Why Cooler Insulation Matters More Than You Think

Are coolers insulated? Yes, all coolers use some form of insulation to slow heat transfer and keep contents cold. However, the type and quality of insulation varies dramatically between models.

Quick Answer:

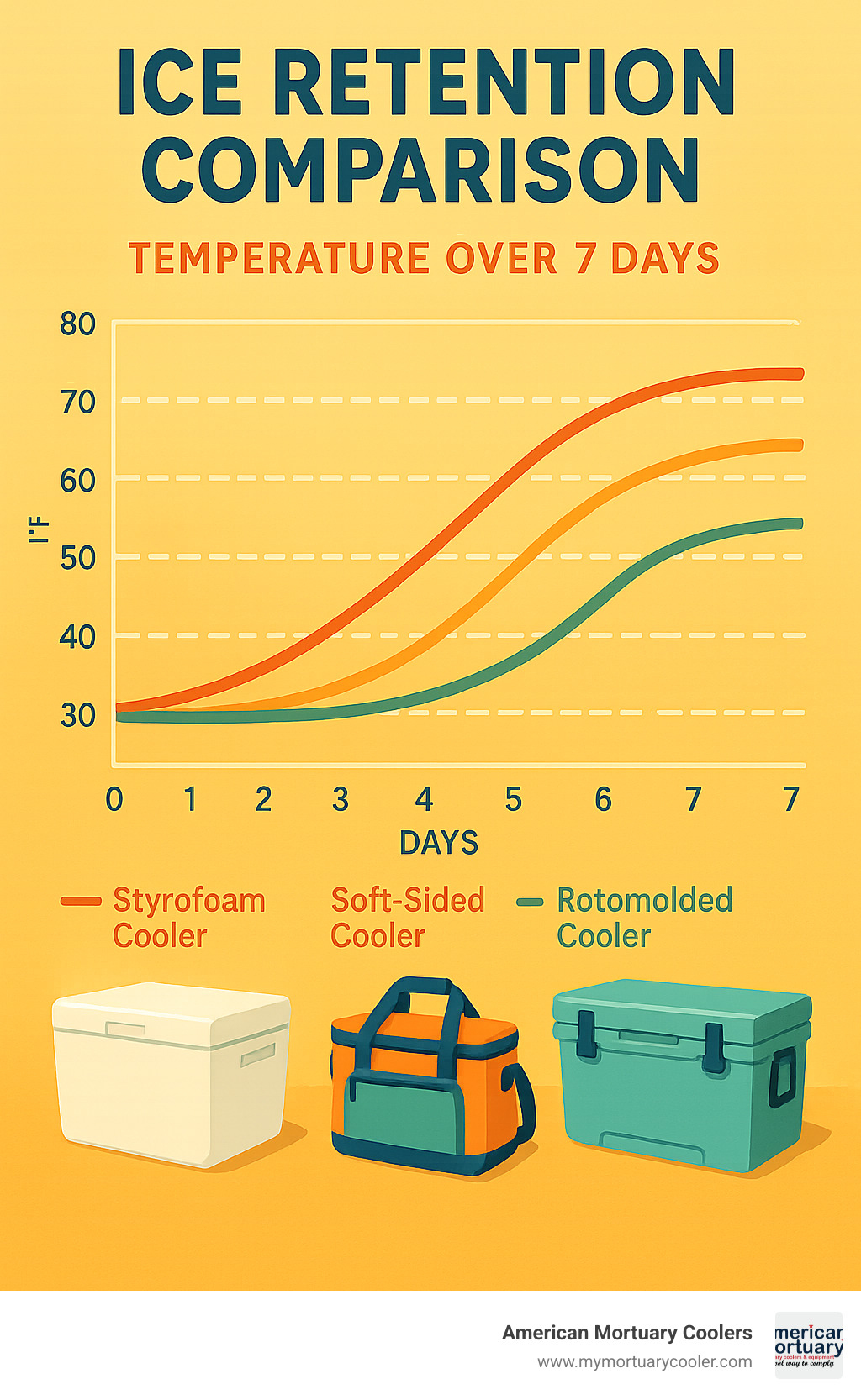

- Budget coolers: Use basic styrofoam insulation (24-48 hours cold retention)

