Why Lift Électrique Solutions Are Essential for Modern Operations

Lift électrique systems represent the backbone of vertical transportation in today's buildings, accounting for approximately 90% of all lift installations compared to just 10% for hydraulic alternatives. These electric-powered lifting solutions use motor-driven cable systems with counterweights to move people and materials efficiently between floors.

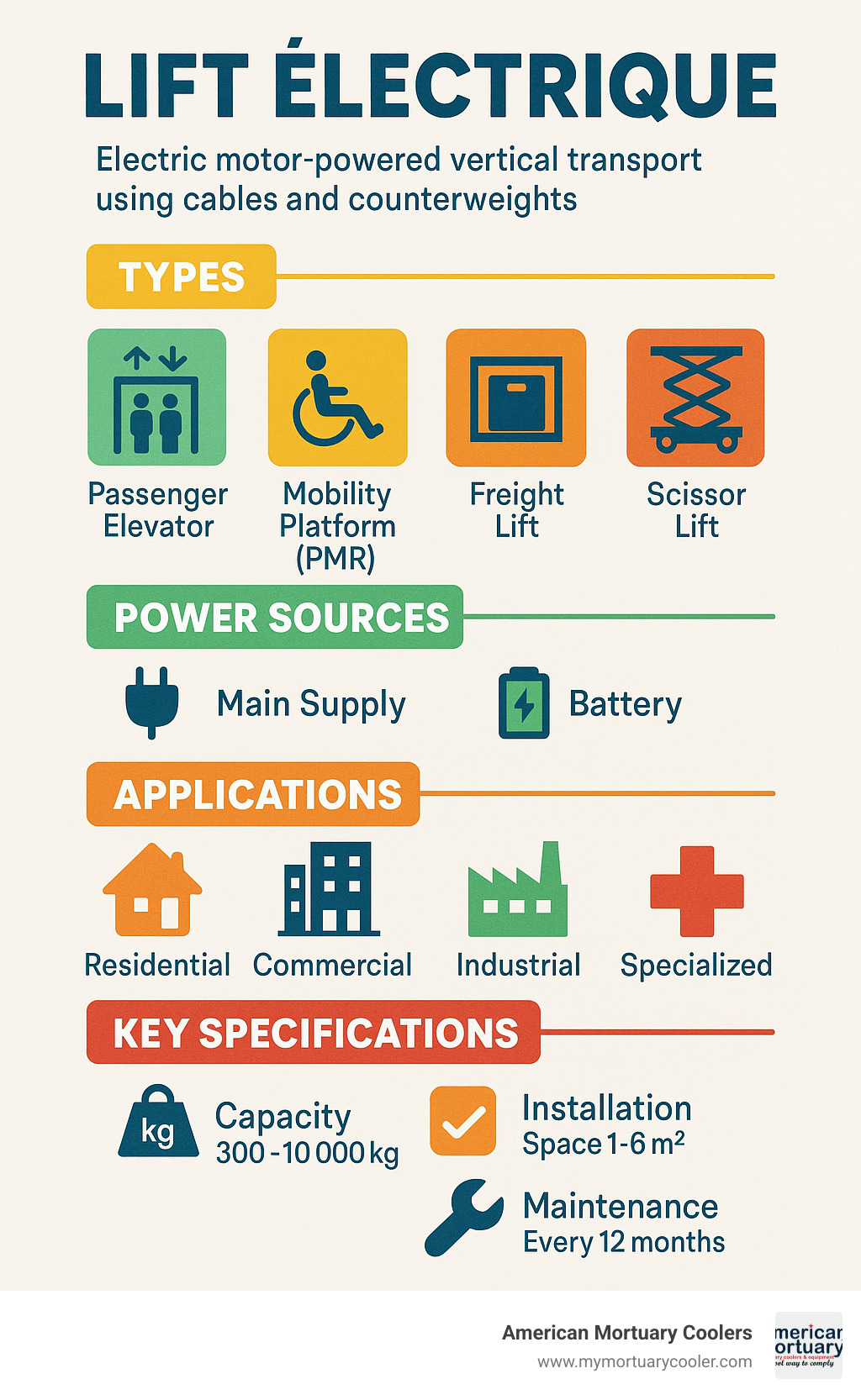

Quick Overview: Lift Électrique Essentials

- Definition: Electric motor-powered vertical transport using cables and counterweights

