Finding the Perfect Walk-In Cooler Size for Your Facility

Standard walk in cooler size options typically range from 6'x6' to 12'x12', with 8'x8', 8'x10', and 10'x10' being the most common configurations. Most units have a standard ceiling height of 8 feet, though 9 and 10-foot options are available for specialized needs.

| Walk-In Cooler Size | Cubic Storage | Approx. Capacity |

|---|---|---|

| 6'x6' (36 sq ft) | 288 cu ft | 8,640 lbs |

| 8'x8' (64 sq ft) | 550 cu ft | 16,500 lbs |

| 8'x10' (80 sq ft) | 671 cu ft | 20,130 lbs |

| 10'x10' (100 sq ft) | 800 cu ft | 24,000 lbs |

| 12'x12' (144 sq ft) | 918 cu ft | 27,540 lbs |

Selecting the right walk-in cooler size impacts operational efficiency, energy costs, and storage capacity. An undersized unit may lead to overcrowding and spoilage, while an oversized cooler wastes space and increases energy costs.

I'm Mortuary Cooler, a national-level mortuary cooler supplier helping clients determine the optimal walk in cooler size for their specific needs. My expertise has helped funeral homes across the country maximize efficiency while maintaining proper temperature control.

Walk in cooler size basics:

Understanding Standard Walk-In Cooler Size Options

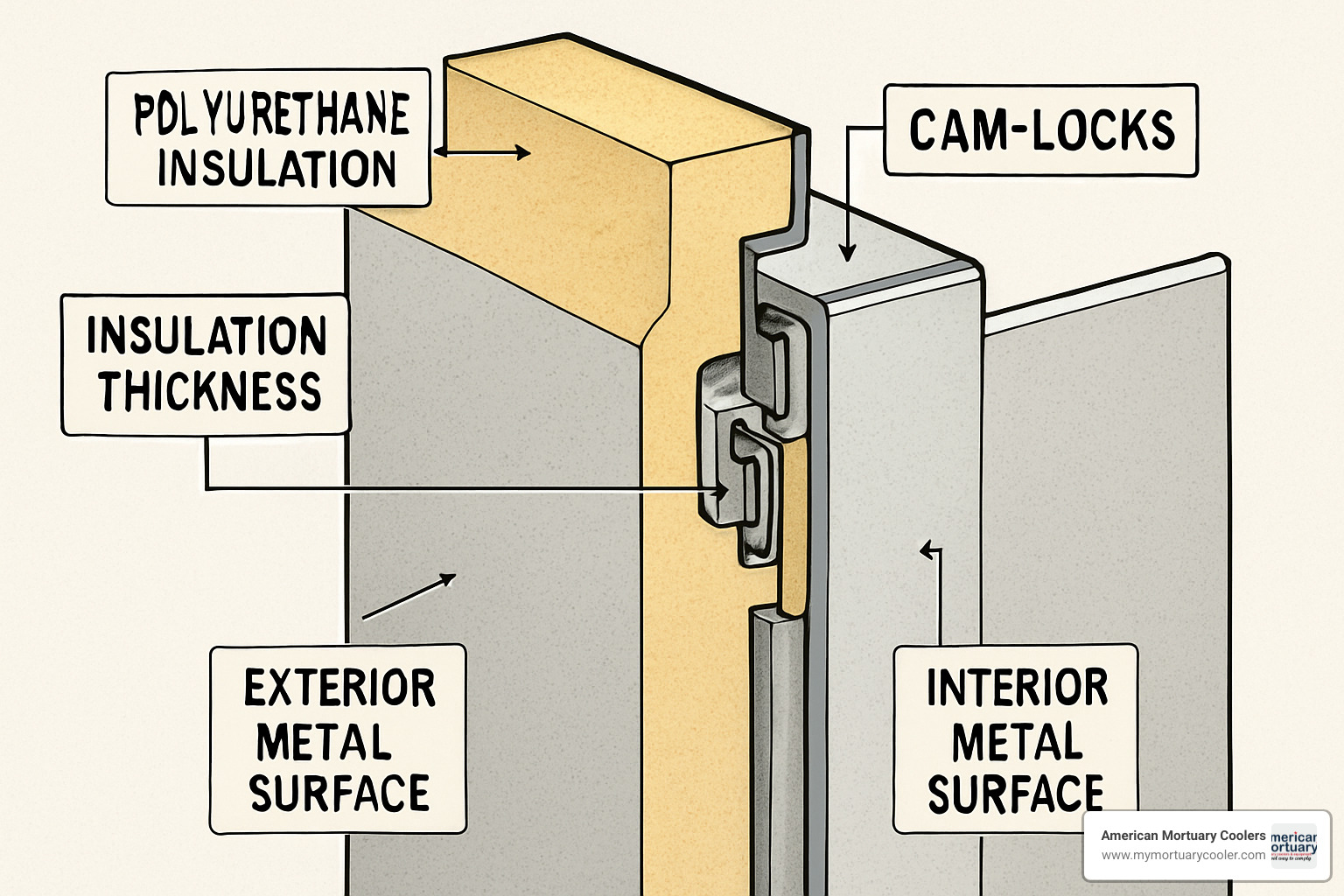

Walk-in coolers are built using modular insulated panels that connect with cam-locks to create a secure, airtight refrigerated space. This modular approach allows American Mortuary Coolers to customize units to fit your exact needs.

Walk in cooler size options typically follow industry standards:

- 6'x6': Perfect for smaller operations where space is at a premium

- 8'x8': Our most popular mid-range option, providing about 550 cubic feet of storage

- 8'x10': A slightly larger footprint offering 671 cubic feet

- 10'x10': A substantial unit delivering 800 cubic feet of storage

- 10'x12': Extended storage for facilities with higher volume requirements

- 12'x12': Our standard large-scale solution with 918 cubic feet of refrigerated space

While 8-foot ceilings are standard, many clients opt for 9 or 10-foot heights to maximize vertical storage. For specialized needs, we can create units with taller ceilings, though these require additional structural support.

