Why Quick Drinking Fountain Repair Matters for Your Facility

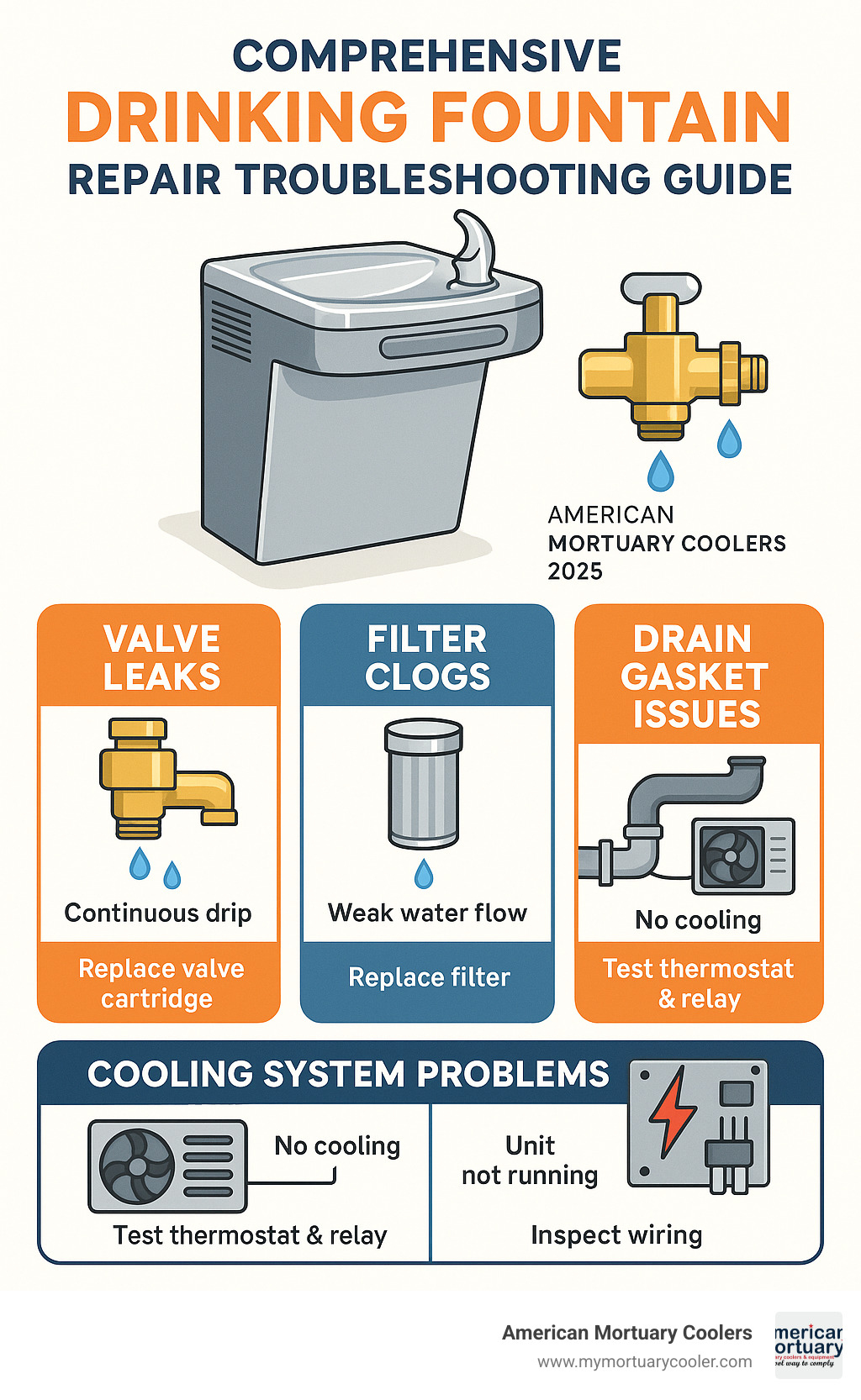

Drinking fountain repair becomes critical when your facility's hydration stations fail, affecting staff productivity and visitor satisfaction. The most common issues include continuous water flow from worn valves, internal leaks at drain gaskets or cooling tanks, low water pressure from clogged filters, and cooling system failures.

