Why Walk-In Fridge Sizing Matters for Every Commercial Operation

Walk in fridge sizes range from compact 6×6 foot units to massive 40×40 foot warehouses, with popular configurations being 8×8, 8×10, 10×10, and 10×12 feet.

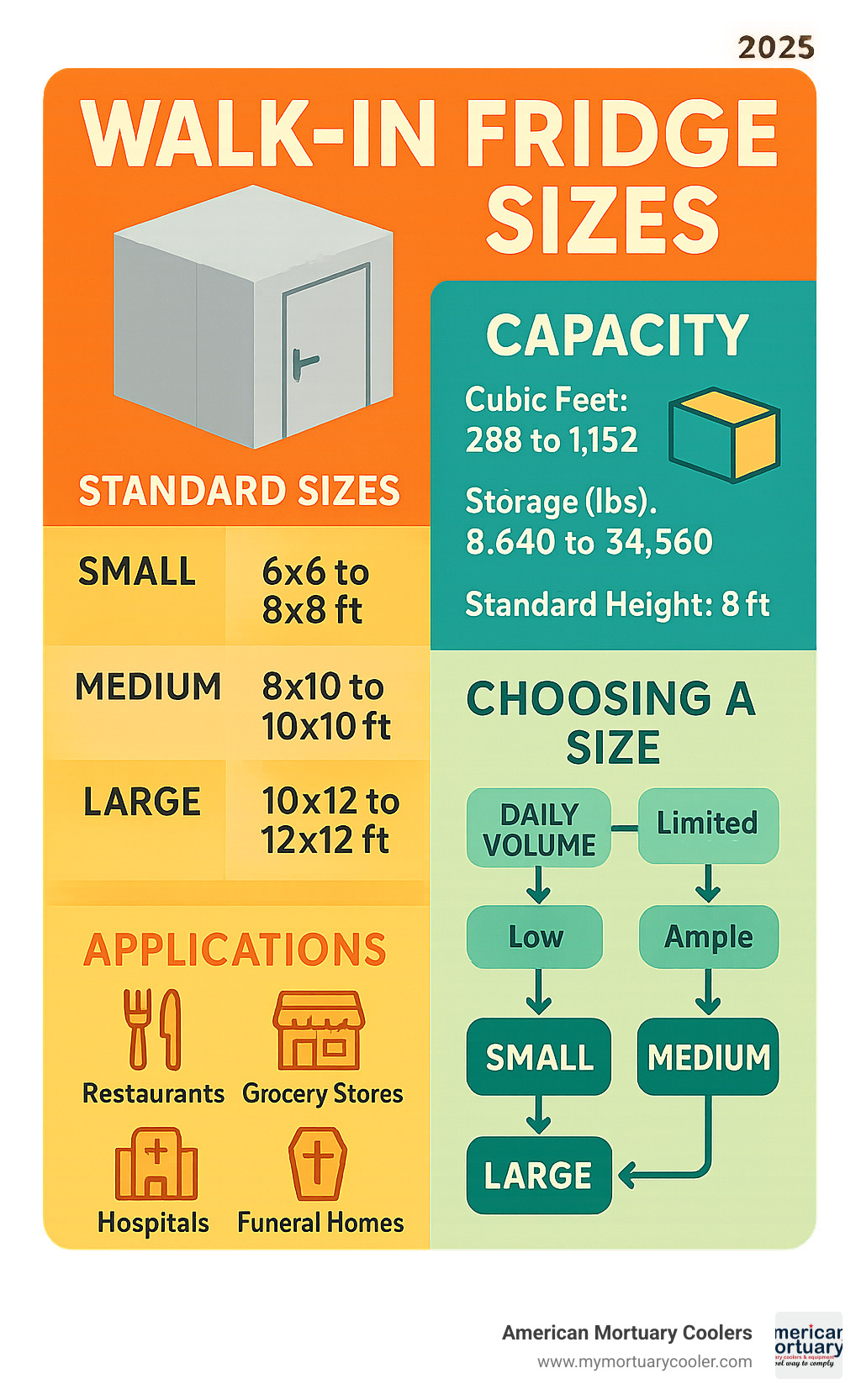

Standard Walk-In Fridge Sizes:

- Small: 6×6 to 8×8 feet (288-550 cubic feet)

- Medium: 8×10 to 10×10 feet (671-777 cubic feet)

- Large: 10×12 to 12×12 feet (777-918 cubic feet)

