Why Refrigerated Cooling Powers Modern Life

Refrigerated cooling is the process of removing heat from a space or substance to lower its temperature below ambient levels, using mechanical systems that circulate refrigerant through a continuous cycle of compression, condensation, expansion, and evaporation.

Key aspects of refrigerated cooling:

- Primary function: Removes heat to maintain temperatures between -76°F to 41°F depending on application

- Core technology: Vapor-compression cycle using compressor, condenser, expansion valve, and evaporator

- Essential applications: Food preservation, medical storage, industrial processes, and specialized facilities

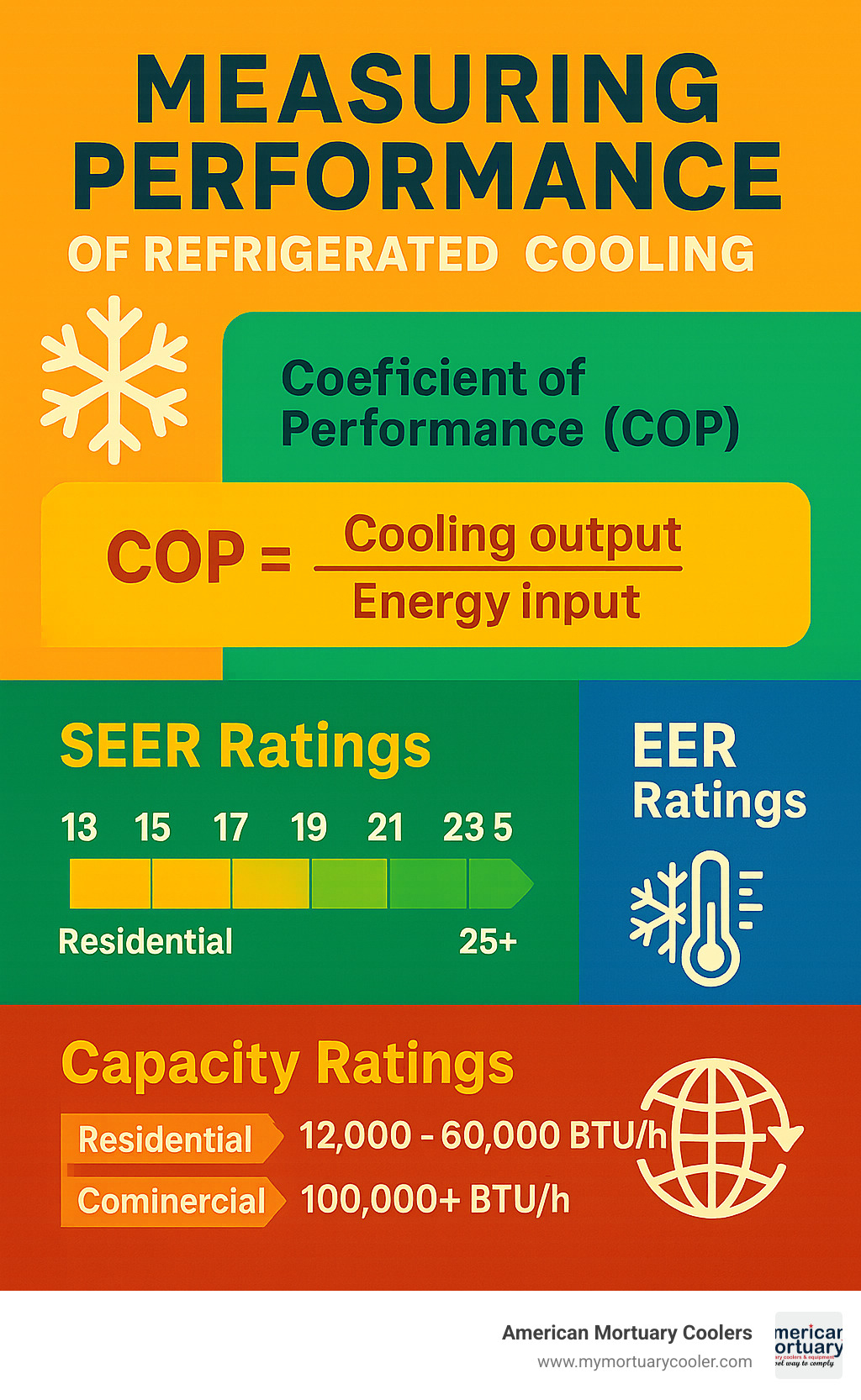

- Performance metrics: Measured in BTU/h, kW capacity, and Coefficient of Performance (CoP)

