Why R452A is Reshaping Refrigeration in the Funeral Industry

R452A is a hydrofluoroolefin (HFO) refrigerant blend designed as a lower global warming potential replacement for R404A and R507 in commercial refrigeration systems. Here's what you need to know:

Key R452A Facts:

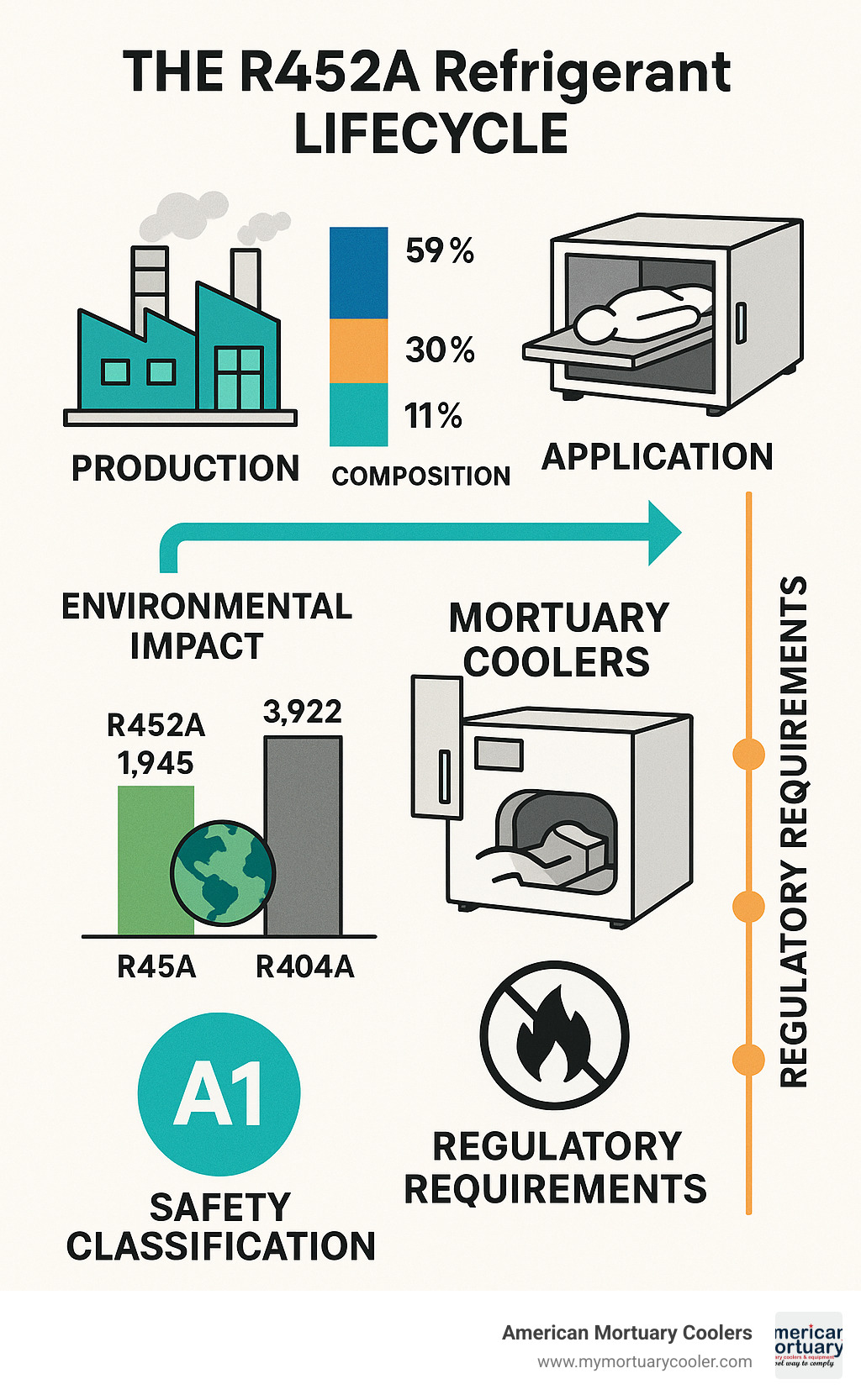

- Composition: 59% R125, 30% R1234yf, 11% R32 (zeotropic blend)