Quick Diagnosis Checklist:

- Continuous drip from spout = Replace valve cartridge

- Internal water pooling = Check drain gasket, cooling tank, or push-in fittings

- Weak water flow = Clean strainer screen or replace filter

- No cooling = Test thermostat, overload, and relay for continuity

- Bad taste/odor = Replace filter (every 6 months minimum)

Most drinking fountain problems stem from just a few key components. Research shows that filter cartridges should be changed at least every six months, while daily cleaning of the mouthpiece and protective guard prevents contamination.

The good news? Many repairs are surprisingly simple DIY fixes. Basic maintenance like cleaning the bubbler orifice every few days and vacuuming condenser fins can prevent costly breakdowns. However, refrigeration issues, electrical problems, or continuous leaks require professional attention.

Drinking fountain repair further reading:

Most Common Drinking Fountain Problems & How to Diagnose Them

Drinking fountain repair calls usually fall into predictable patterns. Whether you're dealing with a stubborn leak or mysterious taste issues, understanding these common problems can save you time and frustration.

Continuous water dripping from the spout typically means your valve cartridge has given up. Internal water pooling around the base usually points to drain gasket problems or loose push-in fittings. When you're getting weak water flow, the culprit is almost always a clogged strainer or tired filter.

Cooling system troubles can range from simple thermostat adjustments to more serious compressor issues. And if users are complaining about bad taste or funky odors, your filter is probably past its prime - filters should be swapped out every six months, minimum.

Before you start any repair work, find your fountain's model number. Look on the bottom panel or inside the unit for something like "EZS81" - those letters and numbers are your key to ordering the right parts later.