- Temperature control: Maintains precise temperatures regardless of external weather conditions

This technology revolutionized how we live, work, and eat. By 1940, over 50% of American households owned refrigerators, changing nutrition and enabling the modern food system. Today, refrigerated cooling accounts for at least 5.1% of increased adult stature in the US through improved nutrition and food safety.

The impact extends far beyond home kitchens. Refrigerated cooling enables global food distribution, supports critical medical equipment, and maintains specialized environments like data centers and mortuary facilities. Without it, fresh produce would spoil within hours, vaccines would lose potency, and many industrial processes would be impossible.

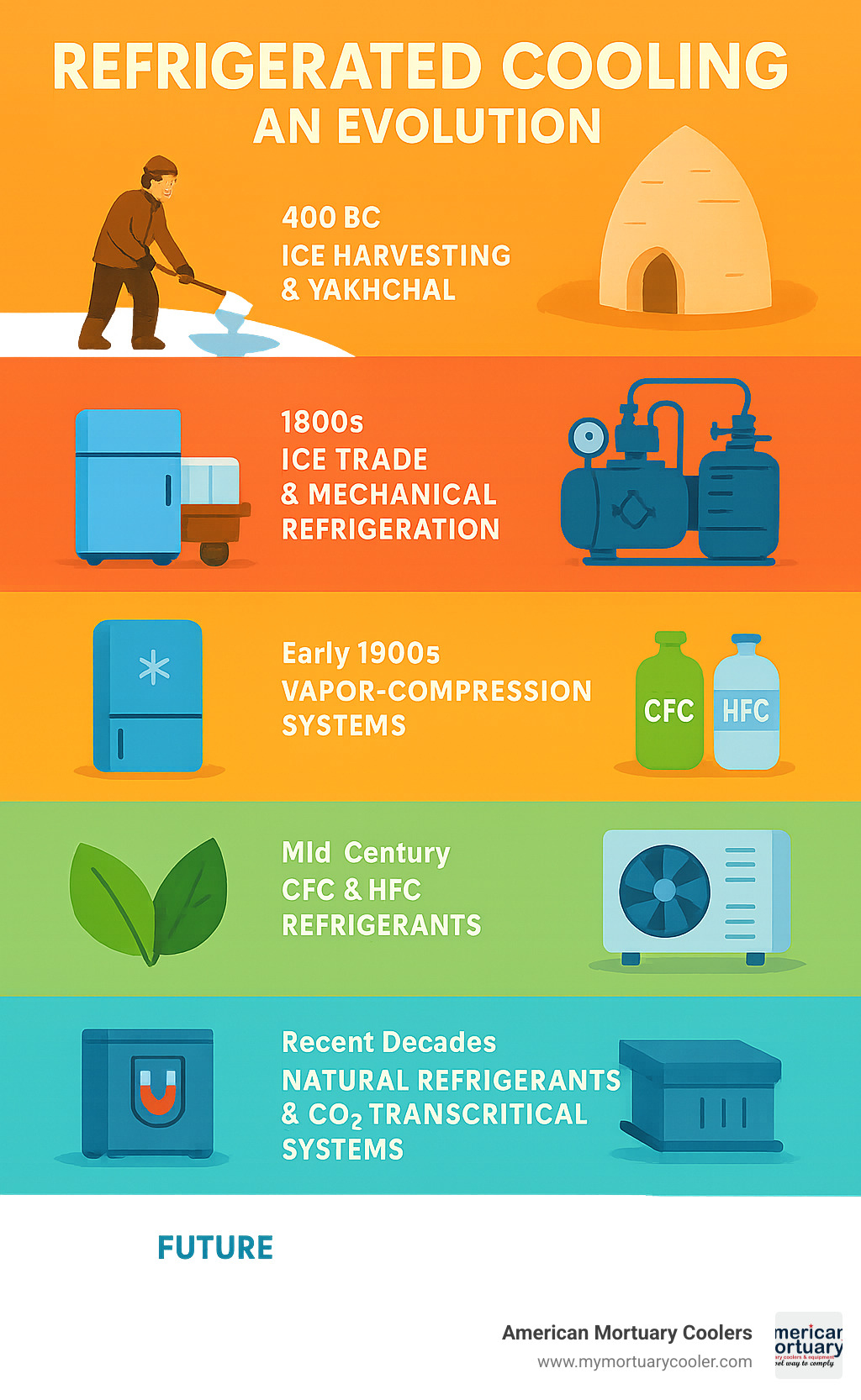

From ancient ice houses to modern magnetic refrigeration prototypes, this technology continues evolving to meet growing demands while addressing environmental concerns about energy use and refrigerant emissions.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in refrigerated cooling solutions for funeral homes and specialized facilities. With experience in commercial refrigeration systems, I help facilities choose the right cooling technology for their specific needs while ensuring reliable performance and energy efficiency.

Easy refrigerated cooling word list:

Why This Guide Matters

Understanding refrigerated cooling is crucial for making informed decisions about equipment that affects nutrition, public health, and climate goals. The optimum temperature range for perishable food storage is 3 to 5°C (37 to 41°F), and maintaining this range prevents bacterial growth that can double every 20 minutes between 4.4°C and 60°C.

This knowledge becomes essential when selecting systems for specialized applications like mortuary facilities, where precise temperature control ensures proper preservation and meets regulatory requirements.

What Is Refrigerated Cooling?

Refrigerated cooling actively removes heat from spaces, unlike fans that just move air or evaporative coolers that rely on water evaporation. These systems use a closed-loop process where refrigerant absorbs heat when cold and under low pressure, then gets compressed to become hot and high-pressure so it can release that heat outside.

What makes refrigerated cooling effective is its ability to maintain precise temperatures regardless of outdoor conditions. Whether it's hot in Tennessee or freezing in Minnesota, these systems deliver consistent performance because they don't depend on weather conditions.

