Understanding Lift Bodies: A Cross-Industry Guide

Lift bodies refer to several distinct types of systems across different industries:

| Type of Lift Body | Description | Primary Use |

|---|---|---|

| Vehicle Body Lift | Spacers installed between chassis and body | Increase tire clearance without changing suspension |

| Lifting Body Aircraft | Aircraft where the fuselage generates lift | Aerospace re-entry vehicles and research aircraft |

| Interchangeable Truck Bodies | Swappable truck bodies on a single chassis | Commercial fleet versatility (dump, flatbed, enclosed) |

| Mortuary Body Lifts | Specialized lifting equipment | Safe transport of deceased in funeral homes |

| Medical Body Lift | Surgical procedure | Removing excess skin after weight loss |

When most people search for "lift bodies," they're typically looking for one of these applications, with vehicle modifications and commercial truck systems being the most common searches.

For over 50 years, specialized lift body systems have been helping professionals work more efficiently and safely across industries. From NASA's pioneering M2-F1 lifting body aircraft in the 1960s to modern Switch-N-Go interchangeable truck bodies that can be swapped in just three minutes, these systems continue to evolve with improved materials and innovative designs.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including specialized lift bodies designed for funeral homes and mortuaries. My expertise in both standard and customized lift body solutions has helped funeral directors nationwide improve operational efficiency while maintaining dignity in their services.

Lift bodies terms simplified:

Why This Guide Matters

Understanding lift bodies can be challenging because the term spans multiple industries with different applications. Whether you're a funeral director looking for efficient body handling solutions, a fleet manager considering interchangeable truck bodies, or an off-road enthusiast researching vehicle modifications, this comprehensive guide will help you steer this complex topic.

In the mortuary industry, companies like Ferno, Mopec, and Mortech offer competing lift body solutions, but at American Mortuary Coolers, we've seen how the right lift body solution can transform operations across our service regions from New York to Los Angeles, and everywhere in between. Our customers in the funeral industry particularly benefit from specialized knowledge about mortuary lift systems that prioritize both efficiency and dignity.

Lift Bodies 101: What They Are and Why They Matter

Ever wondered what exactly a lift body is? You're not alone! This term appears across several industries, and at its heart, it's about systems designed to lift, transport, or use a body structure for functional purposes.

Think of a lift body as a solution to a physical challenge. Whether it's lifting a truck to fit bigger tires or designing an aircraft where the body itself provides lift, these systems solve real-world problems with innovative engineering.

In aerospace, lifting-body aircraft are vehicles where the fuselage generates lift instead of relying on wings. NASA pioneered this concept in the 1960s, though the idea dates back to a 1917 patent. Today, these designs influence modern spacecraft like the Dream Chaser spaceplane.