- Global Warming Potential: 1,945 (45% lower than R404A's 3,922)

- Safety Classification: A1 (non-flammable, low toxicity)

- Applications: Transport refrigeration, commercial DX systems, mortuary coolers

- Compatibility: Direct drop-in replacement for R404A/R507 with POE oils

- Charging Method: Must be charged as liquid to prevent fractionation

The funeral industry faces mounting pressure to reduce environmental impact while maintaining reliable refrigeration. With the EPA's AIM Act phasing down high-GWP refrigerants, R452A offers mortuary facilities an immediate path to compliance without sacrificing performance.

Unlike traditional HFC refrigerants, R452A matches the cooling capacity and discharge temperatures of R404A while cutting greenhouse gas emissions nearly in half. This makes it particularly valuable for funeral homes operating walk-in coolers and transport refrigeration where consistent temperatures are critical.

However, R452A isn't the final destination. With a GWP still well above future targets of 150 or less, it serves as a transitional solution while the industry develops ultra-low GWP alternatives.

As American Mortuary Coolers with experience in commercial refrigeration systems, we've helped numerous funeral facilities steer the transition to lower-GWP refrigerants including R452A implementations. Our background in mortuary equipment ensures you get practical guidance custom to your specific operational needs.

Understanding R452A: Composition, Properties, Environmental Footprint

When you're dealing with refrigeration in the funeral industry, understanding what's actually inside that cylinder matters. R452A isn't just another refrigerant – it's a carefully crafted blend designed to keep your mortuary coolers running efficiently while helping you meet environmental regulations.

Chemical Makeup & Key Physical Data

R452A brings together three refrigerant components in precise proportions. The largest portion – 59% R125 (pentafluoroethane) – handles most of the heavy lifting for cooling capacity. The 30% R1234yf component is the environmental hero here, significantly lowering the blend's global warming potential. Finally, 11% R32 rounds out the mix by boosting efficiency and capacity.

This combination creates what's called a zeotropic blend with a molecular weight of 103.5 g/mol. The temperature glide sits around 3-4 K, which means there's a small temperature difference between liquid and vapor phases at the same pressure. This glide is minimal enough that R452A behaves almost like a single-component refrigerant in your systems.

The physical properties tell an important story for funeral facilities. R452A boils at -47.0°C at atmospheric pressure, with a critical temperature of 75.1°C and critical pressure of 40.1 bar. The liquid density at 0°C reaches 1,237 kg/m³.

Most importantly for safety, R452A carries an A1 classification – meaning it's non-flammable with low toxicity. This makes it much safer to handle than some newer alternatives that require special precautions.

The pressure-temperature relationship closely mirrors R404A, which explains why R452A works as a direct replacement without needing expansion valve adjustments. Your existing compressors will operate within their normal discharge temperature ranges, making the transition smoother for funeral facilities.

Global Warming Potential & Sustainability Scorecard

R452A delivers a substantial 45% reduction in global warming potential compared to R404A's GWP of 3,922, with its GWP of 1,945. For funeral homes looking to reduce their environmental footprint, this represents meaningful progress without sacrificing cooling performance.

The EPA's AIM Act is systematically reducing HFC allowances, targeting just 15% of historic baselines by 2036. This isn't a distant concern – it's happening now, and facilities need compliant refrigerants like R452A to keep operating.

The EU F-Gas Regulation has been driving similar changes across Europe since 2015, proving this isn't just an American trend. Funeral facilities worldwide are recognizing that transitioning to lower-GWP refrigerants isn't optional anymore.

R452A maintains zero ozone depletion potential, continuing our industry's success in protecting the ozone layer. The blend is fully recyclable and reclaimable, supporting responsible refrigerant management practices that funeral facilities can feel good about.

For comprehensive thermodynamic data and ongoing research, the NIST RefProp database provides detailed scientific information about R452A and other refrigerants used in commercial applications.