- Standard Height: 8 feet ceiling

- Storage Rule: 30 pounds of product per cubic foot

- Threshold: Consider walk-ins when you need 80+ cubic feet of cold storage

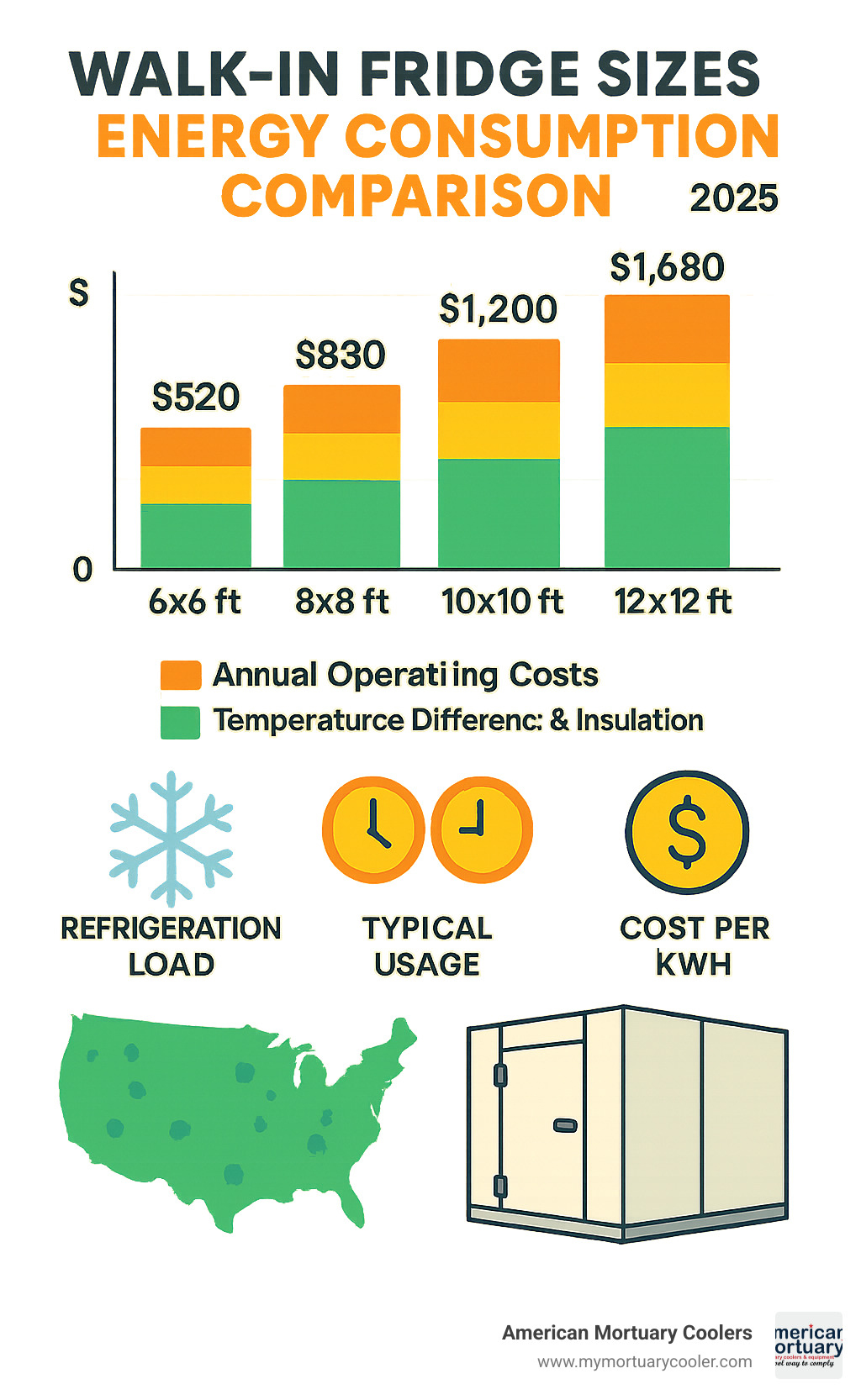

Getting the size wrong costs money. Too small risks product spoilage and lost inventory. Too large wastes energy heating empty space while consuming valuable floor real estate.

Walk-in refrigeration units serve critical roles across industries - from restaurants storing fresh ingredients to funeral homes maintaining dignity for families. The modular panel construction means you can customize dimensions to fit almost any space.

