Why Walk-In Cooler Freezer Combos Are Essential for Modern Food Storage

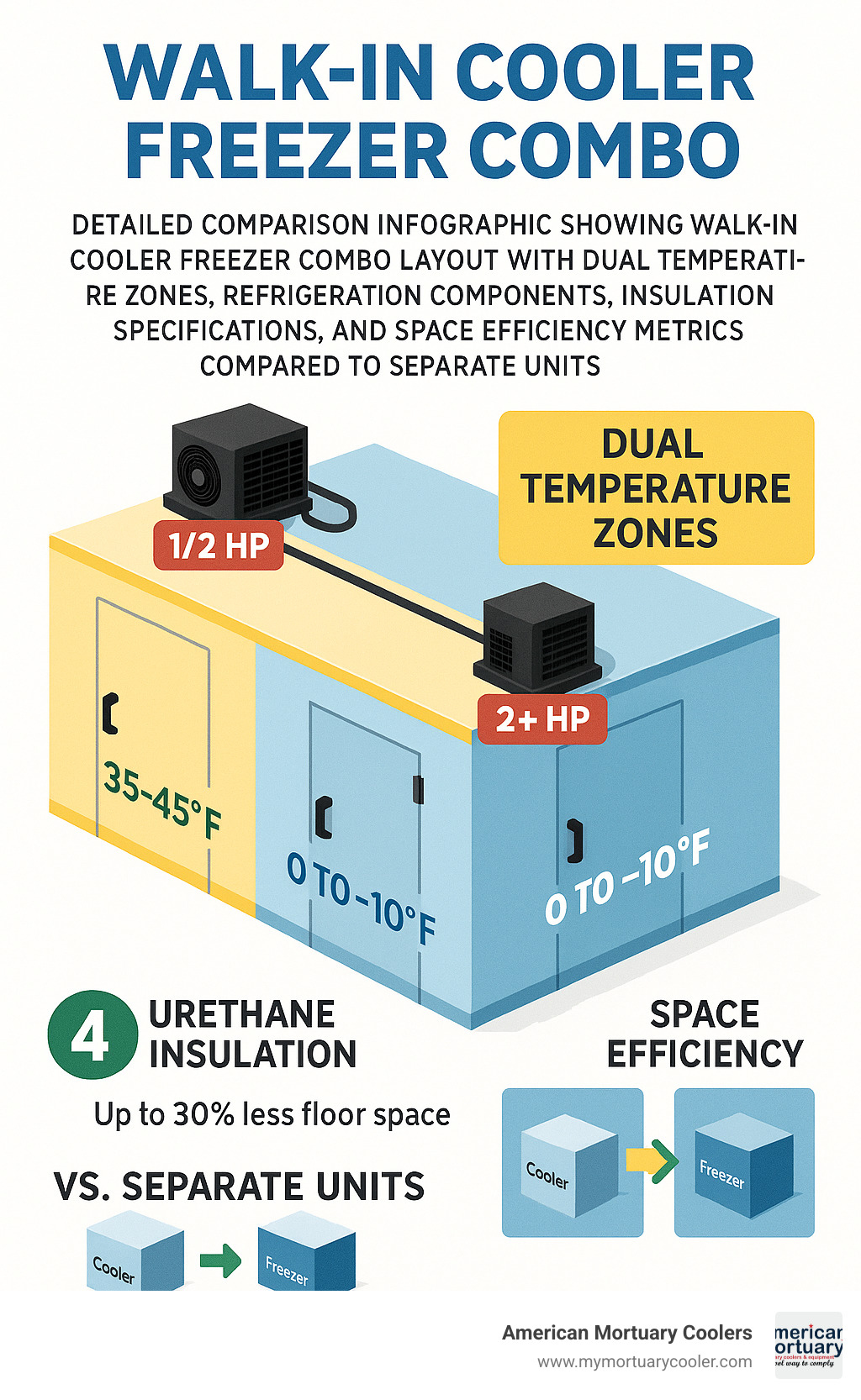

A walk cooler freezer combo combines both refrigeration and freezing capabilities in a single walk-in unit, maximizing storage efficiency while minimizing floor space requirements. These integrated systems serve businesses that need both fresh and frozen storage without the cost and complexity of separate units.

