Why Car Scissor Lifts Are Essential for Modern Automotive Work

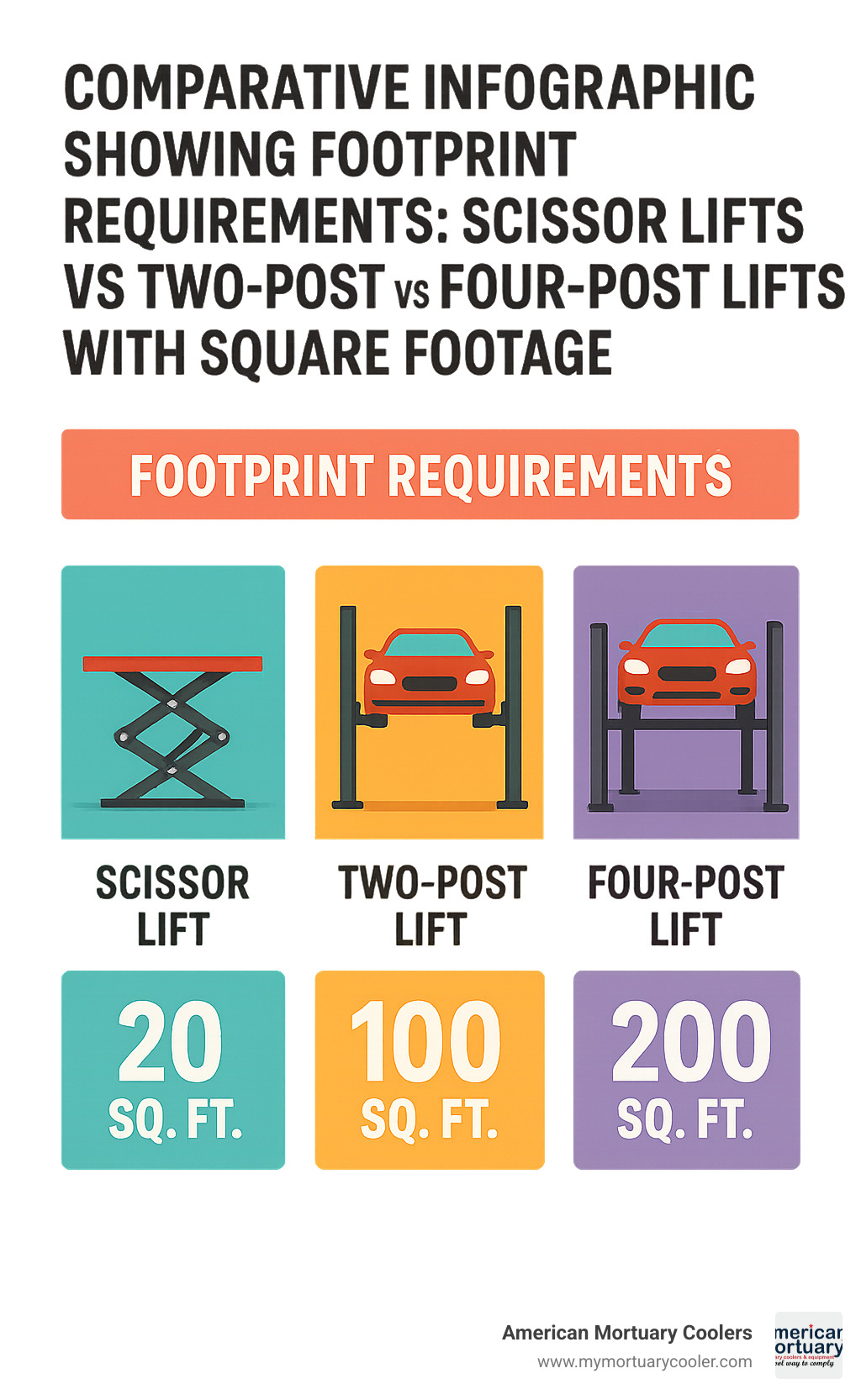

Car scissor lifts are hydraulic or electric lifting platforms that use a crisscross mechanism to raise vehicles vertically for maintenance, repair, and inspection work. These compact lifts have become the go-to choice for automotive shops, dealerships, and home garages that need reliable vehicle lifting without the space requirements of traditional two-post or four-post lifts.

