Why Scalpel Handles Are Essential for Precision and Safety

Scalpel handles are the reusable gripping components that hold surgical blades securely during medical procedures, dissections, and precision cutting tasks. These handles come in numbered sizes (#3, #4, #7, etc.) that correspond to specific blade types, with materials ranging from surgical stainless steel to lightweight plastic.

Quick Reference: Scalpel Handle Basics

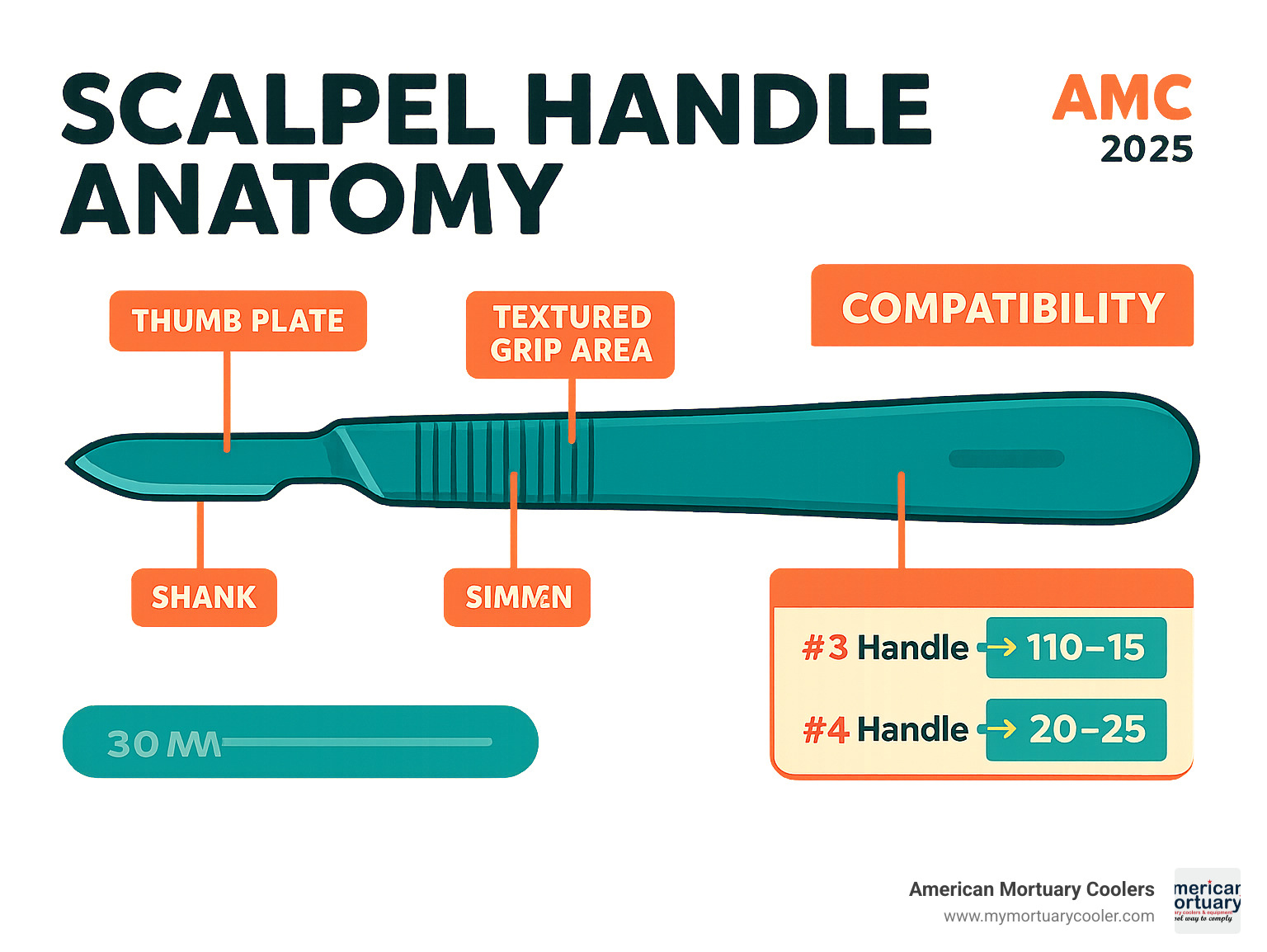

- #3 Handle: Fits blades #10-15 (most common for general use)

