Why Walk-In Coolers Are Essential for Temperature-Controlled Storage

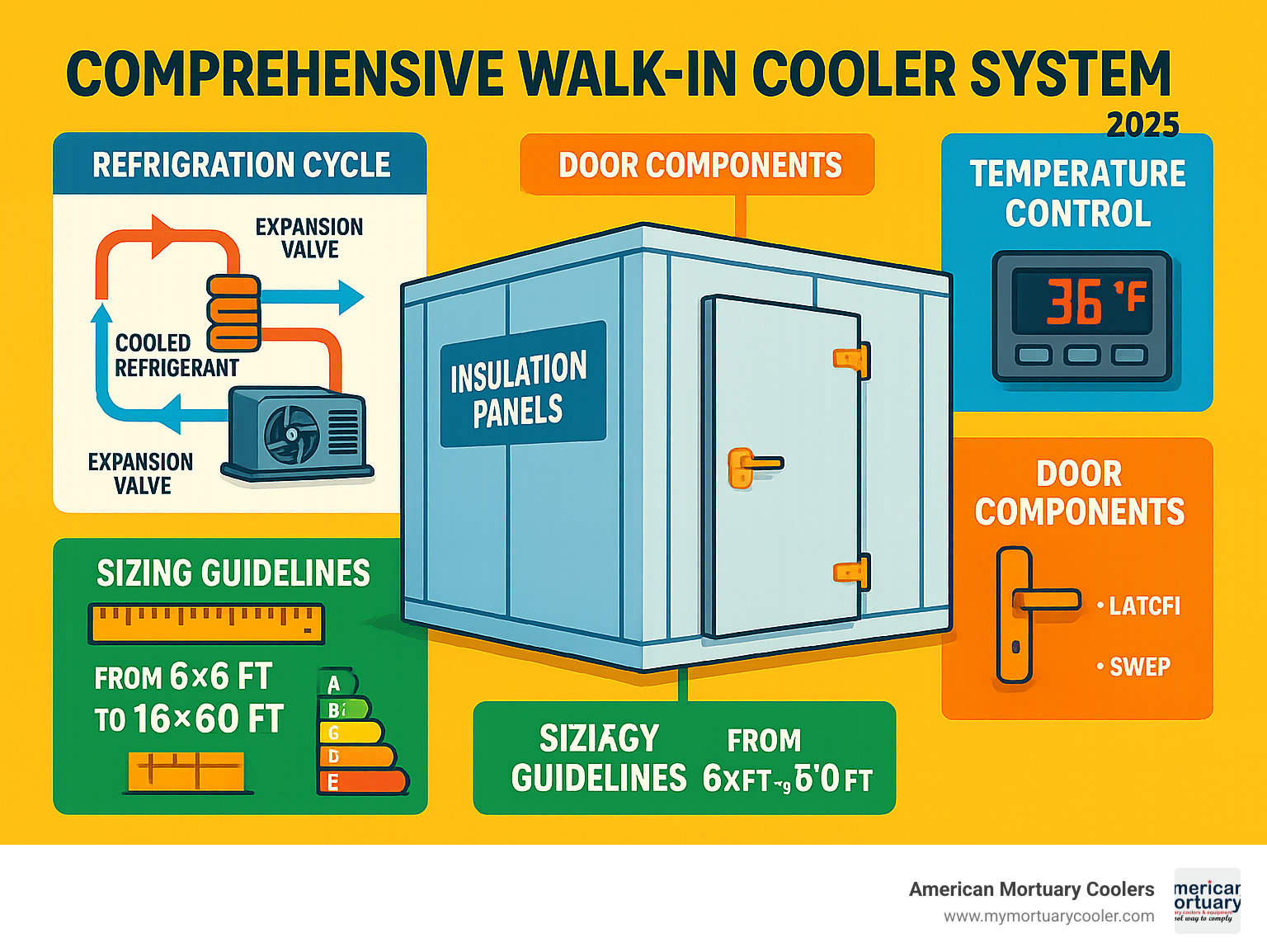

Walk-in-coolers- are large refrigerated storage units that maintain consistent temperatures between 35°F and 38°F, providing businesses with reliable cold storage for perishable goods.

