Understanding Your Refrigeration Needs: Beyond One-Size-Fits-All

Custom refrigeration equipment refers to cooling systems engineered to meet unique requirements that standard units cannot satisfy. If you're searching for solutions custom to your specifications, here's what you need to know:

| What Makes Refrigeration Equipment "Custom" | Examples |

|---|---|

| Size & Configuration | Walk-ins built to exact room dimensions, under-counter units for tight spaces |

| Performance | Specialized temperature ranges, rapid cooling capabilities |

| Application-Specific | Mortuary coolers, marine refrigeration, pharmaceutical storage |

| Materials & Finishes | Stainless steel for medical use, branded exteriors for retail |

| Controls & Monitoring | Smart systems, remote access, data logging |

When standard cooling solutions don't fit your space, meet performance requirements, or satisfy industry regulations, custom refrigeration becomes necessary. Whether you need a walk-in cooler for an oddly-shaped room, a specialized cooling system for sensitive materials, or refrigeration that integrates with existing equipment, customization offers the flexibility to solve these challenges.

I'm Mortuary Cooler, a national-level supplier specializing in custom refrigeration equipment for funeral homes and medical facilities across the United States. My experience spans from compact under-counter units to large-scale walk-in systems designed for specific capacity and workflow requirements.

Quick Custom refrigeration equipment definitions:

Custom Refrigeration Equipment 101: What Makes It Different?

Have you ever tried to fit a square peg in a round hole? That's often what happens when businesses try to make standard cooling systems work for specialized needs. Custom refrigeration equipment is built specifically for your unique challenges rather than forcing you to adapt to what's available off the shelf.

Standard refrigeration units are the one-size-fits-most t-shirts of the cooling world. They're designed for general use, come in predetermined dimensions, and offer basic features for common situations. They're manufactured in bulk to keep costs down, which works if your needs are straightforward.

| Feature | Standard Refrigeration | Custom Refrigeration Equipment |

|---|---|---|

| Design Flexibility | Limited to catalog options | Custom to your exact specifications |

| Space Utilization | Often leaves unused areas | Maximizes every inch of your space |

| Performance | General temperature ranges | Precise control for specific needs |

| Energy Efficiency | Generic efficiency ratings | Optimized for your usage patterns |

| Compliance | Meets basic industry standards | Designed for specialized regulatory requirements |

The engineering flexibility of custom refrigeration equipment allows for performance tuning you can't get off the shelf. At American Mortuary Coolers, we ensure mortuary cooling systems maintain the critical 35-38°F temperature range essential for proper preservation, with built-in redundancy features that standard units don't offer.

How Custom Refrigeration Equipment Beats Off-the-Shelf Units

The beauty of going custom goes beyond just getting equipment that fits your space. Here's why custom refrigeration equipment typically outshines standard solutions:

You'll see real efficiency gains because custom units are sized precisely for your cooling load. This right-sizing eliminates energy waste from oversized systems or performance issues from undersized ones. Many clients report energy savings of 15-30% after switching to properly sized custom solutions.

The exact footprint advantage can't be overstated. Custom solutions use every available inch. We've created mortuary coolers that fit perfectly into converted closets, strangely shaped alcoves, and other challenging spaces where standard units would leave gaps or wouldn't fit at all.

Custom Refrigeration Equipment for Niche Applications

Some industries have such specific requirements that standard refrigeration simply won't work:

Mortuary Storage requires precise temperature control, specialized racking systems for respectful body storage, and often needs to fit into existing spaces with architectural constraints. At American Mortuary Coolers, we build systems that accommodate anywhere from 4 to 30 cadavers while maintaining perfect preservation conditions.

Marine Galleys face challenges like limited space, constant motion, corrosive salt air, and often DC power systems. Custom marine refrigeration must withstand these harsh conditions while fitting into irregular spaces typical on vessels.

