Selecting the Right Surgical Tool for Precision Work

Quick Answer: Scalpel Blade Handle Types and Compatibility

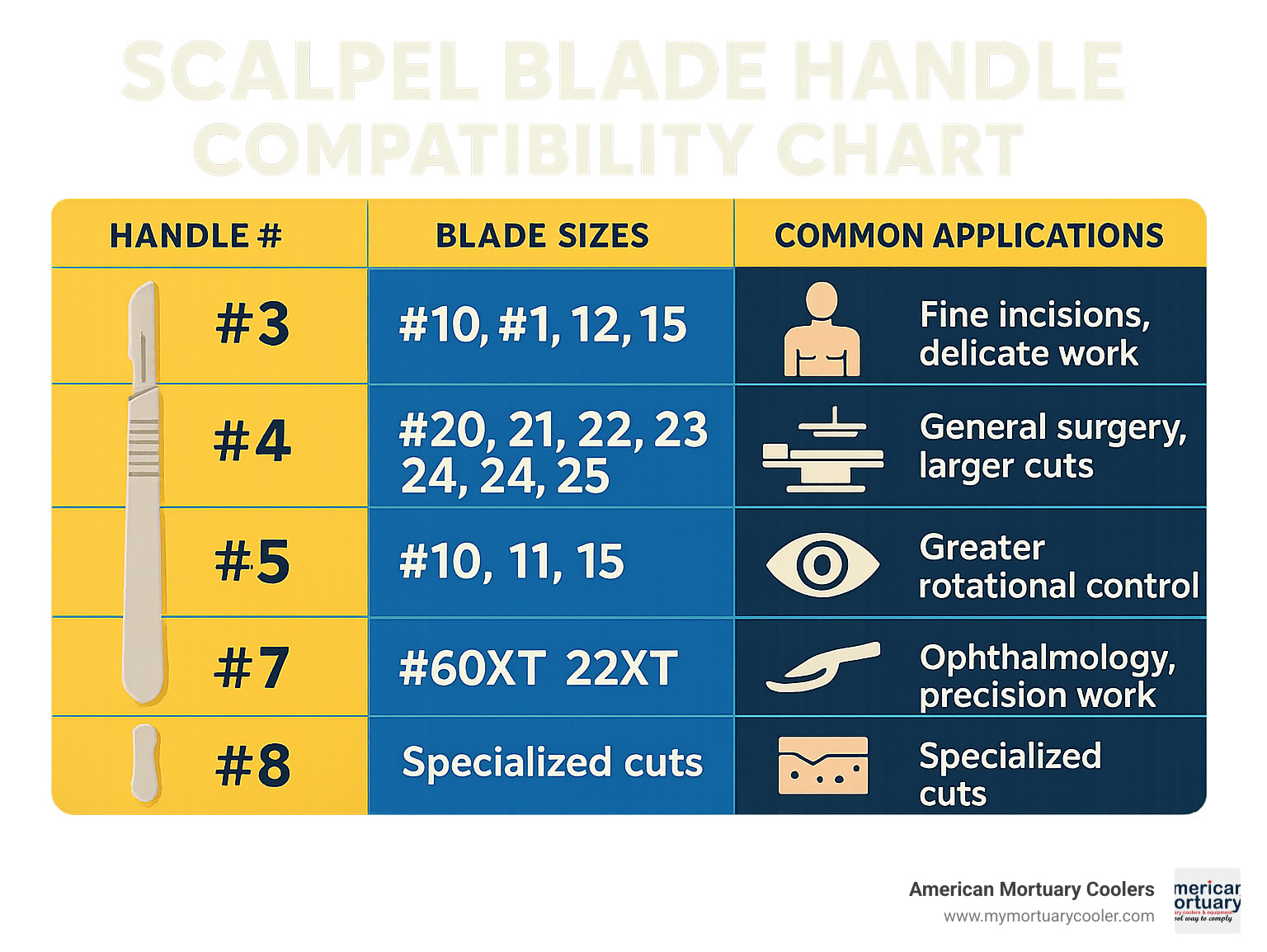

| Handle # | Compatible Blades | Common Uses | Material Options |

|---|---|---|---|

| #3 | #10, #11, #12, #15 | Fine incisions, delicate work | Stainless steel, plastic |

