t chart gets complicated fast. After years of installing mortuary coolers from Tennessee to California, I've learned that environmental factors can throw off even experienced technicians.

Superheat calculation is where most techs start their diagnosis. You're measuring how much vapor refrigerant has been heated above its saturation temperature. Here's the simple process: measure your suction line temperature with a good thermometer, read the suction pressure from your gauge, then find the dew point temperature for that pressure on your P-T chart. Subtract the dew point from your actual temperature - that's your superheat.

Subcooling calculation works the opposite way. You're measuring how much liquid refrigerant has cooled below its saturation temperature. Measure your liquid line temperature, read the liquid line pressure (or use condenser pressure), find the bubble point temperature for that pressure, then subtract your actual temperature from the bubble point.

The telltale signs of undercharge include low suction pressure, high superheat, and that familiar frosted suction line near the compressor. Overcharge symptoms show up as high head pressure, low superheat, liquid slugging sounds, and reduced efficiency that drives up energy costs.

Altitude corrections matter more than most people realize. At our service locations in higher elevation areas, atmospheric pressure changes affect gauge readings. The rule of thumb is simple: subtract about 2 psig from chart values for every 5,000 feet of elevation.

Before you even think about connecting gauges, purge air from your gauge lines with nitrogen. Always perform leak tests at 120-140 PSI nitrogen pressure. Evacuate systems to at least 400 microns before charging. And here's critical: charge R404A as a liquid to prevent blend fractionation that can mess up system performance.

More info about fridge compressors

Bubble Point vs Dew Point: When to Use Each

This trips up more technicians than anything else. The difference between bubble point and dew point isn't just academic - it affects every calculation you make.

Use bubble point (the liquid column) when you're calculating subcooling in the liquid line, setting thermostatic expansion valve bulb temperature, measuring condenser performance, or charging systems. Remember: always charge R404A as liquid to maintain the proper blend ratio.

Use dew point (the vapor column) for calculating superheat in the suction line, setting evaporator pressure regulator controls, diagnosing evaporator performance, and measuring compressor suction conditions.

Troubleshooting with the P-T Chart

Your r404a p-t chart becomes a diagnostic tool when systems act up. Here's what different symptoms tell you.

Frosted evaporator coils usually point to superheat problems. Check superheat using the dew point column. Low superheat under 5°F suggests overcharge or TXV problems. High superheat over 15°F indicates undercharge or restricted refrigerant flow.

High head pressure needs comparison between actual condenser pressure and bubble point temperature at ambient conditions. Air-cooled condensers should run 20-30°F above ambient temperature. Higher differences suggest dirty condenser coils, system overcharge, or non-condensables contaminating the refrigerant.

Low suction pressure combined with high superheat screams undercharge. Could also indicate restricted liquid line or failed TXV. Use your P-T chart to verify evaporator temperature matches the design specifications.

Common Mistakes & How to Avoid Them

After servicing refrigeration systems across multiple states, we see the same mistakes repeatedly.

Using the wrong chart tops the list. R404A charts are absolutely not interchangeable with R22, R507, or other refrigerants. Always verify refrigerant type before consulting P-T data.

Mixing pressure units causes expensive mistakes. Don't confuse psig (gauge pressure) with psia (absolute pressure). International charts may use kPa or bar, so convert carefully.

Ignoring ambient conditions leads to misdiagnosis. Condenser performance varies dramatically with outdoor temperature. Account for seasonal variations in system performance.

Contaminated gauges give false readings. Cross-contamination between refrigerants affects accuracy. Use dedicated gauge sets for R404A systems when possible.

R404A vs Other Refrigerants: Pressure-Temperature Showdown

When you're troubleshooting systems or planning retrofits, understanding how r404a p-t chart values compare to other refrigerants can save you time and prevent costly mistakes. Each refrigerant has its own pressure personality, and mixing them up in the field leads to headaches.

R404A versus the old workhorse R22 shows why many technicians struggled during the early retrofit days. R404A runs at significantly higher pressures - at 40°F, you'll see about 85 psig with R404A compared to just 68 psig with R22. This pressure difference meant that older gauge sets and system components sometimes couldn't handle the increased stress. The oil requirements also changed completely, with R404A demanding POE oil instead of R22's traditional mineral oil.

