Why Electric Lift Tables Are Essential for Modern Workplaces

An electric lift table is a powered platform designed to raise, lower, and position heavy loads at ergonomic working heights, reducing workplace injuries and improving efficiency across industries.

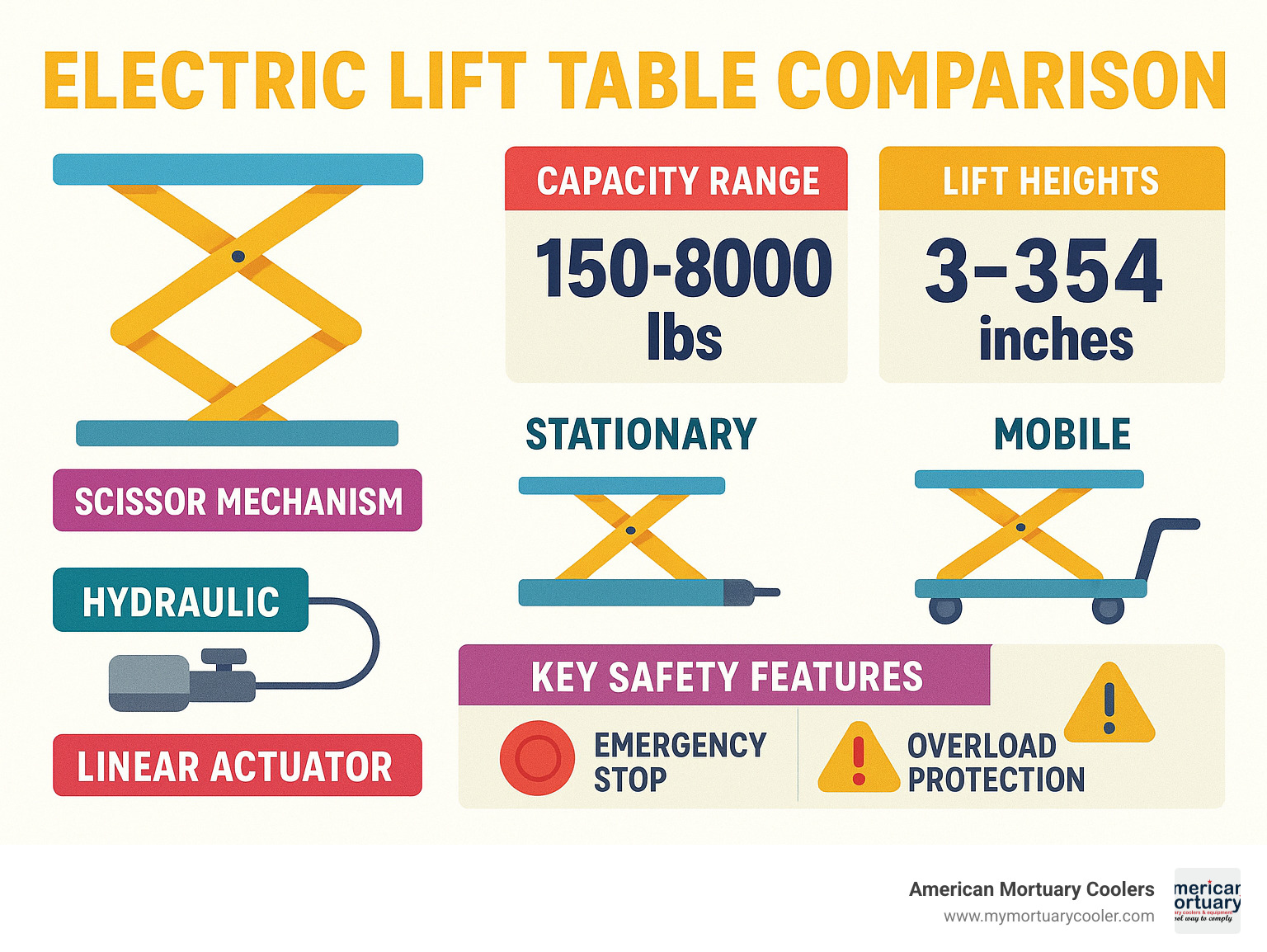

Key Electric Lift Table Facts:

