Understanding the Fundamentals of Freezer Room Technology

A freezer-room is a walk-in insulated chamber designed to maintain temperatures between -18°C to -40°C (-4°F to -40°F) for long-term preservation of temperature-sensitive materials. Unlike standard cold rooms that operate at refrigeration temperatures, freezer rooms create sub-zero environments essential for extended storage applications.

Key freezer-room specifications:

- Temperature range: -18°C to -40°C (-4°F to -40°F)

- Insulation: 100-200mm thick polyurethane panels

- Temperature accuracy: ±0.2°C with proper controls

- Applications: Food storage, pharmaceuticals, research samples, mortuary preservation

- Capacity: Custom sizes from 1.2m x 1.2m up to warehouse scale

- Energy efficiency: R-32+ insulation values required by EISA standards

The technology behind freezers removes heat through a closed-loop refrigeration cycle using compressors, condensers, expansion valves, and evaporators. Modern freezer rooms offer significant advantages over multiple upright units - they reduce floor space requirements, lower operating costs, and require less maintenance while providing better temperature uniformity.

Primary industries using freezer rooms include:

- Food service and distribution

- Pharmaceutical and biomedical storage

- Research laboratories

- Mortuary and funeral services

- Agricultural processing

As a national mortuary cooler supplier with experience in freezer-room design and installation, we've helped funeral homes across the country optimize their cold storage operations. Our background focuses on delivering reliable, American-made solutions that meet the unique space and budget constraints of mortuary facilities.

What Makes a Freezer Room Different From a Cold Room?

Understanding the difference between cold rooms and freezer-rooms is like knowing the difference between your kitchen fridge and your deep freeze. While they might look similar from the outside, they're built for completely different jobs.

| Feature | Cold Room | Freezer Room |

|---|---|---|

| Temperature Range | -2°C to 5°C (28°F to 41°F) | -18°C to -40°C (-4°F to -40°F) |

| Insulation Thickness | 75-100mm | 100-200mm |

| Compressor Load | Lower | Higher |

| Storage Duration | Short-term (days) | Long-term (months/years) |

| Energy Consumption | Moderate | Higher |

| Defrost Requirements | Minimal | Regular cycles needed |

Cold rooms work in the refrigeration zone - that sweet spot between -2°C and 5°C where fresh produce, dairy, and prepared foods stay crisp for days or weeks. Freezer-rooms, on the other hand, operate between -18°C and -40°C for long-term preservation. For specialized applications like vaccine storage, ultra-low temperature freezer-rooms can reach as low as -80°C.

For more detailed information about flooring options that work best in these extreme environments, check out our guide on walk-in floor options.

Key Structural Similarities & Divergences

Both cold rooms and freezer-rooms use modular panels filled with polyurethane (PU) or polyisocyanurate (PIR) insulation with cam-action locking systems and heavy-duty gaskets.

Freezer-rooms require thicker insulation - typically 150-200mm compared to just 75-100mm for cold rooms. The vapor barrier becomes critical in freezer applications, as any moisture that sneaks into the insulation can freeze, expand, and compromise system performance.

Why Upgrade From Upright Freezers to a Dedicated freezer-room?

Making the jump from multiple upright freezers to a single freezer-room offers significant advantages:

Space efficiency - One organized space instead of scattered freezers throughout your facility. Operational savings - One freezer-room uses less energy per cubic foot than multiple upright units, with fewer service calls and less downtime. Workflow improvements - Staff can see everything at once, restocking becomes faster, and inventory management gets simpler.

The temperature stability alone makes the upgrade worthwhile - freezer-rooms maintain more consistent temperatures without constantly fighting door openings from multiple units.

Designing a High-Performance Freezer-Room

Creating a reliable freezer-room requires precision engineering. The best systems achieve temperature accuracy within ±0.2°C at the sensor, with uniform temperatures throughout the entire space staying within ±0.5°C.