- Premium coolers: Feature polyurethane foam or vacuum panels (5-10 days cold retention)

- Soft coolers: Rely on closed-cell foam layers (1-3 days cold retention)

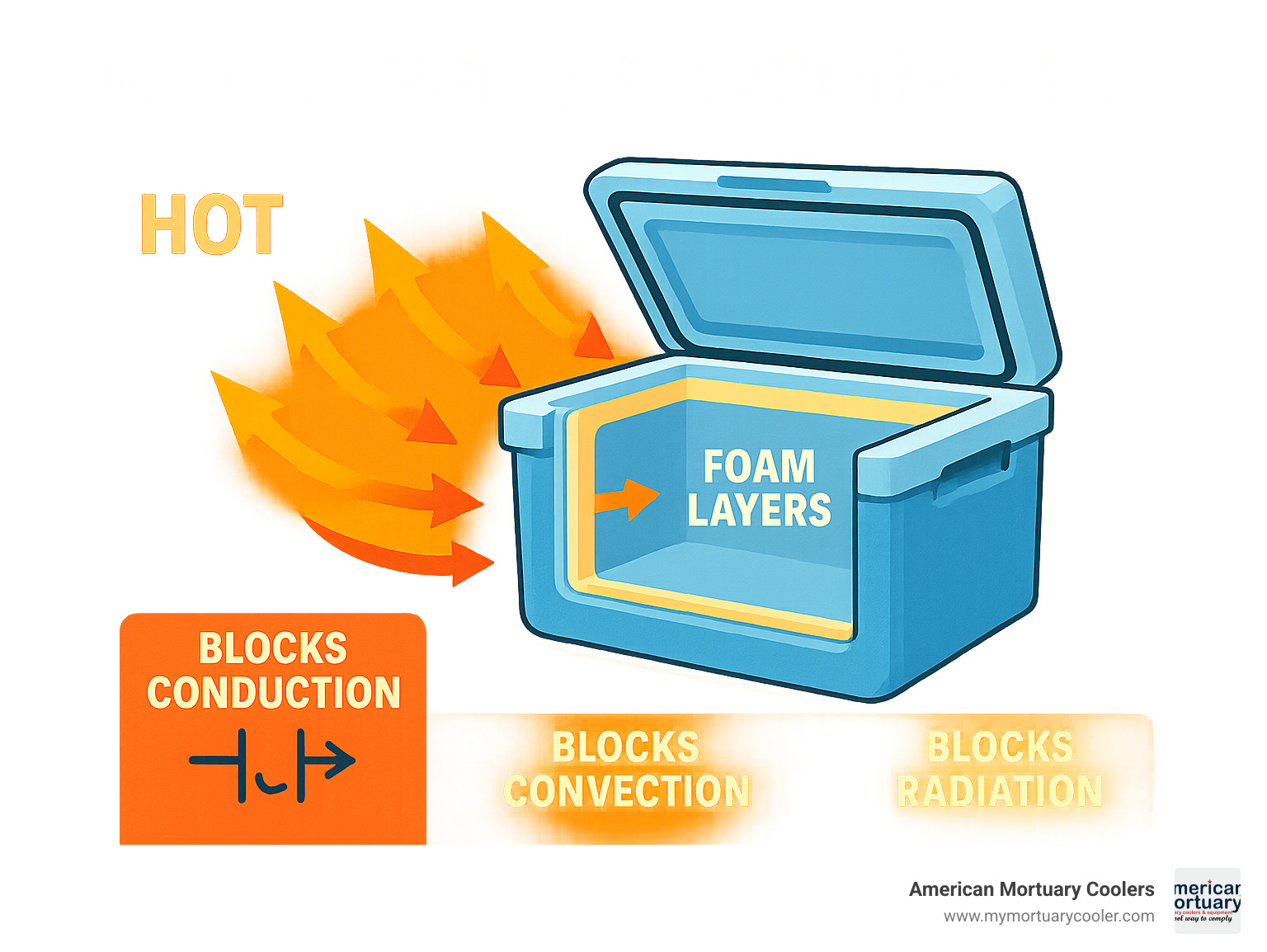

- All coolers: Work by blocking heat transfer through conduction, convection, and radiation

Whether you're planning a weekend camping trip or need reliable temperature control for professional applications, understanding cooler insulation can mean the difference between success and spoiled contents. As one outdoor expert noted: "Can you imagine going to a tailgate, reaching into your portable cooler, and finding that it's not chilly inside at all? Talk about a party killer!"