- Main Types: Passenger elevators, mobility platforms (PMR), freight lifts, scissor lifts, stair lifts

- Key Advantage: Higher speed and elevation capacity than hydraulic systems

- Energy Efficiency: Counterweight system reduces electricity consumption by up to 40%

- Applications: Residential, commercial, industrial, and specialized uses (including mortuary facilities)

The demand for lift électrique solutions continues growing as buildings get taller and accessibility requirements become stricter. From residential mini-elevators that fit in just 0.6 m² of space to heavy-duty mortuary lifts handling 1,000+ lbs capacity, electric lifts offer best versatility.

Modern innovations like lithium-ion batteries are revolutionizing the industry. BYD batteries now charge to 80% in just 30 minutes and retain 70% capacity after 8 years of use, making electric lifts more reliable than ever.

As American Mortuary Coolers, a national-level mortuary equipment supplier, we've worked extensively with lift électrique systems designed specifically for funeral home operations, helping directors choose reliable solutions that meet their space and budget constraints. Our experience spans both residential accessibility lifts and specialized mortuary lifting equipment that prioritizes American craftsmanship and direct shipping.

Basic lift électrique vocab:

Qu'est-ce qu'un lift électrique ? Définition & Différences Clés

Think of a lift électrique as the smart cousin in the elevator family. While hydraulic lifts use pressurized oil to push their way up (kind of like a giant car jack), electric lifts work more like a sophisticated see-saw. They use an electric motor to pull steel cables through a pulley system, with a heavy counterweight on the other side doing most of the heavy lifting.

This counterweight system is where the magic happens. When your elevator car goes up, that counterweight slides down, and vice versa. It's like having a workout buddy who's perfectly matched to your strength - the motor only needs to handle the difference between what's in the car and what the counterweight provides.

The two main types of electric systems are traction (cables and pulleys) and tambour (drum and cable). Traction systems dominate modern installations because they're smoother, faster, and can reach incredible heights. We're talking 300+ meters compared to hydraulic systems that max out around 20 meters.

| Feature | Lift Électrique | Lift Hydraulique |

|---|---|---|

| Maximum Height | 300+ meters | ~20 meters (5-6 floors) |

| Speed | Up to 10 m/s | 0.15-1 m/s |

| Energy Efficiency | High (counterweight system) | Lower (pump motor) |

| Noise Level | Very quiet | Moderate to loud |

| Space Requirements | Machine room or machine-room-less | Oil tank + pump room |

| Maintenance | Lower frequency | Higher (fluid changes) |

| Environmental Impact | Minimal | Oil disposal concerns |

Fonctionnement du lift électrique

The heart of every lift électrique is surprisingly neat. Steel cables (usually 8-13mm thick) connect your elevator car to that all-important counterweight. These cables run over a grooved pulley system that would make any engineer smile.

Modern systems use something called a variateur fréquence (variable frequency drive) to control everything. This smart device tells the motor exactly how fast to spin, ensuring those buttery-smooth starts and stops that make you forget you're even moving.

Here's the beautiful part: the motor isn't actually "lifting" anything in the traditional sense. It's more like a referee in a tug-of-war, providing just enough push to overcome friction and balance out the weight differences. This is why electric lifts sip electricity instead of guzzling it.