Quick Answer: What You Need to Know About Car Scissor Lifts

- Weight Capacity: Light-duty (2,000-8,000 lbs), medium-duty (8,000-20,000 lbs), heavy-duty (20,000+ lbs)

- Lift Heights: Low-profile (up to 36"), standard (70-77"), high-lift (up to 82.6")

- Power Types: Hydraulic (fastest, most durable), electric (quieter), pneumatic (portable)

- Main Types: Mid-rise, full-rise, portable, flush-mount, alignment-ready

- Price Range: $2,200-$25,000+ depending on capacity and features

- Best For: Tire/brake service, detailing, quick-lube operations, tight workshop spaces

The automotive lift market has grown significantly as more shops recognize that scissor lifts offer the perfect balance of lifting power, space efficiency, and affordability. Unlike two-post lifts that require specific ceiling heights and floor layouts, scissor lifts can fit into almost any workspace while providing stable, full-vehicle access from underneath.

Modern car scissor lifts feature advanced safety systems including mechanical locks, anti-burst hydraulic valves, and compliance with ANSI/ALI safety standards. Popular models like the BendPak MD-6XP and TyreON TSC2800E demonstrate how today's lifts combine portability with professional-grade performance.

Who This Guide Is For

This comprehensive guide is designed for automotive technicians working in professional shops, dealerships, and quick-lube facilities who need efficient access to vehicle undercarriages for routine maintenance and diagnostic work.

Shop owners and managers evaluating lift options to maximize productivity while managing space constraints and budget considerations will find detailed comparisons and ROI analysis.

Home hobbyists and DIY enthusiasts who want professional-grade lifting capability in residential garages can find how scissor lifts solve common space and ceiling height limitations.

Top Benefits of Car Scissor Lifts for Modern Workshops

When you're running a busy workshop or working in your home garage, car scissor lifts can be absolute game-changers. These lifting systems pack serious advantages that make them stand out from traditional lifting methods.

The biggest win? Space efficiency. While two-post lifts demand 12-14 foot ceilings and eat up precious bay space, scissor lifts work beautifully in standard 8-10 foot ceiling environments. This means you can transform almost any workspace into a professional lifting station without expensive facility renovations.

Quick setup is another huge plus. The BendPak MD-6XP portable unit can be positioned and ready to lift in under 5 minutes, compared to permanent installation requirements of post lifts.

The open-center access design gives you complete, unrestricted access to the entire vehicle undercarriage. Whether you're tackling exhaust work, transmission service, or thorough inspections, you won't find yourself maneuvering around lift arms.

Your back will thank you for the ergonomic benefits. Say goodbye to crawling around on creepers and struggling with floor jacks. Scissor lifts bring work up to comfortable height, with technicians reporting 40% less fatigue when using mid-rise scissor lifts for routine maintenance.

From a business perspective, the ROI numbers are compelling. A typical mid-range scissor lift around $5,000 usually pays for itself within 12-18 months by enabling technicians to complete 2-3 additional services per day.

Mobility & Space Savings of Car Scissor Lifts

Portable car scissor lifts practically disappear when not needed. The zero-footprint storage capability means these lifts collapse to minimal profile, tucking neatly against walls or into corners.

Wheel kits and mobile platforms take convenience to the next level. The TyreON TSC2800E mobile scissor lift, despite weighing 476 kg and lifting 2,700 kg, can be easily moved by one person using integrated roller bearings.

This mobility between service bays lets you adapt workspace on the fly. Deploy portable lifts during busy periods to create extra lifting positions, then consolidate them during slower times to maximize floor space.

How Car Scissor Lifts Improve Workflow Safety

Safety is built into quality scissor lifts. Built-in safety locks provide multiple secure positions throughout the lifting range. The TyreON TSC2800E features automatic locking on all four arms with electromagnetic release systems.