The foundation starts with proper insulation. Modern polyurethane panels with densities of 42kg/m³ and thicknesses between 100-200mm create an effective thermal barrier, achieving insulation K-values of 0.22 W/(m²·K) or better, easily meeting R-32 insulation values required by EISA energy efficiency standards.

Core Components Explained

Your freezer-room refrigeration system works as a team where each component has a specific job. The compressor acts as the heart, circulating refrigerant and creating pressure differences needed for cooling. Quality manufacturers like Bitzer, Maneurop, Emerson, Copeland, and Tecumseh build hermetic compressors with electronic controls.

Condenser coils reject heat to outside air through copper tubes and aluminum fins. Expansion valves control refrigerant flow, while evaporator coils inside your freezer-room absorb heat from stored products, with forced air circulation ensuring even temperatures throughout.

Achieving Precise Temperature & Humidity Control in a freezer-room

Today's freezer-room control systems offer impressive precision. Digital displays with 0.1°C resolution let you set exact temperatures, while PID controllers automatically adjust system operation to maintain stable conditions.

Data logging capabilities store temperature records with USB interfaces for compliance documentation. Audible and visual alarms alert you immediately if temperatures drift outside acceptable ranges. Defrost cycles prevent ice buildup, while sensor calibration ensures accurate readings over time.

Standard vs Optional Features You Should Consider

Every quality freezer-room includes LED lighting, internal emergency release mechanisms with glow-in-the-dark pull cords, forced air cooling, automatic defrost systems, and temperature recording capabilities.

Optional upgrades include remote monitoring apps for smartphone access, touch-screen HMI controls, glass view ports for inventory checks without opening doors, backup refrigeration systems, and SMS alert systems for immediate notification of temperature deviations.

For detailed cost considerations, check our guide on the cost of walk-in freezers. For maximum reliability, our article on walk-in cooler and freezer combos explains redundancy options.

Technical specifications are available through this scientific research on walk-in temperature stability.

Sizing, Layout & Customization: Choosing the Right Freezer Room

Getting the size right for your freezer-room is like planning a kitchen - you need enough space for today's needs while leaving room to grow. Modular panel systems offer flexibility to start with what you need and expand later.

Standard modular panels work in grid patterns, typically starting at 1200mm x 1200mm for compact applications and scaling up to 3000mm x 3000mm or larger. Most commercial installations use 2200mm height panels, though custom heights accommodate unique requirements.

Calculating Volume, Load & Growth Needs

Your freezer-room needs to handle several types of heat loads. Product heat load occurs when you bring warm products into cold space - the refrigeration system works overtime during this "pull-down" period. Infiltration losses happen every time someone opens the door.

Planning for peak delivery periods prevents headaches during busy times. Smart operators plan for future expansion by sizing systems 20-30% larger than current needs.

Workflow-Friendly freezer-room Configurations

The best freezer-room layout depends on how your team actually works. Galley aisle designs work beautifully - a central walkway with shelving along both walls maximizes storage density while keeping everything accessible.

U-shape shelving configurations excel when organizing different product categories. Roll-in rack systems minimize door-open time by allowing staff to load mobile shelving units outside, then quickly roll them inside.

Separate ante-chambers create buffer zones that protect main storage temperature. The ante-room operates at 2-8°C, allowing staff to organize before entering the main -20°C zone.

Budgeting & Total Cost of Ownership

Smart buyers look beyond initial price to understand true ownership costs. Capital expenses include equipment, installation, site preparation, electrical upgrades, and permits. Operating expenses include energy consumption and maintenance contracts.

Financial incentives can offset much of your investment. Many utilities offer substantial rebates for high-efficiency equipment. Federal tax incentives reward energy-efficient purchases, and accelerated depreciation schedules improve cash flow.

For detailed cost analysis, review our comprehensive cost breakdown guide.

Operating, Cleaning & Maintaining Your Freezer Room

Taking care of your freezer-room doesn't have to be overwhelming. With the right approach, you can keep your system running smoothly while saving money on energy costs.