R404A and R507 are practically twins when it comes to pressure-temperature relationships. Both operate at nearly identical pressures and use the same POE oil, which is why R507 became a popular alternative in some applications. R507's Global Warming Potential is slightly lower at 3985 compared to R404A's 3922, but both face the same phase-down restrictions under current environmental regulations.

The comparison with R410A reveals a completely different pressure world. At 40°F, R410A pushes 118 psig while R404A sits at 85 psig - that's a 33 psig difference that requires beefier equipment and different safety considerations. This is why residential air conditioning gauges won't work properly on commercial refrigeration systems, and vice versa. Both refrigerants use POE oil, but they require different viscosity grades for optimal performance.

R32 represents the future direction with its dramatically lower GWP of 675 compared to R404A's 3922. The pressure ranges are similar enough for some retrofit possibilities, but R32's A2L safety classification (mildly flammable) requires completely different handling procedures and system designs. We're watching this refrigerant closely as funeral homes prepare for long-term compliance.

The capacity and efficiency differences between these refrigerants affect energy costs significantly. R404A typically provides excellent capacity in low-temperature applications, but newer alternatives like R452A offer similar performance with about 45% lower GWP. The discharge pressures and compressor requirements vary enough that retrofit decisions require careful engineering analysis.

When we help funeral homes across Tennessee, Georgia, and our other service regions evaluate refrigerant options, the pressure-temperature characteristics often determine which systems work best for their specific needs. Here's how the numbers compare at common operating temperatures:

| Temperature | R404A | R410A | R452A |

|---|---|---|---|

| 0°F | 33 psig | 52 psig | 35 psig |

| 40°F | 85 psig | 118 psig | 89 psig |

| 100°F | 235 psig | 318 psig | 245 psig |

These pressure differences explain why you can't simply swap refrigerants without considering the entire system design. The r404a p-t chart remains your most reliable reference for current systems, while planning for future transitions requires understanding how alternative refrigerants will perform under the same conditions.

At American Mortuary Coolers, we design our custom systems to accommodate both current R404A requirements and potential future refrigerant changes. This approach helps funeral homes avoid costly system replacements when environmental regulations continue evolving.

Safety, Compliance & Best Resources

Working safely with R404A isn't just about following rules - it's about protecting yourself and ensuring reliable system performance. After years of installing mortuary cooling systems across the country, we've learned that proper safety protocols make the difference between a smooth installation and a costly callback.

R404A carries an A1 safety classification under ASHRAE Standard 34, which sounds fancy but simply means it won't poison you or catch fire under normal conditions. Don't let this fool you into complacency though - the real dangers come from the high pressures involved.

High pressure is your biggest safety concern with R404A systems. These systems can reach over 450 psig when ambient temperatures climb, and at 150°F, you're looking at 456 psig - enough pressure to turn a failed fitting into a dangerous projectile. Always use refrigeration-rated gauges and equipment designed for these pressures. Those cheap automotive gauge sets from the parts store? Leave them for car A/C work.

The POE oil used in R404A systems creates its own set of challenges. This stuff is hygroscopic, meaning it soaks up moisture from the air like a sponge. We've seen too many systems fail because technicians didn't understand this. Keep oil containers sealed tight when not in use, and always evacuate systems to at least 400 microns before charging. The moisture contamination can form acids that'll eat your system from the inside out.

EPA Section 608 certification isn't optional - it's the law. Whether you need Type I, Type II, Type III, or Universal certification depends on your work scope, but you absolutely need one of them. The EPA takes refrigerant handling seriously, especially with high-GWP refrigerants like R404A. Recovery equipment must be certified, and you'll need to keep records of refrigerant purchases and usage.

Cylinder transport follows DOT regulations that are straightforward but important. Secure cylinders during transport, use proper valve protection caps, and make sure your storage area has adequate ventilation. We've never had issues following these basic rules across our service territory from Tennessee to California.

When it comes to disposal and recovery, R404A's high GWP of 3922 means every pound matters environmentally. Use certified recovery equipment and send refrigerant to approved reclamation facilities. Venting to atmosphere isn't just illegal - it's irresponsible.

For reliable field references, we recommend downloading refrigerant apps to your phone and keeping laminated P-T charts in your toolkit. The NRI-PTCHART-2019_16in provides professional-grade r404a p-t chart data that won't fall apart after a few months in your truck.

At American Mortuary Coolers, we ensure all our technicians maintain current EPA certifications and follow manufacturer service guidelines. The funeral industry depends on reliable cooling systems, and proper safety protocols help us deliver that reliability every time.

