Understanding the Versatility of Hanging Scales

Hanging scales weighing scales are devices that determine weight by suspending an item from a hook instead of placing it on a platform. Their portability and ability to handle awkward shapes make them useful everywhere from weekend fishing trips to heavy-duty construction sites.

Quick Reference Guide to Hanging Scales

| Type | Capacity Range | Common Uses | Key Features |

|---|---|---|---|

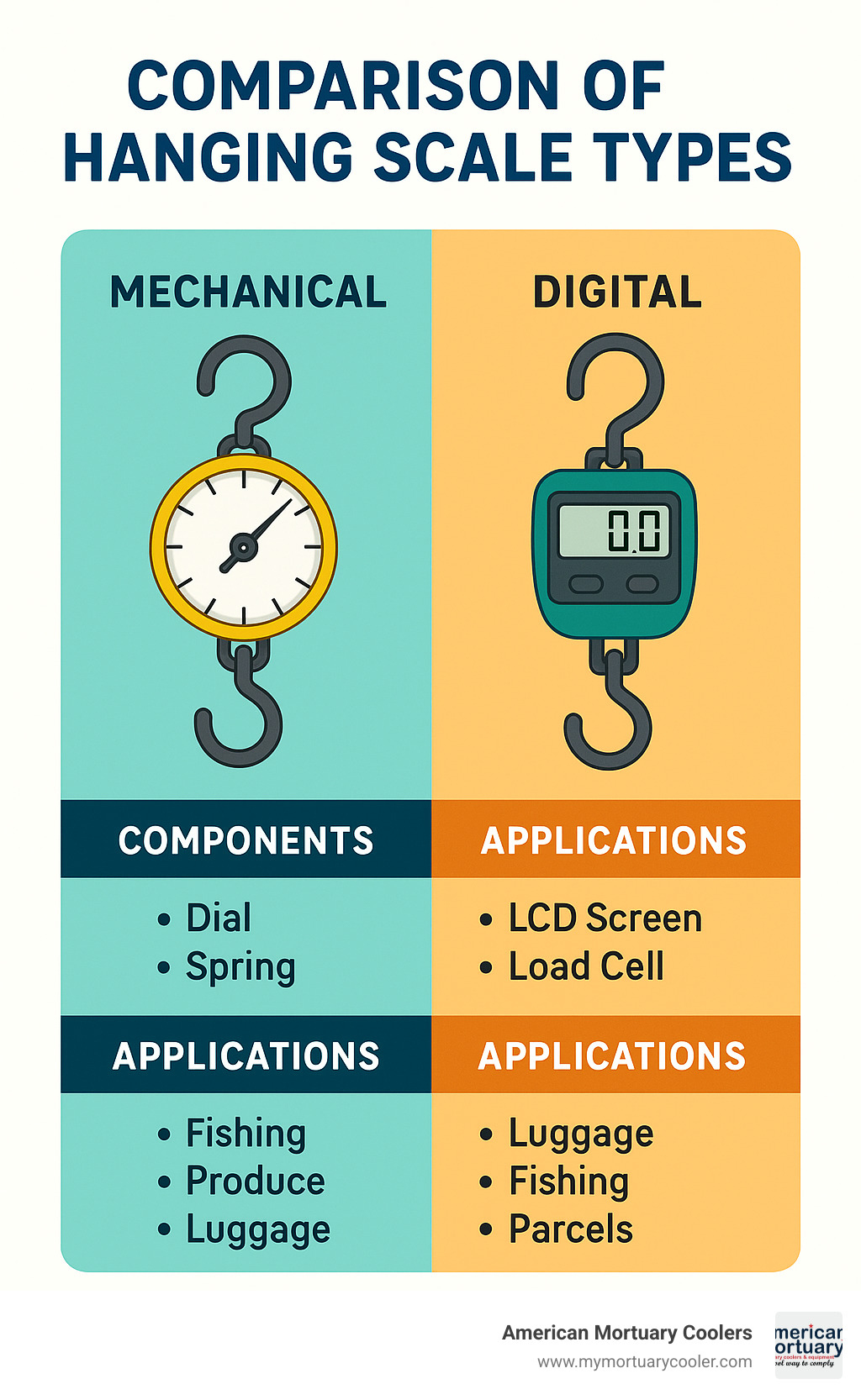

| Mechanical | 1-100 lbs | Fishing, produce, luggage | No batteries, dial readout |

| Digital Handheld | 10-660 lbs | Luggage, fishing, parcels | LCD, tare, unit switch |

| Industrial Crane | 500-10,000 lbs | Warehousing, manufacturing | Remote display, data log |

| Heavy-Duty Crane | 10,000-400,000 lbs | Construction, ports | Wireless, safety alarms |

