Why Understanding Refrigerator Rooms Is Critical for Your Facility

A refrigerator room is a large, insulated chamber designed to maintain precise temperatures for bulk storage of perishable items. Unlike standard refrigerators, these walk-in coolers offer substantially more space and better temperature control for commercial applications.

Key refrigerator room characteristics:

- Temperature range: Typically 0°C to 10°C with ±0.5°C uniformity

- Size options: From compact 8' x 8' units to massive 40' x 40' installations

- Storage capacity: Significantly more efficient than multiple standard refrigerators

- Applications: Food service, floral storage, mortuary facilities, and laboratory use

- Configuration types: Walk-in coolers, freezers, or dual-temperature systems

Research shows that walk-in coolers can range from 68 sq. ft. to over 1,600 sq. ft., offering flexible storage solutions that save up to 72% in upfront costs compared to conventional refrigeration when using innovative systems like CoolBot technology.

Whether you're running a funeral home, restaurant, or distribution center, choosing the right refrigerator room involves understanding temperature requirements, space constraints, energy efficiency, and regulatory compliance.

Modern refrigerator rooms feature:

- Modular panel construction for easy installation

- Smart temperature monitoring and alerts

- Energy-efficient LED lighting systems

- Emergency escape mechanisms for safety

- Custom sizing to fit specific facility needs

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping facilities select and install the right refrigerator room solutions for their unique requirements.

Refrigerator room further reading:

Refrigerator Room Basics: How It Differs From Standard Refrigerators

When considering cold storage for your facility, understanding how a refrigerator room differs from standard refrigerators can save you thousands of dollars and countless headaches.

The Temperature Control Game-Changer

Your home refrigerator might keep leftovers cold, but it's playing in the minor leagues compared to commercial refrigerator rooms. While household units wobble around within a 2-4°C range, a proper refrigerator room maintains temperature uniformity of ±0.5°C or better throughout the entire space.

This precision matters significantly. The temperature range typically spans 0°C to 10°C for cooler applications, with the real advantage in how consistently these temperatures are maintained. The compressor-condenser cycle works on the same basic principles, but with components built to handle serious workloads.

Your home fridge struggles when loaded with groceries after a big shopping trip. A commercial refrigerator room handles frequent door openings and large product loads without breaking a sweat. The airflow systems are designed to recover quickly and maintain critical temperature uniformity.

Scientific research on cold-room produce quality shows how important proper airflow design is for maintaining product quality.

What Is a Refrigerator Room?

A refrigerator room is essentially refrigeration scaled up for serious business use. Also called a walk-in cooler or cold room, it's a large insulated chamber where you can actually walk inside to access stored products.

The construction includes insulated panels (typically 4-6 inches thick with R-values of 29 or higher), a refrigeration system (either mounted directly or remotely), properly sealed access doors, interior lighting, safety features, and precise temperature controls.

What makes these systems versatile is their adaptability. We've installed units serving as cold pantries for restaurants, floral preservation chambers for wedding venues, and specialized mortuary coolers for funeral homes. Each application gets customized to specific needs.

You'll encounter different types: walk-in coolers operating at 0°C to 4°C for fresh products, walk-in freezers running at -18°C to -21°C for frozen storage, dual-temperature units with separate zones, and specialized applications like mortuary or pharmaceutical storage.