| #4 | #20, #21, #22, #23, #24, #25 | General surgery, larger cuts | Stainless steel, plastic |

| #5 | #10, #11, #12, #15 | Greater rotational control | Stainless steel (round) |

| #7 | #10, #11, #15 | Ophthalmology, precision work | Stainless steel |

| #8 | #60XT, #22XT | Specialized cuts | Stainless steel |

A scalpel blade handle is the foundation of precision cutting in medical, mortuary, and laboratory settings. This seemingly simple tool is actually part of a sophisticated system designed to give professionals complete control during critical procedures. Whether you're performing post-mortem examinations, surgical procedures, or laboratory dissections, choosing the right handle can mean the difference between clean, precise work and frustrating complications.

The numbered handle system (such as #3, #4, and #7) isn't arbitrary - it's a standardized approach that ensures compatibility with specific blade sizes. This system, governed by ISO 7740 standards, helps professionals quickly identify which components work together safely and effectively.

For those new to the field, understanding the differences between reusable stainless steel handles (priced between $8-18) and disposable plastic options ($4-8) can have significant implications for both budgeting and performance. While reusable handles offer superior durability and feel, disposable options eliminate sterilization concerns and reduce cross-contamination risks.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment with extensive experience helping professionals select the right scalpel blade handle for their specific needs. My background in supplying precision instruments to funeral homes and medical facilities has given me insight into how these tools perform in real-world settings.

Handy scalpel blade handle terms:

Understanding the Scalpel Blade Handle

Ever picked up a scalpel blade handle and felt that perfect balance in your hand? There's something reassuring about holding a well-designed instrument, especially when precision matters most. At American Mortuary Coolers, we know our refrigeration systems are just one part of the professional mortuary toolkit - the instruments you use daily deserve just as much attention.

What Is a Scalpel Blade Handle?

A scalpel blade handle is the unsung hero of precision cutting. It's the sturdy, reliable partner that holds the blade steady while you work. Think of it as the foundation that transforms a sharp piece of metal into a precision instrument.

The scalpel blade handle features a clever tang and slot system at its business end that securely locks disposable blades in place. This simple but ingenious design hasn't changed much over decades because it just works so well.

When you hold a quality handle, you'll notice several key parts working together. The tang provides the secure connection point for the blade, while the shaft gives the tool its length and balance. The grip zone (often featuring subtle texturing) ensures the handle stays put in your hand, and that little safety ridge? It's there to keep your fingers safely away from the sharp edge.

All of this engineering follows the ISO 7740:1985 standards - not the most exciting dinner conversation, perhaps, but these standards ensure that when you order blades from trusted names like Swann-Morton or Bard Parker, they'll fit your handle perfectly. No surprises, no compromises.

How Handle Anatomy Affects Control

The way a scalpel blade handle feels in your hand directly impacts your work quality. It's like the difference between writing with a cheap ballpoint pen versus a well-balanced fountain pen - both will mark the paper, but one makes the experience much more comfortable and precise.

Weight and balance matter tremendously. Stainless steel handles (typically 40-60g) provide a reassuring heft that helps steady your hand during procedures requiring firm pressure. For more delicate work, a lighter handle might offer better feedback and reduce fatigue during long sessions.

The textured knurling on quality handles isn't just for show. Those tiny cross-hatched patterns prevent the handle from becoming slippery when exposed to fluids - an essential feature in mortuary settings where gloved hands and various fluids are part of daily work.

That subtle safety ridge you feel under your finger serves a vital purpose. It creates a tactile boundary that helps prevent your fingers from accidentally sliding forward onto the sharp edge during use. It's a small feature that can prevent painful accidents when you're focused on your work.