Energy-Efficiency Best Practices

EC fans use 30-50% less energy than standard motors. Variable-speed compressors adjust power based on actual cooling needs. Night curtains create extra barriers against warm air, while automatic door closers prevent accidentally open doors.

Condenser heat reclaim systems capture heat your freezer removes and redirect it to warm other building areas. For daily operations, maintain 2-inch clearance around shelving and position your lowest shelf 6 inches above the floor.

Routine Maintenance Checklist for a freezer-room

Daily tasks include checking temperature readings, ensuring alarms work, inspecting door seals, and watching for ice buildup on evaporator coils. Keep temperature logs current for compliance.

Weekly maintenance involves cleaning condenser coils, checking drain pans and lines, sensor calibration using NIST-traceable standards, and testing defrost cycles.

Monthly tasks include refrigerant leak detection tests, inspecting electrical connections, cleaning interior surfaces with approved sanitizers, and reviewing energy consumption trends.

Annual professional service includes compressor oil analysis, complete control system calibration, and updating maintenance documentation.

Safety & Compliance Essentials

Internal emergency release mechanisms must be accessible from inside with glow-in-the-dark antimicrobial pull cords. Motion-activated lighting and pressure relief ports prevent dangerous situations. Non-slip flooring rated for freezer temperatures prevents accidents.

Compliance requirements include HACCP temperature logging, FDA regulations for food storage, and OSHA standards for workplace safety. Local health departments often have additional inspection requirements.

For mortuary applications, learn more about morgue temperature requirements to ensure industry standard compliance.

Future Trends & Innovations

The freezer-room industry is experiencing a revolution in technology that's making cold storage smarter, cleaner, and more reliable than ever before. These advances aren't just fancy gadgets - they're solving real problems that operators face every day, from rising energy costs to unexpected equipment failures.

Natural refrigerants are leading the charge toward environmental responsibility. R-290 (propane) and CO₂ systems deliver excellent cooling performance while drastically reducing environmental impact compared to traditional synthetic refrigerants. These natural alternatives align with global regulations that are phasing out high-GWP (Global Warming Potential) refrigerants over the next decade.

The shift toward AI-driven predictive maintenance is changing how we think about equipment care. Instead of waiting for something to break, machine learning algorithms analyze vibration patterns, temperature fluctuations, and energy consumption to predict when components need attention. This technology helps operators schedule maintenance during convenient times rather than dealing with emergency breakdowns during busy periods.

Solar integration with battery backup is becoming increasingly practical for freezer-room operations. Modern inverter systems seamlessly blend solar power with grid electricity, reducing operating costs while providing protection against power outages. Battery backup systems can maintain critical temperatures for hours during electrical failures, protecting valuable inventory.

The demand for modular ultra-low chambers capable of reaching -80°C is growing beyond research facilities. Funeral homes, medical facilities, and specialty storage providers are finding applications for pharmaceutical-grade preservation within standard freezer-room footprints. These specialized compartments offer extreme temperature capabilities without requiring entirely separate systems.

Sustainability regulations continue evolving at both federal and state levels, pushing equipment manufacturers to develop solutions that exceed current energy efficiency standards. These regulations aren't just about compliance - they're driving innovation that reduces operating costs while protecting the environment.