The science behind keeping things cold is surprisingly complex. Premium hard-sided coolers with polyurethane foam insulation can maintain temperatures below 40°F for up to 6.8 days, while cheaper models with basic styrofoam typically last only 4 days under the same conditions.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in temperature-controlled storage solutions. Through years of working with funeral homes and understanding how critical proper insulation is for mortuary applications, I've gained deep expertise in evaluating whether are coolers insulated effectively for different professional and personal needs. This background gives me unique insight into what makes insulation truly reliable when it matters most.

Know your are coolers insulated terms:

Why You Should Care About Cooler Insulation

Understanding cooler insulation isn't just about keeping your drinks cold—it's about outdoor safety, preventing foodborne illness, and successful trip planning. The FDA recommends keeping perishable foods below 40°F (4°C) to prevent harmful bacterial growth. When your cooler's insulation fails, you're not just dealing with warm beverages; you're potentially facing serious health risks.

Poor insulation performance can turn a perfect camping trip into a disaster. We've seen countless stories of families having to cut trips short because their food spoiled, or worse, dealing with food poisoning from consuming items that weren't kept at safe temperatures. Quality insulation is your first line of defense against these problems.

Are Coolers Insulated? The Science of Keeping Cold

Here's something that might surprise you: coolers don't actually "keep cold in"—they keep heat out. It's like trying to keep light out of a dark room rather than keeping darkness in. This simple shift in thinking helps explain why are coolers insulated so carefully.

Heat wants to move from warm areas to cold areas, and it has three sneaky ways of doing this. Conduction happens when heat travels through solid materials—like when you touch a hot pan and feel the burn. Your cooler's walls need thick insulation to block this direct heat transfer.

Convection is heat moving through air currents. Every time you crack open that cooler lid, warm air rushes in like an unwelcome party crasher. That's why good seals matter so much.

Radiation is heat traveling through space itself—the same way the sun warms your face. Quality coolers often have reflective inner linings that bounce this radiant heat right back where it came from.

