Understanding Today's Walk-In Cooler Solutions

Walk-in cooler solutions are essential refrigeration systems that provide temperature-controlled environments for storing perishable products in commercial, agricultural, and specialty settings. If you're looking for the right walk-in cooler solution, here's what you need to know:

- Types: Indoor, outdoor, modular, custom-built, mobile, and combination units

- Temperature Range: Typically maintains 33°F to 38°F (0.5°C to 3.3°C)

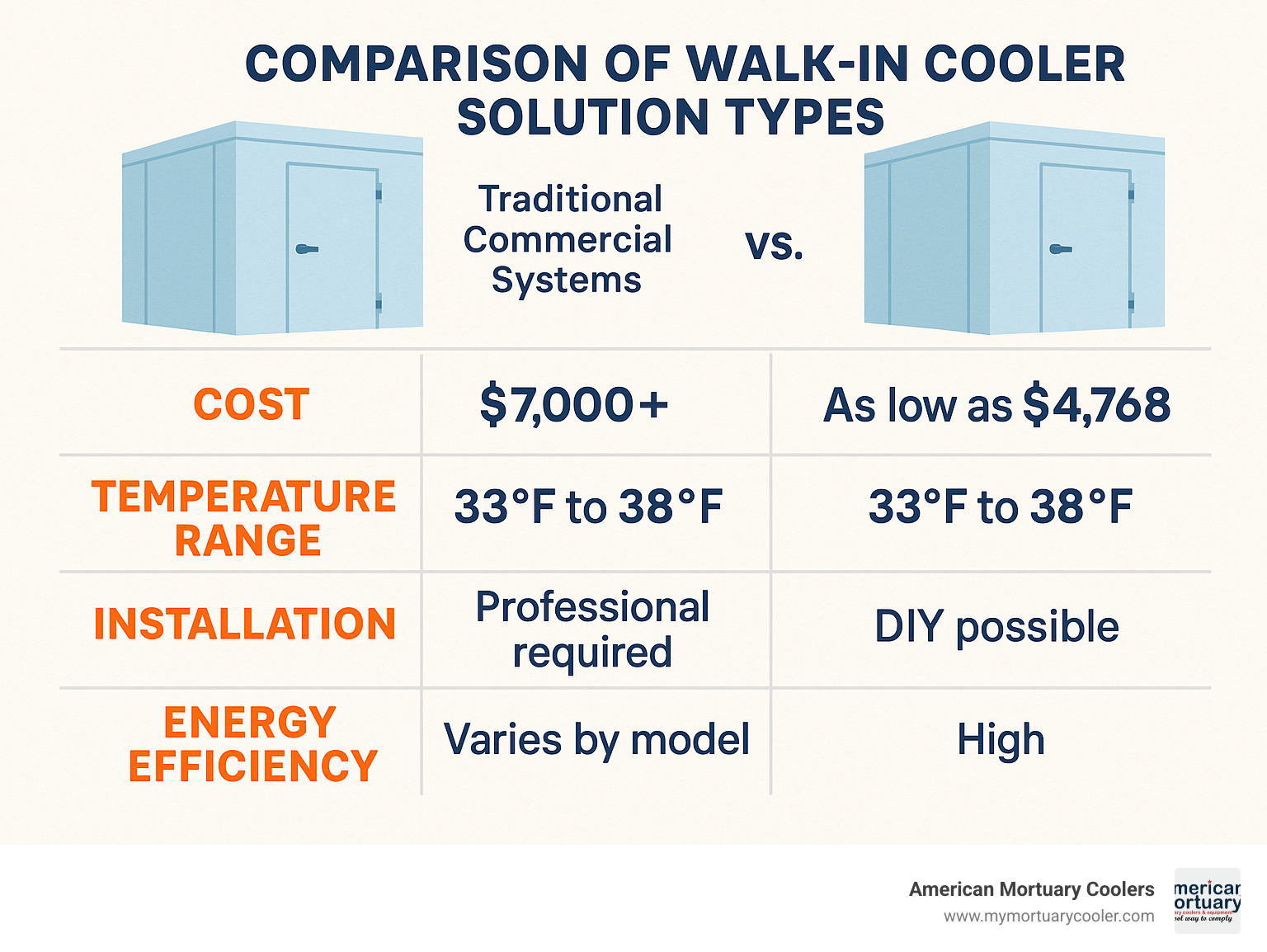

- Cost Options: Traditional systems ($7,000+) vs. alternative solutions like CoolBot (saves up to $2,232)

- Key Components: Insulated panels, refrigeration system, doors, flooring, and controls

Walk-in coolers differ significantly from standard refrigerators, offering spacious interiors you can physically enter to stock, organize, and retrieve stored items. They serve as the backbone of cold storage for countless businesses where temperature control directly impacts product quality and safety.