Low-pressure hydraulic systems operate at safe 6-8 bar pressure with built-in safety valves and anti-burst protection, significantly reducing risk of catastrophic failures.

The stable platform design eliminates heart-stopping moments with floor jacks. Wide platform base and four-point contact keep vehicles rock-solid throughout lifting, providing peace of mind every technician deserves.

How Car Scissor Lifts Work & Key Components

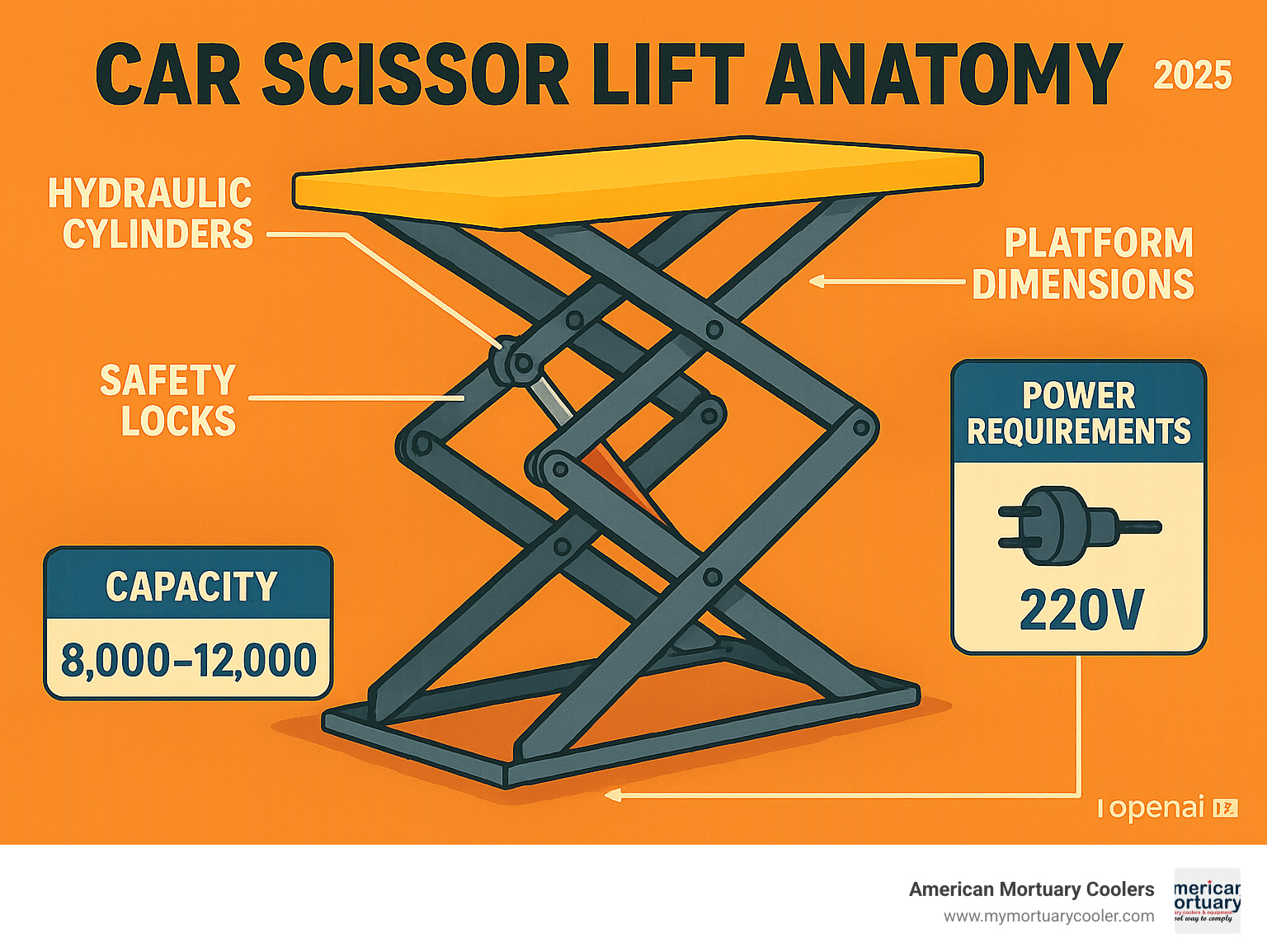

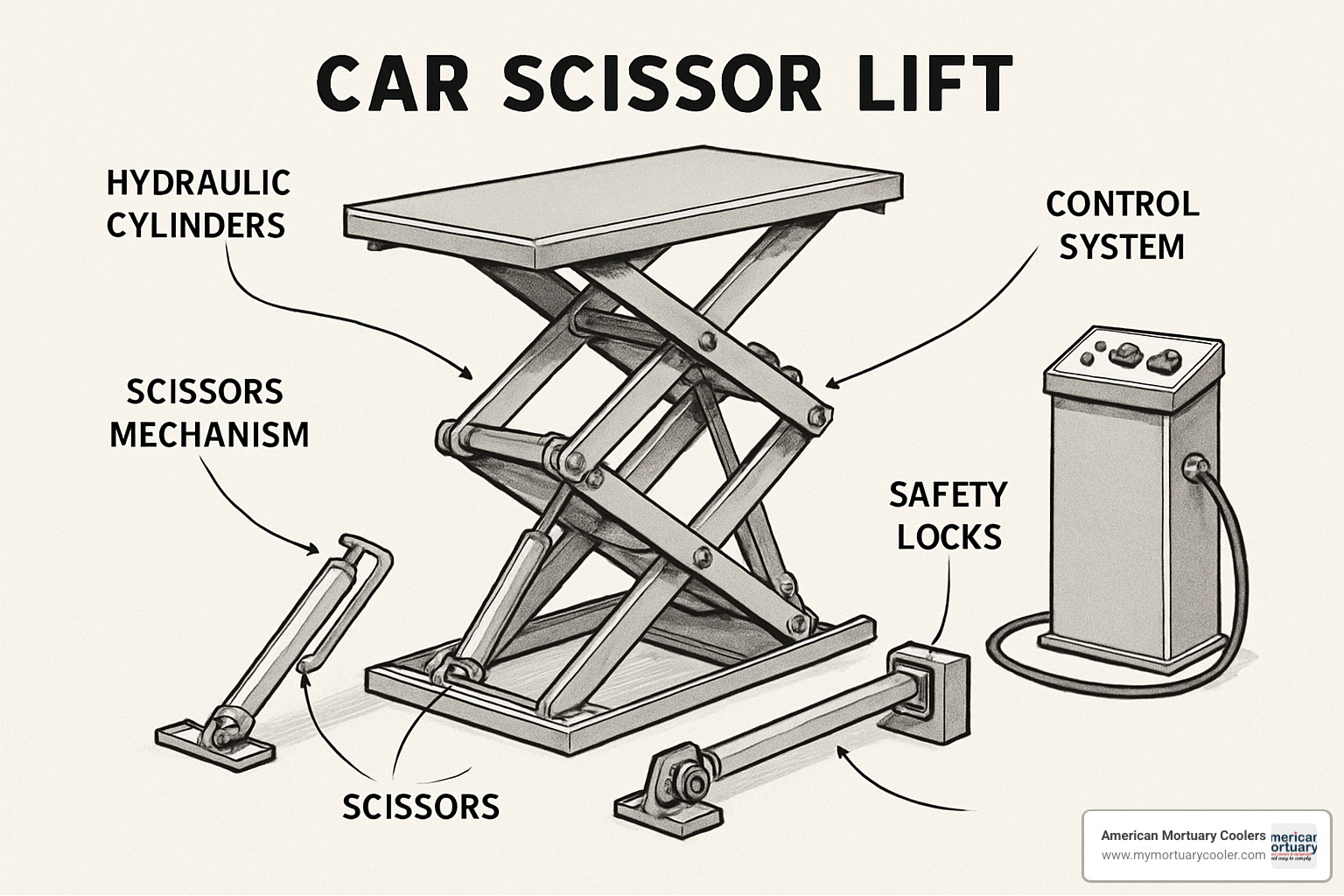

The magic behind car scissor lifts lies in their brilliantly simple design. The crisscross "scissors" mechanism converts horizontal hydraulic cylinder push into smooth vertical lifting motion - like scissors opening, but engineered for serious lifting power and safety.