Key benefits of walk-in cooler freezer combos:

- Space savings: Up to 30% less floor space than separate units

- Cost efficiency: Single electrical connection and shared wall construction

- Temperature zones: Cooler section (35-45°F) and freezer section (0 to -10°F)

- Customizable: Available in widths from 6' to 16' and lengths up to 60'

- Installation options: Indoor, outdoor, freestanding, or thru-wall configurations

Walk-in combo units typically feature dual refrigeration systems - a smaller 1/2 HP unit for the cooler side and a larger 2+ HP system for the freezer compartment. The units use 4-inch urethane insulation with R-32 ratings to meet EISA energy standards.

Common applications include restaurants, cafeterias, convenience stores, grocery stores, hotels, and specialized facilities like funeral homes that require reliable temperature control for sensitive applications.

Simple walk cooler freezer combo glossary:

How Walk-In Combos Work & What They're Made Of

A walk cooler freezer combo operates as two separate refrigeration systems sharing one smart structure. The cooler section uses a smaller 1/2 HP condensing unit while the freezer needs a beefier 2+ HP system to maintain zero and below temperatures. Each evaporator operates at different pressures and temperatures, maintaining distinct environments side by side.

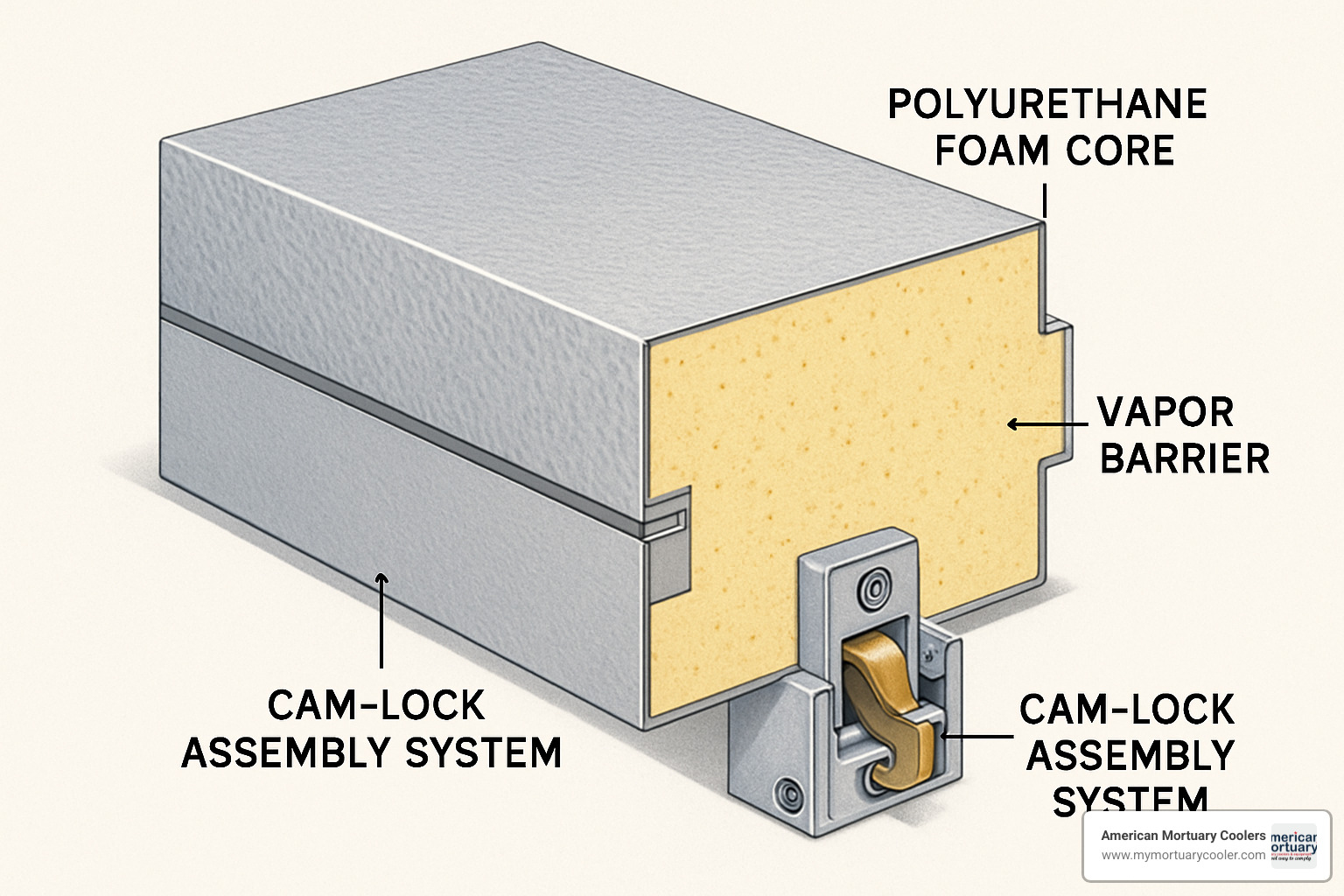

The advanced vapor barrier system prevents moisture from the cooler section from entering the freezer and creating frost buildup. The polyurethane foam insulation acts as both a thermal barrier and moisture seal.

Construction uses modular cam-lock panels that snap together without tools. These panels typically achieve R-32.4 ratings, exceeding the required R-32 insulation standard. The cam-lock system uses gasketed fasteners creating airtight seams while allowing future modifications.

Modern refrigeration controls manage multiple temperature zones and optimize defrost cycles automatically, running more efficiently and maintaining consistent temperatures.

Core Refrigeration Components

The compressor pumps refrigerant through your entire system. Most quality combo units use scroll compressors for reliability. You'll typically see Copeland units for indoor setups and Heatcraft systems for outdoor installations.