Hanging scales read the gravitational force on a suspended load. Mechanical models rely on springs; digital versions use electronic load cells. Digital units often add conveniences like data logging or Bluetooth without sacrificing toughness.

Key terms you may see while shopping:

What You'll Learn

This guide walks through scale types, capacity ranges (under 1 lb to 400,000 lb), must-have features, care tips, safety basics, and how hanging scales compare with other weighing tech.

Why "Hanging Scales Weighing Scales" Matter Across Industries

Ever wondered how farmers weigh produce in the field or how ports log the exact mass of shipping containers? Hanging scales weighing scales solve those challenges without needing a level floor space.

Agriculture uses them for feed sacks, milk cans, and freshly harvested crops. Anglers verify the weight of trophy fish, while recycling centers pay suppliers fairly by weighing bales and scrap right at the hook.

Logistics operators appreciate how a hanging scale copes with odd-shaped parcels that would topple on a flat platform. On construction sites, rugged crane scales integrate with overhead cranes to weigh beams or machinery while theyre already in the air.

"Hanging Scales Weighing Scales" for Small Loads

Portable models (often under 110 lb capacity) slip into a toolbox or carry-on bag. Travelers avoid airline fees, anglers capture brag-worthy stats, and postal clerks weigh letters without clearing counter space.

"Hanging Scales Weighing Scales" for Heavy Duty Loads

Industrial crane scales tackle 500 lb to 400,000 lb. Foundries, ports, and construction firms depend on them for inventory control and safety compliance. Features such as wireless readouts and 5:1 safety factors keep staff informed and protected.

Understanding How Hanging Scales Work

Hanging scales weighing scales work on a beautifully simple principle: they measure the force of gravity pulling down on whatever you've hooked to them. But there's some clever engineering happening behind the scenes!

When you hang something from a scale, you're essentially asking it to measure the downward force. In mechanical scales, this force stretches a spring, while in digital scales, it causes tiny deformations in a load cell. Either way, your scale is converting that physical force into a readable weight measurement.