R452A vs. Legacy Refrigerants: Performance, Efficiency & Limitations

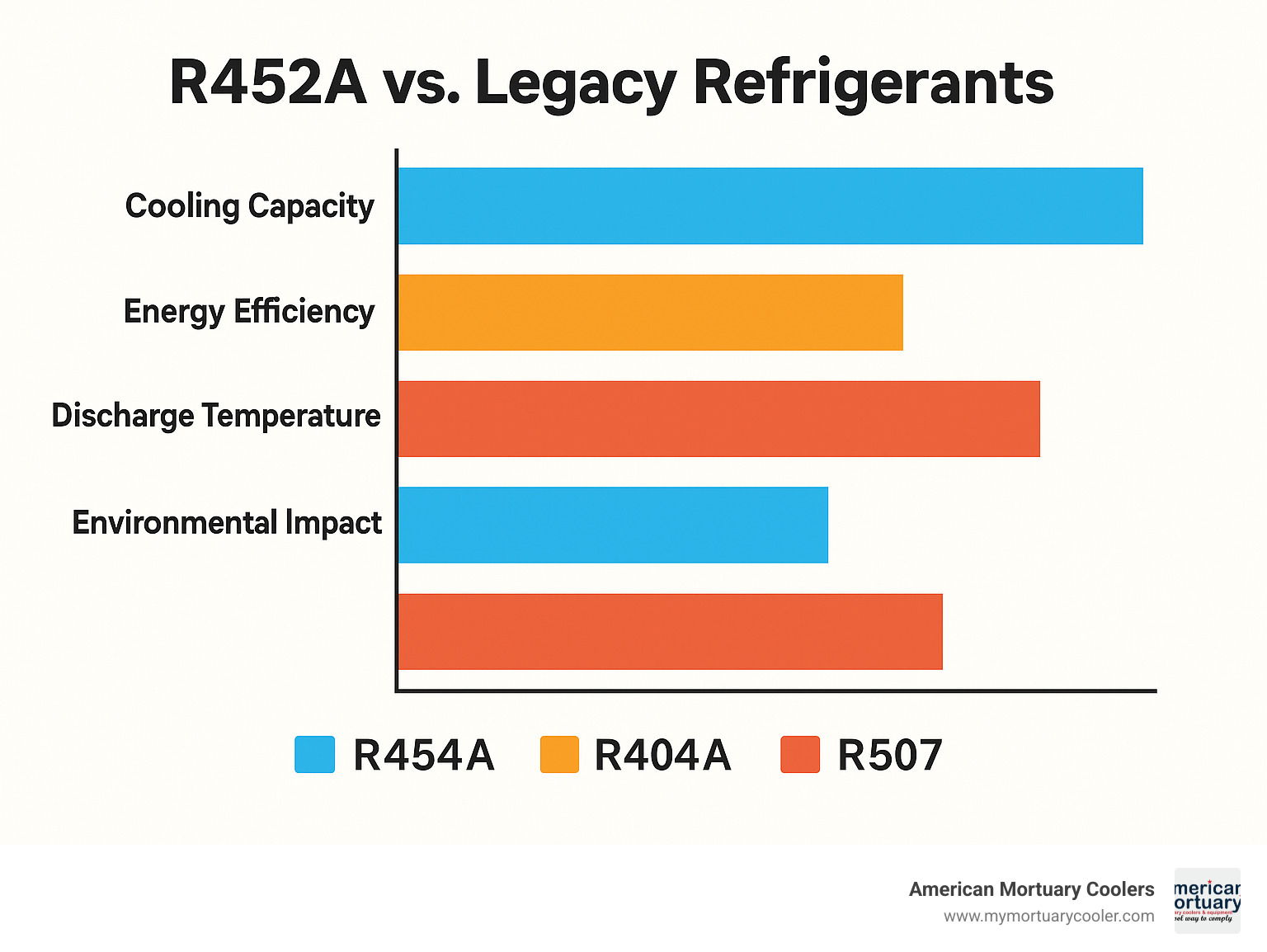

When you're running a funeral home, the last thing you want is surprises with your cooling systems. The good news about R452A is that it performs almost identically to the R404A and R507 you're already familiar with, while cutting your environmental impact nearly in half.