- Capacity Range: 150 lbs to 80,000 lbs (68 kg to 36,287 kg)

- Lift Heights: 3 inches to 354 inches (76 mm to 9,000 mm)

- Injury Reduction: Up to 50% fewer manual lifting injuries

- Popular Types: Scissor (90% of market), mobile, stationary, low-profile

- Price Range: $1,500 to $10,000+ depending on capacity and features

Electric lift tables have become essential equipment in warehouses, assembly lines, and specialized facilities like funeral homes. Most electric lift tables use hydraulic cylinders powered by an electric pump, though newer models feature oil-free linear actuators for cleaner operation.

The technology continues to advance with features like IPM motors that reduce power consumption by 30% and ultra-low platforms that lower to just 3.2 inches for easy loading.

As Mortuary Cooler, I've worked extensively with funeral homes nationwide to specify the right electric lift table solutions for their unique space and operational requirements.

Terms related to electric lift table:

How an Electric Lift Table Works & the Main Types

If you've ever watched an electric lift table smoothly raise a heavy pallet to the perfect working height, you might wonder what's happening beneath that platform.

What Is an Electric Lift Table?

Think of an electric lift table as your hardworking assistant that never gets tired. It's essentially a powered platform that transforms electrical energy into precise vertical movement, positioning loads exactly where you need them.

The heart of every electric lift table includes a sturdy platform for your loads, a lifting mechanism (usually scissor-style), an electric motor with pump assembly, and controls that put you in charge. Modern units also include safety features like emergency stops and overload protection.

Core Lift Mechanisms Explained

Most electric lift tables rely on one of three main lifting systems, each with its own strengths.

Hydraulic cylinder systems are the workhorses of the industry, dominating the market because they're proven and powerful. When you hit the up button, an electric pump pressurizes hydraulic fluid that extends cylinders connected to the scissor mechanism. These systems handle the heaviest capacities and provide rock-solid stability.

Linear actuator systems represent the newer generation of technology. Instead of hydraulic fluid, they use electric motors driving ball screws or gear mechanisms directly. With no oil to leak and smoother operation, these dry ball-screw systems are perfect for clean environments or facilities that want minimal maintenance headaches.

Pneumatic systems use compressed air instead of hydraulic fluid, though you'll mainly find them in lighter-duty applications or specialized clean room environments.

The scissor mechanism itself is where the real engineering beauty shines. As cylinders extend or actuators push, the scissor arms spread apart like opening scissors, multiplying the force and raising the platform steadily. Double-scissor designs stack two scissor assemblies for greater lift heights, while tandem configurations synchronize multiple units to handle extreme loads up to 17,600 pounds.

The variety includes low-profile models that squeeze down to just 3.2 inches when lowered, mobile units that add wheels for portability, stationary platforms for maximum stability, and column-type lifts that offer a different approach entirely.

Choosing the Right Electric Lift Table: Key Features & Specs

Picking the perfect electric lift table for your facility requires understanding which specifications actually matter for your specific situation.

Load capacity is where most people start. You'll find options ranging from lightweight 150-pound models up to industrial giants handling 80,000 pounds. Always size your table at least 25% above your heaviest expected load for safety and dynamic forces.

Lift height determines how ergonomically you can position your work. Ultra-low profile models start at just 3.2 inches when lowered, while some units reach up to 354 inches high. Most users find 30 to 48 inches of lift height covers their ergonomic needs.

Platform size must accommodate your largest loads with room for stability. Standard sizes run from compact 17.8" × 37.5" units up to massive 118" × 47" platforms.

Duty cycle tells you how hard you can work your table. Light-duty models might handle 10-20 cycles per hour, while heavy-duty units can run continuously through 100,000 cycles or more.

Power requirements vary between single-phase AC, three-phase AC, or DC battery systems. Battery-powered mobile units typically use 12V systems with 8.5-hour charge times.