Your condensing unit houses the compressor, condenser coil, and fan motor. Indoor units are air-cooled for controlled environments. Outdoor units include weatherproof protection and low-ambient controls that adjust automatically when temperatures drop.

The low-silhouette evaporator coils minimize ice buildup through proper sizing and airflow. These coils feature electric defrost systems that automatically melt ice without affecting stored products.

Temperature-Zone Engineering

Your cooler section maintains 35-45°F - perfect for fresh produce, dairy, and prepared foods. The freezer zone holds steady at 0 to -10°F, handling frozen meats, ice cream, and long-term storage items.

Pressure-relief ports prevent doors from getting stuck. When you open a freezer door, warm air rushes in and expands. Without pressure relief, doors can become nearly impossible to reopen due to vacuum pressure.

Airflow management keeps temperature zones separate. Each compartment has its own air circulation system with strategically placed fans and baffles.

Materials & Insulation Science

Most walk cooler freezer combo units use 4-inch urethane foam insulation, providing excellent thermal resistance and structural strength. Quality combo units typically achieve R-32.4 ratings through advanced foam formulations and smart panel construction.

Fire safety features Intertek fire-rated panels meeting CAN/ULC-S138 standards. Many building codes require these panels, especially in commercial kitchens.

Scientific research on fire-rated panels shows how modern construction balances thermal performance with fire safety.

Panel construction features 26-gauge galvanized steel exteriors with stucco embossed finishes that resist wear and clean easily. Interior surfaces use stainless steel or smooth galvanized finishes designed for daily use.

Choosing the Right walk cooler freezer combo for Your Operation

Finding the perfect walk cooler freezer combo starts with measuring your available space. You'll need floor measurements, ceiling height, door swing clearance, and delivery access. The smallest units start at 6' wide, perfect for small cafés. Larger operations can go up to 16' wide and 60' long. Most restaurants find their sweet spot around 10' x 20'.

Indoor units are typically cheaper and easier for service access. Outdoor units free up interior space but cost about 25% more for weatherproofing and low-ambient controls.