Some specialized handles include ergonomic finger rests that make a world of difference during extended procedures. When you're performing a detailed post-mortem examination that stretches on for hours, these thoughtful design elements can significantly reduce hand fatigue.

At American Mortuary Coolers, we've noticed that professionals who understand these subtle design features tend to make better choices when selecting their instruments. Whether you're working in Atlanta, Chicago, or anywhere across the country, the right scalpel blade handle can make your precision work both safer and more comfortable.

Types, Sizes & Compatibility of Scalpel Handles and Blades

Ever feel overwhelmed by all those numbers and sizes when looking at scalpel blade handles? Don't worry – you're not alone! The numbering system might seem confusing at first, but it's actually designed to make your life easier by ensuring handles and blades fit together perfectly every time.

The Scalpel Blade Handle Size Chart

Think of scalpel blade handles like shoes – getting the right fit matters! The #3 handle, measuring about 12.5 cm (4.9"), is your go-to for delicate work with its flat, thinner grip. It pairs beautifully with #10, #11, #12, and #15 blades for those precise incisions where a gentle touch matters most.

Need to reach deeper into cavities while maintaining precision? The #3L handle extends to 17.5 cm while still accepting those same fine blades. For more substantial cutting tasks, the #4 handle (14 cm) offers a sturdier grip and works with larger blades in the #20-#25 range.

The #5 handle brings something special to the table – its round design (14.8 cm) provides excellent rotational control while still accepting fine blades like the #10-#15. For specialized work, the #7 handle (16 cm) offers exceptional balance for ophthalmology and precision tasks, while the heavy-duty #8 handle accommodates specialized blades like the #60XT and #22XT.

For the tiniest, most detailed work, the 10 cm miniature handle pairs with micro-blades for those ultra-precise dissections.

All these handles and blades follow the ANSI/ISO 7740 specifications – which is a fancy way of saying they're universally compatible across manufacturers. At American Mortuary Coolers, we've noticed most professionals in our service areas (from NYC to LA and everywhere in between) keep both #3 and #4 handles in their toolkit to handle whatever comes their way.

Specialty & Lighted Handles for Niche Procedures

Sometimes, a standard handle just won't cut it (pun intended!). That's where specialty scalpel blade handles come into play.

Ever tried working in a poorly lit cavity? Lumohs lighted handles solve this common frustration by incorporating LED illumination right at the cutting site. It's like having a tiny spotlight exactly where you need it – particularly valuable during those challenging post-mortem examinations.

For the unique demands of autopsy work, the Post-Mortem PM40H handle offers a more substantial grip that won't slip even in challenging conditions. Its robust construction handles repeated sterilization like a champ.

Need to approach from an unusual angle? The Adjustable Blake handle features an ingenious screw mechanism that lets you modify the blade angle – perfect for those hard-to-reach areas or confined spaces.

The Beaver ENT handle might have been designed for ear, nose, and throat procedures, but many professionals have finded it works beautifully for specialized post-mortem examinations requiring extra precision.

For those long, demanding procedures, the Cygnetic handles offer improved ergonomics that reduce hand fatigue – your fingers will thank you after a full day's work!

Safety-conscious professionals might want to check out the Qlicksmart safety system, which offers clever blade removal devices that eliminate those nerve-wracking moments when changing blades – a common source of workplace injuries we'd all like to avoid.

Here at American Mortuary Coolers, we understand that great tools complement our custom mortuary coolers and refrigeration solutions. Whether you're in the Southeast, Southwest, or Pacific regions, our team can help you find the specialty handles that make your specific procedures safer and more efficient.

Materials, Reusable vs Disposable & Ergonomic Innovations

When it comes to a scalpel blade handle, the material it's made from matters just as much as its design. As we've helped mortuary professionals across the country find the right equipment, we've seen how material choices affect both performance and budget.

Comparing Handle Materials & Lifecycles

Let's talk stainless steel first – the workhorse of the mortuary world. A good surgical-grade stainless scalpel blade handle feels substantial in your hand (usually 40-60g) and provides that perfect balance that makes precision work feel natural. These handles aren't cheap – typically $8-18 each – but they're built to last through 500+ autoclave cycles over 5+ years when properly maintained.