- #4 Handle: Fits blades #20-25 (larger, heavier cutting)

- #7 Handle: Pen-shaped for fine, detailed work

- Materials: Stainless steel (reusable), plastic (economy), titanium (premium)

- Key Features: Textured grip, alignment marks, autoclave-safe construction

The modern scalpel handle system was patented by Morgan Parker in 1915, and that basic locking design remains largely unchanged today. As one surgical education podcast notes: "Morgan Parker, a 22-year-old engineer, originally designed today's locking scalpel system."

Proper handle selection affects both precision and safety. The wrong handle-blade combination can lead to poor cutting control, while inadequate grip texturing increases slip risk during procedures. Handle materials must withstand repeated sterilization cycles while maintaining their structural integrity.

I'm Mortuary Cooler from American Mortuary Coolers, and I've spent years helping funeral professionals select durable, reliable equipment including precision instruments like scalpel handles. My experience sourcing quality mortuary tools has shown me how critical it is to match the right scalpel handles to specific applications for both safety and efficiency.

Learn more about scalpel handles:

What Is a Scalpel Handle and Why It Matters

Think of a scalpel handle as the reliable partner to a sharp blade - it's the reusable grip component that holds disposable surgical blades securely during cutting procedures. Unlike those all-in-one disposable scalpels you might see in medical dramas, professional-grade handles are built to last and feature a clever locking mechanism that lets you swap blades safely.

The magic happens in how these handles transform your hand movements into precise cuts. Whether you're performing delicate surgical work or detailed dissection, the handle acts as the crucial link between your skill and the blade's edge. When lives or important work depend on millimeter precision, you need a handle that won't let you down.

Scalpel handles come in two main varieties when it comes to materials. Reusable handles are typically crafted from surgical-grade stainless steel and can withstand thousands of sterilization cycles. Disposable options use medical-grade plastics for single-use applications or when cross-contamination prevention is paramount.

The material choice extends beyond just steel and plastic. Stainless steel handles offer best durability and that solid, balanced feel that experienced users prefer. Plastic handles provide a lightweight, cost-effective solution that's perfect for educational settings or procedures where disposal is preferred. For those seeking the ultimate in performance, titanium handles deliver exceptional strength while remaining surprisingly light in hand.

Core Components of Scalpel Handles

Every quality scalpel handle is engineered with four essential elements that work together seamlessly. The thumb plate serves as your primary control surface - that flat area where your thumb naturally rests. Most quality handles feature textured grooves here that provide secure grip even when wearing gloves or working in challenging conditions.

The shank forms the handle's backbone, typically measuring between 4.9 and 5.8 inches depending on the specific model. This isn't just empty space - it houses the internal mechanics that make blade attachment possible while providing the structural integrity needed for precise work.

At the business end, you'll find the locking slot - a precisely machined opening where magic happens. This slot is engineered to exact tolerances, ensuring that blade shanks slide in smoothly but lock securely once in position. The precision here directly affects both safety and cutting performance.

Alignment marks might seem like simple diagonal lines, but they're your guarantee of proper blade seating. These etched marks on both handle and blade must line up perfectly before the blade slides forward into its locked position. It's a simple system that's prevented countless accidents over the decades.