Hydraulic circuits provide the muscle. A pump pressurizes hydraulic fluid, pushing cylinders that extend and contract. As cylinders extend, they push scissors legs apart, lifting your vehicle. The system includes pressure relief valves, flow control valves, and safety check valves for protection.

Electric motors do the heavy lifting. Most modern lifts use 2.2 kW motors on standard 220V or 380V power. The TyreON TSC2800E uses its 2.2 kW electric-hydraulic motor to hoist 2,700 kg in just 30 seconds.

The scissors legs handle tremendous forces with precision-cut steel components. Quality lifts use hardened steel with proper heat treatment and heavy-duty bearings at pivot points for reliability.

Safety locks are your insurance policy. These mechanical devices engage automatically or manually to lock the lift at specific heights. If hydraulics fail, these locks keep your vehicle secure.

The pressure valve system provides multiple safety nets. Relief valves prevent over-pressurization, check valves stop accidental lowering, and flow control valves manage lifting speed. These features are required by Scientific research on hydraulic safety standards.

Hydraulic vs. Electric vs. Pneumatic Drives

Hydraulic drive systems are workhorses offering blazing-fast lifting speeds and constant-use capability. They provide smooth, powerful operation with excellent control. The trade-off is hydraulic fluid maintenance and occasional leaks. Perfect for busy commercial shops.

Electric drive systems are low-maintenance heroes. No hydraulic fluid means longer maintenance intervals and cleaner operation. They're significantly quieter but offer slower lifting speeds. Ideal for shops prioritizing convenience over raw speed.

Pneumatic systems shine in portable applications with existing compressed air. They offer good lifting speed and are relatively maintenance-free, but require reliable air supply and don't provide the precise control of hydraulic systems.

Typical Weight Capacities & Lifting Heights

Light-duty car scissor lifts handle 2,000 to 8,000 pounds - perfect for compact cars to full-size SUVs, covering about 90% of vehicles in most shops.

Medium-duty lifts step up to 8,000 to 20,000-pound range, tackling larger vehicles like commercial vans and heavy pickup trucks with reinforced platforms and more powerful hydraulic systems.

Heavy-duty models support over 20,000 pounds, with specialized units like the Omer KAR54-N-5000 lifting an incredible 99,000 pounds for commercial and industrial applications.

Lifting height determines work capability. Low-profile lifts raise vehicles up to 36 inches for tire and brake work. Standard lifts reach 70 to 77 inches for comfortable undercarriage access. High-lift models achieve up to 82.6 inches for comprehensive service work.

Types of Car Scissor Lifts & Best Use Cases

Understanding different car scissor lifts types helps you find the perfect fit for your workspace and needs. Each style targets specific applications for maximum efficiency.

Mid-rise scissor lifts are automotive workhorses, raising vehicles 45-50 inches - perfect for tire changes, brake service, and routine maintenance. The BendPak MD-6XP offers 6,000 pounds capacity while staying completely portable with no concrete anchors required.

Full-rise scissor lifts reach 70+ inches, providing full standing room underneath for major repairs, exhaust work, and detailed inspections requiring comfortable access to every undercarriage area.

Low-profile scissor lifts solve common problems with vehicles sitting too low for standard platforms. These units slip under cars with 4-5 inches ground clearance, perfect for sports cars and lowered vehicles. Our practical guide to comparing low profile scissor lifts covers these options in detail.

Alignment scissor lifts are purpose-built for wheel alignment work. Models like the AMGO AX-12A come equipped with slip plates, turn plates, and precise positioning capabilities alignment technicians need.