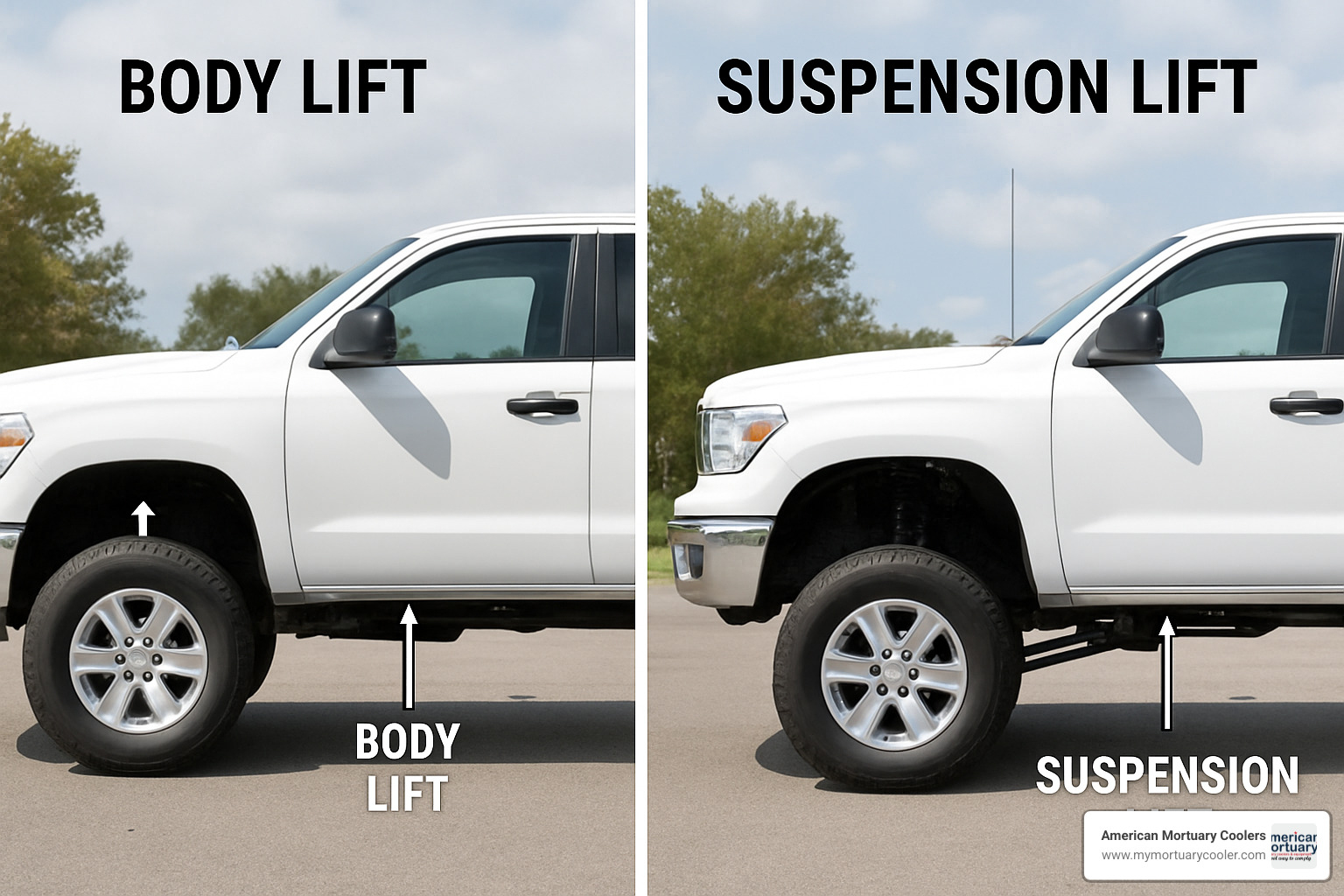

For off-road enthusiasts, vehicle body lifts are modifications that raise a vehicle's body from its frame using spacers. Unlike suspension lifts, these don't increase ground clearance but do make room for larger tires without affecting suspension geometry. These became popular in the 1970s as off-roading gained mainstream appeal.

In the commercial truck world, interchangeable truck bodies are game-changers for fleet efficiency. Systems like Switch-N-Go let a single truck chassis support multiple body types – from dump trucks to flatbeds to enclosed service bodies – that can be swapped in minutes.

For funeral services, mortuary lift bodies are essential tools designed for dignified handling of deceased individuals. These specialized lifting devices, like the JD3000 body lift crane and Ultimate 1000 LIFT, typically feature stainless steel construction and can safely lift up to 1,000 pounds.

In the medical field, a body lift refers to a cosmetic surgical procedure that removes excess sagging skin and fat, typically after significant weight loss.

Types of Lift Bodies

The variety of lift bodies across industries shows how versatile this concept is. In aerospace, NASA's famous examples include the M2-F1, HL-10, and X-24 series, with modern applications extending to the European Space Agency's IXV (Intermediate eXperimental Vehicle).

For vehicles, body lifts typically raise trucks by 1-3 inches using precision-engineered spacers. They're a budget-friendly way to accommodate larger tires without changing suspension geometry or affecting ride quality.