Many of our clients in the Northeast and Midwest prefer investing in premium German steel handles. Yes, they cost more upfront, but they maintain their finish and resist corrosion even after years of daily use. As one funeral director in Chicago told me, "I've had the same handle for seven years, and it still looks and performs like new."

On the other end of the spectrum, plastic or polymer handles offer a different set of advantages. They're much lighter (15-30g), which some professionals prefer for detailed work. At $4-8 each, they're more affordable upfront, though designed for limited use. Many facilities keep some disposable handles on hand for cases where cross-contamination is a particular concern.

For those willing to make a serious investment, titanium alloy handles ($40-100) offer the best of all worlds – lightweight yet incredibly durable, naturally antimicrobial, and hypoallergenic. We've seen growing interest in these premium options, particularly from high-volume facilities in metropolitan areas like Los Angeles and New York.

The economics of reusable versus disposable is pretty striking when you break it down. A quality stainless steel handle costing $12 used for 500 procedures works out to about 2.4 cents per use. A single-use $5 disposable handle is... well, $5 per use. That 200x cost difference explains why established facilities typically invest in reusable options.

Of course, disposables eliminate sterilization time and costs, which can be significant depending on your facility's setup. For more insights on selecting the right tools for your mortuary, check out our article on Tool Talk: A Deep Dive into Mortuary Tools.

Modern Safety & Ergonomic Features

Today's scalpel blade handles have come a long way from the basic models of decades past. Modern designs incorporate thoughtful features that improve both safety and comfort.

Take graduated markings, for instance – such a simple addition, but incredibly useful when you need to make precise measurements during a procedure without switching tools. This feature is particularly appreciated during detailed post-mortem examinations.

The integrated blade remover notch is another game-changer for safety. Rather than juggling separate tools or risking injury with improper removal techniques, this built-in feature makes blade changes much safer. One mortician in Tennessee told us, "After I nicked myself changing blades twice in one month, I switched to handles with removal notches and haven't had an issue since."

The shape of your handle matters too. Round designs like the #5 handle (5.8 inches long) give you better rotational control when you need to make curved incisions. Flat handles like the #3 and #4 provide more stability for straight cuts. It's not about which is "better" – it's about choosing the right tool for your specific technique.

For those particularly concerned about safety, the KLEEN Blade Management System has been gaining popularity among our clients. It allows for hands-free blade attachment and removal, dramatically reducing sharps injury risk – a real concern in busy mortuary settings.

We've also seen growing interest in handles with anti-slip fluted surfaces. When you're working with gloved hands around various fluids, that extra grip security makes a significant difference in control and confidence.

And here's a budget-friendly tip we share with many of our customers: disposable foam grips. For just $1-2 each, these simple accessories can make standard handles more comfortable during lengthy procedures and provide insulation when working with cold tissues.

At American Mortuary Coolers, we understand that even the best refrigeration systems need to be complemented by the right tools. Whether you're in the Rocky Mountains, the Southeast, or anywhere in between, we're happy to help you select scalpel blade handles with the ergonomic features that will improve both safety and performance in your specific setting.

Safe Blade Attachment, Removal, Cleaning & Sterilization

Working with a scalpel blade handle is a bit like dancing with a partner that has a very sharp edge—you need to know the right moves to stay safe. In my years helping mortuary professionals select the right equipment, I've seen how proper handling techniques can prevent injuries and extend the life of these essential tools.