Insulation thickness affects both performance and dimensions. Standard panels are 4 inches thick with an R-value of approximately 25.4. For superior energy efficiency, 5.5-inch panels boost that to an R-value of 38.

Our panels typically max out at 46 inches wide, balancing structural stability and ease of installation.

Common walk in cooler size chart

Understanding how footprint translates to storage capacity is crucial when selecting your walk in cooler size:

| Walk-In Size | Floor Area | Interior Volume | Storage Capacity | Typical Application |

|---|---|---|---|---|

| 6'x6'x8' | 36 sq ft | 288 cu ft | 8,640 lbs | Small café, boutique floral shop |

| 8'x8'x8' | 64 sq ft | 512 cu ft | 15,360 lbs | Medium restaurant, small funeral home |

| 8'x10'x8' | 80 sq ft | 640 cu ft | 19,200 lbs | Large restaurant, medium funeral home |

| 10'x10'x8' | 100 sq ft | 800 cu ft | 24,000 lbs | Commercial kitchen, large funeral home |

| 12'x12'x8' | 144 sq ft | 1,152 cu ft | 34,560 lbs | Large-scale food service, medical center |

A helpful rule of thumb: each cubic foot of cooler space can safely store approximately 28-30 pounds of product.

Your actual usable space will be somewhat less than the total interior volume due to air circulation needs, shelving systems, door clearance, and refrigeration units. We typically recommend adding a 40-50% buffer to your base requirements.

Relationship between panel height & storage

Height is often the unsung hero of walk-in cooler design. A 10'x10' cooler with a 10' ceiling instead of the standard 8' gives you an additional 200 cubic feet of storage—a 25% increase without taking up more floor space!

For funeral homes and mortuaries, taller ceilings provide necessary clearance for specialized equipment like body lifts and tiered storage systems.

If your operation uses material handling equipment, forklift access typically requires ceiling heights of 10-12 feet, while even manual pallet jacks need sufficient clearance.

Many clients maximize vertical space with mezzanine shelving systems. For walk-ins exceeding 12 feet in height, we integrate additional structural support into the panel system.