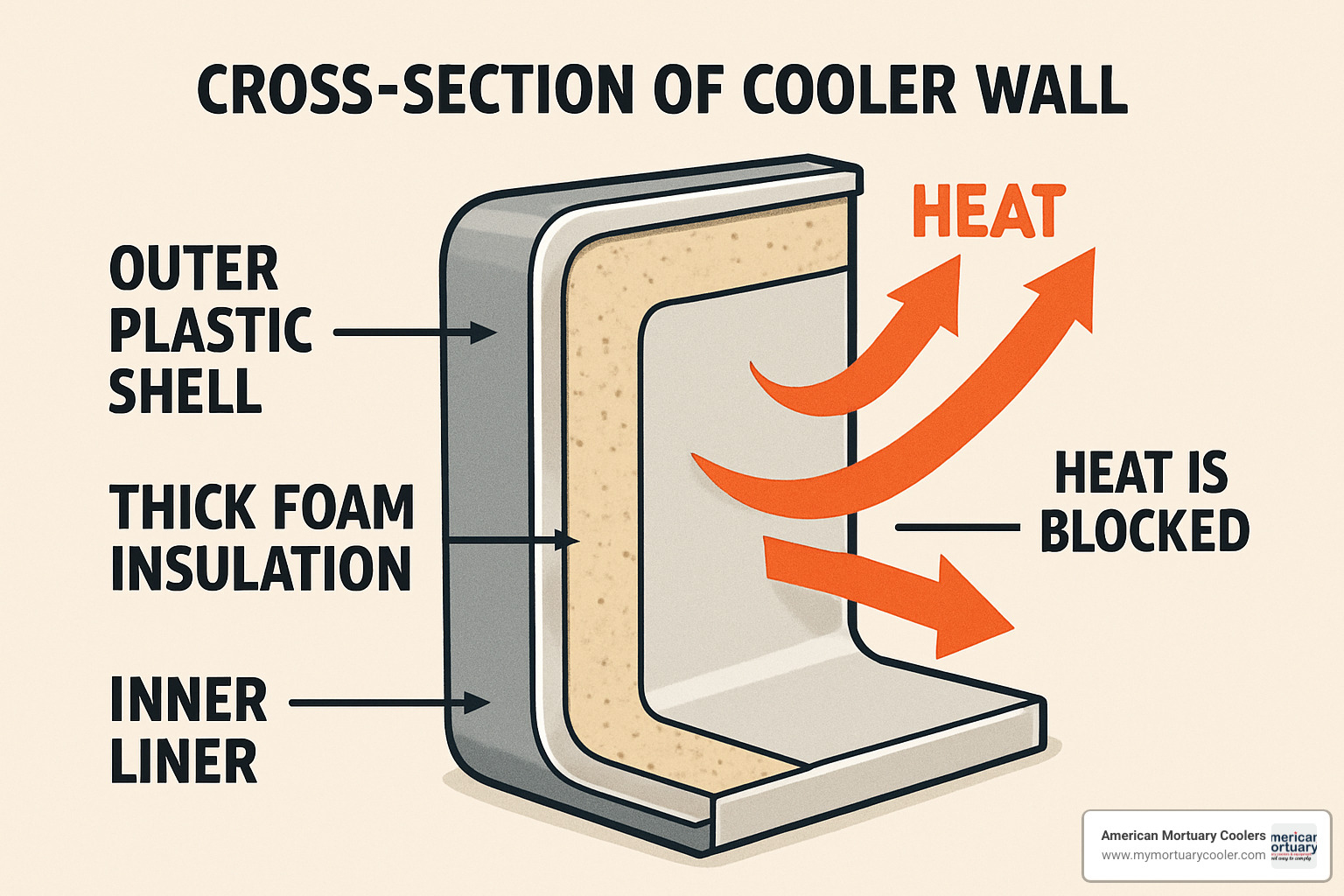

The thickness of insulation makes a huge difference in performance. Premium coolers pack in dense foam that creates multiple barriers to heat transfer. This is measured by something called R-value—basically, how stubborn the material is about letting heat pass through. Higher R-values mean your ice lasts longer.

How do coolers work & why are coolers insulated?

The real magic happens with something called latent heat of melting. When ice melts, it stays at exactly 32°F until every last crystal turns to water. This phase change absorbs massive amounts of heat energy while keeping your food at a steady, safe temperature.

That FDA rule about keeping food below 40°F isn't just a suggestion—it's your shield against foodborne illness. Dangerous bacteria love temperatures between 40°F and 140°F, doubling their numbers every 20 minutes in this danger zone. Quality insulation keeps you safely out of this range.

In our work with mortuary coolers, we've learned that temperature consistency isn't negotiable. The same principles that keep our professional units performing reliably apply to your camping cooler. It's all about creating an effective barrier against heat infiltration through smart insulation design.

Common weak points: lids, seals, and why are coolers insulated there too?

Even the best-insulated cooler walls become useless if heat pours in through a poorly designed lid. Think of it like having a great winter coat with a broken zipper—all that insulation goes to waste.

Lid insulation is where many budget coolers fail miserably. They use hollow lids with just an air gap instead of proper foam insulation. This creates a thermal highway right above your ice and food.

Gaskets and seals separate the good coolers from the great ones. High-quality silicone rubber gaskets compress tightly when you close the lid, creating an airtight barrier. This single feature often determines whether your ice lasts four days or seven days.

Bear-proof latches aren't just about keeping wildlife out—they're proof that the cooler maintains its seal under extreme pressure. When a cooler earns IGBC (Interagency Grizzly Bear Committee) certification, you know those hinges and latches will keep working even when stressed.

Don't forget about drain plugs—these little guys can be sneaky heat leaks if they don't have proper gaskets and thermal breaks. The best coolers treat every potential opening as a place where insulation matters.