The Coefficient of Performance (CoP) measures efficiency - how much cooling you get compared to energy input. Modern systems typically achieve CoP values of 3-4, meaning they deliver three to four times more cooling than the electricity they consume.

For detailed technical specifications and industry standards, scientific research on refrigeration fundamentals provides comprehensive information for various applications.

Key Principles Behind Refrigerated Cooling

The science behind refrigerated cooling uses energy to reverse heat's natural flow from warm to cold places. The genius lies in latent heat - when refrigerant changes from liquid to gas inside the evaporator, it absorbs enormous amounts of heat without getting hotter itself, similar to how sweating cools your body.

Pressure and temperature work together in this system. Compressing refrigerant gas increases both pressure and temperature, allowing heat release even when outside air is warm. When high-pressure liquid passes through the expansion valve, pressure and temperature drop dramatically, creating cold conditions needed to absorb heat.

Refrigerated Cooling vs. Standard Cooling

The fundamental difference is active heat removal versus passive heat management. Standard cooling methods like fans or evaporative systems work only with ambient temperature, while refrigerated systems actively extract heat to achieve sub-ambient temperatures.

Evaporative cooling adds moisture to air, limiting effectiveness in humid climates and requiring open ventilation. Refrigerated systems operate as closed loops, providing complete control over temperature and humidity.

| Feature | Refrigerated Cooling | Evaporative Cooling |

|---|---|---|

| Temperature Range | Below ambient to -76°F | Ambient minus 10-20°F |

| Humidity Control | Yes, removes moisture | No, adds moisture |

| Climate Dependency | Works in any climate | Best in dry climates |

| Energy Use | Higher | Up to 80% less |

| Installation Cost | Higher upfront | 50% less upfront |

| Maintenance | Annual service needed | Regular pad cleaning |

For specialized applications like mortuary cooling, refrigerated cooling is typically the only viable option because it provides precise temperature control and humidity management required for proper preservation and regulatory compliance.

Core Technologies & Methods

Refrigerated cooling offers several technologies, each suited for specific applications. The vapor-compression cycle dominates most residential, commercial, and industrial applications due to its reliability, efficiency, and cost-effectiveness.