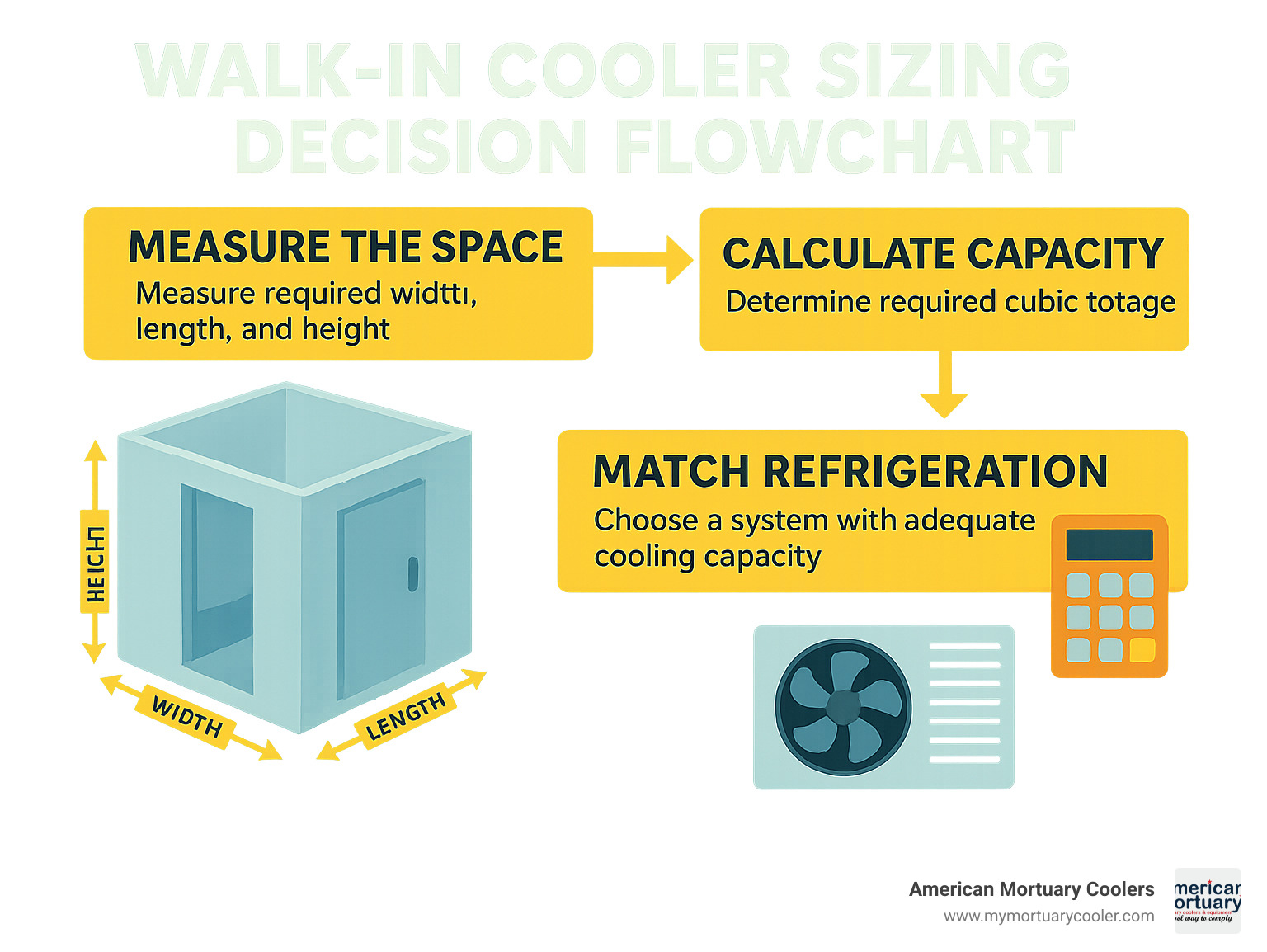

Calculating & Selecting Your Walk-In Cooler Size

Figuring out the right walk in cooler size can feel challenging, but I've developed a straightforward approach to make it easier.

For restaurants and food service, we recommend 1 to 1.5 cubic feet of cooler space per meal served daily. For funeral homes, plan for about 24-30 cubic feet per body with standard racking.

Once you have your basic volume needs, convert that to weight capacity. Each cubic foot of walk-in space safely stores about 28-30 pounds of product. So if you need to store 6,000 pounds, you'll need at least 200 cubic feet of space.

Always add an extra 40-50% capacity to your baseline to accommodate unexpected inventory surges, future growth, and proper air circulation. For our 200 cubic-foot example, we'd recommend closer to 300 cubic feet for optimal performance.