Attaching & Removing Blades on a Scalpel Blade Handle

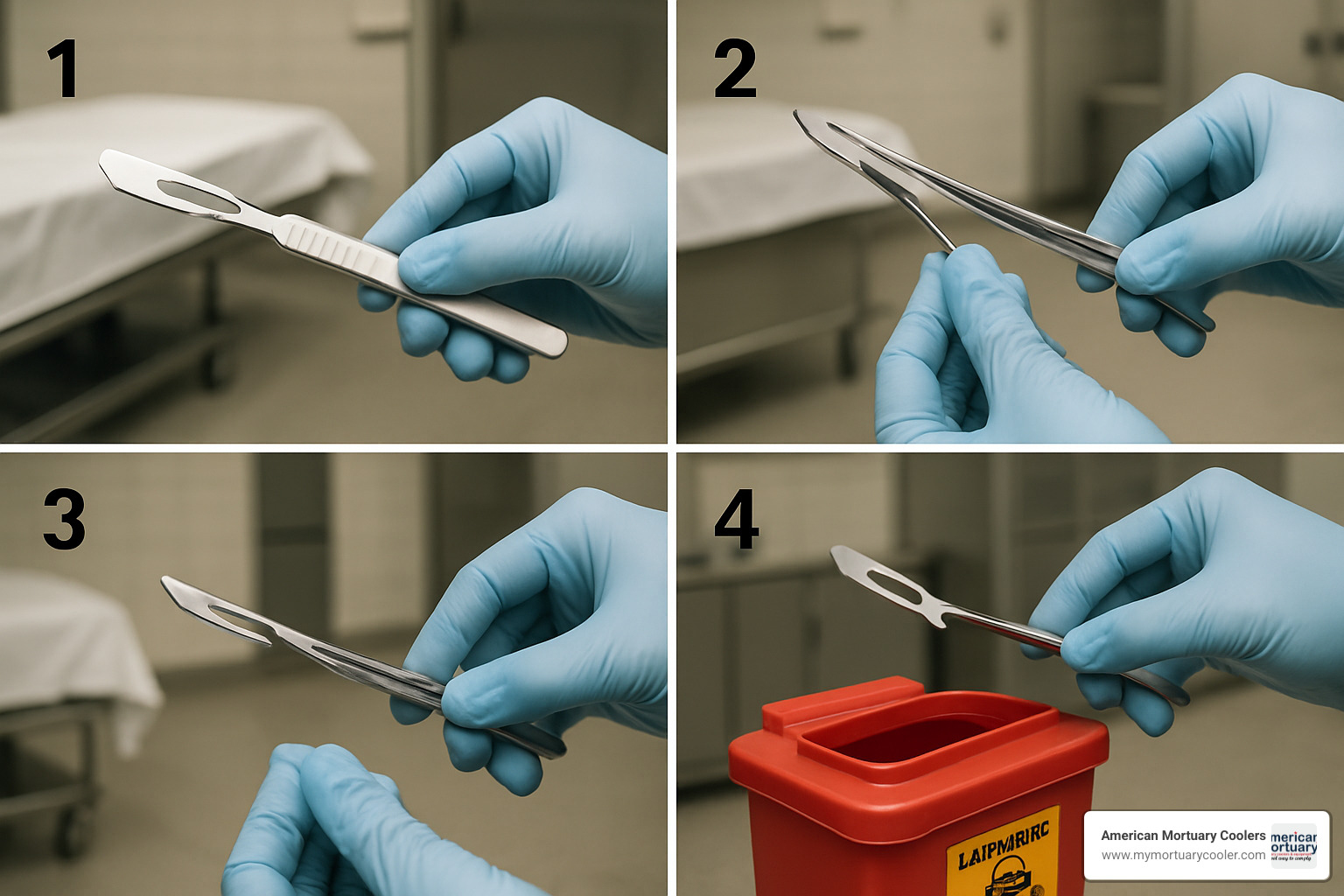

The moment of changing blades is when most sharps injuries occur. Think of it as the most dangerous 30 seconds of your day—worth taking extra care to get right.

When attaching a fresh blade to your scalpel blade handle, always start by opening the blade packet at the designated end, which exposes only the non-cutting edge. Never use your fingers to handle the blade—that's what forceps or needle holders are for! Hold your handle with the slot facing upward, then align the blade's center hole with the raised post. With a gentle sliding motion forward, you'll feel a satisfying click as the blade locks into place. The diagonal lines on both pieces should line up perfectly, like puzzle pieces finding their home. Give it a gentle tug with your forceps to confirm it's secure.