Insulation Materials, Eco-Friendly Technologies & Standards

| Material | Thermal Conductivity (W/m·K) | Typical Retention | Cost | Environmental Impact |

|---|---|---|---|---|

| Styrofoam (EPS) | 0.025-0.040 | 24-48 hours | Low | Moderate |

| Polyurethane Foam | 0.022-0.035 | 5-7 days | Medium | Low (with eco-friendly blowing agents) |

| Vacuum Panels | 0.004-0.020 | 7-10 days | High | Low |

When people ask are coolers insulated effectively, the answer depends entirely on what's inside those walls. The cooler industry has come a long way from the simple styrofoam boxes of decades past, and the materials science behind modern insulation is genuinely fascinating.

Traditional extruded polystyrene (the technical name for styrofoam) dominated the market for years because it was cheap and did an okay job. But "okay" doesn't cut it when you're planning a week-long camping trip or need reliable temperature control for professional applications. Modern polyurethane foam creates millions of tiny, sealed air bubbles that are much better at blocking heat transfer than styrofoam's larger, less uniform structure.

The environmental story gets interesting here. Companies like Ecomate have developed eco-friendly blowing agents that not only perform better thermally but also eliminate the harmful chemicals traditionally used in foam production. These SNAP-approved alternatives deliver measurably better insulation while being completely environmentally sustainable—a true win-win.

Vacuum panels represent the cutting edge of cooler technology, achieving thermal conductivity ratings up to 10 times better than traditional foam. Aerogel, originally developed by NASA, offers similar performance at a fraction of the thickness. These materials command premium prices, but they deliver performance that would have seemed impossible just a few years ago.

IGBC bear-proof certification has become more than just a wildlife safety feature—it's proof that a cooler can maintain its insulation integrity under extreme stress. When a 200-pound tester jumps on a cooler and it still keeps ice for a week, you know the insulation system is built to last.

Polyurethane Foam & Rotomolding

The magic of polyurethane foam lies in its closed-cell structure. Imagine millions of tiny air bubbles, each completely sealed off from its neighbors. This creates an incredibly effective barrier to heat transfer that's far superior to the open-cell structure of cheaper materials.

Rotomolding construction takes this a step further by allowing manufacturers to create seamless cooler bodies with 2-inch thick walls throughout. Instead of assembling separate pieces (which creates thermal weak spots), rotomolded coolers are formed as single units. The foam is then pressure-injected to ensure uniform distribution and maximum density.

In our experience manufacturing mortuary coolers, we've seen how pressure-injected polyurethane provides both insulation and structural strength. The foam actually reinforces the cooler walls, making them nearly indestructible while maintaining superior thermal performance. It's the same principle whether you're keeping ice cream cold for a picnic or maintaining critical temperatures in professional applications.

Vacuum & Aerogel Panels: Cutting-Edge Options

Yeti's V-Series coolers showcase what's possible with vacuum insulation technology. These vacuum-insulated panels achieve thermal conductivity as low as 0.004 W/m·K—performance that was unimaginable in traditional cooler design. The downside? These premium coolers can cost over $1,100, but they deliver ice retention up to 10 days under controlled conditions.

NASA-grade aerogel represents another frontier in cooler insulation. Comprising over 90% air by volume, aerogel offers ultra-low conductivity comparable to vacuum panels but at one-third the thickness. This could revolutionize portable cooler design by delivering premium performance in lighter, more compact packages.

These cutting-edge materials aren't just marketing gimmicks—they represent genuine advances in materials science that deliver measurable performance improvements. Whether the premium price is worth it depends on your specific needs and how much you value extended ice retention.

Certifications & R-Values Demystified

Understanding R-values helps cut through marketing hype and compare cooler performance objectively. While manufacturers love to throw around terms like "5-day ice retention," R-values provide standardized thermal performance metrics that are independent of testing conditions.

IGBC certification involves rigorous testing that goes far beyond bear resistance. Coolers must maintain seal integrity while withstanding extreme abuse—proof that the entire insulation system remains intact under real-world stress. This certification has become the gold standard for serious outdoor enthusiasts.