This performance similarity isn't just marketing speak – it's backed by real-world testing across thousands of installations. For mortuary facilities making the switch, this means you get the environmental benefits without sacrificing the reliable cooling your operations depend on.

Cooling Capacity, COP, Discharge Temperature

R452A delivers cooling capacity that matches R404A almost perfectly – we're talking 99-100% of the original performance across both low and medium temperature applications. Your walk-in coolers will maintain the same temperatures, and your transport units will keep their cargo just as cold during transfers.

The energy efficiency actually improves slightly with R452A. Most systems see a coefficient of performance (COP) that's 2-4% better than R404A, which translates to lower electricity bills. It's not a huge difference, but every bit helps when you're managing operating costs.

What really matters for retrofit situations is that R452A produces the same compressor discharge temperatures as your current refrigerant. This means your existing compressors won't run hotter, your thermal protection systems continue working properly, and you won't face unexpected equipment failures after the conversion.

Transport refrigeration units have shown particularly good results with R452A. Funeral directors report the same fuel efficiency and reliability they experienced with R404A, which is crucial when you're transporting remains and can't afford cooling failures.

The one trade-off you'll notice is that R452A typically requires 5-10% more refrigerant charge than R404A systems. This adds a bit to your material costs during retrofits, but the performance benefits and regulatory compliance advantages make it worthwhile.

Is R452A a Long-Term Solution?

Here's where we need to be honest with you – R452A is more of a stepping stone than a final destination. With a global warming potential of 1,945, it's still well above the long-term targets regulators are aiming for, which are typically 300 or less.

Think of R452A as a bridge technology that gets you where you need to be today while the industry figures out tomorrow's solutions. It provides immediate GWP reductions and regulatory compliance without forcing you to wait for next-generation refrigerants that may still be years away from commercial availability.

Price volatility is something to keep in mind for your long-term planning. As HFC phase-downs continue and supply becomes more restricted, R452A costs will likely increase. It's smart to factor these potential price jumps into your refrigerant management budget.

Most industry experts believe R452A will remain relevant for the next 5-10 years. That gives facilities plenty of time to plan for the next transition while benefiting from immediate environmental improvements. For funeral homes that need compliance today but want to avoid multiple equipment overhauls, it's often the most practical choice available.

Applications & Retrofit Guidelines for R452A

When it comes to real-world applications, R452A has proven itself across a wide range of refrigeration systems. The blend shines particularly bright in transport refrigeration, where refrigerated trucks and trailers depend on consistent cooling performance. For funeral homes, this reliability translates directly to peace of mind when transporting loved ones between facilities.

Commercial direct expansion systems have accepted R452A with excellent results. Walk-in coolers, display cases, and condensing units all perform beautifully with this refrigerant blend. The funeral industry's heavy reliance on walk-in coolers makes this track record especially meaningful.

At American Mortuary Coolers, we've guided numerous funeral facilities through R452A conversions across our service area. From our Tennessee headquarters to installations throughout the contiguous 48 states, we've seen how proper implementation makes all the difference. The key is understanding that while R452A is forgiving, attention to detail during installation pays dividends in long-term reliability.

Industrial condensing units and mortuary coolers represent another sweet spot for R452A. The blend's ability to maintain precise temperatures under varying load conditions makes it ideal for facilities that can't afford temperature fluctuations. If you're looking to optimize your cooling system design, our guide on How to Master Walk-In Cooler Design in 5 Simple Steps offers valuable insights that apply beautifully to R452A installations.

Compatible Lubricants & Materials

The good news about R452A is its compatibility with polyolester (POE) lubricants - the same oil type that R404A and R507 systems already use. This compatibility makes retrofits much smoother since you often don't need to change the oil completely. However, we always recommend checking the oil's condition first, especially if it's been in service for several years.

POE oils do have one quirk worth understanding: they're incredibly thirsty for moisture, absorbing water about 100 times more readily than traditional mineral oils. Proper system evacuation becomes absolutely critical - we're talking about achieving moisture levels below 80 PPM to keep everything running smoothly.

