Why American Cooler Technology Leads the Industry

American Cooler systems represent the gold standard in commercial refrigeration, combining decades of manufacturing expertise with cutting-edge insulation technology. When funeral home directors and facility managers search for reliable cooling solutions, they're typically looking for equipment that delivers consistent performance, fits specific space requirements, and comes with strong warranty protection.

Quick Answer for American Cooler Buyers:

- Best known for: Walk-in coolers, freezers, and specialized mortuary cooling systems

- Key advantage: Direct manufacturer pricing with 20-year panel warranties

- Top models: 8x8, 8x12, and 10x10 configurations starting around $6,500-$8,000

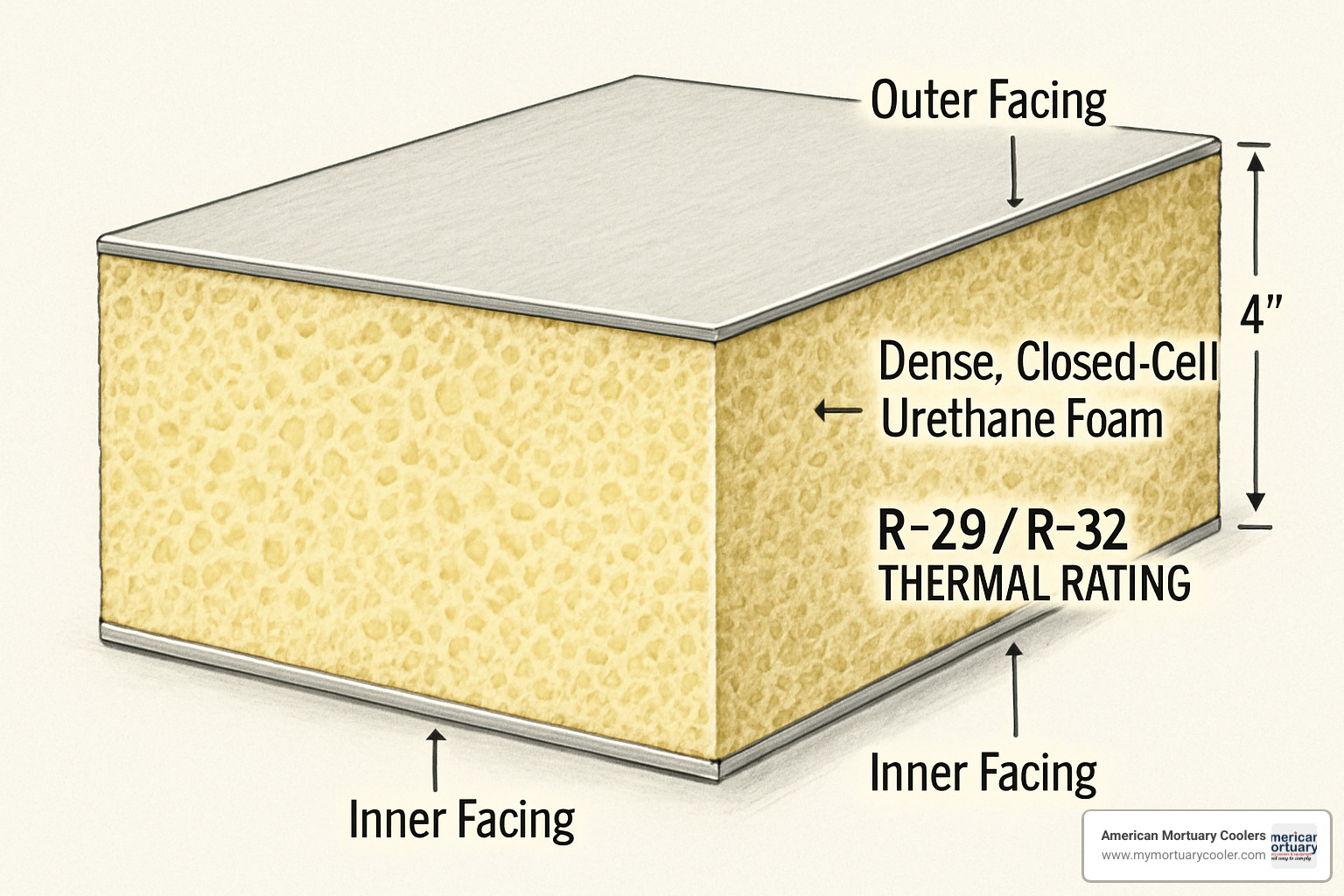

- Standout features: R-29/R-32 insulation ratings, UL-NSF certification, free LED lighting

- Warranty coverage: 20-year panels, 5-year doors/compressors, 1-year parts/labor

American Cooler Technologies has built its reputation on direct-to-customer sales that eliminate dealer markups, while their Lawrence, Michigan facility produces custom-designed insulated enclosures for temperature-critical applications. With over 2,394 Google reviews maintaining a perfect 5-star rating, they've proven their commitment to quality across industries from food service to medical storage.

The company's approach focuses on transparency throughout the entire process - from initial quotes through manufacturing and shipping. Their 4-inch foamed-in-place urethane panels achieve industry-leading R-values while meeting strict Department of Energy compliance standards.

As we at American Mortuary Coolers, a national-level mortuary cooler supplier specializing in American cooler systems, we've seen how the right cooling equipment transforms funeral home operations. Our experience working with American Cooler products has shown us they consistently deliver the reliability and customization options that mortuary professionals need most.

American Cooler terms made easy:

What Makes an American Cooler Stand Out

When you're investing in commercial refrigeration, you want to know exactly what sets one manufacturer apart from the rest. American Cooler has been perfecting their craft since 2002, focusing exclusively on custom-designed insulated enclosures that deliver exceptional performance year after year.

The foundation of every American Cooler system starts with their signature foamed-in-place urethane insulation. This isn't your typical spray foam job - we're talking about precision-engineered 4-inch panels that achieve R-29 ratings for coolers and R-32 for freezers. These numbers translate to real energy savings that add up month after month on your utility bills.