Frequently Asked Questions about r404a p-t chart

Why are there two columns (bubble and dew) on the r404a p-t chart?

This is probably the most common question we get from newer technicians, and it's a great one. The r404a p-t chart has two columns because R404A isn't a single refrigerant - it's actually three different refrigerants mixed together.

Think of it like making coffee with different sized grounds. The fine grounds extract first, while the coarse grounds take longer. Similarly, when R404A changes phases, the three components (R125, R134a, and R143a) don't all boil or condense at exactly the same temperature.

The bubble point shows when the liquid mixture first starts to bubble and turn into vapor. The dew point shows when the last bit of vapor finally condenses back to liquid. For R404A, there's about a 0.7°F difference between these two points - we call this "temperature glide."

Here's when to use each column: Use bubble point when you're working with liquid refrigerant (like calculating subcooling in the liquid line). Use dew point when you're working with vapor refrigerant (like calculating superheat in the suction line).

How do I adjust R404A pressures for altitude?

Working at different elevations can throw off your readings if you're not prepared. We've learned this servicing mortuary coolers everywhere from sea-level locations in Georgia to higher elevations in Colorado.

Your gauges measure pressure relative to the atmospheric pressure around you. Since atmospheric pressure drops as you go higher, your gauge readings will be lower than what the r404a p-t chart shows.

The simple rule we use: subtract about 2 psig for every 5,000 feet above sea level. So if you're working in Denver at 5,280 feet elevation, expect your pressures to read roughly 2 psig lower than the chart values.

This might not sound like much, but it can definitely affect your superheat and subcooling calculations. Always factor in your elevation when diagnosing system performance, especially if you're used to working at sea level and find yourself on a mountain service call.

Can I use an R404A chart for R452A or R448A?

Absolutely not - and this is a mistake that can cost you big time. Each refrigerant has its own unique pressure-temperature relationship, and mixing up charts will lead to improper charging and potential system damage.

We see this question more often now as the industry transitions away from R404A to lower-GWP alternatives. R452A runs about 4-6 psig higher than R404A at typical operating temperatures, while R448A has completely different characteristics and a much larger temperature glide.

If you're retrofitting a system from R404A to one of these alternatives, you need three things: the correct P-T chart for the new refrigerant, proper training on the differences, and updated procedures for your technicians. There's no shortcut here - using the wrong chart will cause more problems than it solves.

At American Mortuary Coolers, we make sure our service teams have the right charts for every refrigerant they might encounter. It's a small investment that prevents major headaches down the road.

Conclusion

Mastering the r404a p-t chart isn't just about memorizing numbers - it's about understanding the language your refrigeration system speaks. When that walk-in cooler starts acting up at 2 AM, or when a funeral home calls because their mortuary cooler isn't holding temperature, the P-T chart becomes your translator.

We've covered everything from basic bubble point readings to altitude corrections, but here's what really matters: precision charging saves money and prevents callbacks. Every degree of superheat matters. Every psi of pressure tells a story about what's happening inside that system.

The refrigeration industry is at a crossroads. With 2025 compliance deadlines fast approaching, R404A systems will face new restrictions and phase-out requirements. But the fundamentals we've discussed - reading pressure-temperature relationships, calculating superheat and subcooling, understanding zeotropic blends - these skills transfer directly to the next generation of refrigerants.

At American Mortuary Coolers, we've seen how proper refrigerant handling makes the difference between a system that lasts 15 years and one that fails in five. Whether we're installing custom mortuary coolers in small-town Tennessee or servicing equipment in busy metropolitan areas, the same principles apply.

The physics don't change, even when the refrigerants do. R452A and R448A may have different GWP values, but they still follow pressure-temperature relationships. They still require proper charging techniques. They still demand respect for the fundamentals.

Here's what separates good technicians from great ones: great technicians understand why the numbers matter. They know that 15°F of superheat isn't just a target - it's insurance against liquid slugging. They recognize that proper subcooling isn't just about efficiency - it's about protecting the expansion valve.

Keep your laminated charts handy, your gauges calibrated, and your knowledge sharp. The funeral homes we serve across all 48 states depend on reliable cooling systems, and that reliability starts with technicians who understand their tools.

More info about the 2025 Freon transition

The future of refrigeration is changing, but the need for skilled professionals who can read a r404a p-t chart accurately will never go out of style. Master these fundamentals, and you'll be ready for whatever refrigerant comes next.