Key Walk-In Cooler Facts:

- Temperature Range: 35°F to 38°F for optimal food storage

- Cooling Time: 3.2 hours for empty 10×10 unit to reach target temperature

- Lifespan: 15-20 years with proper maintenance

- Energy Efficient: Modern units significantly reduce power bills vs. multiple reach-in units

- Customizable: Available in sizes from 6×6 feet up to 16×60 feet

Walk-in coolers operate through a refrigeration cycle where refrigerant absorbs heat inside the unit, passes through an outdoor compressor to release that heat, then returns inside as cooled refrigerant. This continuous process maintains steady temperatures essential for food safety and regulatory compliance.

Industries relying on walk-in coolers include:

- Restaurants and foodservice operations

- Grocery and convenience stores

- Funeral homes and mortuaries

- Medical and pharmaceutical facilities

- Floral and agricultural businesses

- Warehouses and distribution centers

Modern walk-in coolers offer significant advantages over multiple reach-in units - better energy efficiency, easier maintenance access, greater storage capacity, and improved workflow organization.

As American Mortuary Coolers, we've spent years helping funeral home directors steer walk-in cooler selections and installations across the country. Our experience with walk-in-coolers- spans custom mortuary applications, energy-efficient retrofits, and direct shipping solutions.

Understanding Walk-In Coolers Basics

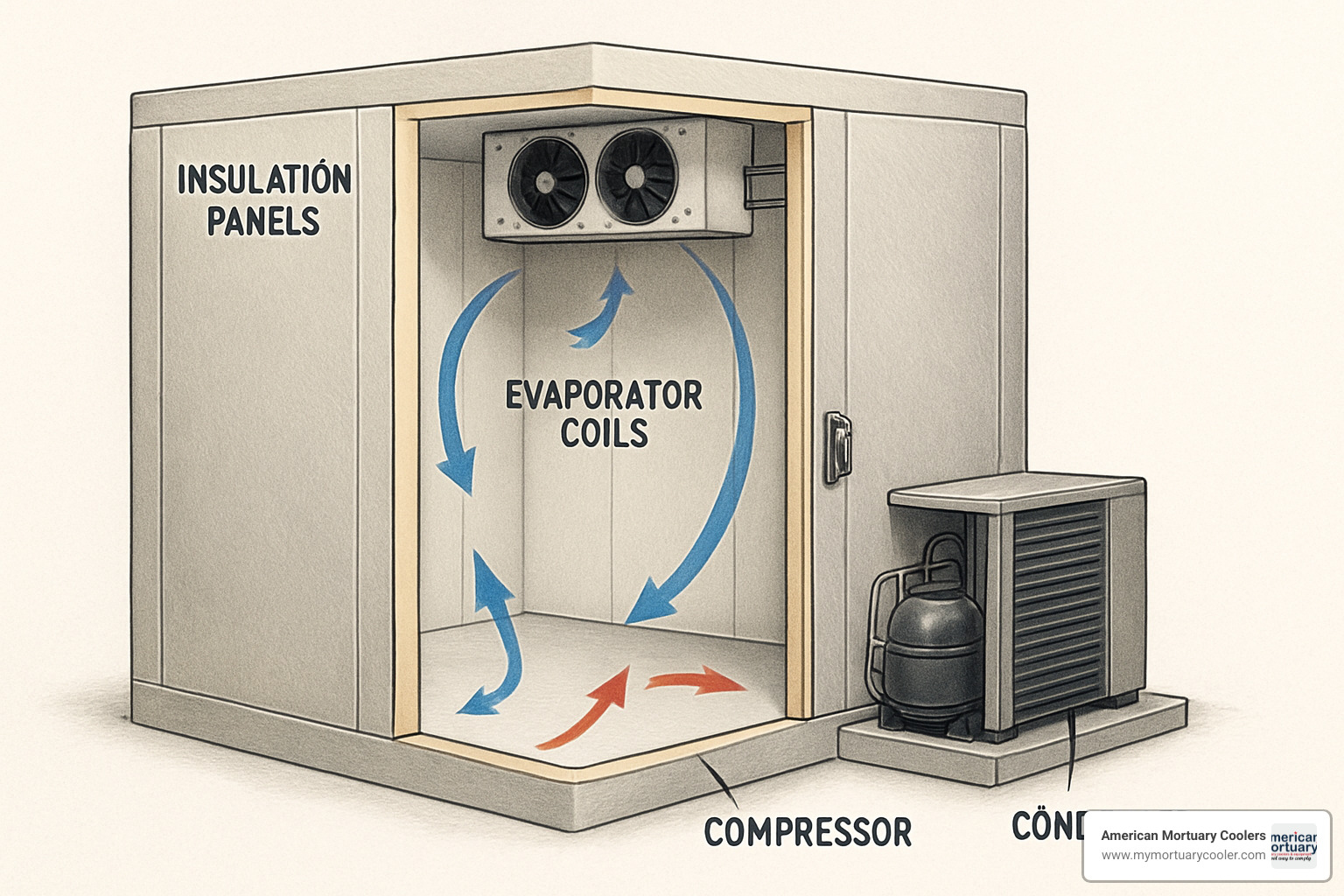

Walk-in-coolers- work like your home refrigerator, just on a much larger scale. Four main components work together: the compressor acts as the heart, pumping refrigerant throughout the system. The condenser releases heat outside, while the evaporator creates the cooling effect inside your cooler. Finally, insulation keeps cold air where you need it.

How Does It Work?

The refrigeration cycle starts when warm air meets cold evaporator coils. The refrigerant inside absorbs heat from warm air, changing from liquid to gas. This phase change creates the cooling effect.