Identifying a Leak Source

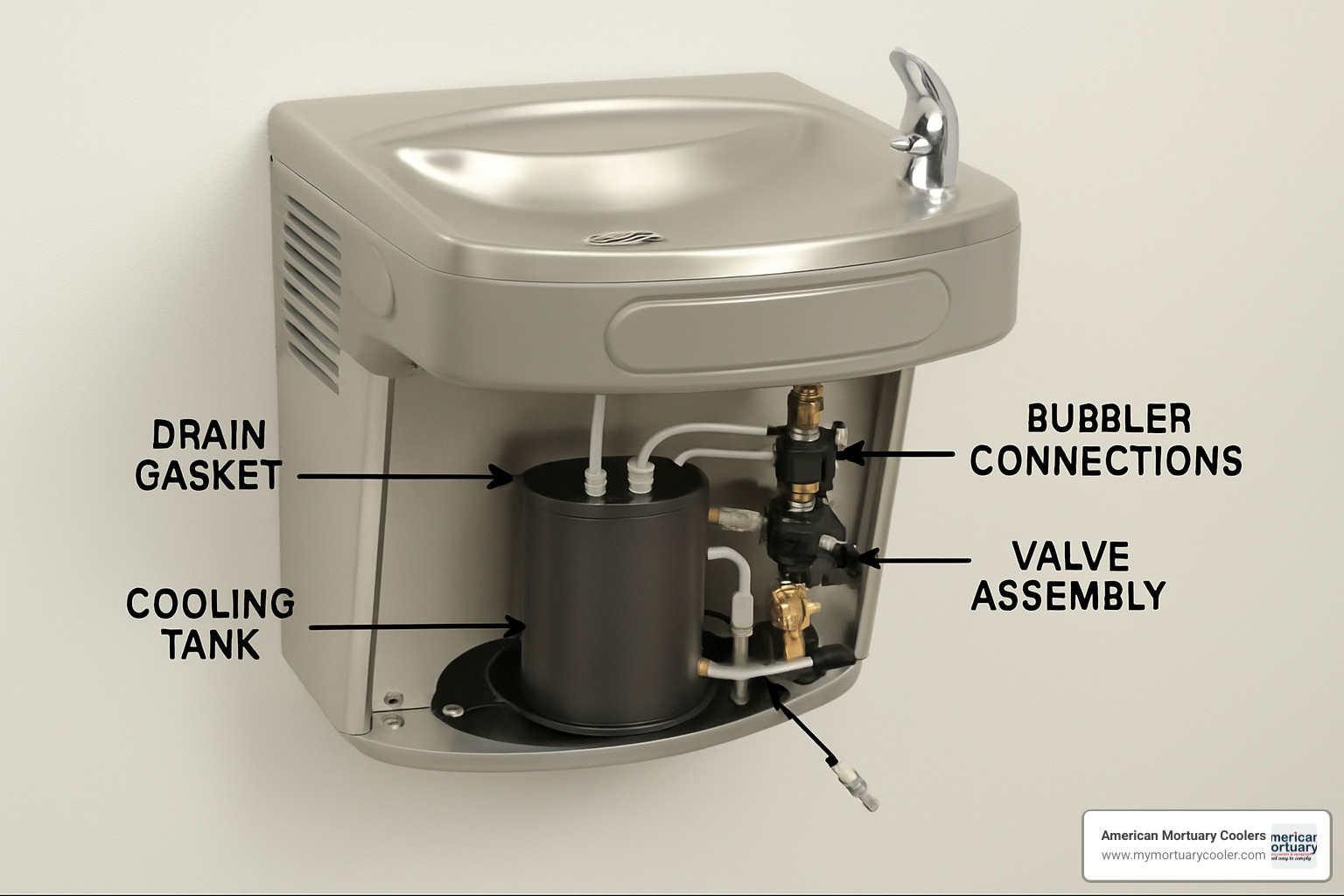

Internal leaks can be tricky because water has a sneaky way of traveling before it becomes visible. The trick is playing detective to find where the water is actually starting its journey.

The drain gasket is usually suspect number one. This rubber seal sits where your basin connects to the drain assembly. If you're seeing water pooling directly under the unit or notice staining on the wall behind a wall-mounted fountain, the drain gasket is likely your troublemaker.

Push-in fittings are another common leak source, especially if your fountain lives in a high-traffic area with lots of vibration. These quick-connect fittings can work loose over time.

Cooling tank leaks are more serious business. If water is showing up inside the unit's housing or the refrigeration system is acting weird, you might have an internal tank problem. This usually calls for professional help.

Here's a simple trick: the paper towel test. Dry everything completely, then place paper towels around any suspicious areas. Check back after 30 minutes of normal use. The wet towels will show you exactly where that pesky leak is coming from.

Troubleshoot Low Water Flow

Nothing frustrates users more than a weak, pathetic water stream. The good news is that low flow problems usually have straightforward solutions if you work through them systematically.

Start with the strainer screen - it's the easiest fix and solves about 60% of flow problems. This little screen catches debris before it can gum up internal components. Pop it out, give it a good cleaning, and see if that does the trick.

If the strainer looks fine, check your filter next. A clogged filter is the second most common flow killer. Filters need replacing every six months minimum - more often if you're in a busy facility.

The regulator spring controls your water pressure and flow rate. When this component wears out or gets knocked out of adjustment, it can really throttle your flow. This one requires some finesse - if you're not comfortable working with pressure regulation, it's worth calling in a pro.

Scientific research on water-flow ergonomics shows that proper flow rates aren't just about user satisfaction - they're important for hygiene too.

Water Quality Issues – Taste & Odor

When users start complaining about funky-tasting water, it's usually your fountain's way of asking for some attention.

Filter age is the most common culprit. Even if your filter doesn't look dirty, it loses effectiveness over time. Swap out any filter that's been in service for more than six months, regardless of how it looks.

Biofilm can develop in stagnant water lines, creating that unpleasant musty or metallic taste users hate. This nasty stuff requires proper line flushing and sanitization.

With growing PFAS concerns, many facilities are upgrading to advanced filtration systems. Modern options like Elkay's WaterSentry PFOA/PFOS filters tackle these emerging contaminants.

For routine cleaning, stick with sanitizing tablets designed specifically for drinking water systems. Never be tempted to use household cleaners or bleach - they can create dangerous chemical reactions.

DIY Drinking Fountain Repair: Step-by-Step Fixes

Rolling up your sleeves for drinking fountain repair doesn't have to be intimidating. Most fountain problems boil down to a few common issues that you can tackle with basic tools and a methodical approach.

Safety comes first, always. Before touching anything, disconnect the power and shut off the water supply. Grab your safety glasses and work gloves before you start, and keep a non-contact voltage tester handy to double-check that power is truly off.