Absorption systems use heat instead of mechanical energy to create cooling, perfect for facilities with waste heat. Thermoelectric cooling relies on the Peltier effect, where electricity creates temperature differences across special materials. Magnetic refrigeration uses magnetocaloric materials that heat up when magnetized and cool down when the magnetic field is removed.

How Refrigerated Cooling Works: The Vapor-Compression Cycle

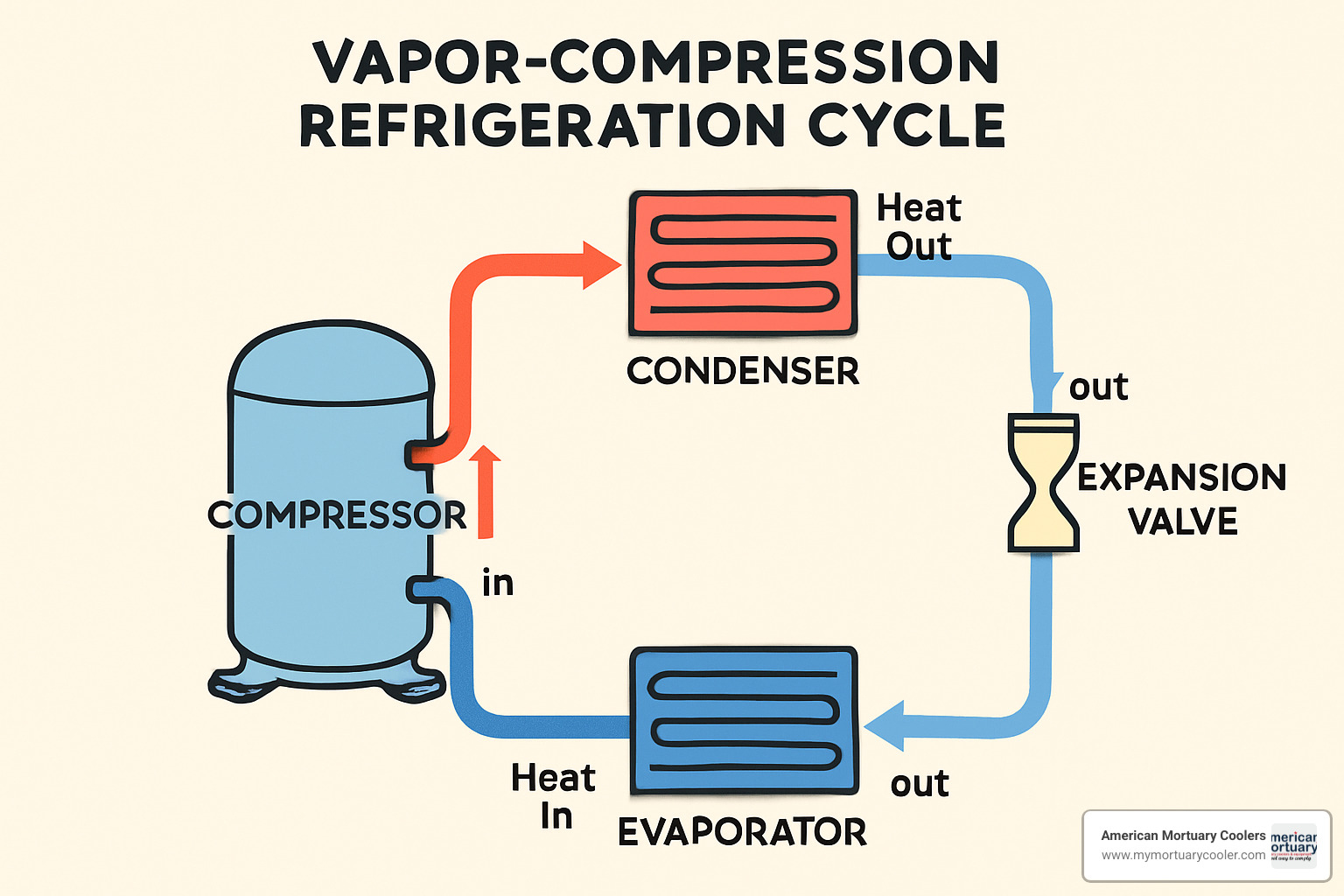

The vapor-compression cycle moves heat from where you don't want it to where you don't mind it through four main components working together.