For detailed model comparisons, check out A Comprehensive Guide to Electric Scissor Lift Options.

| Capacity | Lift Height | Platform Size | Typical Price Range |

|---|---|---|---|

| 660 lbs | 32" | 24" × 36" | $1,500-$2,500 |

| 2,200 lbs | 48" | 36" × 48" | $3,000-$4,500 |

| 4,400 lbs | 36" | 48" × 60" | $5,000-$7,000 |

| 6,600 lbs | 42" | 60" × 72" | $7,500-$9,500 |

Electric Lift Table vs. Manual & Hydraulic Alternatives

Efficiency is the biggest advantage. Electric systems give you consistent cycle times every time with just the push of a button. Manual tables require physical pumping that slows operations and wears out staff.

Maintenance costs favor electric systems over time. While you'll need periodic motor service, you eliminate the biggest headache of traditional hydraulics: oil leaks.

Precision is another area where electric systems shine with programmable exact height presets and repeatable positioning.

Electric Lift Table Specification Checklist

Before committing to any electric lift table, work through these critical questions:

Load requirements: Maximum weight, load dimensions, and whether loads will be centered or off-center.

Operational needs: Cycle frequency per hour, required lift height range, and positioning precision requirements.

Environmental factors: Indoor/outdoor use, temperature range, moisture exposure, and floor conditions.

Mobility requirements: Stationary versus mobile needs, manual push versus powered drive.

Power and budget: Available electrical service, budget range from $1,500 to $10,000+, and required certifications.

Comparing Top Models by Application & Industry

Choosing the right electric lift table depends on your specific industry needs and applications.

Manufacturing and assembly lines require rock-solid positioning with synchronized multi-stage lifts for precision. The automotive industry uses heavy-duty models handling up to 17,600 lbs for engines and transmissions.

Warehousing and distribution centers need mobility. Mobile electric lift carts like the ET-105 Powered Lift Table offer both 1,100 lbs drive capacity and 800 lbs lift capacity for moving items between stations.

Funeral and mortuary operations require quiet operation, stainless steel construction, and gentle positioning. At American Mortuary Coolers, we've worked with funeral homes nationwide, and standard industrial models don't meet these specialized requirements.

Clean-room environments need FDA-compliant models, while lighter-duty 150 lb models serve printing and appliance installation work.

For detailed guidance, check out The Complete Guide to Choosing the Right Scissor Lift Table.

Stationary Scissor Platforms

Loading dock operations rely on ground-entry tables with lowered heights around 12 inches for direct forklift access. Most dock applications need 2,000-6,000 lb capacities with 36-60 inch travel ranges.

Palletizing stations use double-scissor configurations for extended height ranges while maintaining platform stability during stacking operations.

Conveyor integration creates seamless material flow with roller tops or built-in conveyors.

Mobile Electric Lift Carts

Manual push models like the MML series offer capacities from 330-2,200 lbs with 20-45 inch vertical travel. They're perfect for short distances without breaking the budget.

Electric drive models such as the MMLE series add powered movement for longer hauls, reducing operator fatigue significantly.

Heavy-duty mobile units like the LPMC series handle industrial components up to 6,000 lbs.

Ultra-Low & Ground-Entry Tables

Ultra-low profile electric lift tables solve problems regular models can't touch. Models that lower to just 3.2 inches allow pallet trucks to drive directly onto the platform without ramps.

Scientific research on ergonomic height reduction shows that minimizing initial lift height significantly reduces operator strain and injury rates.

Safe Operation, Maintenance & Common Mistakes

Safety should never be an afterthought when operating an electric lift table. Over my years helping funeral homes and other facilities, I've witnessed too many preventable accidents.

The foundation of safe operation starts before you power up the unit. Always check that the floor is level and clear of debris. Load centering is absolutely critical - when loads shift off-center, they create dangerous stress on the scissor mechanism.

Personal protective equipment isn't optional. Safety glasses and steel-toed shoes should be standard. Keep hands and feet clear of pinch points, especially around scissor arms where crushing injuries can occur.