Portable scissor lifts offer ultimate flexibility. The TyreON TSC2800E mobile unit, despite weighing 476 kg and lifting 2,700 kg, moves easily between service bays using integrated rollers, letting you adapt shop layout based on daily workload.

Flush-mount lifts provide the cleanest installation, sitting level with shop floors to eliminate drive-on ramps. Vehicles drive directly onto platforms, creating seamless workflow that looks professional and saves space.

When Car Scissor Lifts Beat Two-Post & Four-Post Options

Tight service bays are where scissor lifts shine. While two-post lifts demand specific spacing and overhead clearance, scissor lifts work comfortably in standard garage bays with 8-10 foot ceilings, maximizing lifting capacity without expensive building modifications.

Detailing operations love scissor lifts because no posts interfere with work. Complete 360-degree access makes undercarriage cleaning faster and more thorough than working around post lift arms.

Tire and brake work becomes more efficient with open design providing unrestricted access to all four wheels simultaneously, unlike post lifts where arms can interfere with certain wheel positions.

Quick-lube operations benefit from speed and simplicity. Vehicles drive on, get lifted, receive service, and drive off without careful positioning that post lifts require. When processing dozens of vehicles daily, time savings add up quickly.

Common Industries & Applications

Automotive dealerships use scissor lifts for warranty work, routine maintenance, and pre-delivery inspections. Professional appearance and smooth operation make them perfect for customer-facing service areas.

Body shops appreciate stable, even support across entire vehicle platforms, preventing frame distortion during bodywork and providing solid foundations for panel work and painting preparation.

Mobile service operations increasingly use portable scissor lifts for on-site repairs. Units like the MD-6XP load into service vehicles and deploy quickly at customer locations.

Motorsport pit operations demand speed and precision, making specialized scissor lifts invaluable in competitive racing for rapid tire changes and mechanical adjustments.

Comparison & Buying Guide: Choosing the Best Car Scissor Lift for Your Workshop

Choosing the right car scissor lift doesn't have to feel overwhelming. The best purchases happen when you know exactly what you need before shopping.

Budget ranges vary widely. Entry-level portable lifts handling 6,000-7,000 pounds run $2,200-$3,500 - perfect for smaller shops or home garages. Mid-range stationary units with 8,000-12,000 pound capacity cost $3,500-$8,000, while professional flush-mount systems run $8,000-$15,000. Heavy-duty commercial units over 20,000 pounds cost $15,000-$25,000+.

Capacity matching is where many buyers make costly mistakes. Don't just consider today's vehicles - think about tomorrow's heaviest vehicles. Add a 20% safety margin to your heaviest vehicle weight.

Platform length matters for longer vehicles. Standard platforms work for most cars, but extended platforms handle longer vehicles without sacrificing stability. The BendPak MDS-6EXTF offers extra length for this challenge.

Lift height depends on work type. Mid-rise lifts reaching 45-50 inches work great for tire changes and brake work. Full-rise lifts reaching 70-82 inches provide standing room for exhaust work and major repairs.

Power requirements need checking during planning. Most residential units use standard 220V single-phase power, but commercial lifts often need 380V three-phase power.

Concrete specifications matter more than expected. Most lifts need at least 4-6 inches of concrete with 3,000 psi strength. Flush-mount installations require precise cutting and often additional reinforcement.

Brands like BendPak, Rotary, and Omer lead the market. BendPak excels in portable lifts, Rotary dominates commercial installations, and Omer builds heavy-duty solutions. Match brand specialty to your needs.

For detailed selection guidance, check our ultimate guide to finding the best scissor lift for sale.

Key Safety Features & Standards for Car Scissor Lifts

Safety isn't just about following rules - it's about getting home safely every night. ANSI/ALI ALCTV-2017 sets North American safety standards for automotive lifts. Quality car scissor lifts should display ALI certification labels.

EN1493:2010 is the European standard. The TyreON TSC2800E meets this rigorous standard, requiring 115% dynamic and 150% static safety load testing well beyond rated capacity.

Mechanical safety locks provide backup protection when everything else fails. These essential safety devices offer multiple lock positions throughout lifting range with positive engagement mechanisms that won't accidentally release.