Benefits Over Conventional Fridges

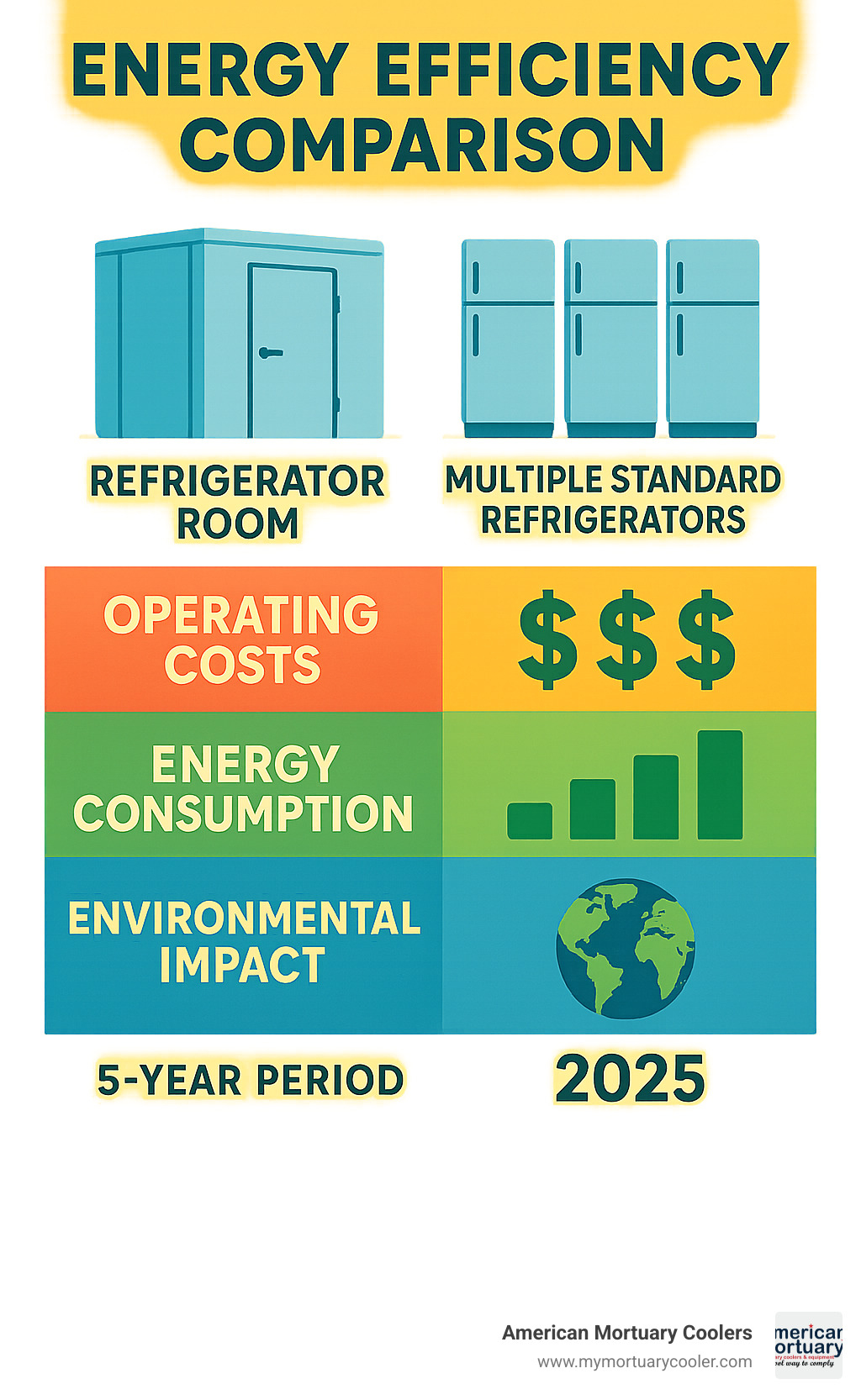

The moment you start doing the math on multiple conventional refrigerators versus a single refrigerator room, the benefits become clear.

Storage efficiency is the first advantage. Instead of cramming multiple standard refrigerators into your facility, one walk-in unit provides equivalent storage of 10-15 household refrigerators while using less total energy per cubic foot and offering walk-in access for better organization.

The energy efficiency advantages show refrigerator rooms can reduce operating costs by up to 40% compared to running multiple standard refrigerators. This efficiency comes from having a single, larger compressor system, better insulation, and fewer door openings per cubic foot of storage.

Workflow improvements make daily operations smoother. Staff can enter the space for restocking and cleaning, providing better inventory visibility and less waste. Large items that would never fit in standard refrigerators? No problem.

Selecting Refrigerator Room Size

Sizing a refrigerator room involves solid guidelines to keep you on track. The residential rule of 4-6 cubic feet per person doesn't apply here.

Commercial sizing depends heavily on your application. Restaurant kitchens typically need 1.5-2 cubic feet per meal served daily. Funeral homes calculate based on capacity requirements. Floral operations usually figure 2-3 cubic feet per $1,000 in weekly flower volume.

Standard dimensions start at 8' x 8' x 8' (68 sq. ft.) and can expand to 40' x 40' x 20' (1,600+ sq. ft.). Sweet spots are 8' x 8' to 8' x 12' for small operations, 10' x 12' to 12' x 16' for medium facilities, and 16' x 20' and beyond for large installations.

For detailed sizing guidance, check out Everything You Need to Know About Walk-In Refrigerator Dimensions.