Your basic tool arsenal should include an adjustable wrench set, Phillips and flathead screwdrivers, needle-nose pliers, and tubing cutters. A multimeter helps with electrical testing, while plumber's tape prevents leaks on threaded connections.

Smart facilities keep common replacement parts on hand: bubbler cartridge repair kits, drain gaskets, push-in fittings, water filters, and valve assemblies. Having these parts ready means you can fix problems immediately instead of waiting for deliveries.

| Repair Type | DIY Cost | Professional Cost | Time Required |

|---|---|---|---|

| Filter Replacement | $15-30 | $75-120 | 15 minutes |

| Bubbler Cartridge | $25-45 | $100-150 | 30 minutes |

| Drain Gasket | $10-20 | $80-130 | 45 minutes |

| Valve Assembly | $40-80 | $150-250 | 60 minutes |

| Cooling System | N/A | $200-500 | 2-4 hours |

Drinking Fountain Repair for Leaks: Parts & Tools

Drinking fountain repair for leaks requires detective work first, then surgical precision. Start with the usual suspects - they cause most headaches.

Gasket kit replacement tops our repair list because these rubber seals take a beating from constant water exposure. When swapping out a drain gasket, clean all the mating surfaces until they're spotless. Apply a thin layer of plumber's silicone for that perfect seal, then tighten the bolts evenly.

Valve cartridge swaps fix those annoying continuous drips that drive everyone crazy. Most cartridges twist out like oversized light bulbs. The trick is matching the part number exactly.

Tubing repairs demand the right tools. Invest in proper tubing cutters for clean, square cuts. When installing push-in fittings, push that tubing all the way in until you hear it click.

Plumber's tape application has a secret: wrap clockwise when viewing from the thread end. Use 2-3 layers - more creates bulk that prevents proper fitting, less allows leaks.

Drinking Fountain Repair for Low Flow & Pressure

Drinking fountain repair for flow problems follows a logical path from simple to complex. Start easy and work your way up.

Cleaning the strainer solves more flow problems than any other single fix. Remove that screen and rinse it under running water, using a soft brush for stubborn debris. Resist the urge to use sharp objects - one puncture ruins the whole screen.

Filter replacement comes next if the strainer looks good. Modern twist-in cartridges make this job almost foolproof - counterclockwise removes, clockwise installs. Some filters need priming, so run water for 2-3 minutes to purge air bubbles.

Regulator adjustment requires a gentle touch. That regulator screw controls your water pressure and flow rate, but it's sensitive. Make tiny adjustments - maximum 1/4 turn at a time - then test the results.

Flow testing tells you when you've got it right. The perfect stream arcs about 4 inches from the fountain and returns cleanly to the drain.

More info about preventive maintenance can help you avoid these issues entirely.

Quick Filter Replacement & Reset

Modern drinking fountains use twist-in filter cartridges that make maintenance almost enjoyable.

Shut off the water supply first. Locate the filter housing behind an access panel, then turn the old cartridge counterclockwise about 1/4 turn until it releases. Remove and dispose of the old filter according to your local guidelines.

Installing the new cartridge reverses the process - turn clockwise until hand-tight. Don't overtighten. Restore water supply and run it for 2-3 minutes to flush out air bubbles.

Reset the filter monitor if your fountain has one. Each manufacturer has different procedures, so check your owner's manual for the exact button sequence.

Disposal guidelines are straightforward for most filters. Standard activated carbon cartridges go in regular waste, but specialty filters might need special handling.