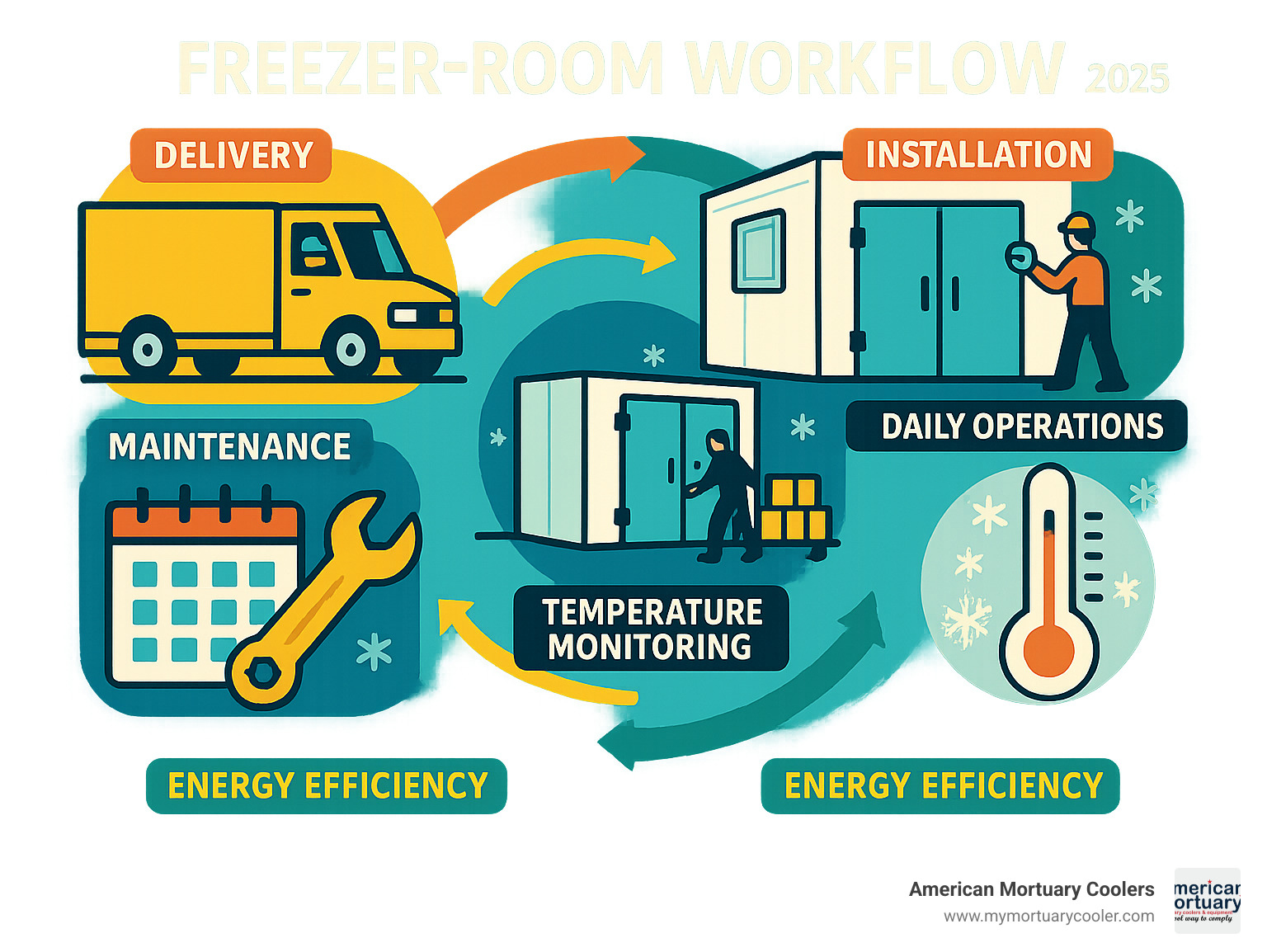

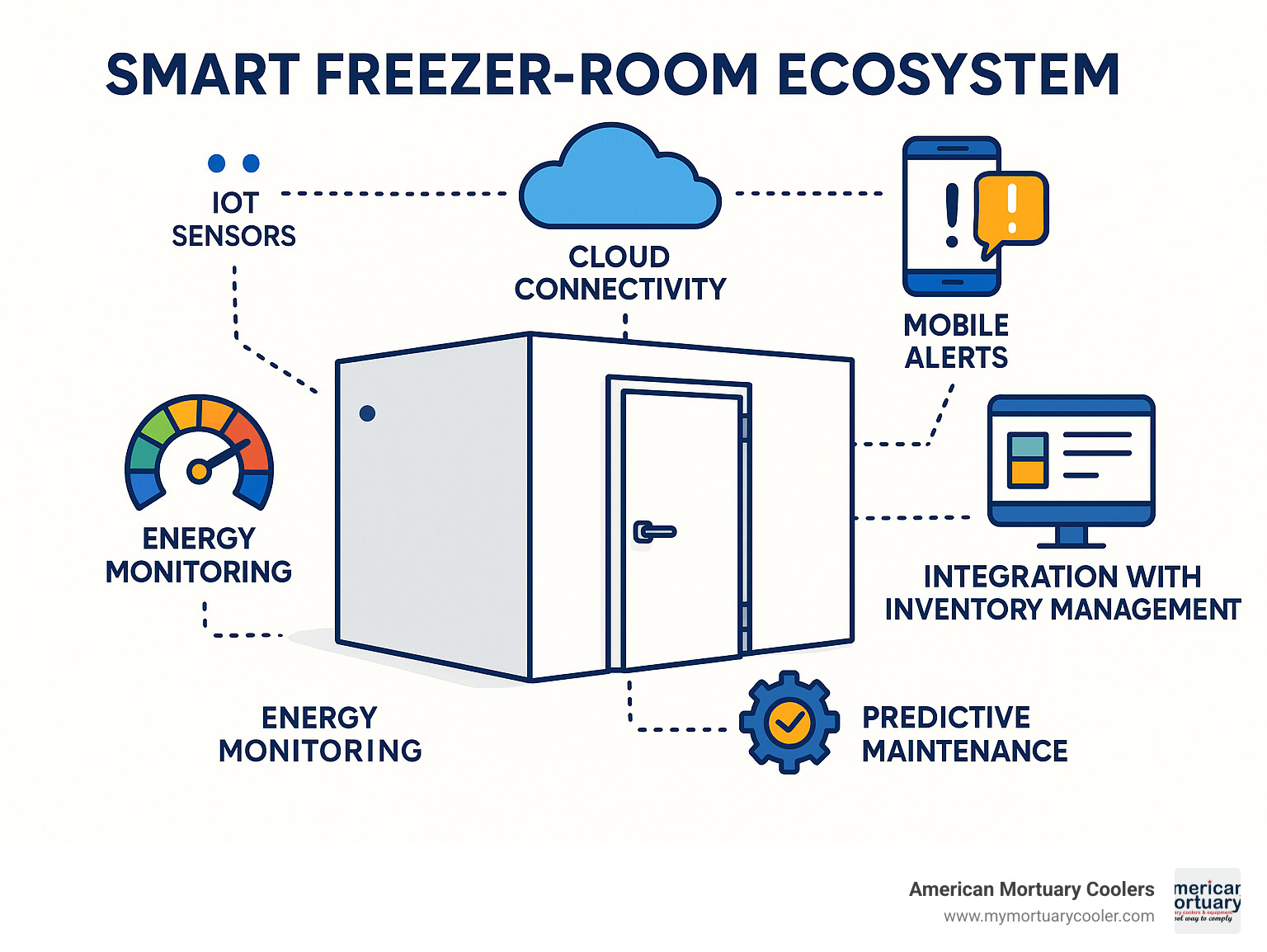

The connected freezer-room ecosystem shown above represents where the industry is heading. IoT sensors, cloud connectivity, and mobile alerts create a comprehensive monitoring network that gives operators complete visibility into their systems from anywhere. This level of connectivity transforms cold storage from a passive storage solution into an active, intelligent system that optimizes itself for maximum efficiency and reliability.

Frequently Asked Questions about Freezer Rooms

What temperature range should a commercial freezer-room maintain?

Most commercial freezer-rooms work best between -10°C and -20°C (that's -14°F to -4°F) for everyday food storage. If you need longer-term preservation, industrial units can go much colder - anywhere from -20°C down to -40°C (-4°F to -40°F). For really specialized stuff like vaccines or research samples, ultra-low temperature units can hit -80°C (-112°F).

Here's the thing - what you're storing makes all the difference. Meat and seafood need to stay around -18°C to -23°C to maintain quality, while ice cream requires much colder temperatures between -26°C to -29°C to keep that perfect texture we all love.