Your drier selection matters more with R452A than you might expect. Molecular sieve driers with XH-6 bonded core, XH-7, or XH-9 specifications work best with POE oils. Standard solid core driers simply don't have the moisture capacity or compatibility needed for reliable long-term operation.

Most system materials play nicely with R452A. Elastomers, seals, and gaskets that worked with R404A typically handle the new blend without issues. Still, for critical applications, we recommend specific compatibility testing to avoid any surprises down the road.

Step-by-Step Retrofit Checklist from R404A/R507

Converting from R404A or R507 to R452A doesn't require major surgery on your refrigeration system. The process is straightforward when you follow proven steps and pay attention to the details that matter.

Start by documenting your current system performance - operating pressures, temperatures, and cooling capacity. This baseline helps you verify that the retrofit achieved the expected results.

Recovery and system preparation come next. Use appropriate recovery equipment rated for at least 300 psig service pressure to remove the existing refrigerant completely. Inspect all system components for wear, leaks, or damage while you have the system open.

System evacuation requires patience but pays off handsomely. Pull the system down to 200 microns minimum, though 400 microns works even better with POE systems. Hold that vacuum for at least 10 minutes to verify system integrity before proceeding.

Charging *R452A requires one critical rule: liquid charging only.* This prevents blend fractionation that could affect performance. Start with approximately 95% of your original R404A charge amount, then fine-tune based on system performance.

System startup and optimization wrap up the process. Monitor operating pressures and temperatures carefully during initial operation. Most systems won't need expansion valve adjustments, but watch for any performance variations. Update all system labels with the new refrigerant type and charge amount.

For a deeper understanding of how these systems work together, our Refrigeration System 101: Understanding the Basics guide provides excellent background information that applies to R452A installations.

Safe Handling, Storage & Regulatory Best Practices

Working with R452A is significantly safer than many other refrigerants, thanks to its A1 safety classification that means it's non-flammable and has low toxicity. But even with these safety advantages, proper handling procedures protect both technicians and equipment from potential problems.

The most critical rule when working with R452A is to always charge from the liquid phase. This isn't just a suggestion - it's absolutely essential. When you charge from vapor, the blend components separate in a process called fractionation, which changes the refrigerant's properties and can damage your system. Think of it like trying to mix a cocktail by pouring the ingredients separately - you won't get the right blend.

All R452A cylinders come equipped with Residual Pressure Devices (RPD) that maintain slight positive pressure inside the cylinder. These devices prevent air and moisture from sneaking in when the cylinder is nearly empty, keeping the refrigerant pure and your systems running smoothly.

Transportation regulations classify R452A under DOT-UN3163 as a liquefied gas, which means standard cylinder handling and transport procedures apply. Always secure cylinders properly during transport and store them in upright positions when possible.

California facilities need to be aware of Proposition 65 requirements for R452A. The blend contains chemicals that may cause cancer or reproductive harm according to California's standards, so proper warning labels are required. You can find detailed information about these requirements at P65Warnings.ca.gov.

Charging & Pressure-Temperature Essentials

Understanding how R452A behaves under different temperature and pressure conditions makes troubleshooting and maintenance much easier. The good news is that the refrigerant's pressure-temperature relationship closely matches R404A, so experienced technicians won't need to learn entirely new operating parameters.

The 3-4 K temperature glide is one characteristic that sets R452A apart from pure refrigerants. This means there's a small temperature difference between when the refrigerant starts to boil (bubble point) and when it's completely vaporized (dew point) at any given pressure. While this glide is relatively small and won't significantly impact system operation, it's something to keep in mind when taking temperature and pressure readings.

Liquid charging is absolutely critical for maintaining proper blend composition. Position cylinders upright or use cylinders with dip tubes to ensure you're drawing liquid refrigerant. Never charge vapor into an evacuated system - this is the fastest way to cause severe fractionation and potentially expensive system damage.

System operating pressures will feel familiar to anyone who's worked with R404A. This pressure compatibility means existing pressure controls, safety devices, and gauges will function properly without requiring adjustments or replacements.