Removing a used blade requires even more caution. With the blade pointing away from yourself and others, grasp the blunt back edge with your forceps. A slight 20-degree bend will disengage the locking mechanism, allowing you to slide the blade forward and off in one smooth motion. The blade should immediately find its way into an approved sharps container—no detours, no exceptions.

Many of our clients have begun using no-touch blade removal devices, which grab and contain the used blade in one motion. While they add about $1-2 per blade change, they dramatically reduce injury risk—a small price for keeping your fingers intact! For a deeper dive into blade options and safe handling, check out our article on A Practical Guide to Comparing Scalpel Blade Options.

Maintenance Protocols for Long-Life Handles

A well-maintained scalpel blade handle can serve you faithfully for years. Think of it as a relationship—the more care you put in, the longer it lasts.

Immediately after use, remove the blade using the safe technique we just discussed. Don't let blood or tissue dry on the handle—it's like letting dishes sit in the sink overnight. A quick rinse under cool running water removes visible debris and makes the cleaning process much easier.

For thorough cleaning, use a soft brush with enzymatic cleaner, paying special attention to that blade slot where residue loves to hide. Stubborn gunk? An ultrasonic cleaner works wonders with the appropriate detergent. Always finish with a distilled water rinse to remove all cleaning agents, then dry completely with a lint-free cloth or compressed air. That slot area needs to be bone-dry to prevent corrosion.

When it comes to sterilization, the autoclave is your best friend—134°C (273°F) for 3-4 minutes does the trick. Some facilities use chemical sterilization or dry heat (160°C for 2 hours), but always follow manufacturer guidelines for these alternative methods.

After sterilization, let those handles cool completely before handling. Take a moment to inspect for any damage, corrosion, or wear—especially around the blade slot and tang area. Many professionals apply a light coat of instrument milk to protect the metal, then store handles in individual sleeves or pouches, like tucking them in for a good night's sleep.

At American Mortuary Coolers, we've found that facilities with consistent maintenance routines get significantly longer life from their instruments. Our team members in Pittsburgh, Dallas, and Chicago often help clients establish these protocols as part of their overall equipment management strategy. After all, even the best mortuary cooler deserves tools that are equally well-maintained!

Regular maintenance checks should become second nature—inspect the blade slot for wear, check for corrosion, ensure the safety ridge remains intact, and verify that textured grip areas still provide that secure feeling in your hand. These small habits add up to years of additional service from quality handles.

How to Select the Right Scalpel Blade Handle for Your Procedure

Choosing the appropriate scalpel blade handle for a specific procedure doesn't have to feel like rocket science, though it does require some thought. After helping professionals from coast to coast select the right tools, we at American Mortuary Coolers have learned that it's about finding that sweet spot between the task at hand, the tissue type, and what simply feels right in your hands.

Decision Matrix by Specialty & Blade Force Needed

When it comes to selecting a scalpel blade handle, the nature of your work should guide your choice. For general post-mortem examinations, a sturdy #4 stainless steel handle paired with #20, #21, or #22 blades provides the durability and control needed for varied tissues. If you're doing fine tissue dissection where precision matters more than power, a lighter #3 stainless steel handle with #10 or #15 blades might be your best friend.

For those long, straight skin incisions that need steady hands, the stability of a #4 stainless steel handle with #22 or #23 blades helps maintain that clean line. Need to reach into deeper cavities while maintaining precision? The extended #3L handle keeps your hand at a comfortable distance while allowing detailed work with #10 or #15 blades.

When working with resistant tissues like cartilage or joint examinations, you'll appreciate the strength of a heavy-duty #4 handle paired with #23 or #24 blades. Cranial procedures demand maximum stability and force, making the #8 heavy-duty handle with #60XT blades the go-to choice.