Whether you're running a restaurant kitchen, managing a floral shop, operating a brewery, or maintaining a mortuary facility, selecting the right walk-in cooler solution involves balancing size requirements, temperature needs, energy efficiency, and budget constraints.

The market offers diverse options ranging from traditional commercial systems with dedicated compressors to innovative alternatives like the CoolBot, which transforms standard air conditioners into powerful cooling units at a fraction of the cost.

I'm Mortuary Cooler, a national-level supplier specializing in walk-in cooler solutions for various industries including funeral homes and medical facilities. My experience with walk-in cooler solutions spans decades, helping businesses find reliable refrigeration that meets their specific storage needs while maintaining compliance with industry regulations.

Walk-in cooler solutions word roundup:

Why This Guide Matters

With rising energy costs and increasing regulatory pressure on businesses to maintain proper food safety and product integrity, finding the right walk-in cooler solution has never been more important. Whether you're exploring options for a new installation or looking to upgrade existing refrigeration systems, this guide will help you steer the complex world of commercial cold storage.

The cold chain market continues to expand, with walk-in coolers representing a significant segment of growth. As energy prices climb and sustainability becomes a priority, businesses need to make informed decisions about refrigeration that balance upfront costs with long-term operational efficiency.

What Are Walk-In Coolers & Why They're Different

Imagine stepping into a refrigerator that's as big as a room—that's essentially what a walk-in cooler is! These spacious refrigerated environments maintain temperatures between 33°F and 38°F (0.5°C to 3.3°C), creating the perfect climate for preserving perishable goods. Unlike their smaller cousins—reach-in refrigerators that you access from the outside—walk-in coolers invite you to step inside, giving you complete access to organize, stock, and retrieve your stored items with ease.