Never exceed the rated capacity. Overloading is the leading cause of equipment failures and workplace injuries. Emergency stops, safety barriers, and lock-out/tag-out procedures exist for good reasons.

For detailed safety guidelines, check out A Practical Guide to Comparing Electric Lift Options.

Maintenance Checklist & Service Intervals

Daily visual inspections catch problems early. Look for hydraulic leaks, check electrical cords for damage, test emergency stop buttons, and run complete lift cycles without load.

Weekly maintenance includes cleaning the platform, checking battery charge levels for mobile units, inspecting scissor pins for wear, and verifying load capacity labels are visible.

Every 100 hours of operation, lubricate all scissor pivot points, check hydraulic fluid levels and condition, inspect electrical connections, and test all safety systems including overload protection.

Annual maintenance should include seal replacement if needed, comprehensive electrical inspection, and structural integrity assessment by qualified technicians.

Common Mistakes to Avoid with Electric Lift Tables

Improper loading tops the mistake list. Never load the table while it's moving, and always ensure loads are stable before lifting.

Ignoring duty cycle limits leads to premature failure. If you need frequent cycling, invest in heavy-duty models rated for 100,000+ cycles.

Bypassing safety interlocks might seem like a time-saver but creates disaster risks. Never disable emergency stops or overload protection.

Inadequate operator training causes more problems than expected. Everyone operating the electric lift table should understand proper procedures and emergency protocols.

Neglecting environmental factors can rapidly deteriorate equipment. Protect electrical components from moisture, dust, and chemicals.

Latest Innovations & Buying Tips

The electric lift table industry is experiencing exciting technological advances that make these tools smarter and more efficient.

IPM (Interior Permanent Magnet) motors deliver 30% energy savings compared to traditional motors, particularly valuable for facilities running multiple units or battery-powered mobile tables.

Synchronized multi-stage systems allow multiple electric lift tables to work together seamlessly, enabling handling of extremely long beams or oversized loads impossible with single units.

Modern tables offer tilt-rotate combinations that position loads at angles up to 45 degrees while rotating them for optimal access. Built-in digital scales provide real-time load feedback, eliminating guesswork and preventing dangerous overloading.

IoT connectivity brings smart features with cycle count tracking, maintenance alerts, and remote monitoring capabilities that predict service needs before breakdowns occur.

Lithium-ion batteries are replacing lead-acid systems in mobile units, offering faster charging, longer life, and consistent power output. Programmable height presets improve efficiency by storing frequently used positions.

When budgeting, capacity has the biggest price impact, followed by lift height and customization options. The typical budget range of $1,500 to $10,000+ accommodates basic portable units to sophisticated industrial systems.

For industry developments, the upcoming PROMAT 2025 trade show will showcase cutting-edge innovations.

Future-Ready Electric Lift Table Upgrades

Auto-leveling technology automatically compensates for uneven floors, maintaining perfect platform stability regardless of position.

AGV integration capabilities allow electric lift tables to interface directly with automated guided vehicles, creating fully automated material handling systems.

Oil-free actuators eliminate hydraulic fluid entirely, using advanced linear actuators and ball screw mechanisms for cleaner operation, reduced maintenance, and more precise positioning control.

Frequently Asked Questions about Electric Lift Tables

When I talk with facility managers and funeral home directors across the country, the same questions about electric lift tables come up time and again. Let me share the answers that help them make confident decisions for their operations.

How do I size an electric lift table for my load?

Getting the sizing right is absolutely critical for both safety and performance. I always tell customers to start with their heaviest load and work from there.

First, weigh your maximum load including any containers, caskets, or fixtures you'll be using. Then add at least 25% to that weight as a safety buffer. This accounts for the dynamic forces that occur during lifting and protects against overloading.

Next, measure your largest load in all dimensions. The platform needs to support your load with room to spare for stability. If you're dealing with off-center loads - which happens frequently in mortuary applications - you might need a larger platform or special positioning fixtures.