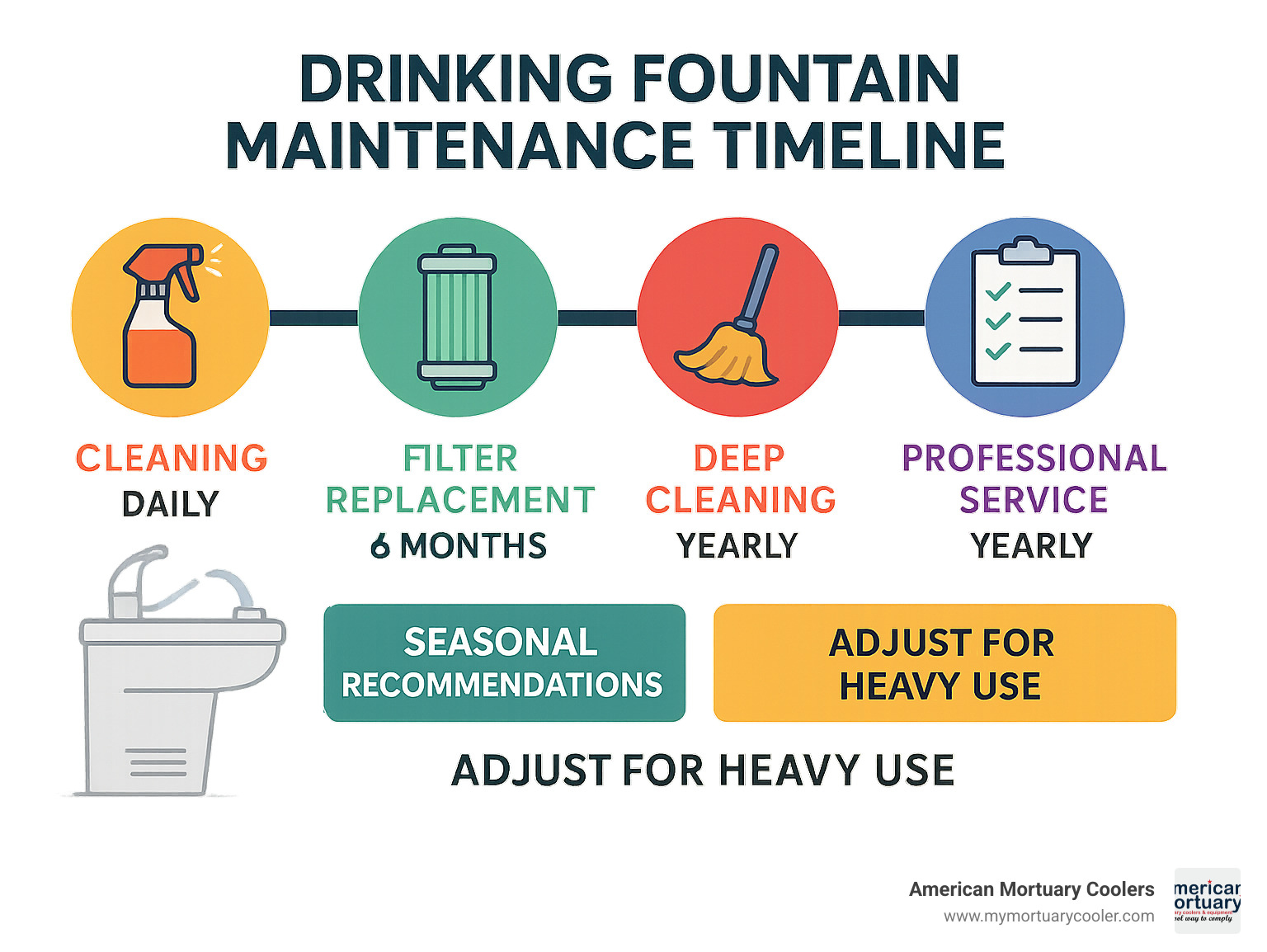

Preventive Maintenance & Cleaning Schedule

Think of drinking fountain repair like car maintenance - a little attention now prevents big problems later. Most fountain failures happen because someone skipped the basics.

Daily cleaning takes just two minutes but makes the biggest difference. Clean that mouthpiece and protective guard with disinfectant every single day. While you're there, take a quick look for obvious leaks and test the water flow and temperature.

Weekly tasks bump up to about ten minutes but catch problems before they become expensive. Wipe down the entire unit with disinfectant, paying attention to corners where grime loves to hide. Check that the water stream arcs properly - it should peak about four inches out and return cleanly to the drain.

Monthly maintenance takes about thirty minutes but protects your investment. Those condenser fins and exhaust louvers collect dust like magnets, and dirty coils work harder and fail sooner. A quick vacuum keeps everything running efficiently.

The big six-month service takes about two hours but prevents most emergency calls. Replace that filter cartridge even if it looks clean - filters lose effectiveness over time. Deep clean everything, flush the water lines, and give the refrigeration system a thorough inspection.