Anti-burst hydraulic valves automatically restrict flow if hydraulic hoses fail, preventing sudden drops and buying time to safely lower vehicles.

Proximity sensors on advanced lifts detect improper vehicle positioning or objects in lift paths, preventing operation until safety conditions are met.

The Certified lift directory helps verify lifts actually meet safety standards before purchase.

Installation & Space Requirements

Proper installation starts with understanding floor thickness and strength requirements. Most scissor lifts need at least 4-6 inches of concrete with 3,000 psi compressive strength. Heavy-duty lifts may require 6-8 inch thickness with additional reinforcement.

Power circuit requirements vary by installation. Single-phase lifts typically need 220V with 20-30 amp circuits, while three-phase commercial units require 380V with 15-20 amp circuits. Get qualified electricians for installation.

Drainage becomes crucial for flush-mount installations. Water accumulation in lift pits leads to corrosion and safety problems. Proper drainage design prevents expensive future problems.

Safe Operation, Maintenance & Compliance

Keeping your car scissor lifts running safely and efficiently requires consistent attention to detail. Successful operations follow simple, systematic approaches to lift care.

Daily inspections should become routine. Start each day checking for hydraulic fluid puddles, inspecting hoses for cracks, and ensuring platform surfaces are clean. Safety locks should move freely, and all controls should respond properly. This five-minute investment prevents major problems.

Load verification is critical for safe operation. Before lifting any vehicle, confirm its weight including cargo, equipment, or parts remaining on the lift. The TyreON TSC2800E handles 2,700 kg total - including everything on the platform.

Safety lock engagement provides backup protection if hydraulic systems fail. After raising vehicles to desired height, always engage mechanical locks before working underneath. Test locks by briefly lowering until locks catch the weight.

Hydraulic fluid maintenance keeps lifts operating smoothly. Most manufacturers recommend fluid changes every 500-1000 operating hours or annually. Use only manufacturer-specified hydraulic fluid - substituting cheaper alternatives often leads to expensive repairs.

Operator training ensures everyone understands proper procedures and safety requirements. Document training to meet workplace safety regulations and protect your business from liability. New employees should never operate lifts without proper instruction.

For specialized applications, our guide on scissor lift rental & specialized lifting solutions for diverse industries covers unique requirements.

Most Common Safety Tips for Car Scissor Lifts

Proper lifting point placement makes the difference between safe operation and disaster. Vehicle owner manuals show correct lift points, usually on frame rails or designated reinforced areas. Never lift on body panels, exhaust pipes, or suspension components.

Respecting weight limits goes beyond just vehicle weight. Consider mechanics working underneath, tools, parts, and additional equipment. Everything counts toward lift maximum capacity.

Personal protective equipment should be consistent. Safety glasses protect from falling debris, proper work boots provide foot protection and stability. Keep protective gloves handy around hydraulic systems.

How Car Scissor Lifts Promote Shop Efficiency & Employee Health

Reducing physical strain on technicians pays dividends in reduced injuries and improved job satisfaction. Car scissor lifts eliminate awkward bending, crawling, and kneeling required with floor jacks.

Faster service cycles result from better working conditions. When technicians position themselves comfortably with easy component access, routine services happen more quickly. Many shops report 25-30% time savings on standard services.

Cleaner, safer workspaces emerge when eliminating floor jack clutter. Scissor lifts contain lifting mechanisms in compact units, reducing trip hazards and creating organized work areas for better efficiency and professional appearance.

Frequently Asked Questions about Car Scissor Lifts

Let's address common questions from shop owners and technicians investing in car scissor lifts. These answers come from years of helping businesses find the right lifting solutions.

What maintenance schedule should I follow?

Your car scissor lift will serve you well with proper maintenance routine.

Hydraulic fluid changes are most critical. Change fluid every 500-1000 operating hours or annually, whichever comes first. Always use manufacturer-specified fluid - don't risk expensive repairs to save money on generic alternatives.