Commercial truck systems like Switch-N-Go offer flexibility with over 30 different body types available for a single chassis. Imagine having one truck that can transform from a dump truck to a flatbed to an enclosed service body in minutes!

In the mortuary industry, specialized lifting devices feature ergonomic designs with locking casters and battery-powered options that prioritize both operator safety and dignity for the deceased. Companies like Ferno, Mopec, and Mortech manufacture these systems, though American Mortuary Coolers offers unique customization options.

How Lift Bodies Have Evolved

The journey of lift bodies across different fields shows remarkable innovation. What started as basic concepts have transformed through advances in materials science and engineering.

In aerospace, we've gone from NASA's wooden-framed M2-F1 "Flying Bathtub" (which was actually towed behind a Pontiac Catalina in the 1960s!) to sleek carbon-fiber spacecraft like the Dream Chaser designed for ISS resupply missions.

Vehicle modifications have come a long way too. The early days of using makeshift materials like hockey pucks for body lifts have evolved into precision-engineered UHMW polyethylene blocks and billet aluminum spacers with integrated bump-stop extensions.

Commercial vehicle systems now feature sophisticated hydraulic or cable hoist mechanisms with wireless controls and patented locking systems. The shift to lightweight aluminum construction has increased payload capacity while maintaining durability.

In mortuary equipment, the progression has been equally impressive. The industry has moved from basic manual hoists to sophisticated battery-powered systems with marine-grade aluminum construction, digital weight scales, and ergonomic controls designed to reduce strain on funeral home staff.

Vehicle Body Lifts vs Suspension Lifts: Choosing the Right Height

Thinking about lifting your truck or SUV? You're facing one of the biggest decisions in vehicle modifications: body lift or suspension lift. Let's break down this choice for your goals, wallet, and driving needs.

I remember talking with a customer who runs a funeral home in Colorado. He needed his service vehicle to handle mountain roads in winter while maintaining a professional appearance. His situation mirrors what many vehicle owners face – balancing practical needs with budget constraints.

Key Differences at a Glance:

| Feature | Body Lift | Suspension Lift |

|---|---|---|

| Installation Method | Spacers between body and frame | Replaces/modifies suspension components |

| Height Increase | Typically 1-3 inches | 2-12+ inches |

| Ground Clearance | No change | Increases |

| Cost | $90-$380 | $400-$5,000+ |

| Effect on Handling | Minimal | More significant |

| Center of Gravity Change | 0.25" per 1" of lift (25% of mass) | 0.9" per 1" of lift (90% of mass) |

| Installation Complexity | Moderate | Complex |

| Additional Parts Needed | Gap guards, bumper brackets, steering extensions | Control arms, shocks, driveshafts, brake lines |

Here's the main thing to understand: a body lift only raises the body from the frame using spacers. This affects roughly 25% of your vehicle's mass, which means a 1-inch body lift only raises your center of gravity by about a quarter inch. The result? You can fit bigger tires without dramatically changing how your vehicle handles.

A suspension lift raises nearly 90% of your vehicle's mass. This gives you true ground clearance gains for off-roading, but also significantly affects handling and stability – and your wallet!

Popular body lift manufacturers include Performance Accessories, Daystar, and Rough Country, while companies like BDS Suspension, Pro Comp, and Fabtech dominate the suspension lift market. At American Mortuary Coolers, we've learned through our work with specialized lifting equipment that choosing the right system for your specific needs isn't just about appearance – it's about safety and functionality.

Installing Lift Bodies on Vehicles Safely

I can't stress enough how important proper installation is when it comes to body lifts. Start with a complete, quality kit that includes all necessary components – not just the spacers, but extended bolts, gap guards for those spaces between the body and bumpers, and steering shaft extensions to maintain proper alignment.

You'll need to address several systems depending on your vehicle and lift height. Shifters might need extension, fuel filler necks could require adjustment, and radiator mounts often need modification. Don't forget about your fan shroud – proper cooling is essential!

Always follow manufacturer torque specifications. Those numbers aren't suggestions – they're calculated to prevent fasteners from working loose over rough terrain. After installation, have your vehicle professionally aligned to ensure proper handling and tire wear.