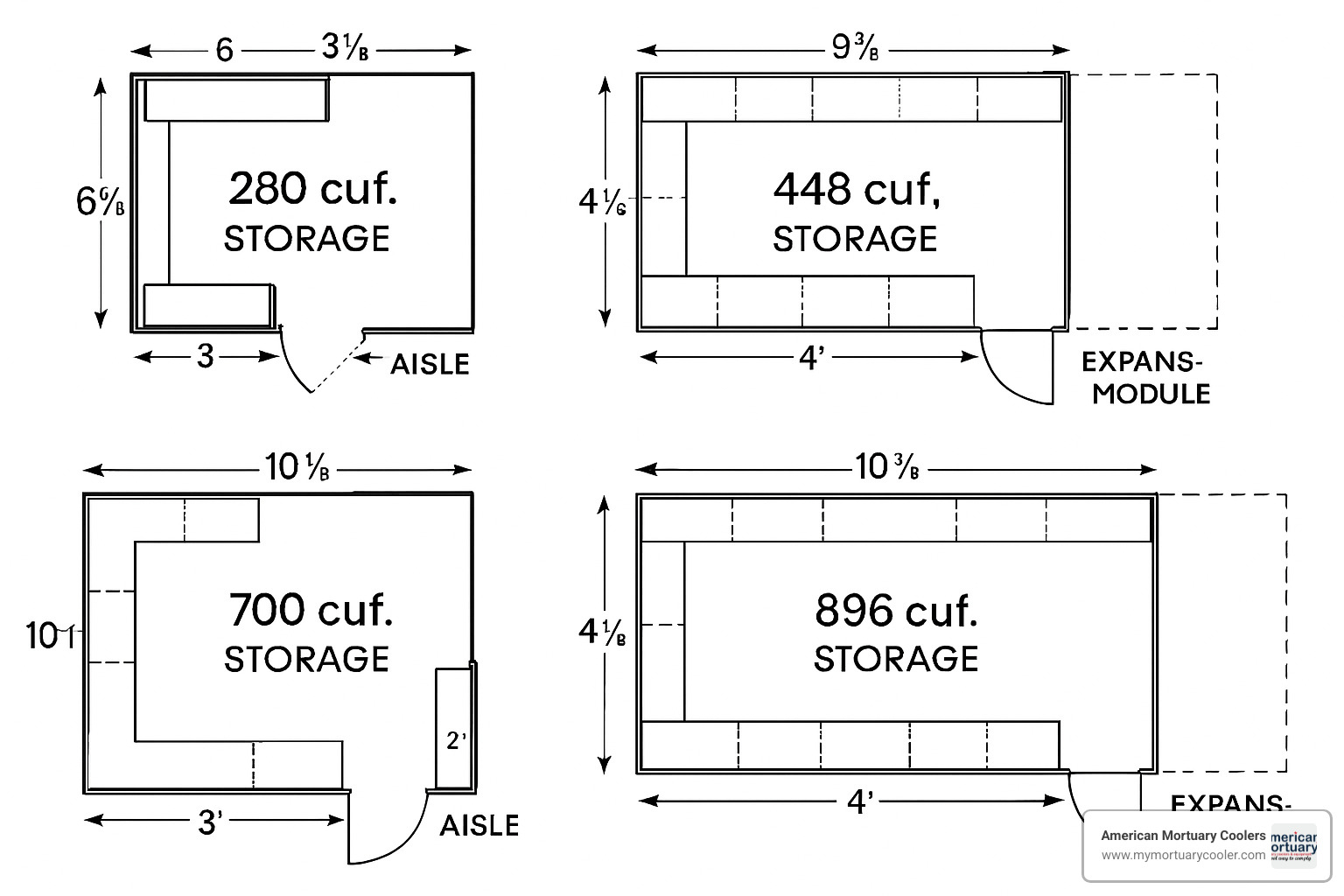

What makes walk-in cooler solutions truly special is their impressive scale and adaptability. While your standard commercial fridge might offer a modest 20-30 cubic feet of storage space, walk-ins can range from cozy 70 square foot units to massive 1,600+ square foot cold rooms custom to your specific business requirements.

The construction science behind these cooling giants is fascinating too. Most walk-ins use specially designed insulated panels with high R-values that efficiently maintain temperature. According to engineering research on thermal conductivity, the polyurethane foam insulation commonly used in quality walk-in coolers provides remarkable thermal resistance—significantly outperforming the insulation found in conventional refrigerators and dramatically reducing heat transfer.

Key Benefits for Business & Agriculture

When you invest in walk-in cooler solutions, you're not just buying refrigeration—you're enhancing your bottom line in multiple ways.

Extended shelf life becomes your new reality, as consistent temperatures significantly slow the spoilage clock for perishable goods. For restaurants, this translates to fresher ingredients and noticeably less waste. One of our restaurant clients reduced their food waste by nearly 30% within three months of installation!

Improved inventory control comes naturally with these spacious units. The days of playing "refrigerator Tetris" are over—walk-ins provide clear visibility of your stock levels, making inventory management a breeze rather than a chore.

The bulk storage capacity allows you to buy in larger quantities, often at better prices. Many of our clients report saving 15-20% on ingredient costs by purchasing in bulk and storing effectively.

Your team will appreciate the improved workflow efficiency too. Instead of repeatedly opening and closing a reach-in unit (and letting precious cold air escape each time), staff can enter the cooler once to handle multiple items, saving time and maintaining more stable temperatures.

For our agricultural friends, walk-in coolers have become game-changers for post-harvest cooling. Farmers can quickly remove field heat from freshly harvested produce, dramatically extending marketable life—particularly valuable for small to medium-sized operations serving local markets or running CSA programs.

Walk-In Cooler Solutions for Every Need

No two businesses have identical refrigeration needs, which is why walk-in cooler solutions come in such wonderful variety.

Indoor walk-in coolers fit seamlessly within your existing building, maximizing interior space while connecting to your building's electrical system. They're perfect when you have the square footage to spare and want to keep everything under one roof.

Working with limited indoor space? Outdoor walk-in coolers might be your answer. With weather-resistant exteriors, these tough units stand up to the elements—some fiberglass models from manufacturers like Polar King can handle impressive snow loads up to 100 pounds per square foot without requiring additional steel framing.

Modular walk-in coolers offer flexibility that growing businesses love. Using clever cam-lock panel systems, they assemble quickly and can be expanded or reconfigured as your needs evolve. They're also energy heroes, typically running up to 20% more efficiently than traditional models.

When standard just won't do, custom walk-in coolers step in to save the day. Need glass display doors for your floral shop? Angled ceilings to fit an unusual space? Specific interior fixtures for your brewery? Custom units deliver precisely what you need.

For businesses on the move, mobile walk-in coolers built on trailers or in converted shipping containers provide cooling power wherever you roam—perfect for event caterers, farmers markets, or temporary operations.

Combination units offer the best of both worlds by incorporating refrigerator and freezer sections in a single footprint. These space-optimizing solutions provide different temperature zones while minimizing installation requirements.

At American Mortuary Coolers, we've witnessed growing demand for specialized walk-in cooler solutions across diverse industries. From restaurant kitchens requiring precise temperature control to funeral homes needing dependable body storage systems, our custom designs address each client's unique requirements while delivering the core benefits that make walk-in refrigeration so valuable.