What really makes American Cooler special is their direct-to-buyer approach. Instead of marking up prices through dealers and distributors, they sell directly to customers like you. This means better pricing, faster communication, and the peace of mind that comes from working directly with the people who actually build your equipment.

Quality control is where American Cooler really shines. Every unit goes through third-party inspection before it leaves their Lawrence, Michigan facility. Combined with UL and NSF certifications plus ASTM E84 testing for smoke and flame spread, you're getting equipment that meets the highest safety standards in the industry.

Their warranty program speaks volumes about build quality. Twenty-year panel warranties are practically unheard of in this industry, but American Cooler backs their work with that level of confidence. Add in 5-year coverage on doors and compressors, plus 1-year parts and labor protection, and you've got comprehensive coverage that protects your investment for decades.

American Mortuary Coolers vs Other U.S. Brands

Having worked extensively with American Cooler systems through our mortuary cooling business, we've seen how they stack up against other manufacturers. The biggest difference is their direct factory support - when you need help, you're talking to the people who actually built your cooler, not a middleman trying to relay messages.

The customization capabilities are where American Cooler really pulls ahead of the competition. While other brands offer a few standard sizes with limited options, American Cooler can accommodate unique requirements like heights up to 28 feet and specialized applications that require precise engineering.

| Feature | American Cooler | Industry Standard |

|---|---|---|

| Panel Warranty | 20 years | 5-10 years |

| Insulation Rating | R-29/R-32 | R-20/R-25 |

| Panel Thickness | 4 inches standard | 3-4 inches |

| Direct Factory Support | Yes | Dealer network |

| Custom Heights | Up to 28 feet | Limited options |

| Free Accessories | LED lights, strip curtains | Usually extra cost |

| Shipping Included | Lower 48 states | Additional charges |

How to Customize Your American Cooler for Specialized Needs

The beauty of working with American Cooler is that customization isn't an afterthought - it's built into their entire process. Their engineering team takes your specific challenges and creates solutions that work perfectly for your situation.