Future-proofing means thinking beyond today's needs. Consider business growth projections, seasonal fluctuations, potential new product lines, and possible facility relocations. Modular panel construction makes expansion or relocation much more manageable.

Types & Configurations of Refrigerator Rooms

Choosing the right refrigerator room is like picking the perfect tool for the job - there's no one-size-fits-all solution, but there's definitely a perfect match for your specific needs.

Walk-in coolers remain the most popular choice for fresh storage applications. These units maintain 0°C to 4°C, making them perfect for funeral homes needing precise temperature control or restaurants storing fresh ingredients. The consistent temperature and humidity control can extend product life significantly.

Walk-in freezers operate between -18°C and -21°C. These require beefier insulation and more robust refrigeration systems, essential for long-term frozen storage.

Dual-temperature systems are sophisticated refrigerator room setups handling different temperature zones within the same space. Advanced systems can operate from -34°C to +30°C, providing flexibility that would require multiple separate units otherwise.

Specialized applications include mortuary coolers needing ultra-precise control, floral coolers requiring specific humidity settings, and laboratory cold rooms meeting strict regulatory requirements.

For more details, check out A Comprehensive Guide to Walk-In Coolers.

Integral vs Remote Refrigeration Systems

This decision comes down to your facility's layout and priorities.

Integral systems mount the condensing unit right on your refrigerator room - usually on the roof or side wall. Everything's contained in one package, meaning lower installation costs and simpler connections. These units move easier if relocation is needed.

The downside? They're louder and service access can be tricky, especially for rooftop units.

Remote systems separate the evaporator inside your cooler from the condensing unit, which can be located wherever makes sense. This creates quieter operation and improved service access.

The trade-off comes in complexity and cost - requiring refrigerant lines, more electrical work, and dedicated space for remote equipment.

| Feature | Integral System | Remote System |

|---|---|---|

| Installation Cost | Lower | Higher |

| Noise Level | Higher | Lower |

| Service Access | Limited | Excellent |

| Energy Efficiency | Good | Better |

| Flexibility | Limited | High |

Custom-Designed vs Standard Models

Standard models work beautifully for typical applications - they ship faster, cost less, and use proven designs. Most clients needing straightforward refrigerator room solutions find everything they need in off-the-shelf options.

Custom design shines when standard won't work. At American Mortuary Coolers, we've built units for oddly shaped rooms, facilities with specific workflow requirements, and operations needing features no standard unit could provide.

Standard models offer proven performance, typically ship within 30 days, and provide excellent value. Custom solutions become essential when standard dimensions or features won't work.

Modular panel construction makes both approaches possible, creating professional installations whether you choose standard or custom.

DIY & Emerging Solutions

Innovation keeps making cold storage more accessible. CoolBot technology has been a game-changer for smaller operations and budget-conscious facilities.

CoolBot systems use standard air conditioners to create refrigerator room temperatures, showing savings of up to 72% in upfront costs and 40% in operating expenses compared to traditional walk-in coolers.

USAID partnerships have brought CoolBot technology to over 20,000 smallholder farmers globally, proving innovative approaches solve real-world challenges.

DIY installation can work for certain applications but requires careful attention to temperature accuracy, energy efficiency, and safety compliance. For facilities needing precise control or regulatory compliance, professional installation with commercial-grade equipment remains the smarter choice.

Key Features, Technologies & Compliance

Modern refrigerator room systems blend cutting-edge technology with strict safety standards to create storage solutions that are both capable and safe.

Emergency escape systems aren't just nice-to-have features - they're lifesavers. Every unit includes interior panic buttons and emergency releases because OSHA doesn't compromise on worker safety.

LED lighting systems provide excellent visibility while generating minimal heat. LEDs produce significantly more light per unit of energy than fluorescent bulbs, meaning your refrigeration system doesn't work as hard to maintain temperature.

Insulation quality separates professional systems from amateur attempts. Modern refrigerator room panels feature R-values of 29+ for cooler applications, with freezer units pushing R-32 or higher.

Temperature control has become incredibly precise. Advanced controllers maintain ±0.2°C accuracy at the sensor level, with spatial uniformity of ±0.5°C throughout the entire chamber.

Refrigerator Room Smart Features

The refrigerator room industry has acceptd IoT technology, changing basic cold storage into intelligent systems.

Data logging happens continuously, recording temperature, humidity, and energy consumption patterns. This information proves invaluable for regulatory compliance and identifying efficiency opportunities.