Having worked with lifting systems for years, I strongly recommend consulting with a professional installer if you're lifting more than 2 inches or if you're new to vehicle modifications. The safety of you and your passengers is worth the extra investment.

Common Misconceptions About Lift Bodies

Let's clear up some confusion about body lifts:

Many people believe body lifts increase ground clearance, but that's not quite right. The lift itself only creates space between body and frame, allowing for larger tires. It's actually those bigger tires that increase your ground clearance, not the body lift itself.

Another common worry is that body lifts dramatically increase rollover risk. The reality is much less scary – since a 1-inch body lift only raises about 25% of your vehicle's mass, the center of gravity only increases by about 0.25 inches. This has minimal impact on stability compared to suspension lifts.

I've seen folks try to save money with DIY body lifts using hockey pucks, and I always cringe. Homemade spacers simply can't provide the precision engineering, proper hardware, and supporting components that quality kits include. The few hundred dollars you might save upfront can cost thousands in repairs later.

Modern Truck & Commercial Lift Body Systems

Commercial lift body systems have transformed how businesses manage their fleets. Imagine turning a single truck into a multi-purpose workhorse that can handle everything from hauling debris to delivering enclosed cargo – all with just a few minutes of changeover time.

The magic happens through three main types of systems. Interchangeable systems like Switch-N-Go let operators swap between more than 30 different body types in about three minutes using a clever cable hoist mechanism with wireless controls. It's like giving your truck a complete identity change in less time than it takes to make a cup of coffee!

Then there are hooklift systems that use a powerful hydraulic arm with a hook to load and unload bodies. These are the workhorses for heavier applications where brute strength matters. And of course, we still have permanent mount systems – the traditional fixed bodies with integrated lifting mechanisms you see on dump trucks and service vehicles with cranes.

The efficiency gains are remarkable. When one truck can do the work of three specialized vehicles, businesses see immediate benefits: smaller fleet sizes, lower maintenance costs, and crews that can work smarter by pre-loading bodies for different jobs. As our friends at Switch-N-Go explain in their research, this versatility transforms how businesses approach their daily operations.

Leading manufacturers in this space include Switch-N-Go, Stellar, Swaploader, and Ampliroll, each offering unique features and capabilities for different applications.

Innovations in Lift Body Design

The lift body world is constantly evolving, with exciting innovations that make these systems more efficient, safer, and longer-lasting.

Today's designs feature lightweight materials like EV-compatible aluminum platforms that increase payload capacity while helping with fuel economy. Safety has taken center stage with features like patented Dual Pin Interlock systems that prevent accidental disengagement – a critical consideration when you're dealing with heavy loads.

Operation has become simpler too, with wireless remote controls that allow a single person to safely manage loading and unloading. And because these systems often work in challenging environments, manufacturers have adopted corrosion-resistant materials like marine-grade aluminum and stainless steel that stand up to the elements year after year.

We're particularly impressed with the trend toward customization – manufacturers now offer bodies in lengths up to 32 feet with specialized reinforcements for truck-mounted forklifts. This kind of flexibility means businesses can tailor solutions to their exact needs.

At American Mortuary Coolers, we apply these same principles of durability and innovation to our mortuary lift systems. After all, reliability isn't just about convenience in our industry – it's essential for dignity and respect.

Selecting the Right Lift Body for Your Fleet

Choosing the perfect lift body system for your business needs careful consideration of several factors.

First, think about your application requirements. What specific jobs will this system need to handle? Will you need dump capabilities, flatbed functions, enclosed storage, or something more specialized? The beauty of modern systems is their versatility, but you'll want to make sure your choice aligns with your most common tasks.

Next, verify vehicle compatibility by checking chassis GVWR, cab-to-axle measurement, and frame specifications. Nothing's more frustrating than investing in a system that doesn't quite fit your existing vehicles.

Consider the operational efficiency gains you'll achieve. Calculate how much time you'll save with quick-change capabilities versus fixed bodies. For many businesses, this time saving alone justifies the investment.