Pharmaceutical Labs can't afford even minor temperature fluctuations when storing sensitive medications. Their custom refrigeration typically includes redundant cooling systems, continuous monitoring, data logging, and seamless backup power integration.

The Main Types of Custom Solutions on the Market

When exploring custom refrigeration equipment, you'll find diverse cooling solutions designed for specific needs. From walk-in coolers that perfectly fit your space to specialized systems for unique industries, there's a custom option for virtually every cooling challenge.

Walk-In & Reach-In Systems Custom to Your Floorplan

Walk-in coolers and freezers transform almost any space into an efficient cold storage area. The magic behind modern walk-ins lies in their prefabricated panels - precision-engineered panels clad in metal with polyurethane foam insulation inside, offering R-values between 25 and 32. Companies like Arctic Industries have spent decades perfecting these panels, creating systems you can easily assemble, take apart, move, or expand.

Several manufacturers now offer quick-ship options that balance customization and speed. U.S. Cooler uses standardized components in custom arrangements to get you running faster without compromising on fit.

Custom walk-ins offer modular expansion capability. As your business grows, your refrigeration can grow with you by simply connecting new modules to your existing system – sometimes without disrupting operations.

Want to learn more about walk-in features? Check out our complete guide to walk-in cooler features and prices.

Packaged & Containerized Industrial Units

For larger industrial applications, custom refrigeration equipment often comes as complete packaged systems mounted on a single platform.

Skid fabrication has revolutionized industrial refrigeration installation. Companies like Clauger and RD&S build complete refrigeration systems on structural steel frames in their manufacturing facilities before shipping to your site.

These systems offer plug-and-play delivery. Since 2014, Clauger has manufactured over 700 packaged refrigeration systems that arrive practically ready to use – saving weeks or months of on-site assembly and testing.

Modern packaged systems feature sophisticated remote PLC control capabilities. These smart control panels connect to networks, allowing monitoring and adjustment from anywhere.

With environmental regulations tightening, many manufacturers now offer CO₂ transcritical packages that provide eco-friendly refrigeration options for various temperature applications.

Specialty & Extreme-Duty Equipment

Some cooling challenges require custom refrigeration equipment built for extreme conditions or highly specialized purposes.

Here at American Mortuary Coolers, we specialize in morgue body refrigerators – perhaps the most specialized application in the refrigeration world. Our mortuary cooling systems maintain the precise 35-38°F temperature range essential for proper preservation while providing dignified storage solutions.

We design our mortuary coolers with specialized racking systems for respectful handling, with options from compact units for 4-5 bodies to spacious walk-ins accommodating 24-30 remains. The high-quality stainless steel interiors resist corrosion and make thorough cleaning straightforward – critical features in this sensitive application.

Why Go Custom? Key Advantages You Can Bank On

When you invest in custom refrigeration equipment, you're not just buying a cooling system—you're investing in solutions that directly impact your bottom line. Think of it as tailoring a suit instead of buying off the rack—the fit is simply better in every way.

Energy efficiency is perhaps the most compelling reason to go custom. These systems are sized precisely for your actual cooling needs, eliminating the waste from standard units that are often oversized "just to be safe." Our clients typically see energy savings of 15-30%—savings that continue month after month, year after year.

Temperature precision is another game-changer. When preserving human remains, storing critical medications, or aging fine wines, there's no room for temperature fluctuations. Custom refrigeration equipment maintains temperatures within ±1°F compared to the ±3-5°F swings common in standard units.

Navigating industry regulations becomes simpler with custom solutions. Whether dealing with FDA requirements, OSHA standards, UL certification, or specialized ATEX certification, custom systems are built from the ground up to meet these specific standards.

For businesses where customers see your equipment, the aesthetic advantages of custom units can't be overstated. Your refrigeration becomes part of your brand experience rather than an eyesore.

Some manufacturers offer exceptional warranty coverage for their custom refrigeration equipment. True Manufacturing stands behind their Hydrocarbon Units with an industry-leading 7-year warranty covering labor, parts, and compressors.