How Handle Design Affects Precision & Safety

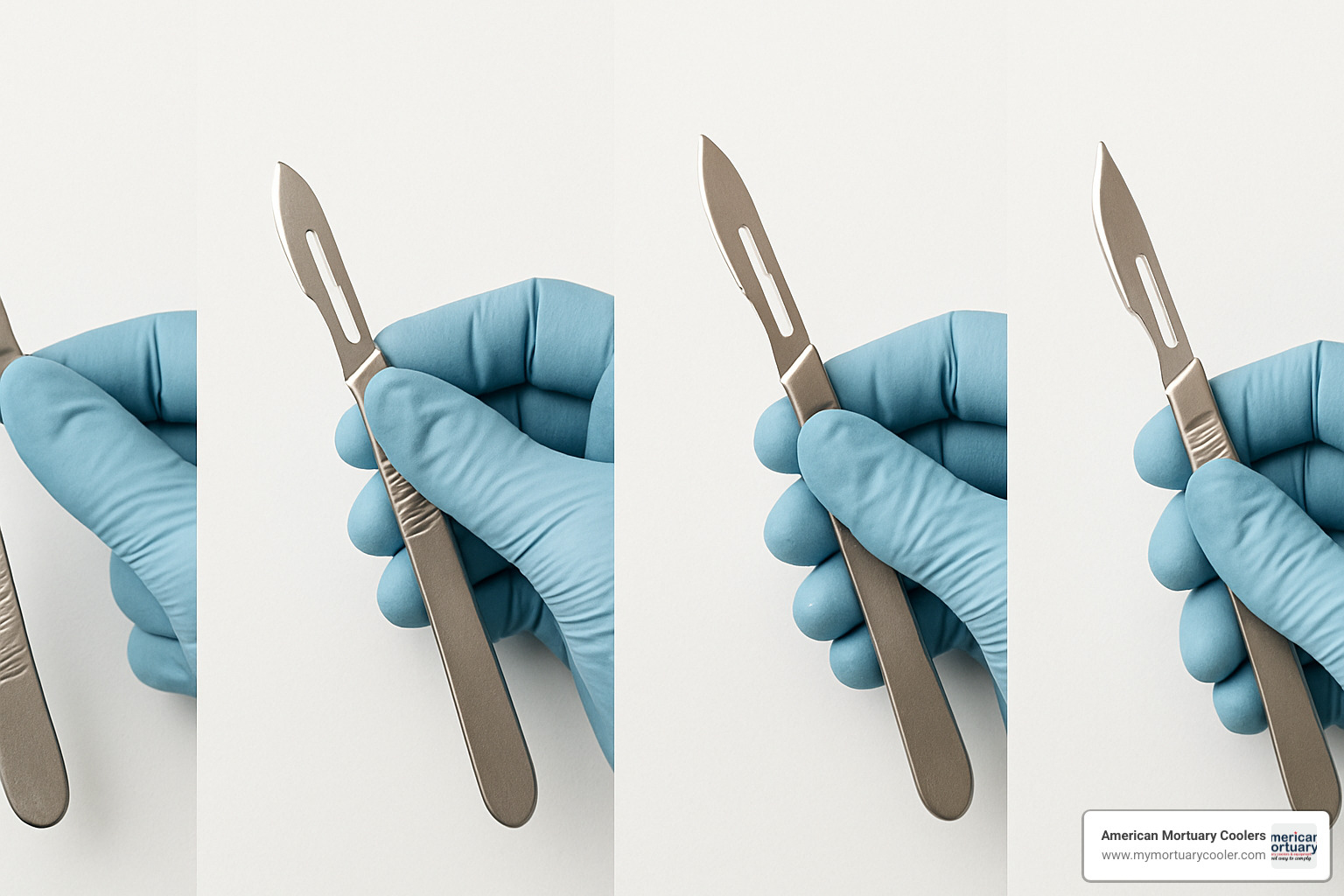

The engineering behind scalpel handles directly impacts how well you can perform your work. Balance isn't just a nice-to-have feature - it determines whether the handle feels natural in your hand during extended procedures. A well-balanced handle reduces hand fatigue and maintains cutting accuracy even when you're working for hours.