Mobile alert systems keep you connected even when off-site. Temperature deviations, door ajar situations, power failures, and maintenance reminders trigger immediate smartphone notifications.

Predictive maintenance capabilities detect early trouble signs - compressor performance changes, refrigerant level drops, fan motor efficiency decline, and defrost cycle irregularities. Catching problems early saves thousands in emergency repairs.

Energy management features optimize consumption automatically through variable-speed compressor controls, demand-based defrost cycles, and load-based fan adjustments.

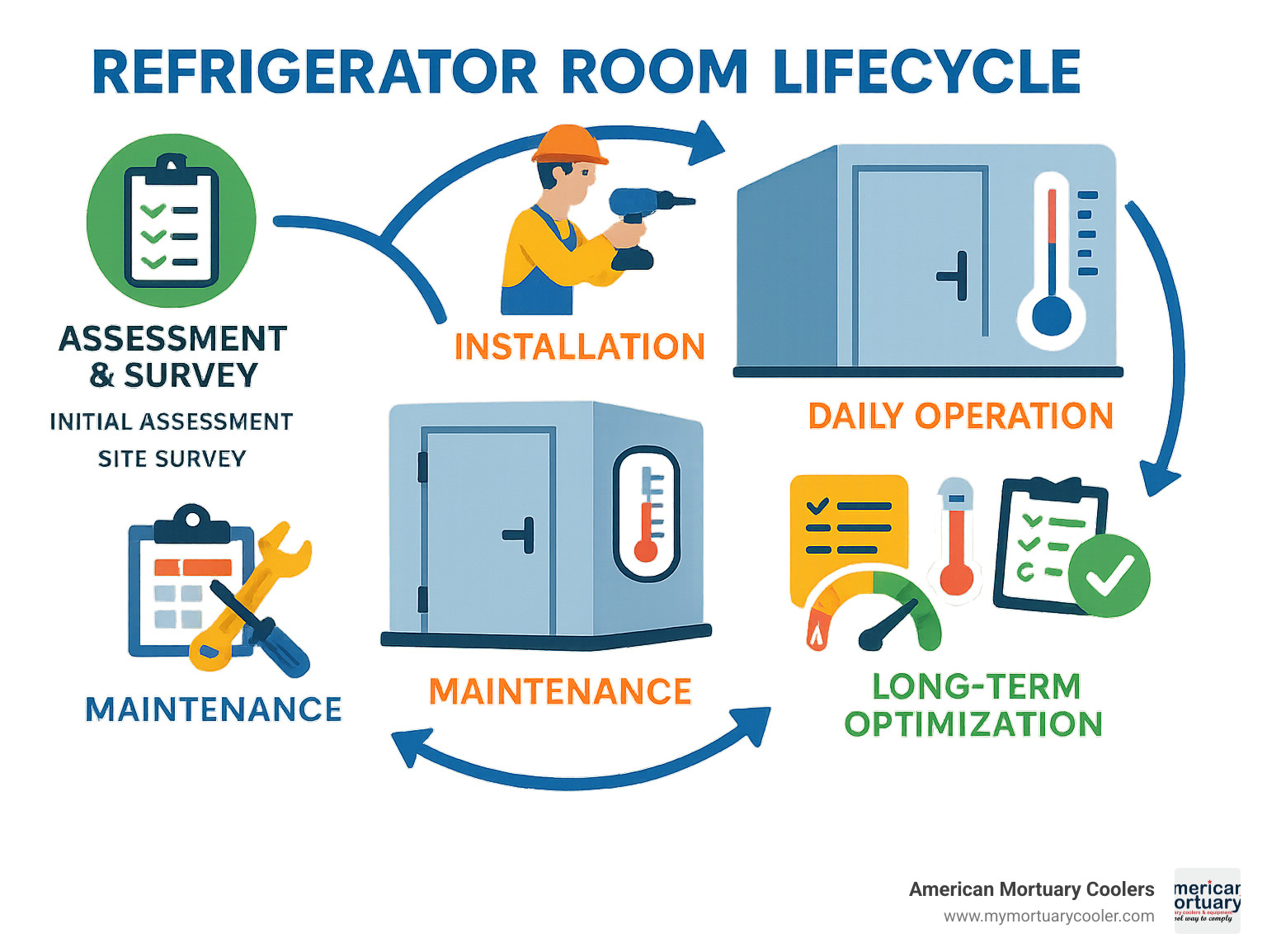

Maintaining Your Refrigerator Room Safely

Keeping your refrigerator room running smoothly requires consistent attention but isn't complicated. Think of it like car maintenance - regular care prevents expensive breakdowns.