More info about customization benefits

Performance & Sustainability Wins

The green advantages of custom refrigeration equipment are increasingly important in today's environmentally conscious world.

Custom systems can be designed with natural refrigerants like CO₂, propane (R-290), or ammonia that have minimal global warming potential. Facilities switching to these refrigerants not only reduce their environmental footprint but often improve cooling performance simultaneously.

Unlike standard units that blast at full power then shut off completely, custom refrigeration can incorporate variable-speed technology that adjusts to actual cooling demands—much like cruise control versus stomping the gas and brake. This approach can slash energy consumption by up to 40%.

Smart heat reclaim features capture what would otherwise be wasted heat and repurpose it for water or space heating. Some facilities have cut their water heating costs in half through this "free" energy source.

Space, Workflow & Branding Perks

In tight spaces and busy workflows, custom refrigeration equipment shines in practical ways that standard units can't match.

When every square inch matters—in crowded bars, compact kitchens, or space-conscious laboratories—custom under-counter refrigeration makes the difference between "it fits" and "it fits perfectly."

Commercial kitchens benefit from refrigeration that integrates seamlessly with cooking lines. Custom prep tables, drawer units, and undercounter refrigeration can match existing equipment heights and depths exactly, creating a cohesive workflow.

Retail applications benefit from custom glass-front display units designed specifically to showcase products while maintaining perfect temperatures. With integrated LED lighting, custom shelving, and branded elements, these units don't just store products—they sell them.