Inside the Box: Components & Technology That Keep It Cold

Ever wonder what makes a walk-in cooler actually work? Let's peek behind those insulated panels and find the cool technology that keeps your products fresh. Understanding these components will help you make smarter decisions when choosing your own walk-in cooler solution.

Anatomy of a Walk-In Cooler Solution

Think of your walk-in cooler as a carefully engineered thermal envelope. At its heart are the insulated panels – typically made of polyurethane foam sandwiched between metal sheets. These panels aren't just walls; they're your first defense against heat. Most quality panels range from 3.5" to 5" thick, with the thicker options providing better insulation (higher R-values). Companies like KPS Global use a special poured-in-place foam technique that eliminates air gaps for maximum efficiency.

These panels connect through an ingenious cam-lock system with gaskets and butyl seals. When locked together, they create an airtight barrier that keeps cold air in and warm air out – essential for any effective walk-in cooler solution.

The doors might seem simple, but they're engineering marvels too. Heavy-duty, self-closing doors with magnetic gaskets ensure a tight seal every time someone enters or exits. Depending on your needs, you might choose standard hinged doors, space-saving sliding doors, or glass display doors that let customers see products without opening the cooler. Many of our clients appreciate practical features like diamond kick plates and triple hinges that stand up to years of heavy use.

The real magic happens in the refrigeration system, which has two main parts working together:

- The evaporator (inside the cooler) quietly pulls heat from the interior space

- The condensing unit (typically mounted outside) releases that captured heat to the outside world

Modern walk-in cooler solutions include digital controls that maintain precise temperatures. Advanced systems even offer remote monitoring through WiFi, sending alerts to your phone if temperatures drift outside safe ranges.

Don't forget about the floor! You can choose insulated floors for freestanding units, or floor-less designs that install directly on pre-insulated concrete slabs. If you'll be moving heavy items in and out, heavy-duty flooring rated for pallet jacks or forklifts is definitely worth the investment.

Traditional Systems vs. CoolBot Walk-In Cooler Solutions

When shopping for walk-in cooler solutions, you'll encounter two distinct cooling approaches – each with its own advantages.

Traditional commercial systems use specialized refrigeration components designed specifically for commercial applications. They're powerful and proven, but typically cost $7,000 or more for equipment and installation. These systems require professional installation by licensed refrigeration technicians and often need separate electrical circuits. They're the industry standard, but that reliability comes at a price.