The key is matching your freezer-room temperature to your specific products. Too warm and you risk spoilage; too cold and you're wasting energy and money.

How do I keep temperature uniformity throughout the room?

Getting even temperatures throughout your freezer-room isn't rocket science, but it does require some planning. The secret sauce is proper airflow design combined with smart product placement.

Forced-air evaporators with adequate fan capacity are essential - they keep air moving throughout the entire chamber. Think of it like a gentle breeze that reaches every corner of your storage space.

Give your products some breathing room. Maintain at least 2 inches of clearance between stored items and the walls so air can circulate freely. Position your lowest shelf 6 inches above the floor - this prevents blocking airflow and makes cleaning much easier too.

Whatever you do, don't block the area around your evaporator unit. It's like putting a hand over someone's mouth - the system can't do its job properly. When everything's set up correctly, modern systems achieve temperature uniformity of ±0.5°C or better throughout the entire space.

What redundancy options protect critical inventory during power loss?

Nobody wants to lose valuable inventory because of a power outage or equipment failure. That's why smart operators build in multiple layers of protection for their freezer-room systems.

Dual refrigeration systems with automatic switchover give you peace of mind - if one system goes down, the backup kicks in immediately. Emergency generators sized to handle your full refrigeration load keep everything running during extended power outages.

For shorter outages, battery backup systems maintain your controls and alarms, so you always know what's happening. In ultra-critical applications, liquid nitrogen (LN₂) backup provides an additional safety net when nothing else will do.

Don't forget about monitoring and alerts. Remote monitoring with SMS and email alerts means you'll know about problems immediately, even when you're not on-site. Local audible and visual alarms alert anyone nearby, while temperature data logging provides documentation for insurance claims if needed.

For truly critical applications, we always recommend redundant refrigeration systems with independent power supplies plus comprehensive monitoring. It might seem like overkill, but it's much cheaper than replacing thousands of dollars worth of spoiled inventory.

The bottom line? Build redundancy into your system from day one. Your future self will thank you when that inevitable power outage or equipment hiccup occurs.

Conclusion

Investing in a well-designed freezer-room transforms how you handle cold storage, whether you're preserving critical research samples, maintaining pharmaceutical integrity, or serving families in their time of need. The right system doesn't just keep things cold – it becomes a reliable partner that works quietly in the background while you focus on what matters most.

At American Mortuary Coolers, we understand that every funeral home faces unique challenges. That's why we've spent years perfecting freezer-room solutions specifically for the funeral industry. From our Tennessee manufacturing facility, we create durable, American-made systems that handle the demanding requirements of mortuary applications with grace and reliability.

What sets us apart is our comprehensive approach. We start with custom design engineering custom to your exact space and operational needs. Our systems feature high-quality components from industry leaders like Bitzer, Copeland, and Tecumseh – names you can trust when reliability matters most. Professional installation and commissioning ensure everything works perfectly from day one, while our ongoing maintenance support keeps your system running smoothly for years to come.

Direct delivery across all 48 contiguous states means we can serve you no matter where you're located. Our regional presence spanning Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA ensures you're never far from expert support when you need it.

The financial benefits of upgrading to a properly designed freezer-room extend far beyond the initial investment. Reduced energy costs, improved workflow efficiency, and reliable long-term performance create ongoing value that compounds over time. Many of our customers find that replacing multiple upright freezers with a single walk-in system pays for itself through energy savings and reduced maintenance headaches.

Whether you're expanding existing facilities or replacing aging equipment, the decision to invest in professional-grade cold storage reflects your commitment to excellence. Your families deserve the peace of mind that comes from knowing their loved ones are cared for with the highest standards – and that starts with reliable, precisely controlled storage conditions.

For detailed guidance on selecting the perfect configuration for your specific needs, explore our complete guide to choosing the right freezer room.

Ready to discuss how a custom freezer-room can improve your operations? Contact us today to explore solutions designed specifically for your space, budget, and workflow requirements. We're here to help you make the right choice for your funeral home's future.