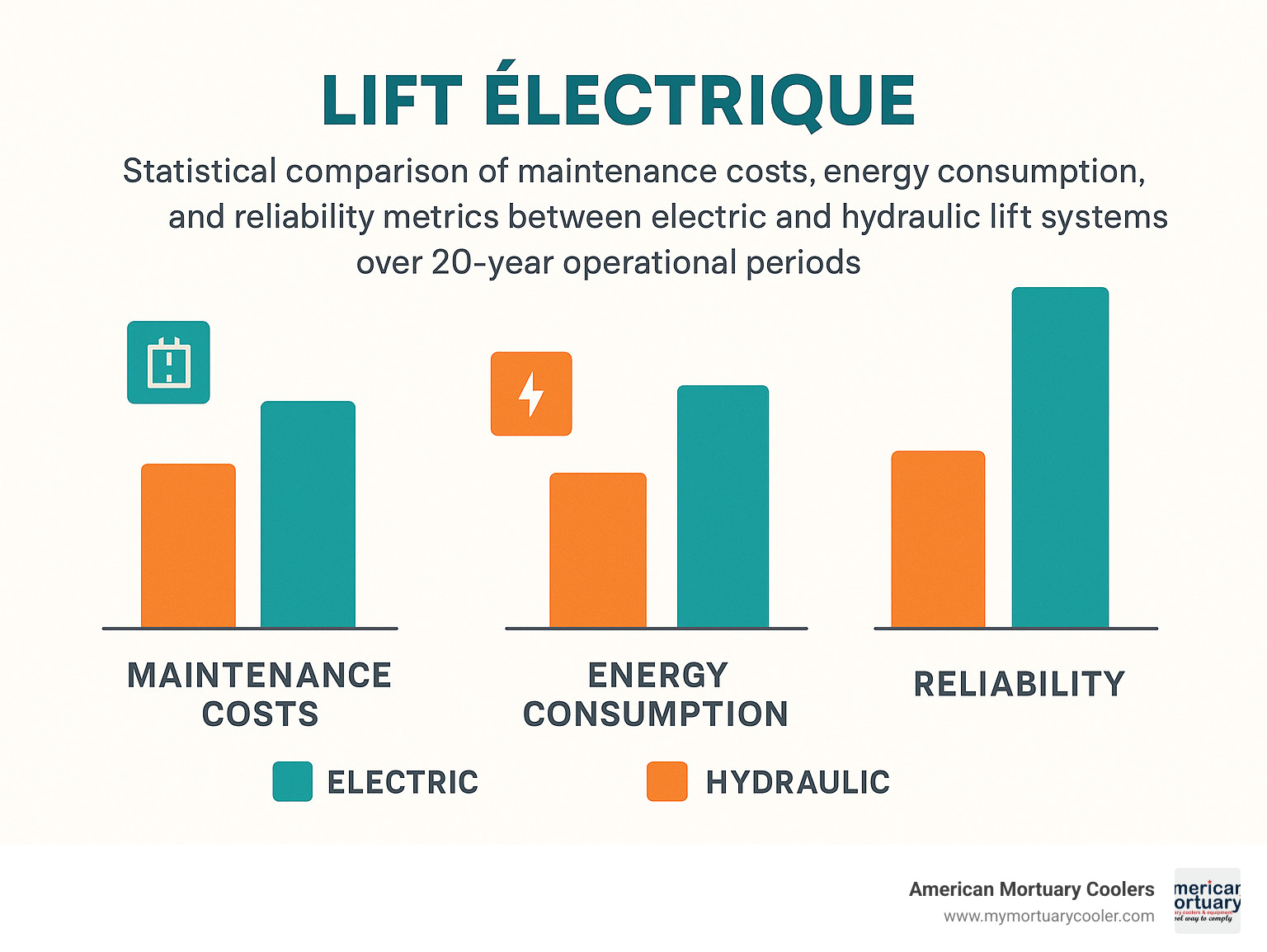

Lift électrique : comparaison hydraulique

When it comes to consommation énergie, electric lifts are the clear winners. That counterweight system we keep talking about? It can reduce energy use by up to 40% compared to hydraulic systems that have to muscle their way up against gravity every single time.

Maintenance tells a similar story. Electric lifts need their cables checked and motors serviced, but they don't require the constant oil changes, filter swaps, and leak repairs that keep hydraulic systems in the shop.