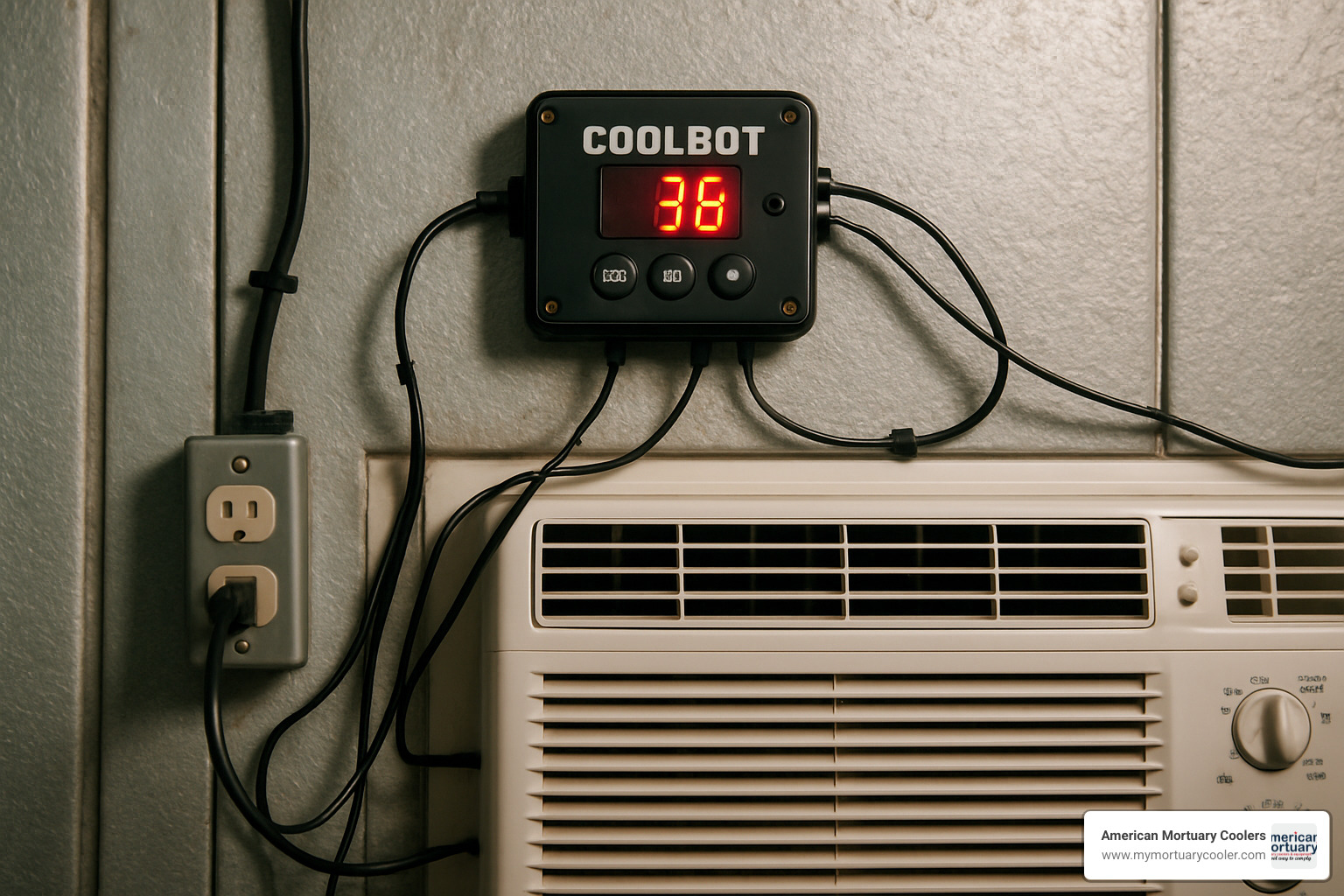

Then there's the innovative CoolBot approach. These clever systems use standard air conditioners paired with a specialized controller to achieve commercial-grade cooling at a fraction of the cost. You could save up to $2,232 compared to conventional systems! Many of our customers appreciate that CoolBot systems can be installed by anyone comfortable with basic DIY projects, run on standard electrical circuits, and offer simpler maintenance.

The CoolBot controller works through a clever hack – it uses sensors and a microcontroller to override the air conditioner's built-in temperature limitations. This allows the unit to cool spaces down to 34°F without freezing up. Over 90,000 users across various industries have adopted this technology, from small farms to restaurants and floral shops.

Curious about the technical details? Check out How the CoolBot Temperature Controller Works for a deeper explanation.

Next-Gen Innovation & Energy Savers

The world of walk-in cooler solutions keeps getting cooler with exciting new technologies:

Seamless fiberglass construction is changing the game. Companies like Polar King offer one-piece fiberglass exteriors that absorb minimal heat compared to traditional metal panels. This innovative approach eliminates the seams found in traditional panel construction, reducing thermal conductivity and improving energy efficiency.

Smart technology has arrived in the cold room too. The CoolBot Pro and similar systems connect to WiFi, letting you monitor temperatures from your smartphone, track 30-day temperature history, and receive emergency alerts if something goes wrong. Imagine the peace of mind knowing you'll get an immediate notification if temperatures drift during a holiday weekend!

Energy efficiency continues to improve with variable-speed technology. Modern systems use smart compressors and fans that adjust their output based on actual cooling needs, significantly reducing energy consumption compared to traditional single-speed systems that constantly cycle on and off.

For outdoor installations, particularly on farms or remote locations, solar-assisted systems can offset energy costs and provide backup power during outages – a perfect blend of sustainability and practicality.

Even the way panels connect has improved. Advanced cam-lock systems make installation faster while creating more secure seals between panels. This improves overall efficiency and makes future expansion possible if your business grows.

At American Mortuary Coolers, we stay at the forefront of these technologies because we understand that reliability is non-negotiable in the funeral industry. We carefully select the best innovations to offer our clients the most effective refrigeration solutions for their specific needs – whether that's a traditional system for a large funeral home or a CoolBot solution for a smaller facility looking to maximize value.

Choosing, Designing & Installing the Right Walk-In Cooler

Finding the perfect walk-in cooler solution feels a bit like solving a puzzle – you need all the right pieces to fit together for your specific needs. Let's break down this process into manageable steps so you can make the best choice for your business.

Critical Factors Checklist for Walk-In Cooler Solutions

When I talk with clients about walk-in cooler solutions, I always emphasize that proper planning prevents poor performance. Start by honestly assessing your storage needs – not just for today, but for where your business might be in 3-5 years.

Space planning is crucial. You'll need enough room for your products, plus adequate aisle space for staff to move around comfortably. I've seen too many businesses outgrow their coolers within a year simply because they underestimated their needs.