As Mortuary Cooler with years of experience helping businesses select the right walk in fridge sizes, I've seen how proper sizing directly impacts both operational efficiency and bottom-line costs.

Walk in fridge sizes terms made easy:

Who Needs This Guide?

Restaurants and Commercial Kitchens need walk-ins when serving more than 250 meals per day or requiring over 80 cubic feet of cold storage.

Florists require specialized temperature control for fresh flowers, often needing clear door panels for product display.

Breweries and Beverage Operations store large quantities of temperature-sensitive products, with many opting for 10×12 or larger units.

Healthcare Facilities including hospitals and clinics need reliable cold storage for medications and vaccines with strict temperature monitoring.

Funeral Homes represent a specialized market where American Mortuary Coolers has deep expertise, providing dignified storage solutions with precise temperature control across the contiguous 48 states.

What Is a Walk-In Fridge & Why Size Matters

A walk-in fridge is your own personal cold room. Unlike reach-in refrigerators where you stretch from outside, a walk-in lets you step inside to access what you need.

The capacity difference is dramatic. Typical reach-in refrigerators hold 20-30 cubic feet. Walk in fridge sizes start around 288 cubic feet for a small 6×6 unit and can grow to warehouse-sized spaces holding over 10,000 cubic feet.

Why does sizing matter?

Energy costs take a hit when you get sizing wrong. An oversized unit air conditions empty space all day. Go too small and your system works overtime, burning out equipment faster.

Workflow gets messy with poor sizing. Kitchen staff struggle in cramped walk-ins, while oversized units waste time with excessive walking distances.

Product safety becomes a concern when things get crowded. Pack too much into small spaces and you block airflow, creating warm spots where spoilage thrives. Federal food codes require commercial refrigeration to stay at 41°F or lower, with most operators targeting 38°F.

Core Components of a Walk-In

Insulated panels form the walls, ceiling, and sometimes floor. These modular panels are typically 4 inches thick with R-25 to R-32 insulation values. Those 4-inch panels reduce interior space by 8 inches on both length and width.

Doors come in widths from 26 to 48 inches. Glass doors let you see inventory without opening, while strip curtains help maintain temperature.

The condenser and evaporator make up your refrigeration system. Self-contained units mount directly on the walk-in, or choose remote setups where the condenser sits separately.

Flooring is optional but provides better temperature control and can handle heavy loads - typically rated for 1,200+ pounds per square foot.

Standard Walk-In Fridge Sizes & Capacity Calculations

Most commercial operations find success with standard dimensions that manufacturers keep in stock for quick delivery. The sweet spot falls between 6×6 feet for tight spaces and 12×12 feet for high-volume operations. Nearly all units come with 8-foot ceilings as standard.

Walk in fridge sizes are measured by exterior dimensions, but interior space matters for storage. Those insulated panels eat into usable area - typically 4 inches of wall thickness all around.

Compact units from 6×6 to 8×8 feet work for small cafés and specialty food stores. A 6×6×8 unit gives you 288 cubic feet - enough for about 8,640 pounds using the 30 pounds per cubic foot standard.

Medium-sized units between 8×10 and 10×10 feet handle most restaurant needs. An 8×10×8 unit stores over 20,000 pounds while fitting in most commercial spaces.

Large units from 10×12 to 12×12 feet serve high-volume kitchens and distribution operations, with storage capacity exceeding 30,000 pounds.

The 80 cubic feet threshold represents an important decision point. Below this capacity, multiple reach-in refrigerators often make more financial sense.

Walk in Fridge Sizes Chart

| Size (L×W×H) | Exterior Sq Ft | Interior Cubic Feet | Storage Capacity (lbs) | Typical Applications |

|---|---|---|---|---|

| 6×6×8 | 36 | 288 | 8,640 | Small cafés, specialty shops |

| 8×8×8 | 64 | 550 | 16,500 | Bars, medium restaurants |

| 8×10×8 | 80 | 671 | 20,130 | Busy restaurants, catering |

| 10×10×8 | 100 | 777 | 23,310 | High-volume kitchens |

| 10×12×8 | 120 | 918 | 27,540 | Large facilities, distribution |

| 12×12×8 | 144 | 1,118 | 33,540 | Warehouses, major operations |

The meal-count formula works well for restaurants: plan for 1 to 1.5 cubic feet per meal served daily.

How to Calculate Internal Capacity

Start with exterior dimensions: 8 feet long, 10 feet wide, 8 feet tall.