The compressor acts like the system's heart, squeezing low-pressure refrigerant gas and increasing both pressure and temperature. This hot, high-pressure gas travels to the condenser, where it releases heat to the outside and transforms back into liquid.

The expansion valve drops both pressure and temperature of the liquid refrigerant dramatically. This cold liquid enters the evaporator, where it absorbs heat from the cooled space and turns back into gas, ready to restart the cycle.

Modern refrigerants like R-410A and R-134a have specific properties perfect for different temperature ranges and applications. The system's effectiveness comes from phase changes - when refrigerant changes from liquid to gas, it absorbs tremendous amounts of heat without getting hotter itself.

More info about x services provides detailed information about compressor operation and troubleshooting.

Alternative Refrigerated Cooling Methods

Absorption chillers use heat energy instead of electricity, perfect for facilities generating waste heat. They use combinations like water-lithium bromide or ammonia-water, where one substance absorbs the other to drive cooling.

CO₂ transcritical systems use carbon dioxide as refrigerant, which has virtually no global warming impact. They operate at higher pressures but perform exceptionally well in cold climates with excellent heat recovery capabilities.

Thermoelectric cooling uses the Peltier effect through semiconductor materials - electricity makes one side hot while the other gets cold. While less efficient for large applications, it's incredibly precise, silent, and perfect for smaller applications like wine coolers and medical equipment.

Magnetic refrigeration uses special materials that heat up when exposed to magnetic fields and cool down when the field is removed. Still developing for commercial use, it promises incredible efficiency without traditional refrigerants.

Scientific research on elastocaloric effect explores another alternative using shape-memory alloys that cool when mechanical stress is removed.

Applications & Societal Impact

Refrigerated cooling touches nearly every aspect of modern life. Home refrigerators maintain 35-38°F for fresh food and 0°F or below for frozen storage. Commercial walk-in coolers work around the clock, maintaining different temperatures for different foods - dairy, produce, and raw meat each need specific conditions.

Industrial facilities use process chillers to cool manufacturing equipment, ensuring consistent product quality in pharmaceuticals, electronics, and food production. Agriculture uses rapid field heat removal systems that cool produce immediately after harvest, making the difference between crisp lettuce and wilted leaves.

Medical and pharmaceutical storage demands the highest reliability. Vaccines, blood products, and medications require precise temperature control with backup systems and constant monitoring. In mortuary refrigeration, systems maintain specific temperatures for preservation while meeting strict health department requirements.

Refrigerated transport enables our global food system. Modern refrigerated trucks maintain temperatures between -40°F and -20°F while carrying up to 24,000 kg of cargo across continents, making international food trade possible.

How Refrigerated Cooling Transformed Food & Agriculture

Before refrigerated cooling, people ate what grew nearby and what was in season. Ice consumption in New York City jumped from 12,000 to 100,000 tons between 1843 and 1856 as people recognized that keeping things cold meant keeping them fresh and safe.

By 1900, Chicago's meat-packing houses had adopted ammonia-cycle commercial refrigeration. By 1914, almost every major food processing facility used artificial refrigeration, enabling centralized food processing and national distribution networks.

The cold chain - maintaining consistent temperatures from farm to table - became the backbone of modern food safety. Delaying cooling by just one hour after harvest can reduce fresh produce shelf life by an entire day or more.

Rural electrification supported this change. In the early 1930s, only 10% of rural American homes had electric power, compared to 90% of urban areas. As electricity reached farming communities, refrigerated cooling enabled better food storage and dramatically reduced waste.

Emerging Niches: Micro & Body-Composting Refrigerated Cooling

Micro refrigeration systems now provide cooling for precision applications, maintaining temperature stability within ±0.1°C for laser equipment, medical devices, and electronics where tiny temperature variations could cause failures.

Variable-speed DC inverter compressors enable both compactness and energy efficiency. Engineers are developing personal wearable cooling devices, portable medical equipment, and specialized industrial processes requiring laboratory-level temperature control in field conditions.

Body composting facilities represent an interesting emerging application, needing precise temperature and humidity control to manage natural composting while meeting strict health and environmental regulations.

More info about Walk-In Refrigeration Units covers larger-scale applications and selection criteria for commercial facilities, including specialized requirements for mortuary and medical applications.