For the detail-oriented among us doing microdissection, a miniature 10cm handle with corresponding miniature blades provides the delicate touch needed. And if you've ever struggled with shadows while working, a Lumohs lighted handle might just be the game-changer you didn't know you needed.

The shape of your blade should influence your handle choice too. Curved blades like the #10 work beautifully with round #5 handles that allow for natural rotational control. Straight-edge blades such as the #22 perform best with flat #4 handles that provide stability for clean, straight cuts. And sometimes, specialized blade shapes require their own corresponding specialty handles – there's no one-size-fits-all in this field.

Handle length isn't just about personal preference – it's functional. Standard handles (12.5-14cm) suit most procedures nicely, while longer handles (17.5cm+) give better access to deep cavities without compromising your view. For the most detailed work, miniature 10cm handles offer improved precision by allowing for finer finger movements.

For more insights on selecting appropriate tools for mortuary procedures, check out our article on Cutting Edge: Understanding Mortuary Tools.

Budget & Brand Considerations

Let's talk dollars and sense – because while functionality should lead your decision, we all have budgets to consider when selecting a scalpel blade handle.

In the economy tier ($4-8), you'll find basic stainless steel or disposable plastic handles that handle standard procedures competently. Move up to the mid-range tier ($8-15), and you're looking at premium stainless steel handles with improved ergonomics and durability that make those long procedures more comfortable. The premium tier ($15-40) introduces specialty handles with advanced features like illumination or graduated markings that can make certain procedures significantly easier. For those who see their tools as career investments, the professional tier ($40-100) offers titanium or premium German steel handles with lifetime warranties – tools that might outlast your career.

When it comes to manufacturers, several names stand out. Swann-Morton has earned its reputation for precision engineering and strict adherence to ISO standards. Bard-Parker offers an extensive range with consistent quality backed by their historic brand. If you're looking for innovative designs, Havalon has been making waves in specialized applications. For the research-minded or those performing specialized procedures, Fine Science Tools offers exceptional precision instruments. And Cincinnati Surgical provides durable, economical options with good availability when budgets are tight.

The value equation is worth considering too. A quality stainless steel handle at $12 used for 500 procedures (after proper sterilization) costs about 2.4 cents per use – quite the bargain when you think about it. Single-use disposable handles eliminate sterilization concerns but average $5 per procedure. For facilities with predictable usage patterns, bulk purchasing can reduce costs by 15-30%, which adds up quickly.

At American Mortuary Coolers, while our bread and butter might be custom mortuary coolers, we understand that our clients need comprehensive solutions. Whether you're in the chilly Northeast, the humid Southeast, or anywhere in between, our team can help you evaluate the cost-benefit equation for different handle options based on your specific needs and budget constraints. After all, the right tools make all the difference – something we understand whether we're designing coolers or helping you select the instruments you'll use with them.

Frequently Asked Questions about Scalpel Blade Handles

We get calls and emails every day from mortuary professionals with questions about scalpel blade handles. After helping hundreds of funeral homes across the country with their equipment needs, we've noticed some questions come up time and again. Let me share the answers to these common questions in a way that might help you too.

Which blades fit the #3 scalpel blade handle?

The #3 scalpel blade handle is the go-to choice for precision work, accepting blade sizes #10, #11, #12, and #15. These smaller blades are perfect when you need to make careful, detailed incisions.

At 12.5 cm (about 4.9 inches) long, the #3 handle has a flat design that sits comfortably in your hand while giving you excellent control. Many of our clients in smaller funeral homes prefer this handle for its versatility and precision.

If you're working with deeper tissues but still need the precision of these smaller blades, consider the #3L (long) handle. It gives you that extra reach while using the same blade sizes. I remember a mortician in Nashville telling me how switching to the longer handle made a world of difference for his comfort during longer procedures.

Are reusable scalpel blade handles worth the investment?

In most cases, absolutely yes! While the upfront cost might make you hesitate, reusable scalpel blade handles quickly prove their value. Let me break it down:

A quality stainless steel handle costs around $12 and can be used for 500+ procedures after proper sterilization. That works out to about 2.4 cents per use. Compare that to disposable handles at $5 each, and the math becomes pretty convincing.