Subtract panel thickness from length and width. Standard 4-inch panels reduce each dimension by 8 inches total. Your 8×10 exterior becomes 7'4" × 9'4" interior.

Convert to decimal feet: 7.33 × 9.33 × 7.67 = 524 cubic feet of usable space.

Apply the storage density rule of 30 pounds per cubic foot: 524 × 30 = 15,720 pounds total capacity.

Build in a growth buffer of 10-15% additional capacity for business growth.

More info about Walk-In Cooler Sizes provides additional sizing details.

Choosing the Right Walk-In Fridge Size for Your Operation

Picking the perfect walk in fridge sizes balances your actual needs with space and budget constraints.

Start with storage needs assessment. For restaurants, use the meal-count formula: 1 to 1.5 cubic feet per meal served daily. A café serving 200 meals needs 200-300 cubic feet, pointing toward an 8×8 unit.

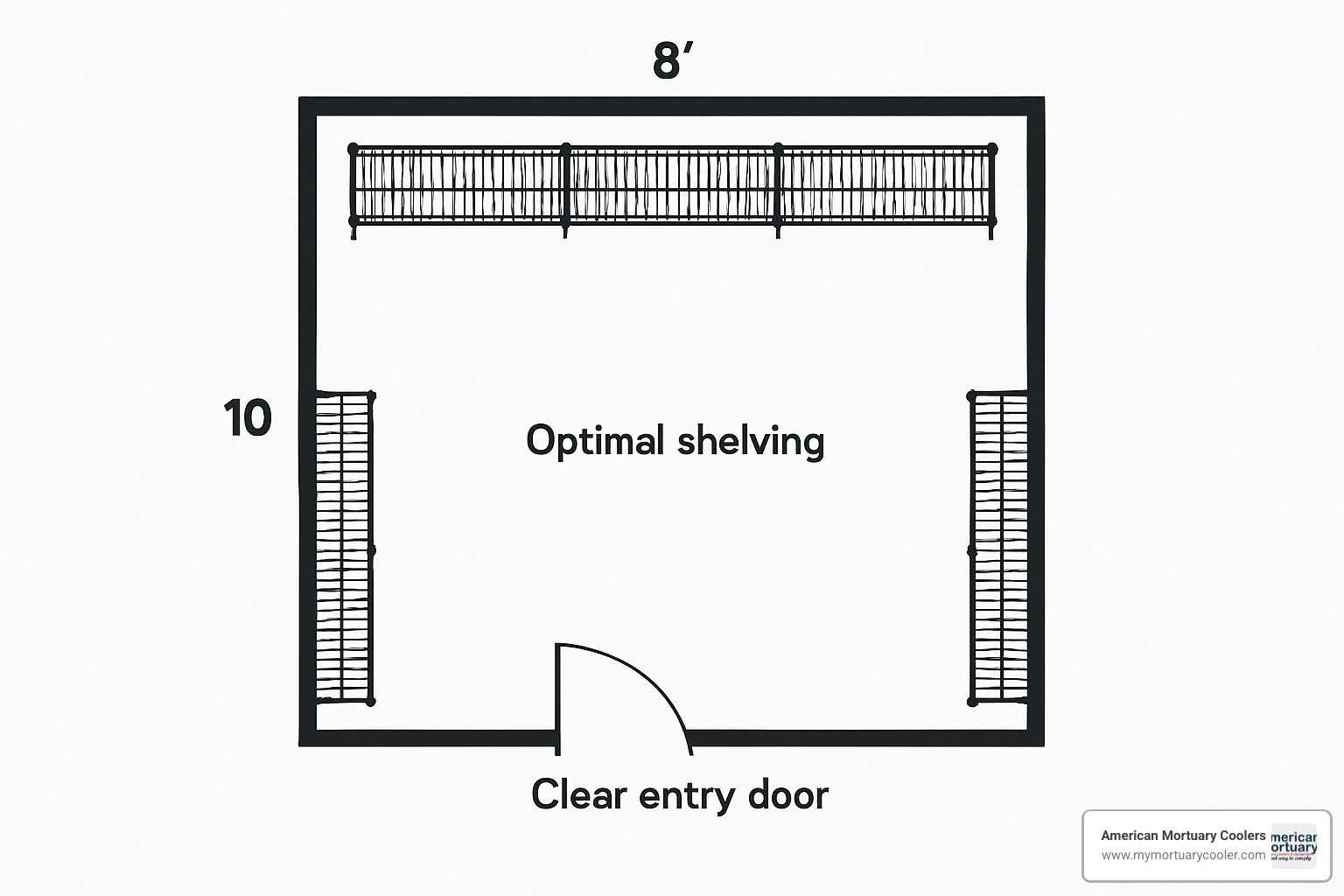

Available floor space requires careful measurement. Subtract several inches around all sides for ventilation and maintenance access. Don't forget door swing clearance.