Daily & Weekly Tasks

Mouthpiece sanitization isn't negotiable - it's your first line of defense against disease transmission. Use EPA-approved disinfectants designed specifically for drinking water contact surfaces. The key is following the contact time on the label, then rinsing thoroughly.

Basin cleaning prevents bigger headaches down the road. Those mineral deposits and biofilm don't just look bad - they harbor bacteria and restrict water flow. Wipe down the basin and surrounding surfaces daily.

Stream height verification catches problems early. The water should arc smoothly without splashing users or missing the drain entirely. If the pattern looks off, a quick adjustment with the regulator screw usually fixes it.

Bi-Annual Filter & Deep Clean

Filter replacement timing matters more than appearance. Mark those change dates on your calendar and stick to them. High-traffic facilities like schools and gyms might need quarterly changes.

Line flushing after filter changes isn't optional. Run water for five to ten minutes to purge old water and activate the new filtration media. This also reveals installation problems before users find them.

Refrigeration cycle testing requires attention, not tools. The compressor and fan should cycle on and off regularly as the thermostat calls for cooling. Continuous operation or failure to start means trouble that needs professional attention.

Lime Scale Prevention & Removal

Water hardness determines your maintenance strategy. Test your water to understand what you're dealing with. Some areas have naturally soft water that rarely causes problems, while others battle constant mineral buildup.

Commercial descaling products work better than home remedies for serious buildup. Use products designed specifically for drinking water systems and follow the label directions exactly.

White vinegar handles light mineral deposits safely and effectively. Soak removable components overnight, then scrub gently with a soft brush.

Water softening makes sense for persistent lime scale problems. If you're constantly battling mineral buildup, consider installing a water softener upstream of your fountains.

Professional cleaning services handle severe lime scale buildup that's beyond typical DIY capabilities.

When to Call a Pro & Where to Find Parts

Sometimes you need to know when to put down the wrench and pick up the phone. While I'm all for DIY drinking fountain repair, there are certain situations where attempting repairs yourself can be dangerous or make problems worse.

The smell of burning electrical components is an immediate red flag - shut off power and call a professional right away. The same goes for any visible sparking or electrical arcing.

Refrigeration issues often fall into professional territory too. If you see oily residue around fittings, that's refrigerant leaking out along with compressor oil. Your compressor shouldn't run continuously without producing cold water, and those refrigeration lines definitely shouldn't be covered in frost.

Electrical problems that keep tripping breakers are another clear sign to call for help. Repeatedly resetting a breaker without finding the root cause is like ignoring a fire alarm.

For parts, I always recommend starting with OEM suppliers for critical components. Major brands like Elkay, Oasis, and Halsey Taylor maintain excellent parts networks with detailed diagrams that make ordering the right part much easier.

More info about parts diagrams

Red Flags You Shouldn't Ignore

Frosted refrigeration lines look interesting but signal serious problems. Ice buildup on suction lines usually means refrigerant issues, moisture contamination, or defrost system failures.

When breakers keep tripping, resist the urge to keep resetting them. This behavior suggests electrical overload, short circuits, or ground faults. Each time you reset that breaker, you're potentially creating a fire hazard.

Refrigeration oil leaks are particularly concerning because refrigeration systems are sealed units. If oil is leaking out, refrigerant is leaking too.

Listen to your fountain too. Grinding, squealing, or banging sounds from the compressor area often indicate bearing failure or internal damage.

Sourcing OEM & Universal Parts Fast

Bubbler kits are comprehensive solutions that include cartridges, springs, and seals for complete valve rebuilds. OEM kits ensure everything fits perfectly and works as designed.

Solenoid valves control bottle filler operation and automatic shut-off functions. Getting the voltage and fitting specifications exactly right is crucial here.

Push bars and activation components see heavy use and benefit from OEM quality. Generic replacements might work, but they often don't provide the same tactile feel or durability.

Filter selection matters more than many people realize. While universal filters exist, OEM filters are tested and certified for specific flow rates and contaminant reduction.

Store location Contact UsStore location

Frequently Asked Questions about Drinking Fountain Repair

How often should I disinfect and deep-clean a fountain?