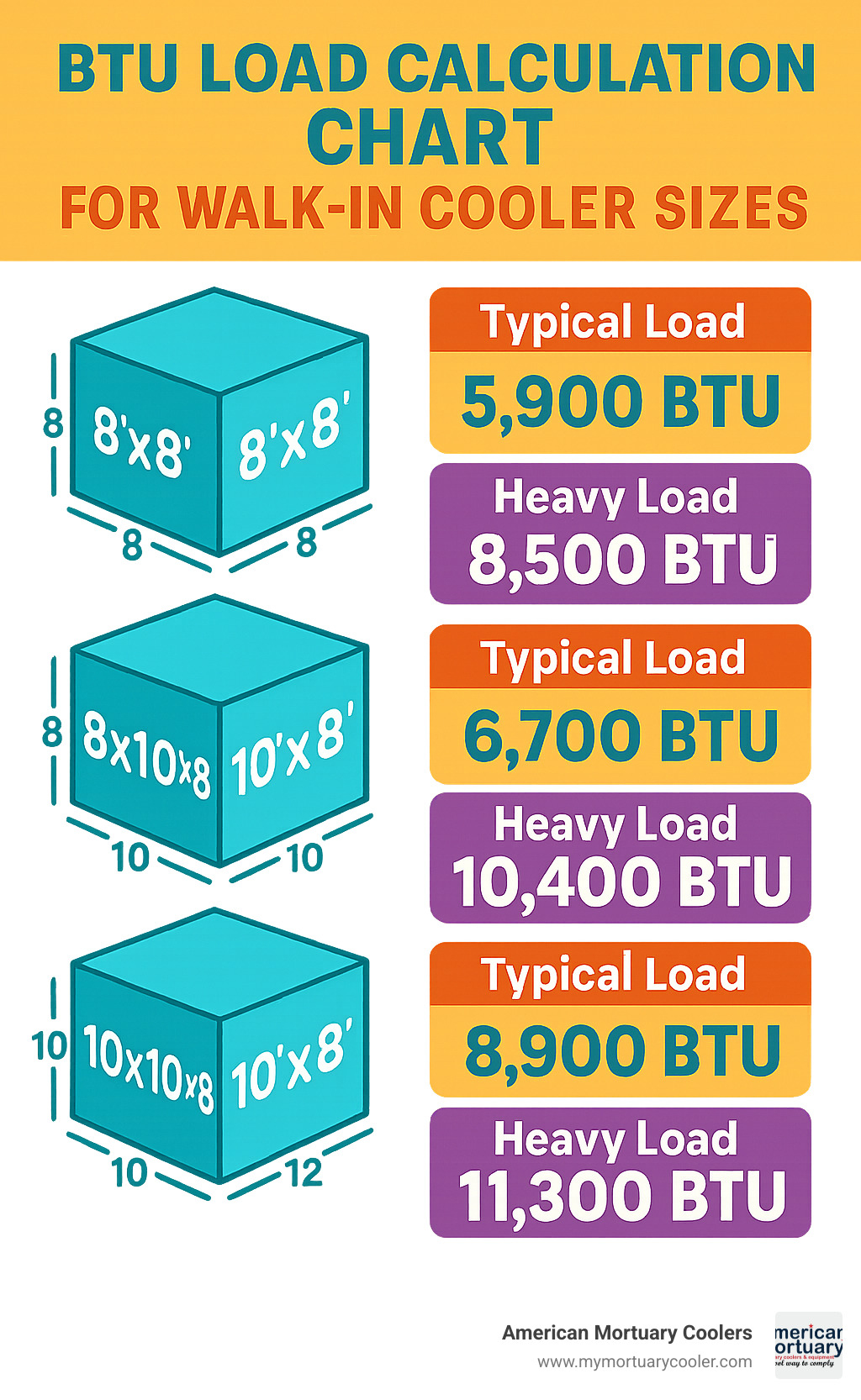

According to Heatcraft's calculations, an 8'x8'x8' cooler maintaining 35°F needs approximately 5,884 BTUH for typical usage or 7,470 BTUH for heavy-duty operations. A 10'x10'x8' cooler requires about 8,230 BTUH (typical) or 9,800 BTUH (heavy load).

Several factors affect refrigeration needs: ambient temperature, product temperature when loaded, door opening frequency, personnel access, and heat-generating equipment inside.

For more detailed guidance, check out our Beginners Guide to Walk-In Cooler Sizing Charts.