Ceiling clearance needs consideration. Standard 8-foot walk-ins need additional height for refrigeration equipment. Self-contained systems need 2 feet of clearance above the unit.

Indoor versus outdoor placement offers trade-offs. Outdoor installation frees indoor space but requires weather protection and proper permitting.

Key Sizing Factors

Product load considerations vary between industries. Different products have varying storage densities and airflow requirements.

Ambient temperature affects system performance. Units near heat sources require additional refrigeration capacity.

Personnel traffic adds heat load with each door opening. High-traffic operations benefit from strip curtains and may need larger refrigeration systems.

Regulatory requirements can't be ignored. Food safety regulations and industry standards may dictate minimum capacities.

Walk in Fridge Sizes vs BTU Load

Refrigeration capacity gets measured in BTUH (British Thermal Units per Hour). For 35°F coolers, a 6×6×8 unit typically needs 4,986 BTUH under normal conditions, jumping to 6,540 BTUH for heavy-load applications.

Freezer applications at 0°F require different calculations. That same 6×6×8 unit needs 5,544 BTUH normally or 7,290 BTUH for heavy loads.

These calculations assume 4-inch urethane insulation and standard ambient conditions. For detailed load calculations, the Scientific research on refrigeration load provides comprehensive guidance.

Self-contained versus remote systems offer different advantages. Self-contained units simplify installation but require adequate clearance. Remote systems work better for space-constrained installations.

Design Details That Influence Usable Space & Efficiency

Getting walk in fridge sizes right is just the beginning. Design details make the difference between efficient operation and costly mistakes.

Ceiling heights offer your first decision point. While 8 feet is standard, you can choose 7½ to 10 feet. Taller isn't always better - 10-foot ceilings provide more storage but require more energy to cool the extra volume.

Shelving layout determines storage efficiency. Run shelving along perimeter walls with 40-inch center aisles for cart access. Never block evaporator fans with boxes or equipment.

Strip curtains cut energy consumption by 20-30% by keeping cold air from escaping during door openings.

Lighting has improved with LED systems that provide better visibility while producing less heat than old fluorescent fixtures.

Flooring options matter for heavy loads. Insulated floors improve temperature control and provide structural support for equipment.

Insulation ratings between R-25 and R-32 are standard. Higher R-values mean better efficiency but thicker panels and less interior space.

Indoor vs Outdoor Installations

Indoor installations keep cold storage protected and easily accessible. Leave 2 inches clearance around panels for ventilation, and 2 feet above for ceiling-mounted systems.

Outdoor installations free up indoor space and can improve condenser efficiency in cooler outdoor air. But they need extra protection:

- Vinyl roof shields panels from weather

- Rain hood prevents water infiltration

- Low-ambient kit for climates below 50°F

- Permitting requirements for outdoor mechanical equipment

For comprehensive dimensional guidance, check our More info about Everything You Need to Know About Walk-In Cooler Dimensions.

Common Pitfalls & Pro Tips

Here are costly mistakes I've seen companies make when choosing walk in fridge sizes:

Oversizing because "bigger is better" wastes energy cooling empty space. Stick to actual needs plus a 10-15% growth buffer.

Undersizing creates airflow problems and temperature inconsistencies. The 80 cubic feet threshold exists because that's where walk-ins become practical and economical.

Ignoring future growth costs more than sizing right initially. Think about where your business will be in a decade.

Forgetting service clearance makes maintenance expensive. Leave breathing room around your unit for technician access.

Cheap insulation costs more long-term. Polyurethane with R-32 values pays for itself through lower energy bills.

Maintenance planning is often overlooked. Regular coil cleaning and door seal inspections extend equipment life significantly.

Standard Size vs Custom Build

Standard sizes offer speed and value. Quick-ship models arrive in 2-10 days with proven performance and readily available parts.

Custom builds work when standard sizes won't fit your space or needs. They take longer and cost more but sometimes provide the only workable solution.