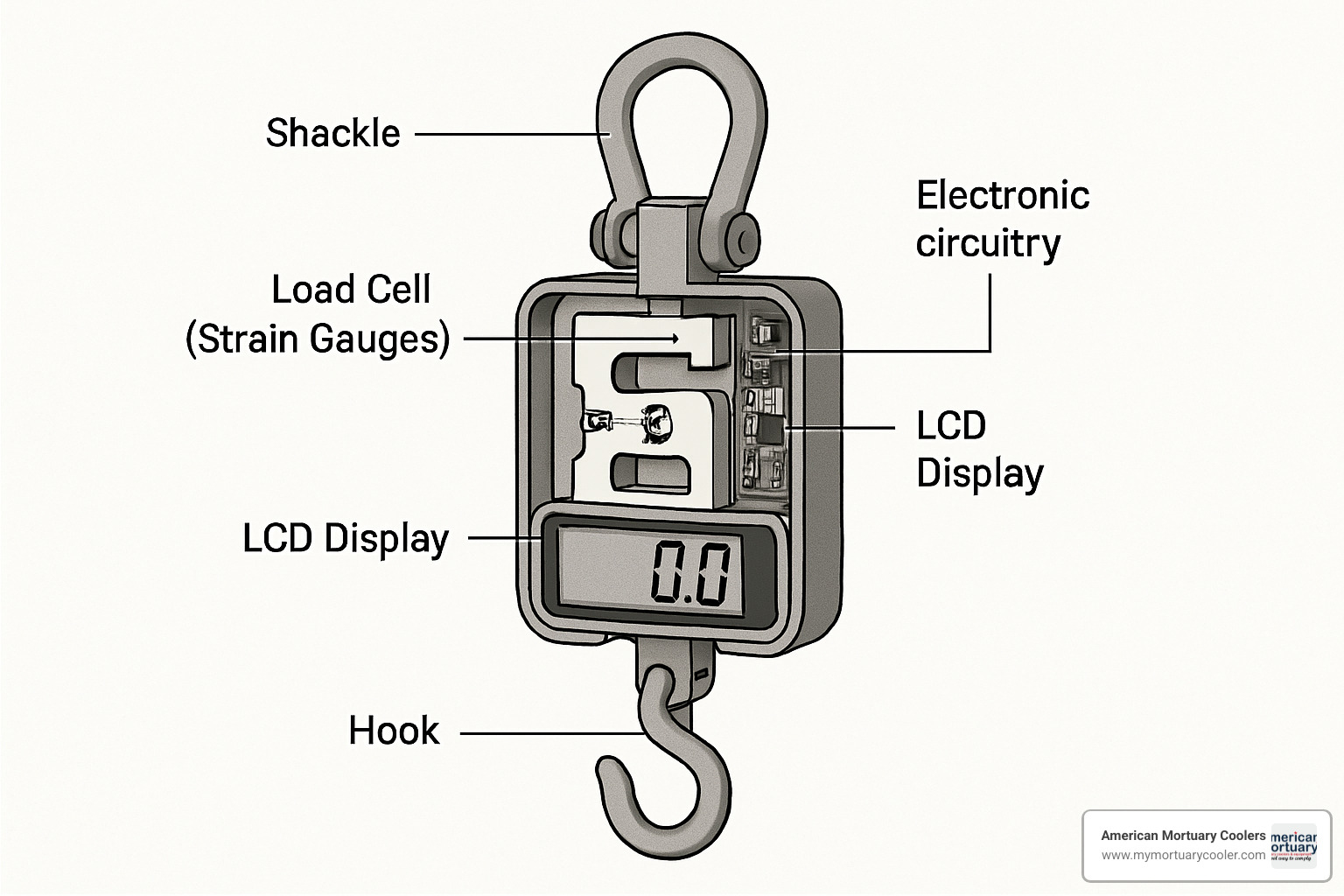

The hook and shackle components might seem simple, but they're critical engineering elements. They need to be strong enough to support the maximum weight while providing a secure attachment point. Many industrial models feature rotating shackles that lock into place, making it easier to connect awkward items safely.

Accuracy doesn't happen by accident! All hanging scales weighing scales require proper calibration using certified weights. This calibration process establishes the relationship between the force being measured and the weight displayed.

Recent scientific research on strain gauges has shown remarkable improvements in sensitivity and durability, allowing modern digital scales to achieve accuracy within 0.1% of the measured weight – that's within an ounce for every 60 pounds!

Mechanical vs. Digital: Key Differences

Mechanical hanging scales feature a simple dial face with a needle indicator – what you see is what you get! Their biggest advantage? No batteries required. This makes them perfect for remote locations or harsh environments where power sources are unreliable.

These mechanical workhorses tend to be more rugged overall. They'll keep working after being dropped, splashed, or exposed to extreme temperatures that might fry electronic components. The tradeoff? They're typically less precise and lack the bells and whistles of their digital cousins.

Digital hanging scales have revolutionized weighing with their bright LCD displays (often backlit for those dark corners of the warehouse), higher precision, and smart features. Most offer tare functions to subtract container weight, multiple unit options, and auto-shutoff to save battery life. Many newer models include Bluetooth connectivity and data logging to track weights over time.

Inside a Crane Scale Load Cell

The real magic of modern digital hanging scales weighing scales happens inside the load cell – typically a shear beam design that's specifically engineered for hanging applications.

This precision component is a marvel of engineering. When weight is applied, the metal element deforms ever so slightly (we're talking microscopic levels here). Strain gauges bonded to this element change their electrical resistance in proportion to this deformation. The scale's electronics measure this change and convert it to the weight reading you see on the display.

Industrial crane scales build in several protective features to ensure reliability:

Overload protection prevents damage when someone inevitably tries to weigh something too heavy. IP ratings (like IP65 or IP67) tell you how well sealed the unit is against dust and water. Temperature compensation circuitry ensures you get the same reading whether it's a frosty morning or a sweltering afternoon.