Monthly bolt torque checks should become routine. Focus on critical fasteners like lift arm pivots, safety lock mechanisms, and platform attachments. Constant vibration and heavy loads gradually loosen connections.

Annual ALI inspections are strongly recommended for commercial operations. Many insurance companies require comprehensive inspections, and some local regulations mandate them. Professional inspections catch potential problems before they become expensive repairs.

Can I install a car scissor lift on existing concrete?

This common question usually has a yes answer - with important considerations.

Existing concrete needs minimum standards before safe installation. Most lifts require at least 4-6 inches thickness with 3,000 psi compressive strength. Buildings from the last 20 years probably meet requirements. Older buildings might need engineer evaluation.

Reinforcement becomes necessary for flush-mount installations or heavy-duty lifts. This might mean adding rebar, pouring thicker sections, or installing reinforcement plates. Most concrete contractors familiar with automotive equipment handle these modifications.

Flush-cut installation requires precision and should be left to professionals. Concrete cutting and excavation must be exact for proper depth, drainage, and structural integrity.

How much do quality car scissor lifts cost?

Car scissor lifts pricing varies widely based on capacity, features, and build quality:

Budget-friendly portable lifts cost $2,000-$3,500 for home workshops and light commercial use. Units like the Titan MRL-6000 offer solid value with 6,000-7,000 pound capacity.

Professional mid-rise lifts typically cost $3,000-$8,000, offering the best capability and value balance. The BendPak MD-6XP combines excellent portability with professional-grade performance.

Full-capability lifts cost $10,000-$25,000 for high-volume operations, including flush-mount options, alignment capabilities, and heavy-duty construction for constant use.

Specialized heavy-duty lifts over $30,000 handle extreme loads. The Omer KAR54-N-5000 with 99,000-pound capacity represents this category for industrial applications.

Quality lifts typically pay for themselves within 12-18 months through increased productivity and reduced labor costs.

Conclusion

Car scissor lifts have revolutionized how automotive professionals and enthusiasts approach vehicle service. From cramped home garages to busy dealership service bays, these versatile lifting systems deliver the perfect combination of power, efficiency, and space-saving design that modern workshops demand.

The beauty of scissor lifts lies in their adaptability. A mobile unit like the TyreON TSC2800E can transform a basic garage into a professional-grade workspace, while flush-mount systems provide seamless integration for high-volume operations. The key is understanding your specific needs - whether that's 6,000-pound capacity for weekend projects or heavy-duty performance for commercial truck service.

Safety remains paramount in any lifting application. Quality car scissor lifts from established manufacturers incorporate multiple safety systems, comply with rigorous ANSI/ALI standards, and provide the reliability that professionals depend on daily. The investment in proper equipment pays dividends through reduced workplace injuries, faster service times, and improved technician satisfaction.

As American Mortuary Coolers, our expertise runs deep in specialized lifting and cooling solutions. While our primary mission involves crafting custom mortuary coolers for funeral homes nationwide, our understanding of heavy-duty lifting requirements spans multiple industries. We've seen how the right lifting equipment transforms operations.

Our nationwide reach across the Southeast, Southwest, Pacific, Northeast, Midwest, and Rocky Mountain regions gives us unique insight into diverse operational needs. From Tennessee's humid climate requiring improved rust protection to California's seismic considerations for permanent installations, regional factors matter when selecting lifting equipment.

The automotive service industry continues evolving, with electric vehicles, advanced diagnostics, and changing service requirements. Modern car scissor lifts adapt to these changes through improved designs, specialized configurations, and improved safety features. Investing in quality equipment today positions your operation for tomorrow's challenges.

Whether you're upgrading from floor jacks, expanding service capacity, or equipping a new facility, the right scissor lift becomes an integral part of your success story. The combination of improved efficiency, improved safety, and reduced physical strain creates value that extends far beyond the initial purchase price.

Choose your lifting solution thoughtfully, considering not just immediate needs but future growth and changing requirements. Quality lifts serve reliably for decades when properly maintained, making them one of the best investments an automotive operation can make.

For comprehensive information about specialized lifting applications, explore our detailed guide on specialized lifting solutions.