Daily tasks take minutes but make huge differences. Visual inspection of door seals, temperature log verification, interior cleanliness checks, and proper product loading prevent most problems.

Weekly maintenance includes condenser coil cleaning, drain pan inspection, door hinge lubrication, and checking for airflow obstructions.

Monthly inspections require detailed system performance reviews, refrigerant level inspection by qualified technicians, electrical connection inspection, and safety system testing.

Sanitation protocols vary by application but always matter, including food-safe cleaning products, regular deep cleaning schedules, and proper storage procedures.

For specialized guidance, see Maintaining and Cleaning Your Mortuary Cooler for Longevity.

Latest Innovations & Trends

The refrigerator room industry continues evolving rapidly, driven by environmental concerns, energy costs, and operational convenience.

Natural refrigerants like CO2, ammonia, and hydrocarbons gain popularity due to lower global warming potential. Solar-assisted systems offer compelling economics with hybrid systems using solar power during peak sunlight hours.

Magnetic cooling technology represents the future of refrigeration, though commercial applications remain in development. Modular battery backup systems address power outage concerns, maintaining temperatures during grid failures.

For broader perspectives, see What is a cold room and why do you need it for your products?.

Cost, Installation & Ownership Considerations

Understanding the real costs of a refrigerator room helps you make smart decisions that protect your bottom line for years.

Walk-in coolers start around $6,498 for basic 8' x 8' units and can reach $16,000+ for larger systems. Total project costs include site preparation (level concrete slab, adequate electrical service, proper ventilation), permits, professional installation, and system commissioning.

The good news: properly sized refrigerator room systems can slash operating costs by up to 40% compared to running multiple standard refrigerators. That's real money back in your pocket monthly, making the initial investment pay for itself faster than expected.

Ongoing costs include electricity (your biggest ongoing expense), routine maintenance, replacement parts, and regulatory compliance. When you factor in energy efficiency and reduced maintenance needs versus multiple smaller units, the math works strongly in your favor.

For financial details, check out The Complete Guide to Commercial Walk-In Freezer Cost.

Budgeting & ROI

Smart business owners look beyond upfront costs to understand real return on investment a refrigerator room delivers.

Your initial CapEx includes purchase price, installation, and permits. OpEx benefits start immediately - reduced energy costs, improved efficiency, and decreased maintenance headaches adding up to serious savings.

Used equipment deserves consideration. Properly reconditioned used refrigerator room systems can match new equipment reliability while cutting capital requirements significantly. Factor in remaining warranty coverage, energy efficiency, and parts availability.

Available incentives shouldn't be overlooked. Many utilities offer rebates for energy-efficient refrigeration, and government programs provide tax credits substantially reducing your net investment.

ROI becomes compelling when factoring reduced product loss from better temperature control, improved workflow efficiency, and the professional image a proper refrigerator room creates.

Installation & Safety Checklist

Getting your refrigerator room installed correctly the first time saves headaches, money, and ensures optimal performance.

Site preparation is critical. That level concrete slab isn't negotiable. We also need verified electrical service matching your system's requirements, clear access paths for delivery, and all necessary permits approved.

Safety drives installation. Our team uses proper PPE, follows strict lifting procedures, and maintains electrical safety protocols. Only certified technicians handle refrigerant work.

Post-installation testing includes comprehensive temperature uniformity testing, door seal integrity verification, and safety system testing including emergency releases and alarms.

Ensuring Regulatory Compliance

Proper refrigerator room compliance protects both your operation and investment.

Regulatory landscape covers OSHA confined space safety requirements, local health department regulations for food storage, and fire safety/building codes varying by jurisdiction.

Industry-specific standards include NSF Standard #7 for food equipment sanitation, UL listing for electrical safety, EPA refrigerant rules, and FDA guidelines for pharmaceutical applications.

Documentation isn't optional - it's protection. Maintain installation records, maintenance logs, temperature monitoring data, and safety inspection reports for compliance and regulatory reviews.

At American Mortuary Coolers, we ensure every refrigerator room installation meets or exceeds applicable requirements with necessary certifications and complete documentation packages.

Frequently Asked Questions About Refrigerator Rooms

When considering a refrigerator room for your facility, you probably have questions. Here are the most common concerns our customers bring to us at American Mortuary Coolers.