Energy codes from regulations like EISA (Energy Independence and Security Act) require minimum R-25 insulation for commercial coolers, with R-32 for freezer applications. These standards ensure consistent performance across different manufacturers and help establish baseline expectations for thermal performance.

For a deeper dive into how different insulation materials compare, check out The Ultimate Guide to Comparing R-Value Insulation Charts. Understanding these metrics can help you make informed decisions about which cooler will truly meet your needs.

Hard vs Soft Coolers: Performance & Optimization

When people ask are coolers insulated, the answer depends greatly on whether you're looking at hard or soft coolers. The difference is like comparing a winter coat to a light jacket—both provide insulation, but they're designed for completely different situations.

Hard-sided coolers can pack in 2-3 inches of dense foam insulation because they don't need to fold or bend. Soft coolers, on the other hand, must stay flexible and portable, limiting them to thinner insulation layers. This fundamental difference shapes everything about their performance.

The numbers tell the story clearly: premium hard-sided coolers keep food safely cold (below 40°F) for 6-8 days, while even the best soft coolers typically max out at 72 hours. But here's the thing—sometimes you don't need a week of ice retention. Sometimes you just need something that won't break your back on a day hike.

Hard-Sided Champions for Week-Long Ice

Rotomolded hard coolers are the heavy-duty champions of the cooling world. Think of them as the pickup trucks of coolers—built tough and designed to work hard. Models like the Yeti Tundra 65 and RTIC 45 didn't earn their reputations by accident.

These coolers achieve their legendary 6-7 day retention through serious engineering. The thick wall construction means up to 2 inches of pressure-injected polyurethane foam surrounding your contents. That's more insulation than some house walls! The seamless rotomolded design eliminates weak spots where heat could sneak in.

What really sets these apart are the premium silicone seals that maintain their grip through thousands of opening cycles. Combined with bear-proof latches that ensure consistent pressure, these coolers create an almost airtight thermal envelope.

In real-world testing, the Yeti Roadie 48 kept beverages below 50°F for 7.5 days and maintained food-safe temperatures for 6.8 days. The RTIC 45 delivered nearly identical performance at a friendlier price point, proving you don't always need to pay premium prices for premium insulation.

Soft-Sided Convenience for Quick Trips

Soft coolers are the sports cars of the cooling world—lightweight, nimble, and perfect for when you need to get in and out quickly. They maximize portability through clever design rather than brute-force insulation thickness.

Quality soft coolers use closed-cell foam inserts that are typically 0.5-1 inch thick. While that might sound thin compared to hard coolers, it's surprisingly effective for shorter trips. The reflective linings made from Mylar or aluminum bounce radiant heat away from your contents, while durable nylon shells resist UV damage and wear.

The flexible zipper seals with thermal strips do a remarkable job minimizing air exchange, considering they're not dealing with rigid gaskets. High-quality soft coolers can maintain cold temperatures for 24-72 hours—perfect for day trips, lunch transport, or any situation where you're more worried about your back than maximum ice retention.

Maximizing Any Cooler's Insulation

Regardless of whether are coolers insulated with thick foam or thin flexible layers, smart packing techniques can dramatically extend performance. It's like knowing how to drive efficiently—the same car can get vastly different mileage depending on technique.

Pre-chilling is your secret weapon. Cool both the empty cooler and its contents before packing. This simple step can add 6-12 hours to ice retention by eliminating the thermal load of warming up room-temperature items.

The 2:1 ice ratio rule means using twice as much ice as contents by volume. More ice creates more thermal mass to absorb heat infiltration. Strategic packing puts your most temperature-sensitive items at the bottom in direct contact with ice, while less critical items go on top.

Shade placement makes a huge difference. Moving from 80°F to 90°F ambient temperature increases thermal load by 18-20%. That shady spot under the pavilion isn't just more comfortable for you—it's essential for your cooler's performance.

Minimizing openings is crucial because every time you open the cooler, cold air escapes and warm air rushes in. Plan your access to grab everything you need in one go rather than making multiple trips.

For those wanting to go the extra mile, How to Insulate a Cooler DIY modifications can boost the performance of existing coolers through additional insulation layers and seal improvements.