At American Mortuary Coolers, we understand the importance of precise weight measurements in the funeral industry, where respectful handling requires knowing exact weights for proper equipment selection and safe transport procedures.

Types & Capacity Ranges of Hanging Scales

Whether youre weighing a two-pound trout or a 20-ton steel column, theres a hanging scale weighing scale built for the job.

Analog pocket scales: spring-based veterans handling up to 10 lb when batteries are impractical.

Digital handheld scales: capacities up to 110 lb with LCDs, tare buttons, and auto-off perfect for luggage and small parcels.

Fish-specific models add waterproof casings and measuring tapes that anglers love.

Crane scales step in from 500 lb upward, many offering remote displays and data export. Dynamometers go a step further by logging peak forces for test labs and safety checks.

| Category | Capacity Range | Precision | Common Applications |

|---|---|---|---|

| Light Duty | 1-110 lb | 2% to 0.01 lb | Luggage, fish, produce |

| Medium Duty | 100-1,000 lb | 0.1-1 lb | Game animals, small freight |

| Heavy Duty | 1,000-10,000 lb | 1-5 lb | Machinery, bulk material |

| Industrial | 10,000-400,000 lb | 5-50 lb | Containers, structural steel |

Choosing the Right Scale: Features, Certifications & Safety

Shopping for hanging scales weighing scales can feel overwhelming with so many options available. Let's focus on the features that really matter for your specific needs.

The auto-tare function is a genuine time-saver – with just one button press, you can subtract the weight of containers or packaging. Unit switching lets you toggle between pounds, kilograms, and sometimes even Newtons without doing mental math.

For testing applications, peak hold capability captures the maximum weight registered during a measurement – incredibly helpful when you need to record the highest force applied. If you're working with heavier loads, remote control operation isn't just convenient – it's a safety essential, allowing you to stand at a safe distance during weighing.

When it comes to power options, rechargeable batteries offer both environmental and cost benefits. And don't overlook the housing material – cast aluminum provides an excellent balance of durability and weight, while stainless steel offers superior protection against corrosion in humid environments.

Safety should never be an afterthought, especially with industrial scales. Look for models with overload alarms that provide clear warnings when you're approaching capacity limits. For heavy-duty applications, a 5:1 safety factor rating is the industry standard – meaning the scale can technically handle five times its rated capacity in emergency situations. Quality forged steel shackles and safety latches prevent accidental load disengagement.

Here at American Mortuary Coolers, we understand the importance of reliable weighing equipment. While our main focus is creating custom mortuary refrigeration systems, we know that precise weight measurements are essential for proper handling in funeral homes across our service regions, from Tennessee to California.

Legal-for-Trade & NTEP Explained

If you're using hanging scales weighing scales for commercial transactions – where money changes hands based on weight – you need to understand NTEP certification. It's not just important; it's legally required.

NTEP (National Type Evaluation Program) certification means your scale has passed rigorous testing by the National Conference on Weights and Measures. Think of it as the gold standard for scale accuracy and reliability in commercial settings. These scales maintain accuracy within specific tolerances and include tamper-resistant features to prevent unauthorized adjustments.

Many NTEP models feature visible calibration seals that show if anyone has altered the scale's settings. Breaking these seals can void the certification, so they're taken quite seriously.

I've seen businesses face substantial fines for using non-certified scales in commercial transactions. Models like the CS1500 Crane Scales come with NTEP approval out of the box, making them ready for legal-for-trade applications.