Temperature requirements vary widely depending on what you're storing. While standard coolers maintain 33°F to 38°F, pharmaceutical products often need much more precise temperature control. Be clear about what your specific products demand.

Location matters tremendously. Indoor installations must work within your existing building constraints, while outdoor units need to withstand whatever Mother Nature throws their way. If you're in an area with heavy snowfall, units like those from Polar King can handle snow loads up to 100 pounds per square foot – an important consideration for safety and longevity.

How often will staff access the cooler? This might seem minor, but high-traffic coolers experience significant temperature fluctuations. If your door will open more than six times hourly, you might need strip curtains or air curtains to maintain stable temperatures.

Energy efficiency isn't just good for the planet – it's good for your budget too. Look for insulation with R-values of 29 or higher for coolers (32+ for freezers) to meet Federal EISA requirements and keep those utility bills in check.

Don't forget about regulations. Your cooler needs to meet NSF, UL, and local health department standards, especially critical for food service and medical applications. We can help steer these requirements so your installation passes inspection with flying colors.

From Sketch to Switch-On: Step-By-Step Roadmap

The journey to your new walk-in cooler solution follows a predictable path, though timelines vary based on complexity. Here's what to expect:

We start with a thorough needs analysis, where we discuss your specific requirements and help translate them into technical specifications. For custom installations, we typically recommend a site assessment to identify any potential challenges before they become problems.

Next comes the quotation and design phase. At American Walk-In Coolers, we provide detailed drawings and specifications so you know exactly what you're getting. Once you approve the design, we move to panel fabrication, where your custom panels and refrigeration components are built with careful quality control.

Delivery logistics are handled seamlessly – we ship nationwide across the contiguous 48 states, bringing all components right to your location. Then comes the exciting part: assembly and installation. Modern cam-lock panel systems make this process surprisingly straightforward, though the complexity depends on your specific system.

After the refrigeration setup, we conduct thorough testing and commissioning to ensure everything maintains proper temperature and functions as designed. Finally, we offer a walkthrough to verify operation and provide guidance on getting the most from your new system.

While simple modular units might be up and running within days of delivery, custom installations typically take a few weeks from order to completion. We'll keep you informed every step of the way.

New vs. Used: Budget & ROI Breakdown

The "new versus used" question comes up in almost every conversation about walk-in cooler solutions. While budget often drives this decision, thinking long-term pays dividends.

New coolers offer significant advantages: lower operating costs, comprehensive warranties (typically 20 years on panels, 5 years on doors and compressors), current energy efficiency standards, and customization to your exact needs. They provide peace of mind through predictable performance and reliability.

Used equipment, while 30-50% cheaper upfront, comes with tradeoffs: limited or no warranty coverage, potentially higher energy consumption, and a shorter expected service life. As one of our vendors cleverly puts it, "Clever business owners always search for used equipment first to stretch their budget."

I've helped many clients steer this decision, and the right choice depends on your specific situation. Temporary needs or severe budget constraints might make used equipment sensible. But for most businesses, new equipment delivers better long-term value through energy savings, reduced maintenance, and longer service life.

Protecting Your Investment: Maintenance & Service

Think of your walk-in cooler solution as you would a vehicle – regular maintenance prevents costly breakdowns and extends its life.

Simple quarterly cleaning of condenser coils prevents dust and debris from reducing efficiency and straining the system. Monthly door gasket inspections catch small tears before they cause big temperature problems. These small habits make a huge difference in performance and longevity.

Temperature accuracy is critical – verify it regularly with a calibrated thermometer. Modern systems like CoolBot Pro take this worry away with continuous monitoring and alerts if temperatures drift outside acceptable ranges.

Annual professional inspection of your refrigeration system helps identify potential issues before they cause failures. Think of it as preventive medicine for your cooler. And in busy environments, physical protection like bollards and kick plates prevent expensive damage from carts or equipment.

For detailed guidance on finding reliable service providers, our article on Walk-In Cooler Service 101: Find Reliable Repair Providers offers practical advice.

At American Mortuary Coolers, we've seen how a small investment in regular maintenance prevents emergency repairs and extends equipment life. When your cooler operates at peak efficiency, you save money and ensure the safety of whatever you're storing – whether that's food, flowers, or the deceased entrusted to your care.

Industry-Specific Walk-In Cooler Solutions & Success Stories

When it comes to keeping things cold, one size definitely doesn't fit all. Walk-in cooler solutions vary dramatically across industries, each with their own unique requirements and challenges. Let's take a peek inside how different businesses are using these essential cold storage systems to solve their specific challenges.