Balancing walk in cooler size with growth plans

When selecting the right walk in cooler size, consider your 10-15 year business outlook. Are you planning to expand services? Will you need to handle seasonal rushes? Might your inventory mix change?

Modular walk-in coolers can be disassembled and reconfigured with additional panels to increase size. However, your refrigeration system might need upgrading, expansion requires surrounding space, and reconfiguration causes operational downtime.

For clients with uncertain growth trajectories, we recommend purchasing a unit 10-15% larger than current needs, designing your layout with future expansion in mind, and considering an outdoor walk-in if indoor space is limited.

Standard-sized units (like 8'x10' or 10'x10') typically maintain better resale value than unusual custom dimensions.

Capacity to refrigeration match-up

Matching your walk in cooler size with the right refrigeration system is crucial. An undersized system won't maintain proper temperatures, while an oversized one wastes energy and causes temperature fluctuations.

Refrigeration capacity (measured in BTU/h) calculation involves several components:

- Box load: Heat gain through walls, ceiling, and floor

- Infiltration load: Heat gain from door openings and air exchanges

- Product load: Heat removal needed to cool incoming products

- Miscellaneous loads: Heat from lights, people, and equipment

For quick estimation, Heatcraft's BTUH chart provides reliable figures. Insulation quality significantly impacts refrigeration requirements. Every door opening allows warm, humid air to enter, making your system work harder.

For food storage, proper refrigeration sizing is critical for safety. According to scientific research on safe food storage from the FDA, perishable foods must be kept at 40°F or below to prevent harmful bacteria growth.

At American Mortuary Coolers, we provide detailed refrigeration sizing based on your specific installation parameters and usage patterns.

Factors, Energy & Cost Considerations

When selecting the right walk in cooler size, consider both initial purchase and ongoing energy costs.

Most facilities have physical limitations that determine what size cooler you can fit. At American Mortuary Coolers, we work with you to maximize whatever space you have—even with unusual layouts or awkward corners.

If indoor space is tight, outdoor walk-ins can be an excellent solution, though they'll need additional features like vinyl roofing, rain hoods, and low-ambient kits for colder climates.

Your budget naturally plays a role too. While larger units cost more upfront, they often provide better value per cubic foot of storage. Currently, our standard 8'x8' to 8'x12' units typically range from $6,500-$9,700, with shipping included throughout the contiguous 48 states.

Energy efficiency is where size really impacts long-term costs. With commercial electricity averaging about 13.04 cents per kilowatt-hour, the difference between an efficient and inefficient cooler can mean thousands of dollars over its lifetime.

Insulation thickness makes a significant difference. Standard 4-inch panels give you an R-value of approximately 25.4, while 5.5-inch panels boost that to an R-value of 38. Thicker panels slightly reduce interior space and cost more initially but can dramatically cut energy bills.

Your compressor needs to be properly matched to your walk in cooler size. For example, a 10'x10' cooler with an 8-foot ceiling typically needs a refrigeration system capable of 8,230 BTU for typical use or 9,800 BTU for heavy use when maintaining 35°F.

Most quality walk-ins come with solid warranty protection—typically up to 20 years on panels, with shorter coverage for doors (5 years), compressors (5 years), and parts/labor (1 year).

For more about pricing factors, check our article on Decoding Walk-In Cooler Pricing Factors.

Walk in cooler size vs. operating cost

The relationship between walk in cooler size and monthly bills isn't straightforward. Finding the sweet spot is crucial for your bottom line.

An oversized cooler means higher purchase price, wasted energy cooling empty space, more heat transfer from outside, and wasted floor space.

An undersized cooler leads to insufficient storage, inventory losses, restricted airflow reducing efficiency, and more frequent door openings letting warm air in.

The most efficient walk-in cooler is properly sized for your actual needs. When sized correctly, the refrigeration system runs in optimal cycles, products are stored with adequate air circulation, and door openings are minimized.

Since 2020, all commercial refrigeration equipment must meet stricter Department of Energy (DOE) efficiency standards. Check with your local utility company about possible rebates for energy-efficient commercial refrigeration.

Insulation & door technology

Insulation and door technology directly impact performance and operating costs, regardless of your chosen walk in cooler size.