Freestanding units offer flexibility for future moves or reorganization. Thru-wall installations become part of your building and often run more efficiently.

| Feature | Separate Units | Combo Units |

|---|---|---|

| Floor Space | 100% | 70% |

| Installation Cost | Higher | Lower |

| Energy Efficiency | Good | Better |

| Maintenance | Complex | Simplified |

| Flexibility | High | Moderate |

Sizing & Configuration for walk cooler freezer combo

Most food service operations work best with 60-70% cooler space and 30-40% freezer space. Door placement significantly affects workflow efficiency. External doors on both sections allow staff to access frozen items without walking through the cooler. Interior freezer doors save wall space but can allow warm air infiltration.

Side-by-side layouts provide equal access to both zones. Front-to-back configurations fit better in narrow areas. Some units offer convertible rooms that switch between cooler and freezer temperatures for seasonal flexibility.

More info about sizing provides detailed calculations for compartment ratios.

Installation Requirements & Options

The foundation needs to be level within 1/4 inch - concrete slabs work best. Freezer sections require insulated floors to prevent ground freezing. Most units need 208-230V single-phase power. Drainage is critical, especially for freezer defrost cycles.

Outdoor installations require proper anchoring for wind-load codes. Refrigeration equipment weighs 175-350 pounds, requiring crane or hoist equipment for installation.

Standard & Custom Features

Flush-ceiling refrigeration systems mount equipment above your unit, freeing floor space. Slip-resistant flooring ranges from aluminum diamond plate to specialized non-slip coatings. Hands-free door openers allow operation with foot or elbow activation.

Custom exterior graphics can match building architecture or provide branding opportunities. Thru-wall expansion panels allow future unit extensions without starting from scratch.

More info about feature checklist covers available options and investment value.

Benefits, Energy Efficiency & Cost of Ownership

A walk cooler freezer combo saves up to 30% of floor space by sharing the middle wall between sections. You'll need just one electrical feed instead of running power to separate units, reducing installation complexity and costs.

Reduced line-sets mean fewer connections, less refrigerant, and fewer potential leak points. Most units carry NSF and UL listings for food safety and electrical standards. Low ambient controls adjust operation based on outside temperature, working reliably from 0°F to 110°F ambient.

All modern units meet EISA compliance standards, with many exceeding requirements for better energy efficiency.

Space & Cost Savings of walk cooler freezer combo

Construction costs run 15-25% lower than separate units due to shared wall construction. Labor reduction comes from streamlined installation - one electrical connection and coordinated assembly.

Popular sizes often have quick-ship lead times while custom units take 2-4 weeks. ROI typically pays back in 18-36 months through lower upfront costs, reduced energy bills, simplified maintenance, and better space utilization.

Energy Regulations & Efficiency Upgrades

EC motors adjust speed based on demand, using 20-30% less energy than standard motors while running quieter. High-R doors with extra insulation improve efficiency by 10-15% while maintaining more stable temperatures.

LED lighting uses 60-80% less energy than incandescent bulbs while providing better illumination and lasting longer. Refrigerant leak detectors provide early warnings before small problems become expensive disasters.

Check for utility rebates - many power companies offer cash back for high-efficiency equipment.

Price Ranges & Financing Paths

Standard walk cooler freezer combo units cost $21,000 to $34,000. A popular 10' x 20' unit typically runs around $31,000. Custom units start around $50,000 for special sizes or features.

Leasing typically runs $400-800 monthly depending on terms. Zero-percent financing for 12 months is commonly available. Tax incentives like Section 179 deductions can significantly reduce net costs.

Maintenance, Compliance & Accessories

Maintaining your walk cooler freezer combo requires consistent attention but doesn't have to be complicated. Daily tasks include sanitizing door handles, checking temperature displays, and inspecting door seals. Weekly maintenance involves cleaning condenser coils and checking drain lines.

Quarterly service includes professional refrigeration component inspection, gasket replacement, and temperature control calibration. Annual service covers complete system inspection and refrigerant level checks.

Safety compliance includes CAN/ULC-S138 fire-rating and ASTM E84 ratings for flame spread standards. Essential accessories include adjustable shelving, loading ramps, and temperature monitoring alarms.