Those textured grooves you'll find on quality handles serve a vital safety function. They provide slip resistance when your hands become wet or when working with surgical gloves. The groove pattern needs to hit that sweet spot between providing secure grip and being easy to clean thoroughly - because bacteria love to hide in hard-to-reach places.

Weight distribution affects everything from comfort to control. Heavier handles provide stability for demanding cuts, while lighter options reduce fatigue during delicate work. The material choice plays a huge role here - steel handles offer that solid, professional feel, while plastic handles keep things light and maneuverable.

Modern handle design has evolved significantly since the history of the modern scalpel began over a century ago. Today's handles incorporate decades of user feedback and engineering refinement to deliver the precision and safety that modern procedures demand.

Types & Sizes of Scalpel Handles Explained

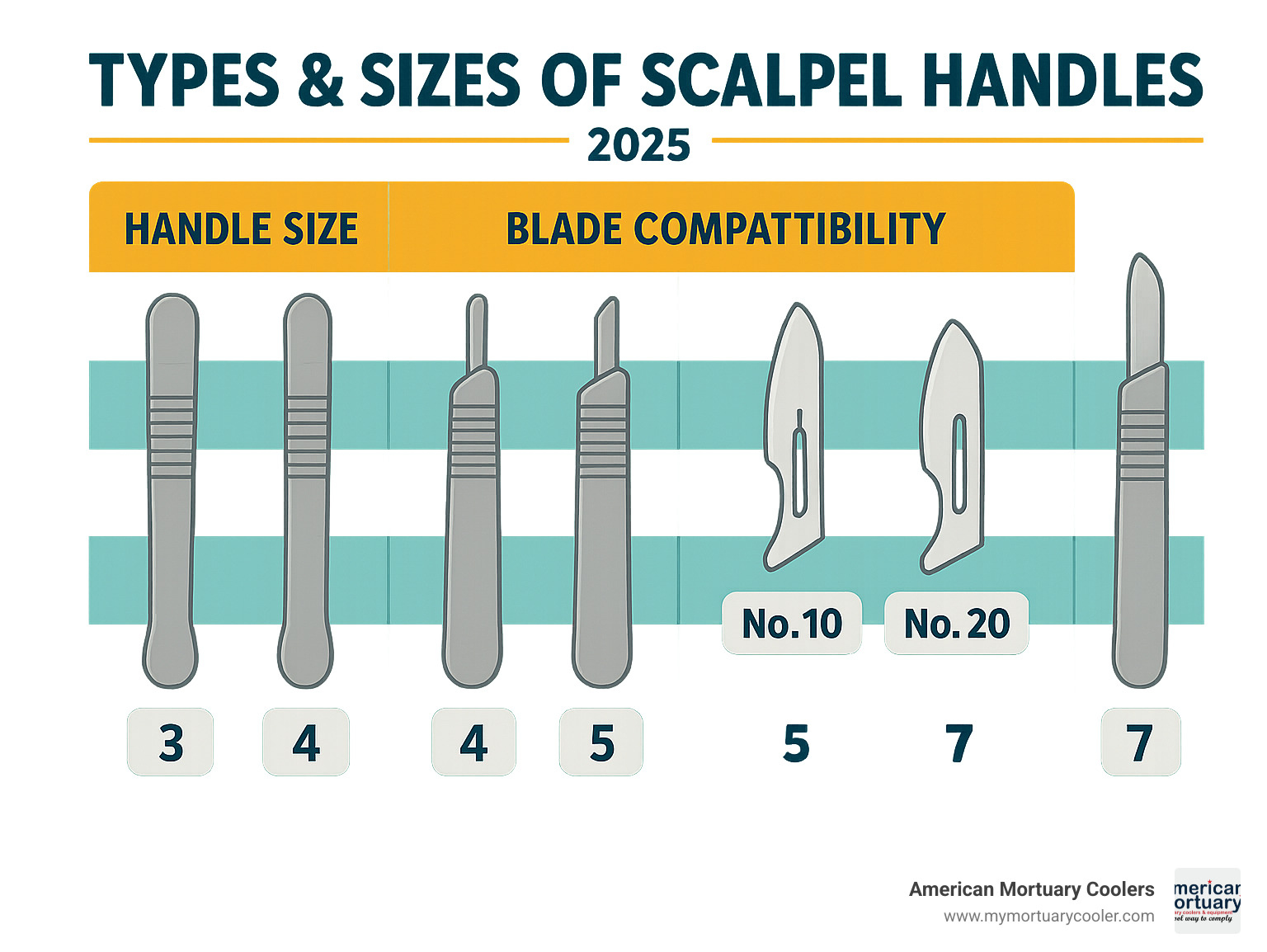

The scalpel handle numbering system follows standards established over a century ago and codified in ISO 7740:1985. This international standard ensures compatibility between handles and blades from different manufacturers worldwide.

Handle Size Reference Table:

| Handle Number | Length | Blade Compatibility | Primary Use |

|---|---|---|---|

| #3 | 4.9" | #10-15 | General surgery, fine work |

| #4 | 5.5" | #20-25 | Larger incisions, heavy cutting |

| #5 | 5.8" | #10-15 | Angled work, posterior access |

| #7 | Pen-style | #10-15 | Delicate procedures, fine control |

| #8 | 5.5" | #60XT, #22XT | Industrial, specialty blades |

| #9 | 5.5" | #10-15 | Extended procedures |

Standard Scalpel Handles (#3–#9)

Handle #3 represents the workhorse of surgical instruments. At 4.9" long and 13mm wide, it accommodates blades #10 through #15, making it suitable for most general surgical procedures. The flat profile provides excellent control for both palmar and pencil grips.

Handle #4 offers increased size and weight for procedures requiring more force or larger incisions. Compatible with blades #20-25, this handle excels in situations where substantial cutting power is needed. The additional weight - while requiring more effort - provides improved cutting stability.

Handle #7 breaks from the traditional flat design with its pen-like round profile. This unique shape makes it ideal for fine, detailed work where precision trumps cutting force. As noted in our research, "The #7 handle is shaped like a long writing pen for fine work."