Height requirements often trip people up. Measure from your lowest loading position all the way to your highest working position. Scissor tables have minimum lowered heights. Standard models might only go down to 12 inches, but ultra-low profile units can get as low as 3.2 inches if you need floor-level access.

Finally, think about how often you'll use the table. If you're lifting loads 10-20 times per hour, a standard model works fine. But for continuous operation or high-volume facilities, invest in a heavy-duty unit rated for 100,000+ cycles.

What routine maintenance keeps an electric lift table running safely?

Proper maintenance isn't just about avoiding breakdowns - it's about keeping your team safe. I've seen too many preventable accidents from neglected equipment.

Daily checks should become second nature. Before each shift, do a quick walk-around looking for hydraulic leaks or fluid puddles under the table. Check that electrical cords aren't damaged and test your emergency stop button - it could save someone's life.

Keep the platform clean and remove any debris. Even small items can jam the scissor mechanism or create slip hazards.

Weekly maintenance doesn't take long but makes a huge difference. If you have a mobile unit, check the battery charge levels. Look over the scissor pins and bushings for signs of wear. Make sure all safety labels are still visible and readable - OSHA inspectors always check for this.

Every 100 hours of operation, or at least once a year, schedule professional service. This includes checking hydraulic fluid levels, inspecting electrical connections, and testing all safety systems. The small investment in professional maintenance prevents expensive repairs and dangerous failures.

Keep detailed records of all maintenance. Your insurance company and warranty coverage depend on it, plus it helps you spot patterns that might indicate bigger issues developing.

Can a single electric lift table handle both lifting and transporting loads?

Absolutely, and mobile electric lift tables are game-changers for facilities that need flexibility. These units combine lifting capability with transportation in one machine.

The key is understanding the capacity differences. A mobile unit like the ET-105 can lift 800 lbs but transport up to 1,100 lbs. The lifting capacity is usually lower because the table needs to maintain stability while liftd.

You have two main options for mobility. Manual push models work great for shorter distances and keep costs down. Your operators push or pull the unit where it needs to go. Powered drive units are worth the extra investment if you're covering longer distances or moving loads frequently throughout the day.

Consider your facility layout when choosing. Smooth concrete floors work fine for manual units, but powered drive becomes essential if you're dealing with ramps, rough surfaces, or long travel distances. Your operators will thank you for reducing their physical strain.

The versatility of mobile units makes them especially valuable in mortuary operations where you might need to move and position loads in different preparation areas or transport rooms.

Conclusion

Choosing the right electric lift table transforms workplace safety and efficiency, but success depends on matching your specific needs with the right equipment specifications. After reviewing capacity ranges from 150 to 80,000 pounds, lift heights up to 354 inches, and innovations like IPM motors that cut energy use by 30%, it's clear this technology continues evolving to serve diverse industries better.

At American Mortuary Coolers, we've spent years helping funeral homes across Tennessee, Georgia, Illinois, and throughout the contiguous 48 states find the perfect lifting solutions for their unique operations. Every mortuary has different space constraints, workflow patterns, and equipment requirements.

Whether you're positioning a 150-pound casket with an ultra-low profile table or handling heavy embalming equipment with a stationary scissor platform, the fundamentals remain the same. Load capacity must exceed your heaviest items by at least 25%, platform size needs to accommodate your largest loads safely, and duty cycle ratings should match your operational frequency.

The technology keeps getting better too. Oil-free linear actuators eliminate hydraulic leaks, IoT connectivity provides maintenance alerts, and programmable height presets speed up repetitive tasks. These translate to real savings in maintenance costs and operator time.

A quality electric lift table pays for itself through reduced workplace injuries, improved efficiency, and happier employees. The 50% injury reduction represents real people going home healthy at the end of their shift.

Remember our specification checklist: know your maximum weight and dimensions, understand lift height requirements, consider mobility needs, and factor in proper training and maintenance from day one.

For detailed guidance custom to your specific situation, check out More info about comparing electric lift options. We're here to help you make the right choice for your facility's long-term success.

The right electric lift table becomes an indispensable part of your daily operations - reliable, safe, and built to last.