Eco-Friendly Advances, Maintenance Tips & Industry Trends

The cooler industry is going green, and it's about time! Modern manufacturers are proving that eco-friendly doesn't mean eco-weak when it comes to insulation performance. Hemp-filled polypropylene insulation is leading the charge as a renewable alternative to petroleum-based foams, delivering the same thermal protection while being kinder to our planet.

EISA compliance has become a game-changer, pushing manufacturers to create more efficient designs that reduce environmental impact throughout the entire product lifecycle. It's not just about what happens in the factory—it's about how these coolers perform and what happens when they eventually reach end-of-life.

UV-resistant shell materials are extending cooler lifespans dramatically. Remember those old coolers that turned brittle and cracked after a few summers? Modern polyethylene formulations laugh at sun damage, keeping coolers functional for five years or longer with basic care. That means fewer coolers heading to landfills and more money staying in your pocket.

Greener Materials & Recool-Type Designs

The future of cooler insulation is growing in fields, not factories. Plant-based polyurethane foams derived from soy and other renewable sources are matching the thermal performance of traditional petroleum-based options. These biodegradable polystyrene alternatives prove that being environmentally conscious doesn't require sacrificing that week-long ice retention you've come to expect.

Recycling programs are finally catching up with consumer demand. Companies like Igloo with their Recool initiatives are introducing take-back programs for end-of-life coolers. The challenge? Separating foam insulation, plastic shells, and metal hardware into proper recycling streams. It's complex, but progress is happening.

Looking ahead, we're seeing development of fully biodegradable coolers for single-use applications. These address the growing concern about plastic waste littering our favorite camping spots and beaches. Nobody wants to find cooler debris when they're trying to enjoy nature.

Simple Maintenance to Preserve Insulation

Here's the truth about cooler maintenance: a little care goes a long way in preserving insulation performance and extending your cooler's life. We've seen too many perfectly good coolers fail prematurely because of neglect.

Regular cleaning with soap and warm water after each use prevents odor buildup and material degradation. For stubborn smells that make you wrinkle your nose, try a baking soda paste or vinegar solution for deep cleaning. Your nose (and your family) will thank you.

Complete drying before storage is absolutely critical. Moisture trapped in insulation creates the perfect environment for mold and mildew, which can literally eat away at your cooler's thermal performance. Always air-dry thoroughly—patience here pays dividends later.

Gasket inspection should become second nature. Check those rubber seals regularly for cracks, tears, or compression loss. A damaged gasket can turn your premium cooler into an expensive ice bucket. Replace them promptly to maintain that thermal barrier.

Don't forget about hinge lubrication and drain maintenance. Smooth-operating hinges ensure proper lid closure and seal compression, while clean drain plugs with intact gaskets prevent sneaky thermal leaks that gradually reduce performance.

Frequently Asked Questions about Insulated Coolers

How long can a well-insulated cooler keep items cold?

The answer to "are coolers insulated" becomes crystal clear when you look at performance numbers. A truly well-insulated cooler can be a game-changer for your outdoor trips.

Premium hard-sided coolers with thick polyurethane foam insulation are the marathon runners of the cooler world. Under 90°F ambient conditions, these champions can maintain food-safe temperatures below 40°F for 6-8 days straight. That's more than a full week of reliable cold storage!

The Yeti Roadie 48 proved this in controlled testing, keeping beverages refreshingly cold (below 50°F) for 7.5 days and maintaining critical food safety temperatures for 6.8 days. Meanwhile, budget models like the Coleman Portable Rolling 50 managed 4.1 days under identical conditions—still respectable, but not quite championship level.

High-quality soft coolers occupy the middle ground, typically delivering 2-3 days of solid cold retention. They're perfect for weekend camping trips or beach days where portability matters more than marathon ice retention.

Budget coolers with basic styrofoam insulation usually tap out after 1-2 days in hot weather. They'll keep your lunch cold for a day trip, but don't count on them for extended trips.

Are eco-friendly insulation materials available for coolers?

Absolutely! The cooler industry has acceptd green technology without sacrificing the performance that makes coolers insulated effectively.