Panel thickness can be adjusted based on your exact thermal requirements. While 4-inch panels handle most commercial applications beautifully, extreme temperature needs or specific energy efficiency goals might call for different specifications.

Height flexibility extends all the way up to 28 feet, making these systems perfect for everything from standard funeral home applications to large warehouse installations. Most facilities work great with standard 8-foot heights, but 10-foot and 12-foot options provide extra storage capacity when your ceiling space allows.

Door options offer incredible flexibility for different applications. Standard entrance doors measure 35½ inches by 78 inches, but solid doors can go up to 42 inches wide. Need something bigger? Hinged doors can reach 6 feet by 10 feet, while sliding doors accommodate openings up to 10 feet by 10 feet.

Digital controls and humidity management systems can be integrated for applications requiring precise environmental control. Whether you're storing delicate floral arrangements or maintaining specific conditions for medical applications, these systems provide the monitoring and control capabilities you need.

Types of American Coolers: From Walk-In to Specialized Applications

When you're shopping for commercial refrigeration, American Cooler has probably thought of your exact needs before. Their product lineup covers everything from standard walk-in coolers that keep restaurants running to highly specialized units for unique applications.

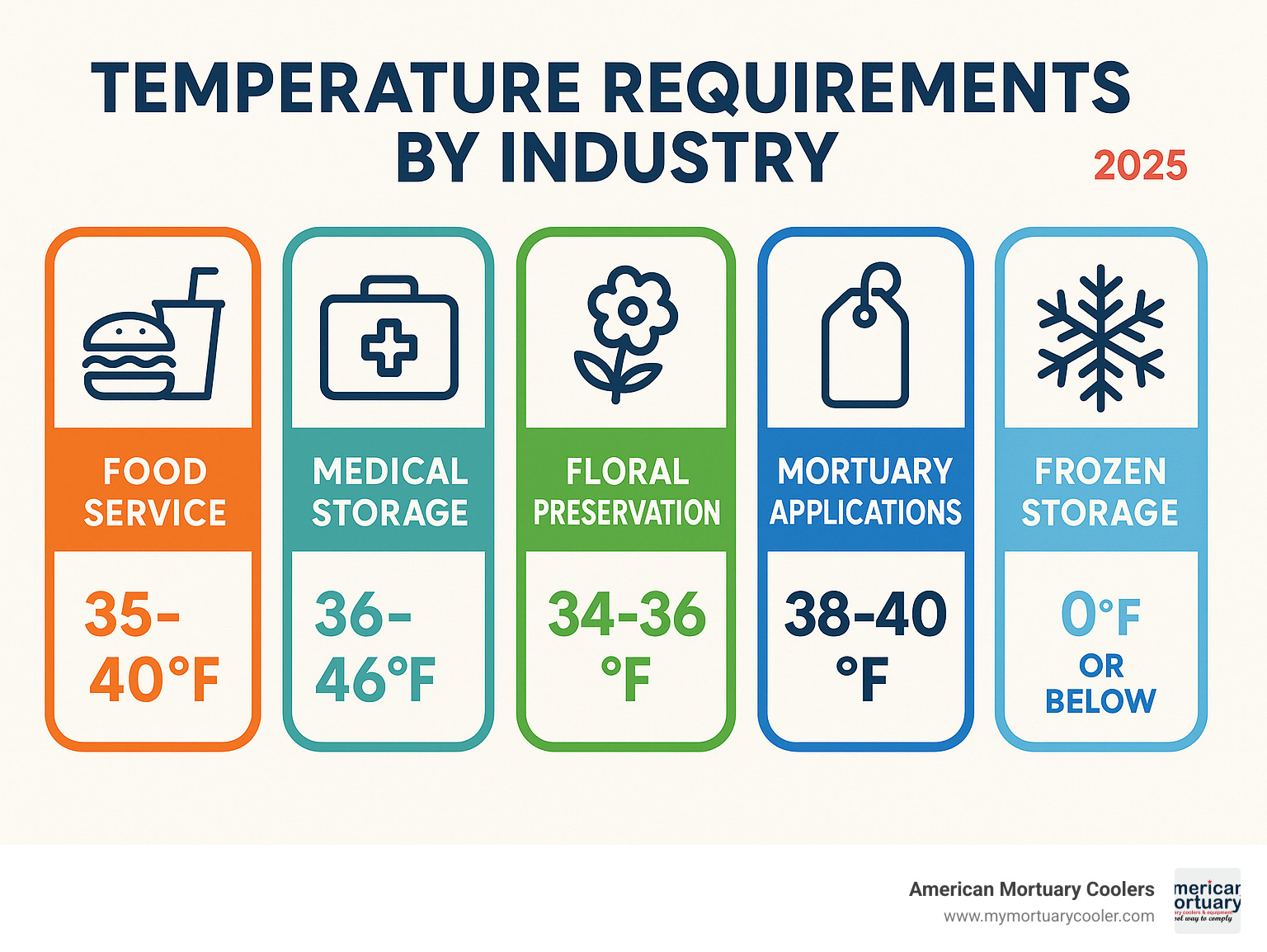

Walk-in coolers form the backbone of their business, and for good reason. Those popular 8x8, 8x12, and 10x10 configurations handle the daily grind for thousands of businesses across the country. These workhorses maintain steady temperatures around 35-40°F and take whatever punishment busy kitchens can dish out.

Step into freezer territory, and American Cooler systems really show their engineering chops. Walk-in freezers use the same rock-solid construction as their cooler cousins, but with beefed-up R-32 insulation and refrigeration systems built to handle sub-zero temperatures day in and day out.

Beer caves occupy a special place in the cooling world. These units combine the temperature control of a standard cooler with the accessibility that retail operations demand. Getting the temperature just right for beer storage isn't as simple as it sounds, but these specialized systems nail that sweet spot while giving customers easy access to their favorite brews.