Extended, Angled, and Ergonomic Variants

Modern surgical demands have driven innovation beyond basic handle designs. Extended handles like the #3L and #4L provide additional reach for deep surgical fields where standard handles limit visibility or access.

The #3LA (angled) variant features a 30-degree offset that proves invaluable for posterior and palatal procedures. This angled design allows surgeons to maintain proper wrist positioning while accessing difficult anatomical locations.

Comfort grip handles address the ergonomic challenges of extended procedures. These designs feature broader thumb plates, improved texturing, and weight distribution optimized for reduced hand fatigue. Some manufacturers offer hollow broad handles that maintain strength while reducing overall weight.

Materials & Manufacturing Standards

Surgical Stainless Steel remains the gold standard for reusable scalpel handles. These handles withstand repeated autoclave cycles at 121°C while maintaining their structural integrity and corrosion resistance. Premium surgical steel offers superior durability compared to economy grades.

German Stainless Steel represents the highest quality tier, featuring improved metallurgy and precision manufacturing. These handles often carry lifetime guarantees and demonstrate superior edge retention on textured surfaces.

Plastic Composite handles serve specific applications where weight reduction or cost control takes priority. While not suitable for repeated autoclaving, these handles work well for single-use applications or procedures where lightweight instruments reduce user fatigue.

Choosing, Maintaining & Sterilizing the Right Scalpel Handles

Choosing the right scalpel handles isn't rocket science, but it does require some thought. Over the years, I've watched professionals make expensive mistakes by grabbing the cheapest option without considering their specific needs. The key is balancing your procedure requirements with your budget and maintenance capabilities.

Start by thinking about what you'll actually be doing with these handles. Are you performing delicate tissue work that demands precision, or are you tackling heavier cutting tasks? Your procedure type drives everything else - from handle size to material choice. Budget matters too, but quality handles can last decades with proper care, making them surprisingly economical over time.