Most walk-in coolers come with 4-inch thick panels (R-value of approximately 25.4). For facilities with extreme conditions or those looking to minimize energy consumption, 5.5-inch panels deliver an R-value of around 38.

Quality walk-in coolers use foamed-in-place polyurethane, creating a continuous insulation barrier without thermal bridges. The panels connect with cam-locks that ensure tight connections, preventing air leakage.

The door is the most vulnerable point for temperature loss. Modern units feature magnetic door gaskets, heavy-duty triple-hinge assemblies, self-closing mechanisms, and PVC strip curtains to minimize air exchange.

Energy-saving features include vapor-proof LED lighting, digital temperature displays, and door heaters with smart controllers. At American Mortuary Coolers, we include free PVC strip curtains and vapor-proof LED lighting as standard features on all our units.

Design, Installation & Future-Proofing Strategies

Finding the perfect walk in cooler size is just the beginning—how you design and install your unit affects its functionality and longevity.

Position your cooler to minimize the distance between receiving areas and the cooler. Strategic door placement creates natural product flow, and multiple access points can reduce bottlenecks during peak times.

Inside your cooler, thoughtful shelving layout transforms the same cubic footage into more usable space. Maintain at least a 40-inch center aisle to prevent bottlenecks when staff need to pass each other.

During installation, leave 2-3 inches of ventilation space around panels and ensure adequate ceiling clearance for refrigeration components. Don't overlook drainage planning to prevent moisture-related problems.

For flooring, our standard insulated aluminum floors support up to 1,200 pounds of distributed weight. For facilities using carts or forklifts, heavy-duty flooring provides necessary support. Some customers prefer floorless installation utilizing existing concrete with a proper vapor barrier.

Your refrigeration system choice matters too. Remote systems place the condenser away from the cooler, reducing noise and heat. Self-contained systems integrate all components for simpler installation. For critical applications like mortuaries, multiple systems provide valuable redundancy.

Outdoor installations require weather-resistant packages including vinyl roofs and rain hoods. For colder climates, low-ambient kits ensure reliable operation even in freezing temperatures.

The modular design means your cooler can grow with your business or relocate if needed.

For more detailed guidance, check out our article on How to Master Walk-In Cooler Design in 5 Simple Steps.