And let's talk about bruit - or rather, the lack of it. Electric lifts operate so quietly that you might wonder if they're even running. This makes them perfect for funeral homes, hospitals, or any place where peace and quiet matter. Hydraulic systems, with their pumps and motors, can sound like a small factory running in your building.

The empreinte carbone (carbon footprint) difference is significant too. Electric systems don't need oil changes or hydraulic fluid disposal, making them the environmentally friendly choice for modern buildings.

Les Différents Types de Lifts Électriques et Leurs Usages

When you think about lift électrique systems, you might picture the standard passenger elevator in an office building. But the reality is much more interesting - electric lifts come in dozens of specialized forms, each designed to solve specific vertical transportation challenges.

The residential market has acceptd mini-elevators that can squeeze into surprisingly tight spaces. We're talking about systems that need just 0.6 m² of floor space - smaller than most closets. These compact lifts are perfect for families who want to age in place or accommodate a family member with mobility challenges without major home renovations.

In commercial buildings, lift électrique technology handles everything from moving people between floors to transporting heavy equipment. The beauty of electric systems is their consistency - they perform the same way on the first ride of the day as they do on the hundredth.

Lift électrique pour mobilité réduite

Accessibility lifts represent some of the most thoughtfully designed lift électrique applications. Stair lifts use precision electric motors to steer even the trickiest staircases, including those with multiple 180° turns and curved configurations that would challenge any engineer.

Platform lifts designed for wheelchair users (PMR systems) prioritize safety and comfort above all else. These systems typically handle up to 400 lbs while moving at a gentle 10 mm/s - slow enough to feel completely secure, fast enough to be practical. Most include battery backup systems so they'll work even during power outages, which is crucial for anyone who depends on them for daily mobility.

The mini-ascenseur category has gotten surprisingly sophisticated. Modern bi-rail systems integrate so seamlessly into home design that visitors often don't realize they're there until they see them in action. They provide full wheelchair accessibility between floors without dominating the living space.

Lifts industriels & logistiques

Industrial applications have been transformed by lithium-ion battery technology. Chariots lithium GreenLift - BYD systems showcase what's possible with modern electric power - they charge to 80% capacity in just 30 minutes and maintain 70% of their original capacity after 8 years of regular use.

Electric scissor lifts like the Genie GS-3232 reach 9.8m platform height while supporting 227 kg of equipment and workers. For even higher work, boom lifts such as the Genie Z-60 DC extend to 20.16m working height with the same weight capacity. These machines run quietly, produce zero emissions, and require far less maintenance than their diesel counterparts.

The industry shift is remarkable - 70% of Genie's aerial lift lineup is now electrified. This isn't just about being environmentally conscious; it's about lower operating costs, reduced maintenance headaches, and the ability to work indoors without ventilation concerns.

Lifts spéciaux funéraires

In our specialty area of mortuary equipment, lift électrique systems serve a unique and important role. These lifts must operate with the quiet dignity that funeral homes require while providing the reliability that funeral directors need during sensitive times.

Mortuary lifts handle capacities from 500 to 1,000+ lbs and reach heights of 80+ inches for proper working positions. They're typically built with marine-grade aluminum - strong enough for professional use but light enough for easy positioning. Many include optional digital weight scales for precise measurements when needed.

The key advantage of electric actuator models is their elimination of hydraulic fluid entirely. This means no leaks, no fluid changes, and no environmental concerns. More info about lift tables covers the technical specifications that matter most to funeral professionals.

At American Mortuary Coolers, we've learned that funeral directors value silent operation above almost everything else. When you're serving families during their most difficult moments, the last thing you want is mechanical noise disrupting the peaceful atmosphere you work so hard to maintain.

Caractéristiques Techniques, Innovations & Critères de Choix

When you're shopping for a lift électrique, you're looking at technology that's evolved dramatically over the past decade. These aren't your grandfather's simple cable-and-pulley systems anymore. Today's electric lifts are sophisticated machines that combine precision engineering with smart technology to deliver smooth, reliable performance.