Food & Beverage Front-Runners

The restaurant and beverage world has acceptd walk-in cooler solutions with open arms—and for good reason. Your favorite local eatery likely depends on reliable refrigeration to keep ingredients fresh and maintain food safety standards.

Restaurant coolers typically feature food-safe NSF-certified surfaces and heavy-duty flooring that can handle the constant traffic of busy kitchen staff wheeling in carts of supplies. Many restaurants cleverly incorporate multiple temperature zones within a single cooler—keeping delicate greens at one temperature while storing heartier vegetables elsewhere.

Breweries have put their own spin on walk-in cooler solutions with specialized "beer caves" that maintain the perfect 36-38°F environment for storing kegs. I've seen some impressive setups with overhead rail systems that make moving heavy kegs almost effortless. One craft brewery owner told me their 13×13×8' fermentation room maintains a rock-solid 55°F using a CoolBot system, saving them thousands compared to traditional refrigeration options.

Grocery stores have perhaps the most visible coolers, with walk-in dairy rooms and produce coolers that often feature glass display doors so customers can see products without letting all the cold air escape. These retail setups frequently combine cooler and freezer sections in one footprint, maximizing valuable store space.

Fresh Cuts & Blooms

Florists have unique cooling needs that go beyond just temperature. Their walk-in cooler solutions require specialized high-humidity evaporator coils that maintain 90-95% humidity to keep flowers from wilting while still keeping temperatures a crisp 34-36°F.

If you've ever picked up flowers from a shop, you've probably noticed their display coolers with glass doors that showcase the colorful blooms. These systems are engineered with gentle air flow that won't dehydrate delicate petals—a perfect example of how cooling technology adapts to specific product needs.

Farmers have become some of the most innovative users of affordable walk-in cooler solutions. Small organic farms particularly love the CoolBot technology, which allows them to build cost-effective coolers for extending the shelf life of freshly harvested produce. One berry farmer shared how their modest 6×8 cooler maintained at 34°F has been a game-changer for keeping berries market-fresh days longer than before.

These agricultural coolers often need to remove "field heat" quickly—the natural warmth of freshly harvested crops—which requires more powerful cooling capacity than simply maintaining temperature. Many farms also opt for mobile solutions that can be brought right to the edge of fields during harvest seasons.

Mortuary & Medical Applications

Here at American Mortuary Coolers, we've specialized in creating walk-in cooler solutions for funeral homes and medical facilities across the country. This is admittedly a more solemn application, but proper refrigeration is absolutely essential in these settings.

Mortuary coolers maintain temperatures between 35-40°F for optimal preservation while incorporating specialized rack systems that maximize space efficiency. Our standard body boxes are designed to hold three bodies in a compact 7'8" × 3'1" × 5'6½" footprint, with careful attention to creating discrete exterior designs that maintain sensitivity in funeral home settings.

What makes medical and pharmaceutical coolers unique is their need for extraordinarily precise temperature control. These facilities can't afford even minor fluctuations when storing sensitive medications or specimens. That's why these walk-in cooler solutions often feature backup power systems, advanced monitoring with alarm capabilities, and specialized access control for security purposes.

For those interested in learning more about selecting the right mortuary refrigeration, I'd recommend checking out The Essential Guide to Choosing Walk-In Coolers for Morgue Refrigeration: Trust American Mortuary Coolers.

As a Tennessee-based company with locations throughout the United States, we take pride in delivering custom walk-in cooler solutions directly to clients across the contiguous 48 states. Our focus has always been on creating durable, purpose-built systems that meet the unique and sensitive needs of funeral homes and medical facilities.

Frequently Asked Questions about Walk-In Cooler Solutions

How much does a walk-in cooler cost to buy and run?

When you're considering walk-in cooler solutions, I understand that cost is probably one of your biggest concerns. The price tag varies quite a bit depending on what you need:

For purchase costs, traditional commercial walk-in coolers typically run between $7,000 and $30,000 – and that's just the starting point. If you need something particularly large or with specialized features, you might be looking at $50,000 or more.

The good news? Alternative options like CoolBot-driven systems can save you significant money, usually ranging from $4,000 to $10,000 for comparable storage capacity. That's potentially thousands of dollars staying in your business account!

Once your cooler is up and running, the electric bill becomes your main ongoing expense. Most businesses spend between $100 and $500 monthly depending on the size of the unit, how often the door opens, and local electricity rates. I spoke with a bakery owner who switched to a CoolBot system and saved an impressive 350-400 kWh per month – that's real money back in their pocket every billing cycle.