Routine Care & Service Plans

Sanitizing drains prevents odors and bacterial growth. Use approved sanitizers and ensure complete drainage. Defrost scheduling is automated in modern controllers that learn usage patterns and adjust automatically.

Remote monitoring alerts notify you immediately of temperature drift or equipment problems, preventing product losses and emergency service calls. Service contracts typically cost 10-15% of equipment value annually but ensure regular maintenance and priority service.

More info about maintenance provides detailed schedules and troubleshooting guides.

Certifications & Industry Standards

NSF 7 certification ensures food safety standards for commercial use. UL 471 listing covers electrical safety requirements. EISA 2007 compliance mandates minimum energy efficiency including R-32 insulation values.

DOE 2025 regulations will introduce stricter efficiency requirements. Consider future regulations when selecting equipment to avoid early obsolescence.

Add-Ons & Upgrades

Temperature alarms provide warnings when temperatures exceed safe ranges, with advanced systems sending phone notifications and maintaining compliance logs. Hands-free door systems include foot-operated switches, motion sensors, and pneumatic operators.

Glass display doors allow product visibility while maintaining temperature control. Modular shelving systems maximize storage efficiency and adapt to changing inventory needs. Pallet ramps ease loading and unloading of heavy items.

Frequently Asked Questions about Walk Cooler Freezer Combos

What temperature ranges do the cooler and freezer sections maintain?

Your walk cooler freezer combo creates two independent climate zones. The cooler section maintains 35-45°F - perfect for fresh produce, dairy, beverages, and prepared foods. The freezer compartment operates at 0 to -10°F, ideal for frozen meats, ice cream, and long-term frozen storage.

Each compartment has independent thermostat and refrigeration components, so opening one door won't affect the other's temperature. Quality units maintain temperatures within ±2°F of setpoint under normal conditions.

Can I expand or relocate my combo unit later?

Freestanding units can be relocated with professional disassembly and reinstallation. Thru-wall installations are more permanent but can often be expanded using additional panel sections. The modular panel construction makes expansion straightforward using the same cam-lock system.

Many units allow reconfiguring space allocation between cooler and freezer sections. Some offer convertible rooms that switch between operating modes. Expansion kits are available to add length, width, or height to existing units.

How do combo units reduce overall energy bills compared to separate boxes?

Shared wall construction eliminates heat transfer between units and reduces overall cooling load. Single electrical feeds reduce power distribution loss compared to separate lines. Most businesses see 15-25% lower energy bills compared to equivalent separate units.

Improved insulation efficiency comes from fewer exterior surfaces exposed to ambient temperatures. Modern features like EC motors, LED lighting, and smart defrost controls optimize energy consumption by adjusting performance based on actual cooling demands.

Conclusion

Choosing the right walk cooler freezer combo means understanding what matters most for your operation. These dual-zone units prove themselves as smart investments for businesses needing both fresh and frozen storage without managing separate systems.

The benefits are clear: 30% space savings, reduced installation costs, and simplified operations. Most combo units pay for themselves within 2-3 years through lower energy bills and reduced maintenance.

Your decision checklist:

- Available space and traffic flow

- Temperature needs for your products

- Indoor vs outdoor installation

- Budget for upfront and operating costs

- Future growth plans

- Local codes and health department requirements

Modern combo units offer flexibility for any operation - restaurants, convenience stores, or specialized facilities. Working with experienced professionals ensures you get both technical requirements and real-world functionality right.

Quality matters for this investment. A well-built walk cooler freezer combo should serve reliably for decades with proper care. While upfront costs seem significant, the space savings, energy efficiency, and operational simplicity create compelling value.

At American Mortuary Coolers, we've perfected refrigeration solutions for demanding applications. While specializing in mortuary equipment, our expertise in precision temperature control and custom design extends to any operation requiring reliable cold storage.

More info about custom mortuary coolers provides additional resources for specialized refrigeration applications.

A walk cooler freezer combo represents one of the smartest investments in cold storage infrastructure. The combination of space efficiency, energy savings, and operational ease makes these units excellent choices whether starting out or upgrading existing equipment.