The technical specs might seem overwhelming at first, but they tell an important story about what each system can do. Capacity ranges typically run from 320 kg for small residential units up to 2,500 kg for heavy-duty commercial applications. Speed capabilities vary just as widely - from gentle 0.5 m/s operation for accessibility lifts to lightning-fast 10+ m/s systems in high-rise buildings.

What's really impressive is how modern lift électrique systems handle power management. Most residential units run on standard 220V single-phase power, while larger commercial systems use 380V three-phase connections. The real game-changer is regenerative drive technology that actually feeds power back into your building's electrical grid when the lift descends with a heavy load.

Safety features have become incredibly sophisticated too. EN81-20 compliance ensures European-standard safety protocols, while overspeed governors and emergency brakes provide multiple layers of protection. Modern systems include seismic detection that automatically parks the lift at the nearest floor if earthquake activity is detected.

Electric lift: advantages and working principle provides deeper technical insights into how these systems achieve such impressive performance levels.

Lift électrique : innovations 2024

The biggest breakthrough in lift électrique technology this year has been the revolution in battery systems. BYD's lithium-ion batteries are changing everything we thought we knew about backup power and maintenance schedules.

Here's what makes these batteries so special: they charge to 80% capacity in just 30 minutes. That's faster than most people take for lunch. Full charging takes only 1-2 hours, and these batteries maintain 70% of their original capacity even after 8 years of regular use.

But the real kicker? Zero maintenance requirements. No water to add, no terminals to clean, no battery changes for nearly a decade. For funeral directors who need reliable equipment without constant upkeep, this is a game-changer.

Cloud-based monitoring systems now provide real-time diagnostics that can predict problems before they happen. Some systems learn your usage patterns and pre-position the lift car during busy periods, reducing wait times and energy consumption.

Energy regeneration technology captures power generated during descent and feeds it back into your building's electrical system. It's like having a tiny power plant that actually reduces your electricity bills while providing transportation.

Comment choisir son lift

Choosing the right lift électrique starts with an honest assessment of your needs. We've helped dozens of funeral homes through this process, and the key is getting the basics right before you get distracted by fancy features.

Building considerations come first. How many floors do you need to serve? Do you have space for a traditional machine room, or do you need a machine-room-less system? Can your building's structure handle the additional loads? These aren't glamorous questions, but getting them wrong can derail your entire project.

Usage requirements matter more than most people realize. A residential lift that sees 10 trips per day has completely different needs than a commercial system handling 200+ daily cycles. Think about peak usage periods too - will you need the lift most during visitation hours or throughout the day?

Budget considerations should include the total cost of ownership over 20-25 years, not just the upfront price. A slightly more expensive system with lower maintenance costs often saves money in the long run. Don't forget to investigate accessibility grants and financing options that might be available.

At American Mortuary Coolers, we've learned that funeral directors particularly value reliability and quiet operation. When you're serving families during difficult times, the last thing you want is equipment that draws attention to itself. The right lift électrique system should work so smoothly that people barely notice it's there.

The key is finding a system that matches your specific needs without paying for capabilities you'll never use. Sometimes the simplest solution is the best solution.

Installation, Maintenance, Normes & Budget

Getting a lift électrique installed isn't something you tackle over a weekend - it's a carefully orchestrated process that typically takes several weeks and involves multiple skilled trades working together. Think of it like conducting an orchestra, where timing and coordination make all the difference between a smooth installation and a costly headache.

The journey begins with a thorough site assessment. This isn't just measuring spaces - it's about understanding your building's bones. Can the structure handle the additional loads? Is there adequate electrical capacity? Where will the equipment fit without disrupting daily operations? These questions need solid answers before any work begins.

Navigating the permit maze varies depending on where you're located, but most installations require building permits for structural changes, electrical permits for power connections, and lift-specific permits from elevator authorities. If accessibility compliance is involved, expect additional paperwork. In Quebec, contractors need RBQ licensing (like license 8277-1106-03), while Maritime provinces require category B certification (#469196).