Blade compatibility forms the foundation of your selection process. There's no point in buying beautiful #4 handles if all your procedures use #11 blades - they simply won't fit together. Consider whether you need autoclave capability as well. While plastic handles cost less upfront, they can't handle repeated sterilization cycles like stainless steel versions can.

Step-by-Step Handle & Blade Matching

Getting the handle and blade pairing right prevents frustration and safety issues down the road. I've seen too many people struggle with mismatched components, and it's completely avoidable with a bit of planning.

First, identify your blade requirements by looking at your most common procedures. Do you frequently use fine #11 blades for precise incisions, or do you need robust #22 blades for substantial cutting? Write down the blade numbers you use most often - this becomes your shopping list.

Next, match these blades to compatible handles using the sizing system we covered earlier. #3 handles work with blades #10-15, while #4 handles pair with #20-25. Consider your preferred grip style too - larger handles suit palmar grips for powerful cutting, while smaller handles work better for pencil grips during detailed work.

Handle length deserves attention as well. Standard handles work perfectly for most applications, but long variants become essential for deep procedures where reach matters. For comprehensive guidance on blade compatibility, check out our detailed resource on Everything You Need to Know About Knife Handle 3 Compatibility.

Cleaning and Sterilization Protocols

Proper maintenance keeps your scalpel handles working safely for years while protecting everyone who uses them. The cleaning process might seem straightforward, but there's a right way to do it that ensures complete decontamination.

Start with immediate cleaning after each use. Rinse off any visible contamination with running water - don't let organic matter dry and harden on the handle surface. Follow this with a thorough detergent wash using enzymatic cleaners that break down protein deposits hiding in textured grip areas.

An ultrasonic bath provides excellent cleaning for stubborn residues, though it's not always necessary for routine maintenance. The key step is careful inspection before sterilization. Look for damage, wear, or any remaining contamination that could compromise the next procedure.

Autoclave sterilization at 121°C for 15-20 minutes represents the gold standard for reusable handles. Quality handles manufactured to ISO 7740:1985 standards handle thousands of these cycles without problems. After sterilization, store handles in a clean, dry environment to prevent recontamination before their next use.

Regular inspection becomes more important as handles age. While good stainless steel handles last practically forever, repeated thermal cycling can eventually cause material fatigue. Better to catch wear early than deal with a failure during a critical procedure.

Safety Tips for Attachment & Removal

Safe blade handling protects you and everyone around you from needlestick injuries. The rules here are simple but non-negotiable - never handle blades with your fingers, and always use proper technique for attachment and removal.

For safe blade attachment, use artery forceps or tissue forceps to handle the blade. Align those diagonal marks on both the blade and handle carefully - they're there for a reason. Slide the blade onto the handle until it's fully seated, then verify the connection visually. Never test blade security by touching it.

Blade removal follows a similar pattern. Grasp the blade's blunt edge with forceps, lift and bend it slightly away from the handle, then slide it forward off the handle. Drop it immediately into your designated sharps container - don't set it down anywhere first.

Consider investing in hands-free blade removal systems if you handle large volumes. These devices let you dispose of blades safely without any direct handling, dramatically reducing injury risk in busy environments. Some facilities also benefit from craft knife safety systems for additional protection.

The bottom line is that a few seconds of careful technique prevents injuries that can sideline you for weeks. It's worth developing good habits from the start.

Industry Standards, Applications & Leading Manufacturers

When it comes to scalpel handles, quality isn't negotiable. The industry operates under strict guidelines, with ISO 7740:1985 serving as the backbone standard that keeps everything compatible worldwide. This specification covers everything from dimensional tolerances to materials requirements - basically ensuring that a blade made in Germany will fit perfectly on a handle manufactured in Tennessee.

In the United States, scalpel handles are classified as FDA Class I medical devices. This means manufacturers must prove their products are safe and effective through 510(k) submissions before they can sell to medical facilities. European markets have their own requirements too, demanding CE marking to show compliance with Medical Device Regulation standards.