The gaseous refrigerant travels to the compressor, which pressurizes it and sends it to the condenser coils. The condenser releases heat to outside air and turns refrigerant back into liquid. The liquid passes through an expansion valve, reducing pressure and temperature before starting the cycle again.

Proper airflow prevents hot spots that can spoil products. Evaporator fans keep cold air moving throughout your cooler, while condenser fans remove heat efficiently outside.

Main Components

The compressor typically requires 1.5 to 3 horsepower and draws 15 to 30 amps at 208-230V. Modern compressors feature variable-speed technology that adjusts cooling power based on demand.

Your condenser releases absorbed heat to ambient air. Dirty condenser coils can reduce efficiency by 30% or more, making regular cleaning essential.

Evaporator coils handle heat absorption inside the cooler. Low-profile designs minimize ice build-up, while proper sizing prevents excessive cycling.

Digital thermostats maintain precise temperature control within ±2°F. Advanced controls offer defrost scheduling, temperature logging, and remote monitoring.

Insulation in panels uses polyisocyanurate rigid board with 97% closed-cell content, offering superior R-values and moisture resistance. Quality panels meeting Department of Energy requirements can reduce operating costs by 20-40%.

Door hardware includes self-closing hinges with cam-lift mechanisms and heavy-duty gaskets for airtight seals. Safety releases allow exit from inside the cooler.

Shelving systems with NSF approval maximize storage while maintaining airflow. Wire shelving promotes ventilation, while solid shelving works for small items.

Research on air curtain performance shows properly designed airflow systems can reduce energy consumption by up to 15% while maintaining temperature uniformity.

Choosing & Customizing the Right Walk-In Cooler

Finding the perfect walk-in-coolers- for your business requires balancing reliability, efficiency, space, and budget. Today's walk-in coolers offer extensive customization options.