Sustainability, Environmental Concerns & Future Trends

The refrigerated cooling industry is experiencing its biggest change since electric refrigeration began. Environmental concerns are driving real changes in system design and operation.

CFCs were banned due to ozone depletion, replaced by HFCs that don't hurt ozone but are potent greenhouse gases. The Kigali Amendment is now pushing toward natural refrigerants with much lower global warming potential.

Carbon dioxide (CO₂) systems are making a comeback, especially in cold climates where they perform excellently with fantastic heat recovery capabilities. Ammonia remains champion for large industrial applications, offering incredible efficiency with proper safety handling. Hydrocarbons like propane work well in smaller systems.

Energy efficiency standards keep tightening. SEER ratings help compare seasonal efficiency, while MEPS set minimum performance standards. Smart operators use free cooling when outdoor conditions allow, and DUAL-KOOL systems provide energy savings with backup protection.

Measuring Performance of Refrigerated Cooling Systems

Understanding refrigerated cooling performance helps make smarter equipment decisions. Capacity measured in kW or BTU/h tells you cooling power - home refrigerators use 150-300 watts, while restaurant walk-ins need 5,000-15,000 BTU/h.

The Coefficient of Performance (CoP) divides cooling output by energy input. Modern systems achieve CoP values of 3-4, with the best reaching 5 or higher under ideal conditions.

SEER measures efficiency across different seasons and operating conditions, more realistic than simple EER ratings. TEWI (Total Equivalent Warming Impact) considers complete environmental impact over the system's entire life - both refrigerant leaks and electricity use.

Life-cycle cost analysis considers 15-20 years of energy savings, maintenance costs, and potential refrigerant replacement expenses when evaluating equipment investments.

Next-Gen Innovations

Magnetic refrigeration represents the most exciting development, using special alloys that heat when magnetized and cool when the field is removed. Early prototypes show 30-60% better efficiency than traditional systems, with no refrigerants at all.

Solid-state thermoelectric cooling is improving with new semiconductor materials and better heat exchangers, making Peltier devices competitive for specialized applications. They're silent, incredibly precise, and very compact.

Passive radiative cooling panels can cool below ambient temperature without using energy by radiating heat directly to outer space through specific wavelengths that pass through our atmosphere.

Integration with renewable energy is becoming crucial. Solar-powered absorption chillers work hardest when the sun shines brightest - exactly when cooling is needed most. Battery-backed systems provide reliable operation during grid outages, while smart grid integration shifts energy use to times when renewable power is most available.

Maintenance, Safety & After-Sales Service

Proper refrigerated cooling system maintenance protects your investment and ensures reliable performance. Like car maintenance, regular attention prevents expensive breakdowns and extends equipment life.

Regular inspection schedules make the difference. Unit coolers need thorough check-ups twice yearly, while air-cooled condensing units need quarterly attention. Annual oil sampling and accumulator inspection catch problems before they become expensive repairs.

The most important task is keeping coils clean. Dirty evaporator and condenser coils force systems to work harder, driving up energy costs and shortening equipment life. Use only approved, non-acidic cleaners to avoid damaging coil fins.

Fan operation deserves special attention. All fans should spin freely and quietly - grinding, squealing, or resistance indicates trouble ahead. Check electrical connections simultaneously, tightening loose connections and replacing damaged wiring.

Refrigerant management requires professional expertise. Certified technicians understand refrigerant handling complexities, pressure testing, and system charging. They ensure superheat measurements fall within the optimal 30°F-45°F range for peak compressor performance.

Remote monitoring systems and PLC controls are becoming standard, allowing technicians to spot problems before causing downtime through real-time alerts about temperature fluctuations, pressure changes, or component failures.

More info about fixing commercial fridge problems provides detailed troubleshooting guidance for common issues.

Extending the Life of Refrigerated Cooling Equipment

Long-lasting refrigerated cooling equipment requires consistent, scheduled care rather than reactive repairs. Well-maintained systems operate reliably for 15-20 years or more, while neglected equipment often fails within half that time.

Visual inspections should become routine. Look for corrosion, unusual vibration, oil stains, or refrigerant leaks around connections. Moisture indicators provide early warning of system contamination - catching moisture problems early prevents compressor damage.