The beauty of these standards is that they protect both users and patients. When you pick up a #3 handle from any reputable manufacturer, you know exactly what to expect in terms of performance and safety.

Medical vs Surgical vs Taxidermy Scalpel Handles

Not all cutting jobs are created equal, and scalpel handles reflect this reality. Each application places different demands on the equipment, which explains why you'll see such variety in handle designs and materials.

Medical applications typically involve precision work - think diagnostic procedures, minor surgeries, and wound care. Here, control trumps brute force. The #3 and #7 handles dominate this space because they offer exceptional fine motor control. A dermatologist removing a small lesion needs finesse, not power.

Surgical applications tell a different story. Major operations require handles that can withstand significant forces during substantial incisions. The #4 handle excels here, providing the weight and stability surgeons need when making larger cuts through multiple tissue layers. The extra heft actually helps maintain cutting accuracy under these demanding conditions.

Taxidermy applications present unique challenges that most people don't consider. Taxidermists work for hours at a time, changing blades frequently as they prepare specimens. Economy stainless steel handles strike the perfect balance - durable enough for professional use while keeping costs reasonable for commercial operations.

Who Makes Quality Scalpel Handles?

Several manufacturers have earned solid reputations in the scalpel handles market, each bringing something special to the table.

Swann-Morton leads the global market and for good reason. Their comprehensive handle and blade systems consistently demonstrate excellent build quality. What I particularly appreciate about Swann-Morton is their commitment to compatibility - their products work seamlessly across their entire product line.

Bard Parker deserves recognition as a true innovator. They pioneered many of the modern scalpel features we take for granted today. Their handles continue to set industry benchmarks for precision and durability, making them a favorite among demanding professionals.

Cincinnati Surgical has carved out a niche by focusing on surgical-grade instruments with superior ergonomics. If you're looking for handles that reduce hand fatigue during extended procedures, Cincinnati Surgical deserves serious consideration.

Cancer Diagnostics Inc. targets the pathology and research markets specifically. Their handles are optimized for laboratory and diagnostic procedures where precision matters more than cutting power.

Compatibility Considerations (#4, #6, #8 Shanks)

While ISO standards ensure basic compatibility between brands, the devil lives in the details. Subtle differences between manufacturers can affect how securely blades seat and perform. Blade shank dimensions must fall within specified tolerances, but some manufacturers hold tighter tolerances than others.

The critical factors that affect compatibility include shank width and thickness tolerances, locking mechanism engagement depth, alignment mark positioning, and material hardness compatibility. These might sound like technical nitpicks, but they matter when precision counts.

Cross-brand compatibility generally works well for routine applications. However, for critical procedures where blade security is paramount, using matched handle and blade systems from the same manufacturer provides extra peace of mind. It's similar to buying matched components for any precision system - everything just works better together.

As someone who's helped funeral professionals select reliable equipment for years, I've seen how quality components make all the difference in professional settings. The same principle applies whether you're choosing mortuary coolers or scalpel handles - invest in quality from the start, and you'll save money and frustration down the road.

Frequently Asked Questions about Scalpel Handles

Let's tackle the most common questions I hear about scalpel handles from professionals across the mortuary and medical fields. These are the real-world concerns that matter when you're selecting equipment for your facility.

What size scalpel handle fits a #10 blade?

The #10 blade pairs perfectly with a #3 scalpel handle - and this combination is absolutely everywhere in the industry. If you're just starting out or need to stock one versatile handle, this is your go-to choice.

Here's what makes this pairing so popular: the #3 handle doesn't just work with #10 blades. It accommodates the entire #10-15 blade range, giving you incredible flexibility for different procedures. Whether you're making initial incisions with a #10 blade or handling delicate detail work with a #11 blade, that same handle has you covered.