Display coolers take things in a different direction entirely. By integrating glass doors and specialized lighting, they turn temperature control into a sales tool. Walk into any convenience store or deli, and you'll see these units working overtime - keeping products fresh while showing them off to customers.

Now, mortuary coolers represent some of the most demanding applications in the cooling business. These units need precise temperature control, bulletproof durability, and specific dimensions that standard coolers simply can't provide. Through our work at American Mortuary Coolers, we've seen how American Cooler's customization capabilities make them particularly well-suited for funeral home requirements.

Floral coolers might seem straightforward, but they're actually quite finicky. Cut flowers need that narrow temperature window between 34°F and 36°F, plus carefully controlled humidity that prevents both wilting and excess moisture damage. Get either factor wrong, and you're looking at some expensive dead flowers.

For restaurants dealing with hot food that needs to cool down fast, rapid pull-down systems are game-changers. These specialized units pack extra refrigeration punch to bring items from cooking temperatures down to safe storage conditions quickly. Food safety regulations don't mess around, and these systems help businesses stay compliant while maintaining quality.

Here's something interesting: an independent real world ice-retention test put various cooler brands through their paces. American-made units consistently outperformed imported alternatives, with the top performers keeping ice solid for 14-17 days in 90°F heat.

Don't have the capital for an outright purchase? American Cooler leasing options make their systems accessible to businesses that need to preserve cash flow or want flexible financing arrangements.

American Cooler Buying Matrix

Picking the right American Cooler system isn't rocket science, but it does require thinking through several key factors that affect both performance and your bottom line. Size requirements seem obvious, but there's more to consider than just cramming everything into the biggest box your budget allows.