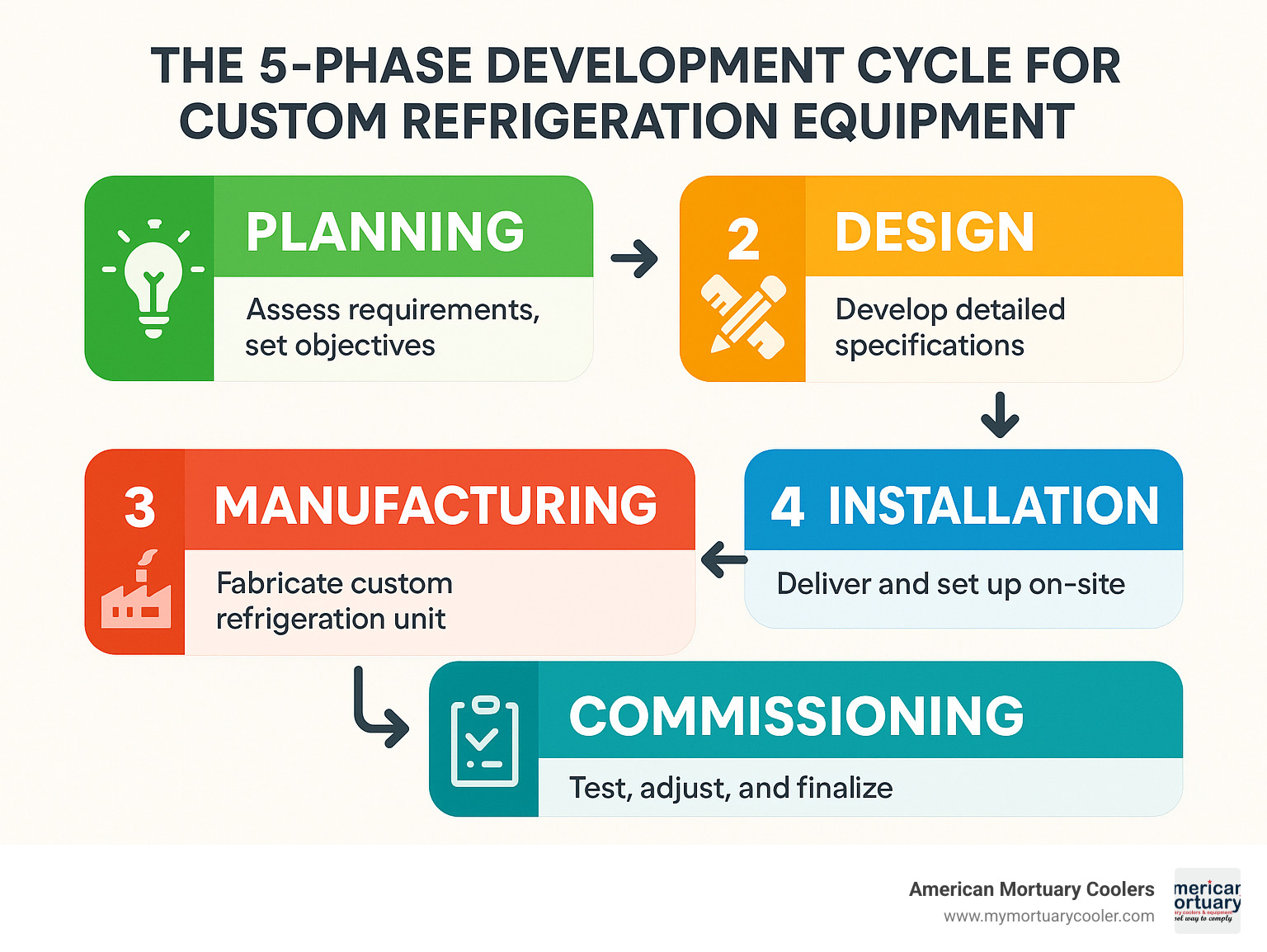

From Concept to Commissioning: The Custom Refrigeration Playbook

There's something magical about watching custom refrigeration equipment come to life. It's not just about bolting together metal parts – it's a carefully choreographed journey from idea to reality.

Designing Your Ideal System

The design phase is where dreams start taking shape. This isn't about grabbing something off a shelf – it's about crafting a solution as unique as your fingerprint.

When designing your custom refrigeration equipment, we start with thermal load calculations that tell us exactly how powerful your system needs to be. At American Mortuary Coolers, we use specialized software that accounts for everything from ambient temperature to door opening frequency. For mortuary applications, maintaining that critical 35-38°F range is essential for preservation.

Insulation choices make a huge difference in both performance and your monthly electric bill. We typically recommend R-32 panels for mortuary coolers – they might cost more upfront, but they'll save you money every month for years to come.

Door placement isn't just practical – it's about respecting workflow and dignity. For mortuary facilities, we carefully plan door locations to minimize unnecessary openings while ensuring staff can move with respect and grace.

For critical applications like body preservation, redundant systems aren't a luxury – they're insurance against system failures at the worst possible moment.

Designing Your Ideal Mortuary Cooler: The Power of Customization

Manufacturing, Quality & Compliance

Once your design is approved, we build your custom refrigeration equipment with meticulous attention to detail.

The manufacturing process requires skilled hands and precision. Those connections might be hidden inside the unit, but they're the lifelines of your system. Companies like RD&S employ specialized welding techniques that ensure every joint is perfect – because even a pinhole leak can compromise the entire system.

Before any unit leaves the factory, it undergoes rigorous pressure testing. We pressurize the entire system with nitrogen and watch for any drop that might indicate a leak. For critical applications, we perform hydrostatic testing – submerging components underwater while pressurized to visually spot even the tiniest bubbles.

Compliance isn't just a checkbox – it's your assurance that the equipment meets rigorous standards. Whether it's UL certification for electrical safety, NSF for sanitation requirements, or CE marking for European markets, reputable manufacturers ensure every unit meets applicable standards.

Installation, Service & Lifecycle Support

Your relationship with your custom refrigeration equipment is just beginning when it arrives at your facility.

Many premium manufacturers, including American Mortuary Coolers, provide factory-trained installation teams who understand the nuances of the equipment. Our installation services cover all our service regions, ensuring your system starts its life correctly.