The biggest decision is choosing between prefabricated units that ship quickly or custom-built solutions custom to your exact needs. Modern panels use ecomate foam or polyisocyanurate insulation with impressive R-values. Today's cam-lock systems create airtight seals that rival seamless construction.

Sizing & Types

Walk-in cooler sizing follows this rule: plan for about 28 pounds of food storage per cubic foot. A standard 10×10 foot cooler provides roughly 22,400 pounds of storage capacity.

The 8×10 foot size works well for smaller operations where space is limited. For larger operations, custom dimensions are available in 11.5-inch increments.

Choose between floorless versus floored units. Floorless coolers install over existing concrete floors, saving money. Floored units include insulated floors that handle foot traffic and wheeled equipment.

Combo boxes provide both cooler and freezer compartments in one structure, perfect when you need both temperature ranges but lack space for separate units.

For detailed sizing guidance, see our resource on walk-in cooler dimensions.

Indoor vs Outdoor Units

Indoor units protect your investment from weather while keeping maintenance convenient. They cost 25% less than outdoor models but consume interior space and require ventilation.

Outdoor units free up interior space and operate as self-contained systems. Weatherproofing adds initial cost, but you gain valuable indoor space. Outdoor installations require level concrete pads and proper drainage.

Key Features & Options

Door options range from standard hinged models to bi-parting doors up to 10 feet wide. Glass display doors work well for retail applications.

Ramps enable wheeled access, while shelving systems maximize storage space. LED lighting with motion sensors cuts energy costs. Temperature alarms with remote notification provide peace of mind.

Safety features include interior releases on all doors and emergency lighting systems.

For comprehensive customization information, explore our guide to custom walk-in cooler options.

Custom Build or Prefab?

Prefabricated units with cam-lock panels offer proven performance with quick delivery. Standard sizes ship in about 10 days, and installation takes 1-2 days. The modular design allows relocation if needed.

Custom-built units with seamless construction represent the premium option, engineered for exact specifications and built to last decades.

Modern cam-lock systems create tight seals with structural integrity rivaling welded construction. For most applications, cam-lock panels offer speed and cost advantages.

Performance, Energy Efficiency & Maintenance

Getting the most from your walk-in-coolers- means understanding performance expectations and maintaining them properly to save on energy bills and avoid emergency repairs.

Temperature Ranges & Cooling Time

Most walk-in-coolers- operate between 35°F and 38°F. This range keeps food fresh while preventing freezing damage. Freezer units maintain -10°F to 0°F.

An empty 10×10 cooler takes about 3.2 hours to cool from 75°F to 35°F. A fully stocked cooler needs 12 to 24 hours to reach optimal temperatures after adding warm items.

If you regularly cool hot products, your system needs 25% to 50% more cooling capacity. Let hot foods cool to room temperature before refrigerating. Keep coolers 75-90% full for optimal airflow.

Federal guidelines require storing food below 41°F to prevent harmful bacteria growth.

Energy-Saving Strategies

Modern walk-in-coolers- can reduce energy costs by 30-50% compared to older units through smart technology and good operational habits.

LED lighting uses 75% less energy than fluorescent bulbs. Add motion sensors to eliminate waste from lights running unnecessarily.

High-quality insulation with R-values between R-25 and R-35 minimizes heat transfer. Variable-speed fans adjust based on cooling demands. Smart defrost controls only run when needed.

Vinyl strip curtains reduce air exchange by 80% during entry/exit. Door closers and alarms prevent heat gain from open doors.

For energy-saving strategies, check business energy savings research.

Routine Maintenance

Monthly: Clean condenser coils and fan blades. Check door gaskets and hinges. Verify defrost drain flow and temperature accuracy. Clean interior surfaces.

Quarterly: Have technicians inspect electrical connections and refrigerant levels. Calibrate thermostats and test safety systems.