Don't forget to look at the total cost of ownership beyond just the initial purchase price. Factor in maintenance requirements and the long-term versatility that might eliminate the need for additional vehicles.

Finally, ensure you have solid dealer support with local service and parts availability. Even the best system will eventually need maintenance or repairs, and having that support nearby can be invaluable.

Safety, Performance & Regulatory Essentials

Safety is paramount when working with any lift body system, whether it's a vehicle modification, commercial truck system, or specialized mortuary lift.

When it comes to lift bodies, safety isn't just a recommendation—it's essential. Each type of system comes with its own specific considerations that shouldn't be overlooked.

For vehicle body lifts, maintaining proper steering geometry is crucial to prevent dangerous handling issues. Regular inspection of all mounting points is something I always emphasize to our customers. Many states have specific height restrictions that vary widely—from 22 inches in some areas to 42 inches in others.

Commercial lift bodies face additional scrutiny. These systems fall under OSHA regulations for lifting equipment, which means operator training isn't optional—it's required. The powerful hydraulics and moving components demand respect and regular maintenance checks. I always tell fleet managers to treat load capacity ratings as absolute limits, not suggestions.

In our mortuary business at American Mortuary Coolers, we understand that mortuary lift bodies serve a uniquely sensitive purpose. These systems must be designed for dignified handling while still meeting rigorous safety standards. Proper disinfection between uses isn't just about cleanliness—it's about professional respect. These specialized lifts must also meet healthcare facility standards, which adds another layer of compliance.

Best Practices for Operating Lift Bodies

Regardless of which lift body system you're using, a few fundamental practices make all the difference.

Comprehensive training should never be skipped, even for experienced operators. Every system has its quirks, and knowing how to handle emergency situations can prevent disasters. I always recommend regular inspections that follow a consistent schedule—weekly visual checks and monthly thorough examinations work well for most applications.

Documentation might seem tedious, but those inspection logs become invaluable if questions ever arise about maintenance history. Trust me on this one—I've seen situations where good record-keeping saved companies from significant liability issues.

When it comes to load management, there's simply no room for "probably fine" thinking. Exceeding capacity ratings or improperly balancing loads creates dangerous situations that can lead to equipment failure or worse. Always be aware of your environment too—I've witnessed operators forget about overhead power lines or soft ground conditions with serious consequences.

At American Mortuary Coolers, we emphasize that personal protective equipment isn't optional. The right gloves, eye protection, and steel-toed boots have prevented countless injuries across all lift body applications. When handling mortuary equipment, this protection takes on added importance for both safety and hygiene.

FAQs on Legal Compliance

"Will my modified truck pass inspection?" This is probably the most common question I hear about vehicle lift bodies. The answer depends on your state's specific regulations. Some states limit height to as low as 22 inches from ground to bumper, while others allow up to 42 inches. Always check local laws before investing in modifications.

Insurance is another frequent concern. You should absolutely notify your insurance provider about any modifications to your vehicle. Some insurers require additional coverage for modified vehicles, while others might increase premiums based on the extent of the modifications. Being upfront prevents nasty surprises if you ever need to file a claim.

For commercial operators, certification requirements vary by employer and application. While the equipment itself must meet ANSI/ASME standards, operator certification depends on company policy and sometimes local regulations. This is an area where it's better to exceed minimum requirements rather than just meet them.

Lift Bodies Beyond Vehicles: Aerospace, Mortuary, Medical

Aerospace Applications

A lifting-body craft relies on its fuselage to create most of its lift, offering better control during re-entry and the option to land on conventional runways. Classic NASA programs like the M2-F1, HL-10, and X-24 proved the concept and directly influenced the Space Shuttle. Today, vehicles such as Sierra Nevada’s Dream Chaser and the European Space Agency’s IXV continue the tradition with lightweight composites and advanced flight computers.