Temperature range needs determine your basic equipment category. Standard coolers handle the 35-40°F range that most food applications require. Freezers work at 0°F and below for frozen storage. Then you have specialized applications that need precise control at specific temperatures.

Your industry shapes everything about cooler design. Food service operations need surfaces that clean easily and NSF compliance for health department inspections. Medical facilities require precise temperature control and monitoring capabilities. Mortuary applications have their own specific requirements for temperature stability and construction durability.

Budget considerations extend way beyond that initial sticker price. Operating costs, maintenance requirements, and expected lifespan all factor into the real cost of ownership. American Cooler's energy-efficient design and extended warranties often make them the smart financial choice, even when the upfront cost runs higher than bargain alternatives.

Key Features to Evaluate Before You Buy

When you're investing in an American Cooler system, understanding the key features can mean the difference between years of reliable service and costly headaches down the road. Let's walk through what really matters when evaluating these systems.

The panel construction forms the heart of any quality cooler. American Cooler's Performance Panel System (PPS) technology uses 4-inch foamed-in-place urethane insulation that creates a seamless thermal barrier without the weak spots you'll find in cheaper alternatives. This isn't just about having thick walls; it's about eliminating those sneaky cold bridges that can drive up your energy bills.

Door packages deserve your closest attention because they're honestly where most coolers fail over time. American Cooler's Super-Door package doesn't mess around - you get heavy-duty triple hinges that won't sag after thousands of openings, magnetic gaskets that maintain their seal even when your staff is rushing, and self-closing mechanisms with inside safety releases for peace of mind.

The floor load capacity of 1,200 pounds per standard unit handles whatever you need to store. This rating covers both the structural strength of the floor system and how well the panels distribute weight - important considerations whether you're storing cases of supplies or heavy equipment.

Lighting systems use UL-approved vapor-proof LED fixtures that give you excellent visibility without adding unwanted heat to your cooler. The pre-wired exterior switch with pilot light is one of those thoughtful touches - you can control the lights without opening the door and letting cold air escape.

Strip curtains come standard with American Cooler systems, providing an extra thermal barrier that reduces temperature loss during door openings. These might look like basic plastic strips, but they can significantly impact your energy consumption if your cooler sees frequent traffic.

Energy consumption varies based on your cooler's size, how cold you need it, and how often it's opened. But here's the thing - American Cooler's superior R-29/R-32 insulation ratings typically mean lower operating costs compared to less efficient alternatives.

Smoke and flame spread ratings per ASTM E84 ensure your cooler meets fire safety compliance for commercial installations. This certification becomes particularly important if you're dealing with strict fire codes or insurance requirements.

Warranty coverage provides impressive long-term protection with 20-year panel warranties, 5-year door and compressor coverage, and 1-year parts and labor protection. This comprehensive coverage reflects the manufacturer's genuine confidence in their construction quality.

For more detailed information about features and pricing considerations, check out More info about walk-in features and prices.

The Step-By-Step Ordering Process

Getting your American Cooler system starts with their clever Insta-Quote system - no more waiting around for days to get pricing information. You simply plug in your requirements online, and within minutes you'll have accurate pricing that reflects exactly what you need.

Once you're happy with the quote and ready to move forward, the engineering review kicks in. This isn't just paperwork - it's where American Cooler's technical team makes sure your cooler design will actually work in your specific location. If you're in states like California, Florida, Oregon, or Washington, they'll handle any special engineering documentation or wet-stamp approvals that local codes require.

The CAD drawings phase is where everything becomes crystal clear. You'll get detailed visual confirmation of exactly what you're getting - panel layouts, door placements, electrical connections, the works. These drawings prevent those "that's not what I expected" moments that can derail a project.

Production scheduling moves efficiently once your drawings are approved. American Cooler's Lawrence, Michigan facility has refined their manufacturing process to balance custom work with reasonable delivery times. They're honest about lead times upfront, which helps you plan your project timeline realistically.