Refrigeration issues have a way of happening at inconvenient times. That's why leading providers maintain networks of qualified technicians available around the clock. Custom Refrigeration has built an impressive network covering over 70 cities in Minnesota alone – ensuring help is never far away.

Modern custom refrigeration equipment often includes sophisticated monitoring systems that spot potential issues before they become problems, allowing for predictive maintenance rather than emergency repairs.

The warranty speaks volumes about the manufacturer's confidence in their product. True Manufacturing backs their hydrocarbon units with a 7-year warranty covering labor, parts, and compressors – the kind of assurance that helps you sleep better at night.

Trends, Costs & Choosing the Right Partner

The world of custom refrigeration equipment is constantly evolving. If you're considering a custom cooling solution, understanding current trends, cost factors, and how to find the right manufacturing partner will save you headaches and money.

Natural refrigerants are leading today's market. CO₂ systems, propane (R-290) units, and other eco-friendly alternatives are rapidly replacing traditional refrigerants as regulations tighten. These systems often deliver superior performance while future-proofing your investment against upcoming refrigerant restrictions.

Smart technology has transformed refrigeration. IoT sensors now allow remote monitoring of temperatures, energy usage, and system performance, often preventing problems before they cause downtime.

Modular, plug-in systems offer the benefits of customization with faster delivery times. These solutions combine pre-engineered components in custom configurations, reducing lead times while still meeting your specific requirements.

Budget & Timeline Factors for Custom Refrigeration Equipment

When budgeting for your custom refrigeration equipment, several key factors will influence both costs and timeline:

Capacity Requirements drive a significant portion of your investment. A system for a small mortuary room naturally costs less than one for a large industrial facility. Right-sizing is crucial—an oversized system wastes money twice: first in the purchase, then in years of inefficient operation.

Material Choices make a substantial difference in both price and longevity. For mortuary coolers, we typically recommend stainless steel interiors despite their 30-40% premium over galvanized steel. The durability, ease of cleaning, and resistance to corrosion pay dividends over the equipment's lifetime.

Regulatory Compliance adds another layer to consider. Systems requiring special certifications involve additional costs and potentially longer lead times.

Shipping Logistics often get overlooked. Large refrigeration components require specialized freight arrangements. At American Mortuary Coolers, we handle all logistics for deliveries across the contiguous 48 states.

Typical lead times for custom refrigeration equipment range from 4-12 weeks depending on complexity. Simple custom walk-ins usually fall at the shorter end, while complex industrial systems require more time.

A Comprehensive Guide to Custom Cooling Solutions

Selecting a Provider Without Getting Burned

Choosing the right partner for your custom refrigeration equipment is perhaps the most critical decision in the entire process.

Engineering Credentials should top your checklist. Verify that your potential manufacturer employs qualified refrigeration engineers with relevant experience in your specific application. Ask about their design process and how they verify system performance before manufacturing begins.

Fabrication Facilities tell you a lot about a company's capabilities. Manufacturers like RD&S with their 32,000 sq ft facility in Philadelphia demonstrate serious investment in quality control and production capacity.

Case Studies provide real-world proof of capabilities. Any reputable manufacturer should share examples of similar projects they've completed. Ask for references from clients with applications similar to yours.

After-Sales Service can make or break your experience. Evaluate the manufacturer's service network, parts availability, and response times. Companies that maintain their own service teams typically provide better support than those who outsource this function.

At American Mortuary Coolers, we take pride in our specialized focus on mortuary refrigeration. Our engineering team understands the unique requirements of funeral homes and medical facilities, and our nationwide service network ensures support is always available.

Frequently Asked Questions about Custom Refrigeration Equipment

How long does a typical custom project take from design to installation?

Each project is unique, but most follow a predictable journey from concept to completion.