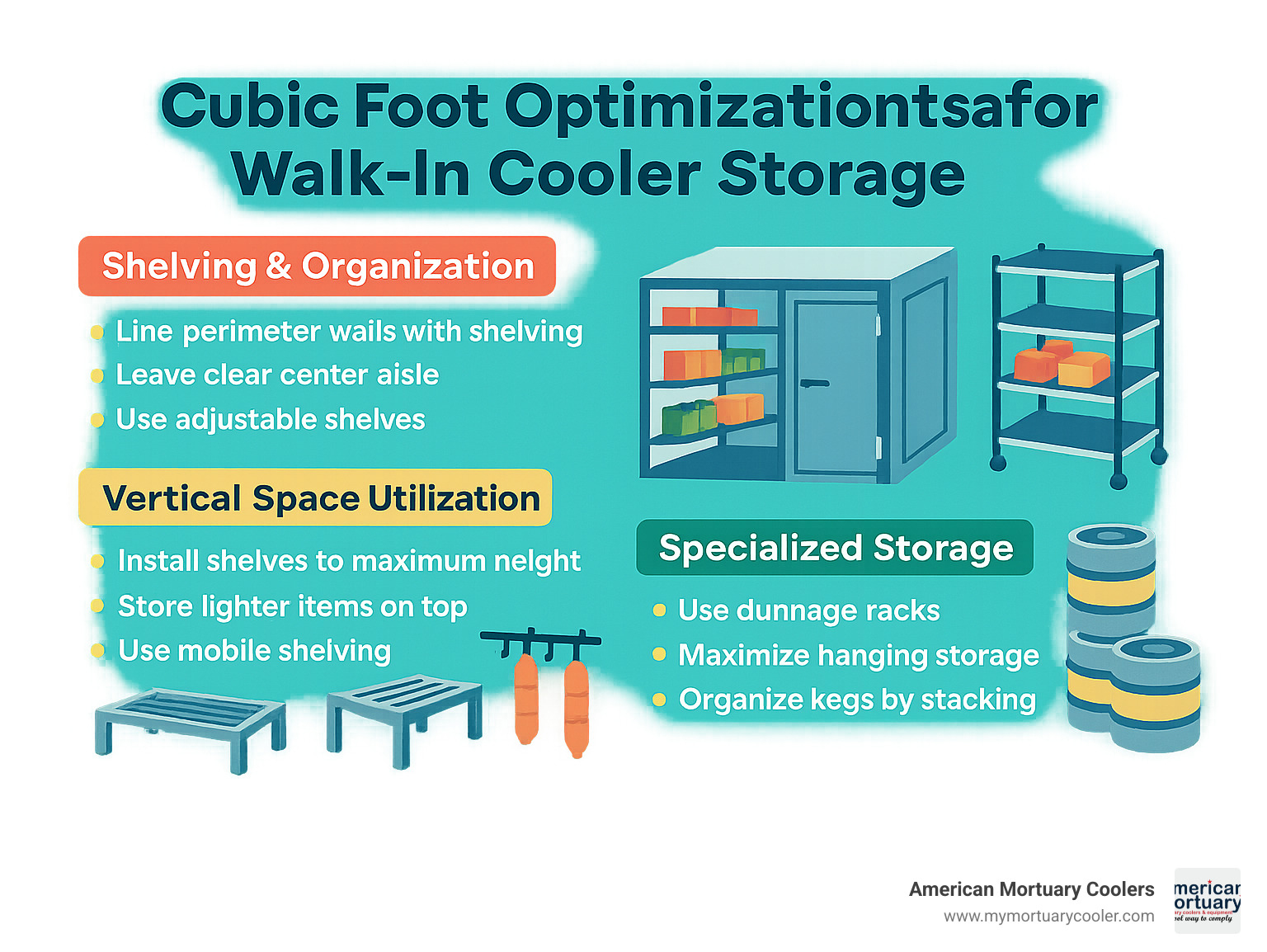

Shelving & organization hacks

The walk in cooler size you choose sets the outer limits of your storage capacity—but smart organization inside can dramatically increase how much you actually store.

Edge shelving maximizes storage capacity by lining the perimeter walls while keeping the center clear. Shelving depth should match your products—typically 18-24 inches works well. Keep the center aisle at least 40 inches wide for staff to comfortably pass.

Don't waste valuable upper space. Well-designed shelving can safely use space up to 6-7 feet. Place frequently accessed items at waist to shoulder height, with lighter, less frequently used items on top shelves.

Specialized storage solutions include dunnage racks keeping products 6-12 inches off the floor, wall-mounted brackets for hanging items, and specialized organizers for beverages. In mortuary applications, body racks with slide-out trays make access dignified and efficient.

Maintain proper airflow by never blocking evaporator fans or refrigeration components. Keep 2-3 inches of clearance between walls and stored items. Wire shelving often outperforms solid shelves by allowing air to flow between levels.

Clear labeling and thoughtful organization save time and reduce door-open periods. Implement systems that group similar items together, use first-in, first-out rotation, and consider color-coding for different product categories.

With these organization strategies, many clients effectively increase usable storage by 25-30% without changing their cooler's footprint.

Planning for future add-ons

Today's perfect walk in cooler size might not meet tomorrow's needs. Smart planning now can save you thousands later when your business grows.

Our prefabricated knock-down panels can be disassembled and reconfigured to create larger spaces. Plan your initial placement with at least one wall accessible for future extension. Your refrigeration system should have some growth capacity built in or be upgradeable.

If floor space is limited, consider vertical improvements. Mezzanine shelving systems can dramatically increase storage density in the same footprint. This is why we often recommend 9-10 foot ceiling heights even when current needs don't require it.

Functional upgrades can transform existing space. Glass display doors can be retrofitted to standard walk-ins. Additional access doors can improve workflow. Even specialized flooring can be installed if load requirements change.

Technology integration represents another avenue for improvement. Temperature monitoring systems, inventory management technology, energy management controls, and remote monitoring capabilities can all be added to existing coolers.

Your refrigeration system offers upgrade opportunities. Redundant systems provide security for critical applications like mortuaries. Variable speed compressors improve efficiency compared to older models.

Practical steps for future-proofing include documenting panel configurations, preserving extra floor space around at least one exterior wall, slightly oversizing electrical service, and considering a refrigeration system with extra capacity.

Frequently Asked Questions about Walk-In Cooler Size

How do I convert menu volume into required cubic feet?