I've seen facilities save significant money by standardizing on #3 handles instead of stocking multiple handle types. It simplifies inventory, reduces training complexity, and ensures your staff always has the right tool available.

How often should reusable scalpel handles be replaced?

Quality stainless steel scalpel handles are built to last - we're talking years of reliable service with proper care. I've worked with funeral homes using the same handles for over a decade without issues.

But you'll know it's time for replacement when the locking mechanism starts showing wear. Watch for blades that don't seat securely or feel loose during use. The textured grip surfaces will gradually smooth out over time, and when they stop providing adequate slip resistance, it's time to upgrade.

Visible damage is an obvious replacement trigger - any cracks, chips, or corrosion means that handle needs to go. Some professionals replace handles preemptively after a certain number of autoclave cycles, but with quality stainless steel, this is often unnecessary if you're maintaining them properly.

The premium manufacturers like Swann-Morton often back their scalpel handles with lifetime guarantees. That's a testament to how long these instruments can last when you invest in quality from the start.

Are plastic scalpel handles autoclavable?

Most plastic scalpel handles aren't designed for repeated autoclave sterilization - and this catches people off guard. The standard plastic formulations will warp, crack, or degrade when exposed to those 121°C autoclave temperatures repeatedly.

If your protocols require frequent sterilization, stick with stainless steel handles. They're specifically engineered to handle thousands of autoclave cycles without breaking down. The upfront cost difference pays for itself quickly when you factor in replacement frequency.

Some specialized plastic handles can survive limited autoclave cycles, but you'll need to verify this with the manufacturer's specifications. Don't assume - heat damage to plastic handles can compromise blade retention, creating serious safety risks.

For single-use applications or procedures where weight matters more than durability, plastic handles serve their purpose well. Just match the handle type to your sterilization requirements from the beginning to avoid costly mistakes.

Conclusion

Choosing the right scalpel handles doesn't have to be complicated, but it does require some thoughtful consideration. After years of helping funeral professionals across Tennessee, Georgia, and beyond select reliable equipment, I've learned that the best handles are the ones that match your specific needs rather than just the cheapest option available.

Blade compatibility should be your starting point. There's no sense buying a beautiful #4 handle if all your procedures require #11 blades. Verify which blade numbers you use most often, then work backward to find the compatible handle sizes. A #3 handle covers the widest range of blades, making it the most versatile choice for general use.

Material selection matters more than you might think. Stainless steel handles cost more upfront but withstand thousands of sterilization cycles without degrading. Plastic handles work fine for occasional use but won't survive repeated autoclaving. If you're doing high-volume work, invest in quality stainless steel from the beginning.

Ergonomic features become crucial during extended procedures. Textured grips prevent slippage when your hands get tired, while proper weight distribution reduces hand fatigue. The #7 pen-style handle excels for fine work, while the broader #4 handle provides better control for substantial cutting tasks.

Maintenance really isn't optional if you want these handles to last. Clean immediately after use to prevent protein buildup, follow your autoclave manufacturer's guidelines, and inspect regularly for wear or damage. A cracked handle isn't just inefficient - it's dangerous.

Proper storage in clean, dry conditions prevents contamination and extends handle life. Replace handles when they show signs of wear rather than waiting for complete failure. Your safety and work quality depend on reliable equipment.

The durability you get from quality scalpel handles makes them worthwhile investments. Whether you're working in a busy funeral home or handling occasional procedures, the right handle improves both safety and precision.

For detailed guidance on selecting the perfect blades to match your handles, check out our A Practical Guide to Comparing Scalpel Blade Options. This resource walks you through blade characteristics and helps you match cutting tools to specific requirements.

At American Mortuary Coolers, we understand that precision instruments represent critical investments in your professional capabilities. Our commitment to helping funeral professionals select appropriate equipment extends beyond our custom coolers to include guidance on all mortuary instrumentation needs.

Safe usage practices and informed equipment choices ensure your scalpel handles will provide reliable service for years while maintaining the precision your work demands. Take care of your tools, and they'll take care of you.