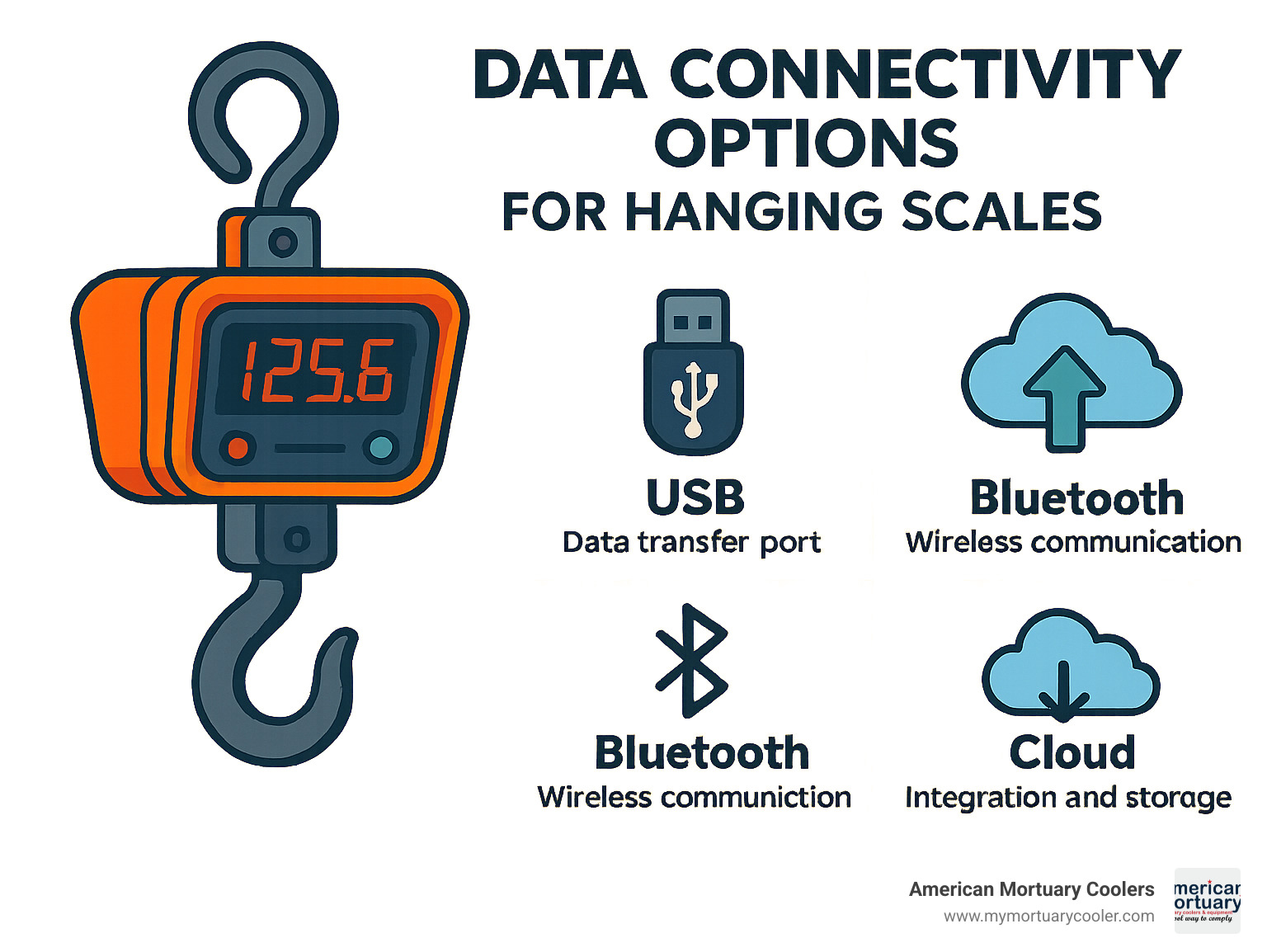

Data Connectivity & System Integration

Today's digital hanging scales weighing scales do far more than just display a number – they're becoming smart devices that connect to your broader business systems.

USB ports allow direct computer connections for downloading weight records, while RS-232 interfaces provide the industrial standard for connecting to legacy systems. For wireless convenience, Bluetooth enables connections to smartphones and tablets without messy cables. WiFi-enabled scales take this a step further, connecting directly to your network for remote monitoring.

Many manufacturers offer companion apps that make exporting weight data to spreadsheets or databases remarkably simple. I've seen this capability transform inventory management for businesses – what was once tedious manual record-keeping becomes automated and error-free.

For larger operations, hanging scales weighing scales can integrate directly with Enterprise Resource Planning (ERP) systems, feeding real-time weight data into production planning, inventory tracking, and billing systems. Cloud connectivity allows businesses to collect data from multiple scales across different locations into a central database.