Don't forget about maintenance! Traditional systems typically require annual service costing about 2-5% of your purchase price. That might seem like a lot, but proper maintenance prevents those middle-of-the-night emergency repair calls that can really hurt your budget.

The good news is that the right walk-in cooler solution typically pays for itself within 2-5 years through reduced product waste, extended shelf life, and improved operational efficiency. It's an investment that keeps giving back.

What certifications should my new cooler meet?

Navigating certifications might seem overwhelming, but they're actually your assurance that your walk-in cooler solution is safe, legal, and built to last.

First and foremost, look for NSF Certification. NSF Standard #7 specifically addresses food service equipment, ensuring all surfaces are food-safe and can be properly cleaned and sanitized. This is non-negotiable if you're storing food products.

UL Listing is equally important – this Underwriters Laboratories certification confirms that all electrical components meet strict safety standards. UL-listed panels have been rigorously tested for flame spread and smoke development, giving you peace of mind about fire safety.

Federal energy efficiency standards (EISA) require R-29 insulation for coolers and R-32 for freezers. Meeting these standards not only keeps you compliant but also reduces your long-term operating costs.

Don't overlook local building codes! These vary widely depending on your location and might include specific requirements for seismic ratings, wind load resistance, or snow load capacity for outdoor units. Your local health department will also have specific approval requirements, particularly crucial for food service, medical facilities, and funeral homes.

At American Mortuary Coolers, we ensure all our walk-in cooler solutions meet or exceed these standards, with special attention to the unique requirements of funeral homes and medical facilities. We've been doing this long enough to know that cutting corners on certifications creates headaches down the road.

Can I retrofit an existing space with a CoolBot system?

Absolutely! One of the things I love about CoolBot technology is how adaptable it is for existing spaces. If you have a well-insulated room just sitting there, you're already halfway to having a walk-in cooler.

The process is surprisingly straightforward. Any room with proper insulation (aim for at least R-25 value) can be converted into a functional walk-in cooler using a CoolBot controller and an appropriately sized air conditioner. The installation typically takes about two hours and doesn't require any specialized tools or advanced technical knowledge – just basic DIY skills.

The CoolBot controller mounts directly onto a standard window air conditioner, essentially tricking it into cooling below its normal limits without freezing up. It's ingenious in its simplicity! Even existing walk-in coolers with aging refrigeration systems can be retrofitted with CoolBot technology, breathing new life into old equipment.

I'm always impressed by the creative ways people use this technology. A church kitchen coordinator told me they converted an unused storage room into a complete walk-in cooler for under $2,000 using the CoolBot system. Now they have ample refrigeration for large events without breaking their budget. Old garages, sheds, and outbuildings have all been successfully transformed into functional cold storage spaces.

For many small businesses and organizations, this retrofit approach makes the difference between having proper cold storage or going without – it puts walk-in cooler solutions within reach for nearly any budget.

Conclusion

When it comes to keeping things cold, walk-in cooler solutions have come a long way. Today's market offers something for everyone – from traditional commercial systems with all the bells and whistles to clever alternatives like the CoolBot that won't break the bank.

Finding your perfect cooling match isn't just about looking at the price tag hanging on the unit. The smartest buyers consider the whole picture: how much energy it'll gulp down over the years, what kind of maintenance headaches you might face, and how long the system will keep humming before it needs replacing.

For specialized needs – like keeping the dearly departed properly preserved – working with folks who really know their stuff makes all the difference. Here at American Mortuary Coolers, we've been at this for decades. We don't just sell coolers; we craft custom solutions that fit your exact needs like a glove. And we'll deliver them right to your doorstep anywhere in the lower 48 states from our home base in Tennessee.

We're proud of our nationwide presence. Whether you're running a funeral home in the misty Pacific Northwest or the sunny Southeast, our team is never too far away. Need a standard mortuary cooler? We've got you covered. Looking for something custom-built for your unique situation? That's our specialty.

The beauty of working with a single, experienced supplier is the peace of mind it brings. You're not juggling multiple vendors or worrying about compatibility issues. Instead, you're getting a complete solution from people who understand exactly what you need – often before you even realize you need it.

Want to maximize your cooling efficiency even further? Our combination units offer the best of both worlds. Check out our Ultimate Guide to Walk-In Fridge and Freezer Combos: Boost Efficiency with Commercial Refrigeration Solutions for a deeper dive into these versatile systems.

Ready to explore what walk-in cooler solutions might work for your business? Give us a call at American Mortuary Coolers. We'd love to chat about your refrigeration needs and put together a quote that's custom-custom just for you. No pressure, no jargon – just honest advice from people who care about getting you the right solution.

After all, keeping things cool is what we do best.