Here's something you'll appreciate: shipping costs are already included in your quoted price for anywhere in the lower 48 states. No surprise freight charges showing up later to blow your budget. This transparent approach makes project planning much easier.

Installation doesn't leave you hanging either. Every cooler ships with detailed manuals and you get ongoing technical support from people who actually know how these systems work. Many customers use local contractors for installation, but American Cooler's support team stays available to answer questions throughout the process.

Financing options make these systems accessible even when cash flow is tight. The programs offer competitive rates and flexible terms that work with real business situations, not just perfect-world scenarios.

For a complete breakdown of what goes into cooler pricing, check out Walk-In Cooler Pricing 101 - it covers all the cost factors you should know about before making your decision.

Placing Your American Cooler Order with Confidence

Here at American Mortuary Coolers, we've built our relationship with American Cooler Technologies specifically to make this process smoother for our customers. Our experience with their systems means we can guide you through the selection process without the usual confusion that comes with major equipment purchases.

Lead times are realistic, not optimistic. We've learned that American Cooler consistently delivers when they say they will, which is actually pretty rare in custom manufacturing. This reliability makes project planning much less stressful.

Freight tracking keeps you in the loop from the moment your cooler leaves the factory until it arrives at your location. You'll know where it is and when to expect it, so you can coordinate installation crews and clear space accordingly.

The after-sales support really shines through in their 2,394 Google reviews with a perfect 5-star rating. That's not luck - it's the result of a customer service team that actually helps when you need them. Whether you have technical questions or need parts down the road, they're there.

Real-World Applications & Case Studies

American Cooler systems have proven their worth across countless industries, each with unique challenges that showcase just how adaptable these cooling solutions really are. When you see the variety of applications these coolers handle daily, it becomes clear why they've earned such a strong reputation.

Food service chains face some of the toughest demands in commercial refrigeration. They need systems that can handle constant door openings, maintain perfect temperatures during rush periods, and keep running reliably day after day. American Cooler systems excel here because their superior insulation and heavy-duty construction handle the abuse while their easy-access components make maintenance straightforward for busy kitchen staff.

Cold storage distribution centers push cooling equipment to its limits with massive product volumes and frequent temperature swings. These facilities can't afford downtime, and American Cooler's robust panel construction and commercial-grade door systems deliver the reliability these operations demand.

Convenience stores have found that American Cooler beer caves and display units do more than just keep products cold - they help drive sales. The combination of precise temperature control and attractive presentation capabilities makes these systems particularly effective in retail environments where product visibility matters as much as preservation.

Scientific laboratories represent another demanding application where American Cooler systems shine. Research facilities need precise temperature control for valuable samples and experiments, and even small temperature variations can ruin months of work. The consistent performance and monitoring capabilities of these systems provide the security that research applications require.

Medical vaccine storage takes precision to another level entirely. When you're storing thousands of dollars worth of vaccines, temperature excursions simply aren't an option. American Cooler's ability to maintain tight temperature control, combined with their reliability track record, makes them a trusted choice for medical facilities nationwide.

Floral warehouses present unique challenges that most cooling systems can't handle. Cut flowers need specific humidity levels along with precise temperature control to maximize their lifespan. American Cooler's customization capabilities allow for the specialized environmental controls these delicate applications demand.

Funeral homes require a different kind of reliability altogether. Temperature control, durability, and professional appearance all matter when you're serving families during difficult times. Our experience at American Mortuary Coolers has shown us how important it is to have cooling systems that perform flawlessly without drawing attention to themselves. For detailed information about mortuary applications, see The Ultimate Guide to Walk-In Morgue Cooler Options.

The Facebook customer gallery tells these stories better than we ever could. Real installations across various industries show how American Cooler systems adapt to different environments while maintaining their professional appearance and reliable performance.

What strikes us most about these applications is how different industries have similar core needs - reliable temperature control, durable construction, and systems that won't let them down when it matters most. Whether you're preserving food, protecting medical supplies, or serving families in their time of need, the fundamentals remain the same.