Component replacement follows predictable patterns. Condenser motors use permanently sealed ball bearings needing no lubrication, but fan blades, filters, and door gaskets wear over time. Proactive replacement costs far less than emergency repairs.

Energy audits identify efficiency improvements while revealing developing problems. Monitoring superheat, subcooling, and amp draw helps optimize performance and catch issues weeks or months before causing obvious symptoms.

Certified technicians bring essential expertise to complex repairs and regulatory compliance, understanding refrigerant handling requirements, electrical codes, and safety procedures that keep systems running safely and legally.

Frequently Asked Questions about Refrigerated Cooling

Facility managers and business owners consistently ask these important questions about refrigerated cooling that affect food safety, operating costs, and environmental responsibility.

How cold should a refrigerated cooling system be for perishable foods?

Getting temperature right protects health and business reputation. The optimal range for perishable food storage is 37 to 41°F (3 to 5°C). This narrow range prevents bacterial growth that can double every 20 minutes between 40°F and 140°F - the "danger zone."

For frozen storage, maintain 0°F (-18°C) or colder. Commercial freezers often run at -10°F to -20°F because they handle frequent door openings and need consistent temperatures throughout the entire space.

Modern refrigerated cooling systems maintain these temperatures automatically, but regular monitoring ensures everything stays on track.

Which refrigerant is most eco-friendly for refrigerated cooling today?

Natural refrigerants offer the cleanest environmental profile available today. CO₂ leads with a Global Warming Potential (GWP) of just 1 - essentially climate-neutral. CO₂ transcritical systems work exceptionally well in colder climates and provide excellent heat recovery.

Ammonia comes in at GWP = 0, making it technically the most environmentally friendly option. It's incredibly efficient for large industrial applications, though requiring specialized handling and trained technicians.

Hydrocarbons like propane (GWP = 3) work beautifully in smaller systems. They're natural, efficient, and have minimal environmental impact.

Old HFC refrigerants are being phased out for good reason - they can have GWP values in the thousands. Switching to natural refrigerants isn't just environmentally responsible; it's future-proofing against changing regulations.

What regular maintenance does a refrigerated cooling unit require?

Most refrigerated cooling systems need professional attention every 6-12 months, depending on usage and location. The most important task is keeping coils clean - dirty coils force everything to work harder. Use only approved, non-acidic cleaners.

Electrical connections need regular attention due to vibration and thermal cycling that can loosen connections over time. Refrigerant levels and leak detection require certified technicians who understand proper handling procedures and can monitor superheat levels (should stay between 30°F-45°F).

Don't forget fan operation and defrost systems. Fans should run quietly and smoothly, while defrost cycles need proper timing. Large systems benefit from annual oil sampling to catch potential problems before expensive failures.

Professional service by certified technicians ensures regulatory compliance while maintaining warranty coverage - an investment that pays for itself through reliable operation and extended equipment life.

Conclusion

From ancient ice houses to today's sophisticated magnetic refrigeration prototypes, refrigerated cooling has transformed how we live, work, and preserve what matters most. This technology enables global commerce, supports life-saving medical treatments, and maintains the specialized environments that modern society depends on.

The journey toward better cooling continues with natural refrigerants that protect our climate, smarter controls that reduce energy waste, and innovative systems that work with renewable energy. These advances mean we can meet growing cooling demands while actually reducing our environmental footprint.

At American Mortuary Coolers, we've perfected custom solutions for funeral homes and specialized facilities throughout the contiguous 48 states. Our equipment provides the dependable performance that families and communities count on during difficult times.

Whether you're considering a compact mortuary cooler or planning a comprehensive walk-in refrigeration system, understanding these cooling principles makes all the difference. The right system operates efficiently for decades, saves money on energy bills, and provides the precise temperature control your application demands. More info about Walk-In Cooler Features and Prices can help guide your next project toward the most suitable cooling solution.

Looking ahead, refrigerated cooling technology promises exciting developments. Magnetic cooling systems could revolutionize efficiency. Solid-state cooling might eliminate moving parts entirely. Passive radiative panels could provide cooling without electricity.

These innovations mean refrigerated cooling will keep supporting essential functions that make modern life possible - while doing it more sustainably and efficiently than ever before.