The regulatory landscape might seem daunting, but working with experienced installers who understand local requirements makes the process much smoother. At American Mortuary Coolers, we've learned that proper planning during this phase prevents costly surprises later.

Étapes d'installation d'un lift électrique

The foundation work comes first. If you're installing a traditional system, creating the lift shaft and preparing the pit area requires precision. Modern machine-room-less systems have simplified this considerably, but proper waterproofing and structural preparation remain absolutely critical.

Next comes the mechanical installation. This is where precision really matters - rails must be aligned within 2-3mm tolerance over the entire travel distance. Even small misalignments can cause premature wear and noisy operation. The motor and control systems get positioned, whether in a dedicated machine room or integrated directly into the shaft space.

The electrical phase involves connecting power supplies, running control wiring, and installing safety systems. Modern lift électrique systems include sophisticated diagnostic capabilities that verify everything is connected properly before the first test run. This built-in intelligence catches wiring errors that might not show up until later.

Testing and commissioning wraps up the installation. This includes comprehensive load testing, safety system verification, and speed calibration. Don't be surprised if minor adjustments are needed - even the best installations require fine-tuning for optimal performance.

Entretien & durabilité

Here's where lift électrique systems really shine compared to their hydraulic cousins - they need significantly less babysitting to keep running smoothly. A well-designed maintenance program keeps your system reliable without breaking the budget.

Monthly attention focuses on the basics: visual cable inspections, door operation checks, lubrication of moving parts, and control system diagnostics. These quick checks catch small problems before they become big headaches.

Quarterly services dig deeper with detailed cable inspections, motor analysis, safety brake testing, and emergency system verification. This is when experienced technicians can spot wear patterns and make adjustments that extend equipment life.

Annual certifications are the comprehensive health checkup your system needs. Complete safety overhauls, load testing, regulatory compliance inspections, and parachute system verification ensure everything meets safety standards. This isn't optional - it's required by law in most jurisdictions.

Modern telemaintenance systems have revolutionized how we monitor lift performance. These smart systems watch your equipment continuously, alerting service technicians to potential issues before they cause downtime. It's like having a mechanic who can spot trouble before your car breaks down on the highway.

Let's talk numbers - because budget planning matters. Initial equipment costs typically range from $15,000 to $50,000+ depending on your specifications. Installation adds another $10,000 to $30,000, with the higher end reflecting complex building modifications.

Annual maintenance contracts usually run $1,500 to $3,000 for standard service, which is reasonable insurance for reliable operation. Energy costs are refreshingly low - expect $200 to $800 annually depending on usage patterns.

The good news? Many jurisdictions offer accessibility grants or tax incentives that can offset 30-50% of installation costs for residential accessibility applications. These programs recognize that mobility shouldn't be limited by stairs.

At American Mortuary Coolers, we've seen how the right lift system transforms workflow efficiency in funeral homes while maintaining the respectful atmosphere families expect. The key is choosing quality equipment and maintaining it properly - an investment that pays dividends in reliability and peace of mind.

Frequently Asked Questions about Lift Électrique

We get a lot of questions about lift électrique systems from funeral directors and facility managers. Having installed countless lifts in mortuary facilities across the country, we've learned that most people have similar concerns about maintenance, installation challenges, and equipment longevity.

Here are the most common questions we hear, along with straight answers based on our real-world experience.

Quel entretien annuel est obligatoire ?

Every lift électrique system needs an annual safety inspection by a licensed technician - this isn't optional, it's required by law in most jurisdictions. The inspection covers all the critical safety components that keep your lift running safely day after day.

During the annual service, technicians test the overspeed governor (the device that stops the lift if it moves too fast), inspect every inch of the steel cables for wear or fraying, and verify that the emergency brake system works properly. They'll also run load tests to make sure the system can still handle its full rated capacity.

The electrical systems get a thorough going-over too. This includes checking all connections, testing the variable frequency drive that controls motor speed, and verifying that door safety mechanisms respond correctly to obstructions.