Leak Detection, Maintenance & End-of-Life

Standard electronic leak detectors designed for HFC refrigerants work perfectly with R452A. Whether you're using handheld detectors for pinpointing specific leaks or continuous room monitors for safety monitoring, existing equipment will serve you well.

One advantage of R452A over some other zeotropic blends is that you can top off systems after minor leaks without recovering all the refrigerant first. The blend composition remains stable enough for direct additions. However, if you're dealing with significant leaks or major repairs, it's best practice to recover the entire charge and start fresh to ensure optimal blend composition.

When systems reach end-of-life, R452A follows standard industry practices for refrigerant recovery and reclamation. The refrigerant can be recovered, recycled, and reclaimed using existing equipment and processes that work with other HFC refrigerants.

Proper recordkeeping of refrigerant quantities, leak repairs, and disposal methods isn't just good practice - it's essential for regulatory compliance and environmental stewardship. Many facilities find that maintaining detailed refrigerant logs helps them identify recurring issues and optimize their maintenance schedules.

Emerging Alternatives & Where R452A Fits in the Low-GWP Roadmap

The refrigeration world is changing fast, and R452A is just one stop on our journey toward truly sustainable cooling. Think of it as a reliable bridge that gets us where we need to go while better solutions finish development.

Several exciting alternatives are emerging that push environmental performance even further. R454A (also known as Opteon XL40) leads the pack with an impressive GWP of just 238 - that's a massive improvement over R452A's 1,945. The catch? It's classified as A2L, meaning it's mildly flammable and requires extra safety measures that many existing systems can't handle without major upgrades.

R450A offers another path forward, delivering a solid 57% GWP reduction compared to R134a while keeping the safe A1 classification. It works well in medium-temperature applications, though it doesn't overlap as much with R452A's typical uses.

For facilities willing to make bigger changes, natural refrigerants like CO₂ and ammonia (NH₃) deliver the ultimate in environmental performance with near-zero GWP. These systems require specialized equipment and extensive safety protocols, making them more suitable for large industrial operations than typical funeral facilities.

At American Mortuary Coolers, we help funeral facilities steer these choices based on their specific needs and timelines. Our experience across the contiguous 48 states has shown us that the "best" refrigerant often depends more on your facility's circumstances than abstract environmental scores.

For those interested in exploring other innovative cooling approaches, our guide Everything You Need to Know About Dura Cool Refrigerant covers another technology that's gaining attention in specialized applications.

Key Differences Between R452A & R454A

The R452A versus R454A comparison perfectly illustrates the choices facing our industry right now. Both refrigerants aim to solve the same problem - reducing environmental impact - but they take very different approaches.

R454A achieves its dramatically lower GWP of 238 through a completely different blend composition. Where R452A combines 59% R125, 30% R1234yf, and 11% R32, R454A uses 68.9% R32 and 31.1% R1234yf. This higher concentration of R32 delivers the environmental benefits but also creates the mild flammability that earns it the A2L safety classification.

The flammability difference isn't just a technical detail - it fundamentally changes how you can use the refrigerant. R454A systems need leak detection equipment, improved ventilation, and sometimes different installation procedures. Many existing systems simply can't accommodate these requirements without expensive modifications.

Performance-wise, the refrigerants behave quite differently too. R452A delivers that near-perfect capacity match with R404A that makes retrofits so straightforward. R454A provides slightly different cooling capacity and efficiency characteristics, which might require system adjustments to optimize performance.

Your choice between these refrigerants often comes down to timing and risk tolerance. Need to comply with regulations quickly without major system changes? R452A gets you there safely. Planning a major facility upgrade and want the best long-term environmental performance? R454A might be worth the extra complexity.

Frequently Asked Questions About R452A

When funeral directors and facility managers consider switching to R452A, they often have practical questions about the transition process. After helping numerous mortuary facilities steer this change, we've found these three questions come up most frequently.

Does R452A require TXV adjustment when retrofitting?

Here's some good news - R452A typically doesn't require thermal expansion valve adjustments when you're switching from R404A or R507. The engineering behind this refrigerant was specifically designed to match the operating characteristics of these legacy refrigerants.