Ecomate® polyurethane foams lead the sustainability charge. These innovative materials use environmentally friendly blowing agents that are 100% sustainable and SNAP-approved by the EPA. They completely avoid harmful CFCs, HCFCs, and HFCs while actually delivering superior thermal performance compared to traditional formulations.

Hemp-filled polypropylene insulation offers another exciting renewable alternative. Instead of relying entirely on petroleum-based materials, manufacturers are incorporating plant-based fibers that provide excellent thermal resistance while reducing environmental impact.

Some forward-thinking companies are experimenting with recycled content in foam formulations, though maintaining consistent performance across batches remains a technical challenge they're actively solving.

The future looks even brighter. Aerogel insulation derived from renewable sources could combine NASA-grade thermal performance with complete environmental responsibility. Imagine having the best insulation technology available while knowing your cooler's footprint is minimal.

Do premium coolers justify their price based on insulation?

This is the million-dollar question—or should I say, the several-hundred-dollar question! The honest answer depends on how you'll actually use your cooler.

Premium coolers cost 3-5 times more than budget models, but they deliver 2-3 times longer ice retention. For frequent outdoor enthusiasts or anyone who needs reliable temperature control, the math often works out favorably.

Think about total cost of ownership rather than just upfront price. A premium cooler that lasts 10+ years with consistent performance might actually cost less per camping trip than replacing cheaper coolers every 2-3 years. Plus, there's real value in the peace of mind knowing your food will stay safe during extended trips.

The durability factor can't be ignored either. Premium coolers often come with impressive warranties—some manufacturers offer 5-year guarantees because they're confident in their insulation systems and construction quality.

For professional applications like our mortuary coolers at American Mortuary Coolers, premium insulation isn't just recommended—it's absolutely essential. When temperature control is literally a matter of professional responsibility, there's no substitute for proven, reliable insulation performance.

If you're a weekend warrior who camps once or twice a year, a mid-range cooler might hit the sweet spot. But if you're planning week-long backcountry trips or need dependable performance for professional use, premium insulation pays for itself through reliability and peace of mind.

Conclusion

So, are coolers insulated? Absolutely—and now you know exactly how that insulation works and why it matters. From the basic styrofoam in your first camping cooler to the NASA-grade aerogel in tomorrow's premium models, insulation technology keeps evolving to meet our changing needs while becoming more environmentally friendly.

Think of it this way: choosing the right cooler insulation is like picking the right jacket for a hike. You wouldn't wear a light windbreaker on a winter mountain expedition, and you shouldn't rely on basic foam insulation for a week-long camping trip. Match your insulation to your trip—soft coolers work beautifully for day trips and lunch runs, while those extended wilderness expeditions demand the serious thermal protection of premium hard-sided models.

Here's what really matters when you're shopping: quality seals beat fancy insulation every time. I've seen too many expensive coolers fail because manufacturers skimped on gaskets and hinges. Even the thickest polyurethane foam walls can't help if heat pours through a poorly sealed lid.

The environmental angle is getting exciting too. Companies using eco-friendly options like Ecomate® foams prove you don't have to choose between performance and planet-friendly materials. These sustainable alternatives often outperform traditional foams while reducing environmental impact—a true win-win.

Don't forget the simple stuff that makes a huge difference. Regular cleaning and seal inspection can add years to your cooler's life and keep it performing like new. A little maintenance goes a long way when you're depending on that insulation to keep your food safe.

At American Mortuary Coolers, we've learned that reliable insulation isn't just about keeping things cold—it's about trust when it matters most. Our experience crafting custom temperature-controlled solutions across Tennessee, Atlanta, Chicago, and nationwide has taught us that quality insulation is never an accident. It's the result of careful material selection, robust construction, and obsessive attention to those little thermal weak points that can ruin everything.

Whether you're planning a family camping trip or need professional-grade temperature control, the fundamentals stay the same. Superior insulation materials, solid construction, and proper sealing create systems you can count on when there's no room for failure.

For those specialized situations requiring custom solutions, our Custom Walk-In Cooler Solutions That Fit Like a Glove expertise translates directly to understanding what makes any cooling system truly dependable. And it all starts with getting the insulation right.