Benefits of lifting-body designs:

- Wider cross-range and maneuverability during descent

- More even heat distribution on re-entry

- Runway landings that reduce recovery costs

Lift Bodies in Mortuary Operations

In funeral service, a lift body is specialized equipment that allows staff to move remains safely and respectfully. Examples include the Ultimate 1000 and JD3000 stainless-steel lifts, both rated for up to 1,000 lb, as well as compact battery-powered lifters that a single operator can use between prep tables, coolers, and caskets. These devices reduce workplace injuries, streamline daily workflow, and preserve dignity—values central to everything we build at American Mortuary Coolers.

Medical Body-Lift Surgery

The same phrase surfaces in medicine, where a body-lift procedure removes excess skin after major weight loss. Although unrelated to equipment, it shows how the term spans very different fields.

For more mortuary-specific details, see our deep dive on lift options here: More info about mortuary lift solutions

Frequently Asked Questions about Lift Bodies

What's the difference between a lift body and a lifting-body aircraft?

When people search for lift bodies, they're often confused by the similar terminology across industries. A lifting-body aircraft is a specialized aerospace design where the fuselage itself generates lift instead of traditional wings—think of NASA's experimental aircraft that influenced the Space Shuttle design.

In contrast, when mechanics and off-roaders talk about lift bodies in the automotive world, they're referring to modifications that create space between a vehicle's body and frame. And in our world of mortuary services, lift bodies are the specialized equipment we use to safely and respectfully handle deceased individuals.

Though they share similar names, these concepts serve entirely different purposes across aerospace, automotive, and funeral industries. The common thread? They all involve innovative approaches to lifting or using body structures more effectively.

Do lift bodies affect vehicle warranties or insurance?

This is one of our most frequently asked questions from customers who also own modified vehicles. The short answer: it depends, but you need to be proactive about it.

For warranties, there's good news. The Magnuson-Moss Warranty Act protects you from having your entire warranty voided simply because you've modified your vehicle with a body lift. However—and this is important—if your modification directly causes a failure, the manufacturer can still deny coverage for that specific component. For example, if your body lift causes steering problems, they might not cover steering repairs.

As for insurance, always notify your provider about any modifications. We've seen too many claims denied because owners didn't disclose their lift bodies. Your insurer might require additional coverage, charge higher premiums, or in some cases, limit coverage for modified components. In rare cases where modifications are deemed unsafe, they might even refuse coverage altogether.

A tip from our team at American Mortuary Coolers: keep detailed records of all modifications, including professional installation receipts and before/after photographs. This documentation can be invaluable for both warranty claims and insurance matters.

How often should commercial lift bodies be inspected?

Safety is something we take seriously at American Mortuary Coolers, and we recommend a consistent inspection schedule for all lift body systems:

Start each workday with a quick visual inspection before operation. Look for obvious damage, fluid leaks, and test the controls to make sure everything responds correctly.

Once a month, set aside time for a more thorough check. Examine all mounting points, hydraulic components, and electrical systems. Look for wear patterns that might indicate future problems.

Annually, invest in a certified inspection from a qualified technician. This should include comprehensive testing and, when applicable, load testing to verify the system can safely handle its rated capacity.

And after any incident—whether it's a collision, overloading situation, or unusual operation—conduct a full inspection before putting the equipment back in service.

For our mortuary lift systems, we recommend these same protocols, with an added emphasis on proper disinfection between uses. In our industry, both safety and dignity are paramount concerns.

Conclusion

From aerospace breakthroughs to funeral-home efficiency, lift bodies solve real-world challenges by making heavy or sensitive tasks safer and faster. Understanding the nuances—whether you need a truck hoist, a battery-powered mortuary lift, or simply want to know how lifting-body aircraft fly—helps you choose equipment that delivers long-term value.

At American Mortuary Coolers, our focus is clear: durable, custom morgue coolers and lift systems delivered directly to any address in the lower 48 states. We work closely with funeral professionals to match every build to the demands of their workflow, budgets, and regional regulations.

If you’re evaluating new handling equipment, explore our blog or reach out to our team. The right lift body can transform your operations—and we’re here to help you find it.