Using, Maintaining & Troubleshooting Hanging Scales

Even robust hanging scales weighing scales benefit from basic upkeep.

- Calibrate with certified weights every 6-12 months.

- Zero out before each session using the tare/zero control.

- Let electronics warm up for a minute in extreme hot or cold.

- Charge or replace batteries on schedule and remove them for long storage.

- Store the scale dry, clean, and unloaded to avoid spring or load-cell fatigue.

Quick Fixes

- Overload error: Remove weight immediately; repeated abuse damages sensors.

- Drifting numbers: Check battery level and eliminate drafts or vibrations.

- Unsteady readings: Stabilize the loadeven small swings affect accuracy.

Safety Checklist Before Every Lift

- Confirm total load (item plus rigging) is below 80 % of scale capacity.

- Inspect hooks, latches, and shackles for wear.

- Keep people clear of the suspended path and wear proper PPE.

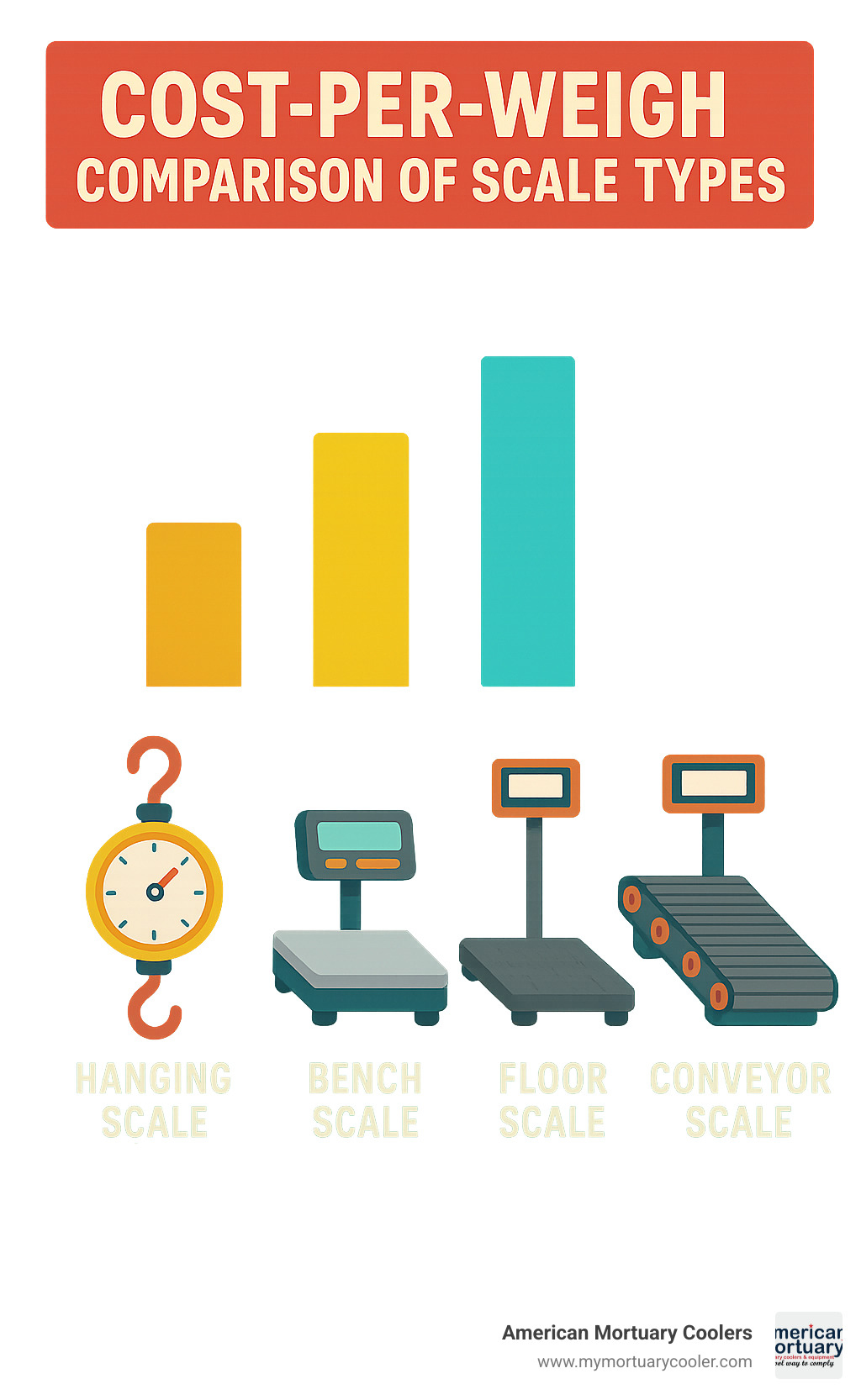

Hanging Scales vs. Other Weighing Technologies

Bench and floor scales require level surfaces and usable floor space. Conveyor and pallet-truck scales streamline production but cost more and stay put once installed.

Hanging scales weighing scales shine when:

- You need portability or lack floor space.

- Items are irregularly shaped or already on a hoist.

- Budgets favor lower upfront cost and simple maintenance.

Limitations include possible swing-induced error and the need for lifting gear, but for many users those trade-offs are easily managed.

Frequently Asked Questions about Hanging Scales

How accurate are hanging scales compared to platform scales?

When it comes to accuracy, hanging scales weighing scales can definitely hold their own against platform scales. Premium digital models achieve impressive accuracy rates up to 99%, but there are some important differences to consider.

Platform scales naturally provide more stable measurements since your items rest securely on a solid surface rather than hanging freely. This stability advantage is especially noticeable when weighing items that might swing or shift when suspended.

Environmental factors play a bigger role with hanging scales weighing scales too. They're more susceptible to wind gusts or workplace vibrations, particularly in busy industrial settings.

The good news is that with regular calibration, your hanging scale can maintain accuracy comparable to platform scales in most applications. For critical precision needs, look for models with higher resolution (smaller weight increments) and features like averaging functions that help compensate for minor load movement.

Do I need an NTEP-certified scale for shipping applications?