Frequently Asked Questions about American Coolers

How long does installation typically take?

Most American Cooler walk-in systems go together surprisingly quickly once everything's on site. You're typically looking at 4-8 hours for assembly of a standard cooler, thanks to their clever cam-lock panel system that doesn't need any special tools.

The real time investment usually happens before you start connecting panels. Getting your site ready, running electrical lines, and coordinating with your refrigeration contractor often takes longer than the actual cooler assembly. The good news is that American Cooler ships detailed installation manuals with every unit, and their technical support team is just a phone call away if you hit any snags.

What certifications should my cooler meet?

American Cooler systems come with UL-NSF approval right out of the box, which covers the two big requirements most facilities need. The UL certification handles electrical safety standards, while NSF approval ensures your cooler meets food safety requirements that health departments look for.

You'll also get ASTM E84 certification for smoke and flame spread testing. This fire safety certification is often required by local building codes, especially in commercial buildings with strict safety requirements.

Department of Energy compliance might not sound exciting, but it can save you money through utility rebates and definitely helps with long-term operating costs. If you're in California, you'll appreciate that American Cooler systems meet Proposition 65 requirements too.

How do warranties and service work across state lines?

Here's where American Cooler's direct-to-customer approach really shines. Your warranty coverage - that 20-year panel warranty, 5-year door and compressor protection, and 1-year parts and labor coverage - works exactly the same whether you're in Maine or California.

Service support combines the best of both worlds: factory-direct technical assistance backed by authorized local service providers. When something needs attention, you can call American Cooler's technical support team directly for troubleshooting help, parts identification, or guidance on repairs.

Parts availability stays consistent nationwide through their distribution network. Common maintenance items and replacement parts typically arrive within a day or two in most markets, so you're not stuck waiting around for critical components.

Conclusion & Next Steps

When it comes to commercial refrigeration that truly delivers, American Cooler systems stand out as a wise investment for any business serious about reliable temperature control. After working with these systems for years, we've seen how they transform operations across industries - from busy restaurants to specialized funeral homes.

The combination of superior R-29/R-32 insulation, direct-from-manufacturer pricing, and that impressive 20-year panel warranty creates exceptional value that's hard to match. You're not just buying a cooler; you're investing in decades of dependable performance backed by a company that stands behind their work.

What really sets American Cooler apart is their commitment to getting things right the first time. Their customization capabilities mean you won't have to settle for a "close enough" solution, and their direct-to-customer approach eliminates the frustrating middleman markup and communication gaps that plague other brands.

Energy efficiency alone often pays for the higher initial investment within just a few years. When you factor in the extended warranty coverage and reduced maintenance needs, the long-term cost advantage becomes even more compelling.

As American Mortuary Coolers, we've built our reputation on helping funeral professionals find cooling solutions that work perfectly for their unique needs. American Cooler systems consistently deliver the reliability and customization options that make the difference between adequate and exceptional performance.

Your next steps should include evaluating your specific cooling requirements - not just storage volume, but access frequency, temperature precision needs, and any special features your industry demands. The Insta-Quote system makes it easy to get accurate pricing without the usual back-and-forth delays.

Consider the total cost picture including installation logistics, energy consumption, and maintenance requirements over the equipment's lifetime. The direct manufacturer relationship means faster service response and consistent parts availability that continues long after installation.

For businesses with unique cooling challenges, Custom Walk-In Cooler Solutions That Fit Like a Glove explores how American Cooler's engineering team can address even the most specialized requirements with creative, cost-effective solutions.

The American Cooler advantage comes from decades of focused expertise, premium materials, and a business model that puts customer satisfaction ahead of dealer profits. Whether you need a straightforward walk-in cooler or a specialized mortuary system with precise temperature control, you're getting equipment designed and built by people who understand what really matters in commercial refrigeration.