For food service operations, start with your busiest day. Count how many meals you serve and multiply by 1-1.5 cubic feet per meal. For 300 meals, you'd need about 450 cubic feet of cold storage space.

Always add an extra 40-50% for unexpected orders, holiday rushes, or delivery timing issues. Taking our 450 cubic feet and adding that buffer gives us 630 cubic feet.

For shelving calculations, determine how many linear feet of shelving you need, then multiply by shelf depth (usually 18-24 inches) to get shelf square footage. Double this figure to account for aisles.

For example, 60 linear feet of shelving that's 2 feet deep equals 120 square feet of shelf space. Double it for aisles and you need 240 square feet of floor area. With a standard 8-foot ceiling, that translates to about a 6'×5' cooler footprint.

What refrigeration capacity matches my box?

For quick estimates, the Heatcraft chart shows that an 8'×8'×8' cooler maintaining 35°F typically needs about 5,884 BTUH under standard conditions, or 7,470 BTUH under heavy usage. A 10'×10'×8' cooler needs around 8,230 BTUH (standard) or 9,800 BTUH (heavy load).

Use "heavy load" calculations for glass display doors, frequent door openings, ambient temperatures above 90°F, or when regularly loading warm products.

The full calculation considers room dimensions and desired temperature, insulation quality, door opening frequency, product temperature when loaded, and additional heat sources.

At American Mortuary Coolers, we run these calculations based on your specific situation. It's better to slightly oversize your refrigeration (by 10-15%) for a safety buffer, but going too much bigger can cause problems with system cycling.

Does a taller walk-in increase energy use?

While a taller walk in cooler size does increase energy consumption, the difference is often smaller than expected.

Taller walls mean more surface area for heat transfer, more air volume to cool initially, and potentially more warm air entering through taller doors. Without proper circulation, warm air tends to rise and collect at the top.

However, good insulation dramatically reduces heat transfer through extra wall surfaces. Most energy use comes from maintaining temperature during operation, not the initial cooldown. Well-designed air circulation systems prevent temperature stratification.

A well-designed 8'×8'×10' cooler will use only slightly more energy than an 8'×8'×8' unit with the same insulation and usage patterns. But you're getting 25% more storage space with that extra height—often worth the marginal energy increase.

For mortuary clients, taller units can improve overall efficiency by allowing better organization and reducing door opening frequency, often offsetting the slight increase in energy use.

Conclusion

Choosing the right walk in cooler size is like finding the perfect fit—not too big, not too small, but just right for your specific needs. After guiding countless funeral homes through this process, I've seen how the right dimensions transform operations while the wrong choice leads to frustration.

Most facilities find their perfect match within standard configurations: the compact 6'x6', versatile 8'x8' or 8'x10', or spacious 10'x10' or 12'x12'. When standard won't do, we create custom solutions for unique spaces.

Trust the math when calculating capacity. The 1–1.5 cubic feet per meal guideline for restaurants or the 28–30 pounds per cubic foot rule serves as your foundation. Always add that crucial 40–50% overflow capacity—I've never met a facility owner who regretted having extra space.

Your refrigeration system and cooler size must work in harmony. The BTU/h calculations ensure your system matches your specific dimensions and usage patterns.

When space is limited, vertical expansion offers tremendous value. Taller units with 9 or 10-foot ceilings increase capacity without claiming additional floor space.

The most successful installations share one trait: forward thinking. Positioning your cooler with at least one wall accessible for future growth protects your investment for years to come.

Don't underestimate the power of thoughtful organization. With strategic shelving and smart layout design, many clients effectively increase usable storage by 25-30% without changing external dimensions.

Here at American Mortuary Coolers, we understand the unique requirements of funeral homes and mortuaries across America. From our Tennessee manufacturing facility, we craft durable, high-quality units that arrive directly at your doorstep anywhere in the contiguous 48 states.

We know that proper temperature control isn't just about efficiency—it's about dignity and care during life's most sensitive moments. That's why our walk-in coolers are designed specifically to meet the exacting requirements of funeral professionals.

For more insights, explore our comprehensive resource: The Ultimate Guide to Choosing a Walk-In Mortuary Cooler.

When you're ready to discuss your specific needs, our team at American Mortuary Coolers is here to help with every step from initial sizing calculations through installation and beyond.