Beyond cost, there's the feel factor. Our clients consistently report that stainless steel and titanium handles simply feel better in their hands. The weight, balance, and tactile feedback make a real difference during detailed work. As one funeral director in Memphis told me, "Once you've used a quality handle, it's hard to go back to disposables."

That said, disposables do have their place. If you're working in a setting without easy access to sterilization equipment, or during training sessions with multiple users, disposables can be a practical choice. We've supplied both options to funeral homes from small-town South Carolina to busy Los Angeles facilities, depending on their specific needs.

What standards regulate scalpel blade handle and blade compatibility?

The main standard governing scalpel blade handle compatibility is ISO 7740:1985 (with its updates). Think of this as the universal language that ensures handles and blades from different manufacturers work together seamlessly.

This standard specifies exactly how the tang, slot, and locking mechanisms should be designed and measured. It also covers material requirements and testing protocols to ensure the handle performs reliably even under demanding conditions.

Why does this matter to you? Because it means you can buy blades from one manufacturer and handles from another without compatibility headaches. When you're busy serving families during their time of need, the last thing you want is equipment issues.

Beyond ISO 7740, these instruments are also subject to FDA regulations in the US and similar oversight in other countries. These standards ensure that regardless of where you purchase your scalpel blade handles, they'll function safely and effectively with standardized blades from reputable manufacturers.

At American Mortuary Coolers, while our primary focus is keeping your mortuary refrigeration running perfectly, we understand that every tool in your facility matters. That's why we're always happy to answer questions about all aspects of mortuary equipment, not just cooling systems.

Conclusion

Choosing the right scalpel blade handle might seem like a small detail, but as we've seen throughout this guide, it can make all the difference in your work. Whether you're performing delicate tissue examinations or making decisive incisions, having the proper tool in your hand matters tremendously.

Let's take a moment to reflect on what we've learned together:

First and foremost, understanding the handle-blade relationship is crucial. Those numbers (#3, #4, #5) aren't just random—they're your roadmap to compatibility. Knowing which blades fit which handles saves you time, money, and potential frustration when you're in the middle of an important procedure.

The material of your scalpel blade handle tells a story about both durability and purpose. While stainless steel continues to be the trusted workhorse in most settings, the emergence of titanium options for those seeking lightweight precision and disposable polymers for specific situations gives you choices that previous generations of professionals simply didn't have.

I've seen how the ergonomic innovations in modern handles can transform a professional's experience. Those textured grips, safety ridges, and balanced designs aren't just marketing features—they're the difference between hand fatigue during lengthy procedures and maintaining steady, confident control throughout.

Safety is something we take seriously at American Mortuary Coolers. The proper techniques for blade attachment and removal we've discussed aren't just good practice—they're essential protections against one of the most common workplace injuries in mortuary settings. Your well-being matters just as much as the quality of your work.

And let's not forget about maintenance. Those few extra minutes spent properly cleaning, inspecting, and sterilizing your reusable handles pay dividends in longevity. A well-maintained scalpel blade handle isn't just an instrument—it becomes an extension of your professional skill.

At American Mortuary Coolers, while our heart and soul is in creating custom mortuary refrigeration solutions, we understand that every aspect of your operation demands attention to detail. Our nationwide team—from our home base in Tennessee to our presence in major cities across all 48 contiguous states—is committed to supporting funeral professionals with both knowledge and quality equipment.

Whether you're outfitting a new facility or upgrading your existing tools, we hope this guide helps you make choices that improve your professional capabilities and the services you provide to families in their time of need.

For more information about our comprehensive mortuary solutions, including our custom-designed coolers and refrigeration systems built specifically for your unique requirements, please visit More info about our mortuary solutions.

In our line of work—whether it's maintaining the perfect temperature or making the perfect incision—having the right tools isn't just convenient, it's essential. And sometimes, the most important tool is simply knowing which tool to choose.