This is one of the most common questions I hear, and the answer depends on exactly how you're using those weight measurements.

Yes, NTEP certification is required if you're charging customers based on weight or using your scale for commercial transactions where payment is determined by weight. This is actually a legal requirement, not just a recommendation.

No, NTEP certification isn't required if you're using your hanging scales weighing scales internally for inventory, pre-checking packages before sending to a carrier, or other non-commercial applications.

It's worth noting that major shipping carriers like UPS, FedEx, and USPS will use their own certified scales to determine your final shipping charges, regardless of what your pre-shipment weighing showed. However, having an accurate scale helps you avoid surprises and disputes over shipping costs.

What's the difference between a crane scale and a dynamometer?

People often use these terms interchangeably, but there are meaningful distinctions between the two devices.

Crane scales primarily measure weight (mass) of suspended loads. They're calibrated in familiar weight units like pounds or kilograms and are optimized for static weighing applications. Most feature simple hooks for load attachment and displays that clearly show the current weight.

Dynamometers, on the other hand, are specialized instruments designed to measure force, which includes but isn't limited to weight. They're typically calibrated in force units like Newtons or pound-force and can measure tension, compression, or torque depending on their design. Many dynamometers include advanced features to capture peak forces or track force over time, making them valuable for testing applications.

In practical terms, many modern digital devices actually combine both functions. The MSI-3460 CHALLENGER 3 Crane Scales, for example, can display readings in pounds, kilograms, or Newtons, effectively serving as both a crane scale and a dynamometer.

At American Mortuary Coolers, we understand that accurate weight measurement is essential across many industries, including the funeral services we support with our specialized cooling equipment.

Conclusion

Hanging scales weighing scales provide a flexible, space-saving answer to weighing everything from carry-ons to containers. Choose a model that matches your capacity, accuracy, and environmental needs, and stick to a simple maintenance routine to keep it performing year after year.

American Mortuary Coolers proudly supplies custom mortuary refrigeration throughout the 48 contiguous statesincluding Johnson City, Atlanta, Chicago, Los Angeles, New York, Pittsburgh, and every region in betweenand we know dependable support equipment matters. For custom solutions, visit our website or contact our team today.