The short answer? Daily disinfection is non-negotiable, but the full cleaning schedule depends on your facility's traffic and usage patterns.

Every single day, you'll want to clean the mouthpiece and protective guard with disinfectant. This isn't just about appearances - it's about preventing disease transmission. Use EPA-approved disinfectants designed specifically for drinking water contact surfaces, apply the product, wait for the recommended contact time, then rinse thoroughly.

Weekly wipe-downs of the entire unit help prevent mineral buildup and maintain that professional appearance. But the real deep cleaning should happen every six months minimum.

High-traffic locations like schools, gyms, or busy office buildings may need quarterly deep cleaning. If you're seeing mineral buildup, taste complaints, or reduced water flow, don't wait for the calendar - it's time for a thorough cleaning.

What tools do I need for a basic bubbler or valve swap?

Good news - most drinking fountain repair tasks don't require a truck full of specialized tools. You can handle basic bubbler and valve work with equipment you probably already have in your maintenance shop.

Your essential toolkit should include adjustable wrenches in 6", 8", and 10" sizes, Phillips and flathead screwdrivers, needle-nose pliers, and tubing cutters. Don't forget the safety basics: safety glasses, work gloves, and a non-contact voltage tester.

Some helpful additions that make the job smoother include a multimeter for electrical testing, a small wire brush for cleaning threads, plumber's silicone or tape, and a shop vacuum for cleanup.

Most bubbler cartridges are designed to twist out like light bulbs, requiring only hand strength. However, mineral buildup can make them stubborn, so keep pliers or a strap wrench handy.

Always remember the golden rule: turn off the water supply before starting work.

How do I adjust the water stream height and temperature safely?

Stream height adjustment is actually pretty straightforward, but temperature adjustment? That's where things get more complex and potentially dangerous.

For stream height, you'll be working with the regulator screw, typically located behind the bubbler assembly. Turn clockwise to increase pressure, counterclockwise to decrease. The key word here is small adjustments - make quarter-turn changes maximum and test the results before going further.

You're aiming for a stream that arcs 4-6 inches from the fountain, returns cleanly to the drain without splashing, and creates a comfortable drinking angle of approximately 30 degrees.

Temperature adjustment is a different story entirely. This requires access to the thermostat inside the unit housing, which means working with electrical components. For safety reasons, always disconnect power before accessing internal components and use a non-contact voltage tester to verify power is actually off.

Honestly, unless you're comfortable with electrical work and have the proper training, temperature adjustments are best left to qualified technicians.

Conclusion

Drinking fountain repair doesn't have to be intimidating when you understand the basics. Most problems boil down to a few common culprits - worn valve cartridges, clogged filters, or simple gasket failures. With the right approach and basic tools, you can handle many repairs yourself and keep your fountains running smoothly.

The real secret is staying ahead of problems through regular maintenance. Daily cleaning takes just two minutes but prevents most water quality issues. Six-month filter changes cost a fraction of what you'll pay for emergency repairs. And that monthly check of your condenser fins? It could save your compressor from an expensive breakdown.

Here at American Mortuary Coolers, we've learned a thing or two about keeping equipment running reliably. Whether it's our custom mortuary coolers serving funeral homes across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, or the drinking fountains in your facility, the principle is the same: good maintenance prevents big problems.

But let's be honest - some repairs are best left to the professionals. When you smell burning electrical components, see refrigerant oil leaking, or hear grinding noises from the compressor, it's time to make that service call. Your safety and your wallet will thank you for knowing when to step back.

The techniques we've shared - from the paper towel leak test to proper filter flushing - come from real-world experience fixing equipment that people depend on every day. We know how frustrating a broken fountain can be, especially in busy facilities where hydration matters most.

Quality parts make a difference. Those cheap universal replacements might save a few dollars upfront, but OEM components last longer and perform better. When you're sourcing parts or need expert advice, don't hesitate to reach out to professionals who understand your specific equipment.

Your users deserve clean, cold water on demand. With proper drinking fountain repair knowledge and a commitment to regular maintenance, you can deliver exactly that. And when you need help with the tough stuff, we're here to support you with the same attention to detail that makes our mortuary equipment industry-leading.

Expert Help for Your Walk-In Cooler: Choosing the Right Specialist