At American Mortuary Coolers, we specialize in custom solutions because funeral homes have unique requirements. Our Tennessee-based team crafts solutions with direct delivery across the contiguous 48 states.

Planning for Expansion

Panel add-ons work with existing installations if you plan initially. Leave space on one side where panels can be removed for extension.

Refrigeration planning can size initial systems for planned expansion or design for easy compressor upgrades later.

Modular shelving adapts as storage needs change without major modifications.

Frequently Asked Questions about Walk-In Fridge Sizes

What ceiling height should I pick and why?

The 8-foot ceiling is your sweet spot for most applications - it's like the Goldilocks of walk in fridge sizes. Not too short, not too tall, but just right for balancing storage capacity with energy efficiency.

Here's when you might want to go different directions. 7½-foot ceilings make sense when you're squeezed for space, maybe retrofitting an existing building where the ceiling height just won't cooperate. You'll lose about 6% of your storage capacity, but sometimes that's the hand you're dealt.

On the flip side, 9 to 10-foot ceilings can boost your storage by 12-25%, which sounds great until you realize your refrigeration system has to work harder to cool all that extra air space. It's like heating a bigger house - more space means higher utility bills.

The math is pretty straightforward: taller ceilings give you more storage but cost more to operate. If floor space is tight but you've got ceiling height to spare, it might be worth the trade-off. Just remember that your initial equipment costs will be higher too.

How much food fits in one cubic foot?

The magic number everyone uses is 30 pounds of food per cubic foot, assuming you're not just cramming everything in there like a college dorm room. This works when you've got proper shelving, reasonable walking space, and a mix of different products.

Some folks prefer the more conservative 28 pounds per cubic foot estimate, which gives you a little breathing room. Think of it as the difference between packing for a weekend trip versus a two-week vacation - you want some extra space.

Different products have their own personalities when it comes to storage density. Dense items like canned goods and beverages can pack in at 35-40 pounds per cubic foot - they're the overachievers of the storage world. Lightweight items like baked goods and produce are more like 15-25 pounds per cubic foot - they take up space but don't weigh much. Mixed inventory in a typical restaurant falls right in that 28-30 pound range.

The key is being realistic about what you're storing. If you're running a bakery, don't plan for maximum density. If you're storing cases of beverages, you might squeeze in more than the standard estimate.

Do temperature set-points affect the size I need?

Absolutely, and this is where things get interesting. Your temperature setting doesn't just affect how cold things get - it affects how hard your system works and potentially how much stuff you can actually store.

35°F coolers are your most energy-efficient option and work great for most fresh foods. They're like the reliable family sedan of refrigeration - they get the job done without breaking the bank on operating costs.

32°F coolers run closer to freezing, which is fantastic for products like fresh fish that benefit from those extra few degrees of cold. Just remember that your refrigeration system works a bit harder, and you need to be careful not to accidentally freeze sensitive items like lettuce.

0°F to -10°F freezers are a whole different animal. They require significantly more refrigeration power, different insulation specs, and sometimes even different panel construction. It's like comparing a bicycle to a motorcycle - they both get you places, but one requires a lot more power.

Here's something interesting: frozen foods often store more densely than fresh products, so you might actually need a smaller unit for the same weight of inventory. But that energy cost difference can be substantial, so factor that into your walk in fridge sizes decision from day one.

Conclusion

Getting your walk in fridge sizes right sets your business up for long-term success. The fundamentals are straightforward: start with the 30 pounds per cubic foot rule, remember walk-ins make sense above 80 cubic feet, account for panel thickness in calculations, plan for 10-15% growth, and match refrigeration capacity to your load requirements.

The upfront investment in proper sizing pays dividends through lower energy bills, reduced product loss, and smoother operations. Consider both initial cost and long-term operating expenses - that slightly larger unit might cost more today but save thousands in energy and replacement costs.

At American Mortuary Coolers, we've built our reputation understanding that one size doesn't fit all. Based in Tennessee, we craft custom cold storage solutions for funeral homes and specialized facilities across all 48 contiguous states. Funeral homes have unique requirements that standard units can't meet, which is why we specialize in custom solutions that fit your exact needs.

Don't let sizing mistakes cost you money through wasted energy, product spoilage, or premature equipment replacement. The difference between good and great decisions often comes down to expert advice before you buy.

For comprehensive sizing guidance and expert consultation, explore our More info about The Definitive Guide to Choosing the Right Walk-In Cooler Size.