The pressure-temperature relationship is so similar that your existing TXV settings will usually provide proper superheat control right out of the gate. This compatibility is one of the biggest advantages of R452A - it truly behaves like a drop-in replacement in most systems.

That said, we always recommend keeping an eye on superheat levels during your initial startup. Every system is a bit different, and minor tweaks might be needed to optimize performance. The matched discharge temperatures and mass flow characteristics that make R452A so effective also mean your expansion valve should work just fine without major changes.

Can I mix R452A with leftover R404A?

This is a hard no - never intentionally mix R452A with R404A or any other refrigerant. We understand the temptation, especially when you have some R404A left in the system after a retrofit, but mixing refrigerants creates a host of problems.

When different refrigerants combine, you get unpredictable performance that can damage your compressor and other system components. Your equipment warranty could also be voided, leaving you with expensive repair bills and no manufacturer support.

If accidental cross-contamination happens (and it does sometimes), the only proper solution is to recover the entire refrigerant charge and start fresh with pure R452A. The contaminated refrigerant needs to go to a certified reclamation facility - it can't be reused or recycled through normal channels.

What oils should be used with R452A compressors?

R452A works with polyolester (POE) lubricants, which is actually great news if you're retrofitting from R404A. Since R404A systems already use POE oil, you often don't need to change the oil during your retrofit.

The key factor is oil condition rather than compatibility. If your existing POE oil is clean and has low moisture content, it can typically stay in the system. However, if the oil has been in service for years or shows signs of contamination, an oil change during retrofit makes good sense.

We generally recommend having your oil analyzed before making the decision. High moisture levels or acid contamination mean it's time for fresh oil, regardless of the refrigerant change. POE oils are much more hygroscopic than older mineral oils, so moisture control is critical for system longevity.

Always check your compressor manufacturer's specific recommendations for your equipment. They'll have detailed guidelines about approved oils and any special requirements for R452A applications in mortuary cooling systems.

Conclusion & Next Steps

Making the switch to R452A isn't just about checking a regulatory box – it's about positioning your funeral facility for long-term success while doing right by the environment. With its impressive 45% reduction in global warming potential compared to R404A, combined with that crucial A1 safety rating and seamless drop-in compatibility, R452A offers funeral directors a smart path forward that doesn't compromise on reliability.

We get it. Running a funeral facility means you can't afford equipment failures or temperature fluctuations when families are counting on you during their most difficult moments. That's why the performance match between R452A and traditional refrigerants matters so much – you get the environmental benefits without the operational headaches.

At American Mortuary Coolers, we've been helping funeral facilities across the country steer these refrigerant transitions for years. From our home base in Tennessee to installations in Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and everywhere in between, we've seen how the right approach makes all the difference.

The reality is simple: high-GWP refrigerants are becoming more expensive and harder to find each year. Facilities that wait too long often find themselves scrambling for solutions when their current refrigerant becomes unavailable or prohibitively costly. R452A gives you breathing room to plan properly while still meeting today's environmental standards.

Every funeral facility is different, which is why we take a custom approach to each installation. Whether you're running a single walk-in cooler or managing multiple refrigeration systems across a large facility, we'll work with you to design a solution that fits your specific needs and budget.

Think of R452A as your bridge to the future. While ultra-low GWP alternatives continue developing, you'll already be operating with significantly reduced environmental impact and full regulatory compliance. Plus, you'll have the peace of mind that comes from working with a refrigerant that's proven itself in thousands of installations nationwide.

For facilities ready to make the transition, proper maintenance becomes more important than ever. Our comprehensive guide on Maintaining and Cleaning Your Mortuary Cooler for Longevity provides the detailed information you need to protect your equipment investment and ensure reliable operation for years to come.

Ready to explore how R452A can work for your facility? Contact American Mortuary Coolers today. We'll evaluate your current setup, discuss your options, and create a transition plan that makes sense for your operations. With our direct delivery across all 48 contiguous states and our commitment to custom solutions, we're your one-stop partner for navigating the changing world of refrigeration technology.