For most custom cooling systems, budget about 7-17 weeks total. The process typically begins with a 1-2 week needs assessment where we learn exactly what you're trying to accomplish. Then we move into the detailed engineering phase (2-4 weeks), where precise specifications are developed. The manufacturing and testing stage usually takes 3-8 weeks, as this is where your system actually comes to life. Finally, shipping and installation add another 1-3 weeks.

At American Mortuary Coolers, we understand that timing can be critical, especially in the funeral industry. We work closely with clients to establish realistic timelines while never cutting corners on quality.

Certain factors can extend these timelines. Complex regulatory approvals, specialty materials with long lead times, or extensive site preparations can all add weeks to the process. Simpler systems using standard components can sometimes move more quickly through production.

Which refrigerants should I choose to stay ahead of 2025 regulations?

The refrigerant landscape is changing rapidly as environmental regulations tighten. Choosing the right refrigerant will protect you from costly retrofits down the road.

The key date is January 1, 2025 – when new regulations will significantly restrict refrigerants with high global warming potential. Systems using R-404A and R-507A will be particularly affected. Several future-proof options are available today:

R-290 (Propane) is ideal for smaller, self-contained units. With zero ozone depletion and minimal global warming potential (GWP of just 3), it's an environmentally excellent choice. It's also highly efficient, though its flammability requires specific safety measures.

For larger commercial and industrial applications, R-744 (CO₂) systems are gaining tremendous popularity. With a GWP of only 1 and non-flammable properties, CO₂ represents the future of commercial refrigeration.

In large industrial settings, R-717 (Ammonia) remains a tried-and-true solution with zero GWP and exceptional efficiency.

What maintenance schedule keeps custom units running at peak efficiency?

Think of your custom refrigeration equipment like a high-performance vehicle – regular maintenance is essential for optimal performance and longevity.

On a monthly basis, focus on the basics: inspect and clean condenser coils, check refrigerant levels, clean motors and fan blades, and inspect door gaskets and seals. These simple steps prevent many common issues.

Quarterly, go deeper by cleaning evaporator coils, checking and calibrating thermostats, lubricating motors and bearings, and inspecting electrical connections. This quarterly rhythm helps catch developing issues early.

Annually, schedule professional service. A comprehensive system inspection by qualified technicians should include testing controls and safety switches, checking relays and contactors, and performing manufacturer-recommended preventive maintenance.

For critical applications like mortuary coolers, professional maintenance isn't an expense – it's an investment in reliability. Remote monitoring systems can provide continuous oversight, detecting subtle performance changes that might indicate developing problems.

Conclusion

When it comes down to it, custom refrigeration equipment isn't just a purchase—it's an investment in your operation's future. The right custom solution can transform a business, solving problems that off-the-shelf units simply can't address.

Consider what matters most in your cooling needs. Is it maintaining that perfect temperature band? Maximizing your available space? Reducing energy costs? Custom solutions excel in all these areas because they're built around your specific requirements rather than forcing you to adapt to standardized dimensions and capabilities.

The magic happens when you find the right partner. This isn't just about buying equipment—it's about working with experts who understand both refrigeration engineering and the unique demands of your industry. The best manufacturers become extensions of your team, guiding you through options and designing systems that truly solve your problems.

Here at American Mortuary Coolers, we've dedicated ourselves to becoming those trusted partners for the funeral industry. Based in Tennessee, we deliver durable, tailor-made mortuary refrigeration direct to all 48 contiguous states. Our team brings specialized knowledge about the unique requirements funeral homes face—from precise temperature control to respectful body handling systems to compliance with industry regulations.

The refrigeration world never stands still. New refrigerants emerge as environmental regulations evolve. Control systems get smarter. Components become more efficient. By choosing custom solutions designed with these advances in mind, you're positioning yourself ahead of the curve, avoiding the frustrating limitations of standard equipment.

Your cooling challenges deserve thoughtful, personalized solutions. We're here to help you steer the options and design a system that fits your space, meets your performance requirements, and delivers long-term value.