Most service contracts run $1,500-$3,000 annually and include both the required inspection and emergency service coverage. In our experience, this is money well spent - catching small problems during routine maintenance prevents expensive emergency repairs later.

Un lift électrique est-il adapté aux bâtiments sans fosse ?

Absolutely! Modern lift électrique systems are actually better suited for buildings without deep pits than you might think. The old assumption that electric lifts need big machine rooms and deep pits is outdated.

Today's machine-room-less electric systems can work with pit depths as shallow as 10-15 centimeters. Some models can even be installed completely flush with the existing floor level. This is particularly helpful in funeral homes where you're retrofitting accessibility equipment into existing buildings.

Interestingly, hydraulic systems often require deeper pits than modern electric lifts. The hydraulic cylinder needs to be buried below ground level, which means significant excavation work. Electric systems use overhead traction, so they're often the smarter choice when you can't dig deep.

We've installed electric lifts in century-old funeral homes where excavation would have been a nightmare. The key is working with experienced installers who understand the flexibility of modern electric systems.

Quelle est la durée de vie des batteries lithium-ion ?

The BYD lithium-ion batteries used in modern lift électrique systems are remarkably long-lasting. After 8 years of regular use, they still retain 70% of their original capacity. That's impressive longevity for any battery system.

What makes these batteries special is their fast charging capability. They reach 80% charge in just 30 minutes and hit 100% capacity in 1-2 hours. This means you can top them off during lunch breaks or between busy periods.

The maintenance story is even better - these batteries need absolutely no maintenance throughout their entire service life. No water to add, no terminals to clean, no individual cells to replace. They just work, year after year.

When the batteries finally do need replacement after 8-10 years, the entire pack gets swapped as a unit. The old batteries go into established recycling programs, so there's no environmental guilt about disposal.

From our perspective at American Mortuary Coolers, this reliability is crucial in funeral home environments where equipment failure during services simply isn't acceptable. The peace of mind that comes with maintenance-free operation is worth the investment.

Conclusion

Making the right choice with a lift électrique system comes down to understanding your specific needs and matching them with the right technology. After years of working with funeral directors across the country, we've learned that the best systems are the ones that quietly do their job day after day, without drawing attention to themselves.

Electric lifts have proven themselves superior to hydraulic alternatives in almost every way that matters. They're more energy efficient thanks to their clever counterweight design, they need less maintenance because there's no messy hydraulic fluid to deal with, and they're incredibly quiet - something that's especially important in sensitive environments like funeral homes.

The technology keeps getting better too. Those BYD lithium-ion batteries that charge to 80% in just 30 minutes? That's a game-changer for busy operations. Smart monitoring systems that can predict problems before they happen? That means fewer unexpected breakdowns and more reliable service when families need it most.

Whether you're looking at a simple residential accessibility lift to help aging clients steer their homes, or you need a specialized mortuary lift that can handle the unique demands of funeral service, electric systems offer the reliability and dignity that your operation deserves.

At American Mortuary Coolers, we've built our reputation on understanding these specialized needs. Our custom solutions and direct delivery across the contiguous 48 states mean you're not dealing with middlemen or generic equipment that doesn't quite fit your space or workflow.

From our Tennessee headquarters to our service areas spanning the Southeast and beyond, we've seen how the right lift électrique system transforms daily operations. It's not just about moving things up and down - it's about creating a smoother, more respectful environment for families during difficult times.

The shift toward electric technology isn't just a trend - it's the smart choice for durability, efficiency, and long-term value. With proper installation and regular maintenance, a quality electric lift system will serve your operation reliably for decades while contributing to a more sustainable and accessible future.

The time to make the switch to electric has never been better. With today's technology, competitive pricing, and available accessibility grants, there's no reason to settle for outdated hydraulic systems or unreliable equipment.

More info about mortuary lift solutions can help you explore your options and find the perfect system for your specific needs. Because when it comes to serving families with dignity and respect, every detail matters - including the equipment that helps you do your job better.