How do I choose temperature and humidity settings?

Getting temperature and humidity settings right depends entirely on what you're storing and industry requirements.

Fresh produce storage needs 0°C to 4°C with tight control - ±0.5°C uniformity throughout your refrigerator room.

Frozen products need -18°C to -21°C. This isn't negotiable - frozen means frozen.

Floral business flowers prefer 2°C to 4°C with 85-95% humidity to prevent drying out.

Mortuary applications typically require 2°C to 4°C with controlled humidity for proper preservation while maintaining compliance.

Pharmaceutical storage often requires 2°C to 8°C depending on specific products. Always check product specifications.

Modern refrigerator room systems achieve humidity control accuracy of ±0.5% when properly designed.

What size refrigerator room do I need for my business?

Sizing your refrigerator room involves current needs, future growth, and workflow considerations.

Restaurant owners should plan for 1.5-2 cubic feet per meal served daily. Serving 200 meals daily means 300-400 cubic feet of storage, plus space for movement and organization.

Funeral homes sizing depends on capacity requirements. Our systems range from 4-5 body capacity units for smaller operations to 24-30 body capacity installations for high-volume facilities.

Floral operations work with 2-3 cubic feet per $1,000 weekly flower volume. Moving $5,000 worth weekly means planning for 10-15 cubic feet minimum.

Distribution centers calculate based on inventory turnover and peak storage needs.

Consider oversizing by 20-30% when planning. Businesses grow, and expanding later costs more than getting it right initially.

What maintenance schedule keeps a refrigerator room efficient?

Keeping your refrigerator room running smoothly requires consistency but isn't complicated.

Daily: Check temperature logs, inspect door seals visually, verify interior cleanliness and organization.

Weekly: Clean condenser coils if accessible, check drain system, look for airflow obstructions.

Monthly: Review system performance, test safety systems (emergency releases, alarms), detailed cleaning and sanitation.

Quarterly: Professional system inspection including refrigerant levels, electrical connections, and control calibration.

Annual: Complete system overhaul by certified technicians including comprehensive inspection, warranty compliance checks, and regulatory compliance documentation updates.

Following this schedule means your refrigerator room runs more efficiently, lasts longer, and keeps you compliant while catching small problems before they become expensive emergencies.

Conclusion

Choosing the right refrigerator room for your facility isn't just about buying equipment - it's about investing in your business's future. After decades of helping facilities nationwide, I've seen how the right cold storage solution transforms operations, saves money, and provides peace of mind.

Your specific needs drive every decision. Whether you're running a small floral shop needing precise humidity control or managing a large funeral home requiring multiple temperature zones, the perfect refrigerator room solution exists.

Size and configuration should match not just today's needs, but where you'll be in five years. Smart initial sizing often saves money long-term, and modular panel construction means you can expand later if needed.

Temperature and humidity requirements vary dramatically between industries. A mortuary cooler operates very differently from a restaurant walk-in, and these differences matter for product quality and regulatory compliance.

The choice between integral and remote refrigeration affects daily operations through noise levels, service access, and energy efficiency. Consider where equipment will live and who will work around it.

Smart monitoring and control systems have revolutionized cold storage management. Real-time alerts, energy monitoring, and predictive maintenance capabilities pay for themselves through prevented product loss and reduced service calls.

Proper cold storage doesn't just keep products cold - it maintains precise environmental conditions that extend product life, ensure regulatory compliance, and streamline daily workflows. Operational savings typically justify the investment within just a few years.

Future-proofing your investment means choosing systems built for longevity and adaptability. Energy-efficient operation, modular expansion capabilities, and compliance with evolving regulations protect your investment for decades.

At American Mortuary Coolers, we've built our reputation understanding that every facility has unique requirements. From Tennessee to California, from small funeral homes to large distribution centers, we've learned that one size doesn't fit all. That's why we specialize in custom solutions custom to your specific needs.

Your investment deserves expertise. Whether you need a specialized mortuary cooling system, compact floral preservation unit, or large-scale commercial walk-in, we bring the knowledge and craftsmanship necessary for long-term success. Our direct delivery across all 48 contiguous states means you get the same quality and service regardless of location.

The right refrigerator room becomes an invisible part of your daily operations - quietly maintaining perfect conditions while you focus on serving customers. That's the mark of truly successful installation.

Ready to explore your options? Check out More info about our walk-in options to see how we can create the perfect cold storage solution for your facility.