Annually: Schedule comprehensive system inspection. Replace worn gaskets and hardware. Check insulation integrity and evaluate energy performance.

Keep detailed maintenance logs for warranty claims and regulatory compliance.

Troubleshooting Common Problems

Ice build-up typically results from damaged door seals or defrost system problems. Check gaskets and train staff on proper door closure.

Temperature fluctuations often indicate refrigeration problems, poor airflow, or excessive heat load. Look for blocked coils or dirty condenser surfaces.

Rising energy bills signal declining efficiency from worn components or operational issues. Energy audits pinpoint specific problems.

Strange noises usually mean mechanical wear or loose components. Address these warning signs early to prevent major repairs.

Recent research on personalized air curtains shows advances in airflow management improving energy efficiency and worker comfort.

Industry Applications & Compliance

Walk-in-coolers- serve diverse industries, each with unique challenges and regulatory requirements. From restaurant kitchens to medical facilities, these systems adapt to meet operational needs while maintaining strict compliance.

Foodservice & Retail

Restaurants depend on walk-in-coolers- for food safety during peak service hours when staff constantly access ingredients. These units provide the recovery speed needed to maintain proper temperatures during busy periods.

Hotels and large foodservice operations often require specialized configurations like keg coolers for draft beer and separate compartments for different food types.

Grocery stores rely on walk-in coolers for display case restocking, overflow storage, and backup cooling during maintenance.

Design considerations focus on durability and easy cleaning. High-traffic door hardware withstands thousands of daily openings, while smooth surfaces facilitate sanitization required by health departments.

Mortuary & Medical Uses

The funeral service industry requires specialized cooling beyond standard commercial refrigeration. At American Mortuary Coolers, we understand the unique challenges funeral directors face.

Walk-in-coolers- for mortuary use must meet stringent requirements for temperature precision, sanitation, and reliability. Our specialized units maintain exact temperatures essential for proper preservation while providing unwavering reliability.

Stainless steel interiors meet health department requirements and ensure thorough sanitization. Specialized shelving accommodates unique storage needs while maintaining proper airflow.

Security features include improved locking systems, restricted access controls, and monitoring capabilities. Backup power compatibility ensures continuous operation during outages.

Medical and pharmaceutical facilities need precise temperature ranges for vaccine storage and sample integrity, often requiring documented temperature stability for regulatory compliance.

For funeral home professionals, our guide to reliable walk-in coolers for funeral homes explores specific features essential for mortuary applications.

Regulatory Standards & Safety

The FDA's 41°F rule for potentially hazardous foods is a hard requirement that can make or break food businesses. Modern walk-in-coolers- include digital systems providing continuous data logging and automatic alerts.

OSHA safety requirements recognize cold environment hazards. PPE requirements include insulated gloves, non-slip footwear, and appropriate clothing. Safety releases on all doors are literally life-saving features.

HACCP compliance requires continuous temperature monitoring, detailed record keeping, and established corrective action procedures. Regular equipment calibration ensures accurate readings.

Essential compliance strategies include installing redundant monitoring systems, maintaining comprehensive logs, training staff on proper procedures, scheduling regular inspections, and implementing backup power for critical applications.

Cost, Lifespan & Innovations

Understanding the total cost picture for walk-in-coolers- helps you make smart decisions that protect your bottom line over decades of use.

Upfront & Operating Costs

Size drives initial cost most - an 8×8 cooler starts around $24,400, while an 8×12 unit runs approximately $30,484. An 8×20 combination cooler-freezer costs around $54,343.

Indoor versus outdoor installation creates a 25% price difference, but outdoor units free up valuable interior space. Site preparation varies from simple concrete pads to complex electrical work.

A typical system draws 15-30 amps continuously, running about 16 hours daily. With commercial electricity averaging 13.04 cents per kWh, annual energy costs range from $2,000 to $8,000.

Budget $500-1,500 annually for professional maintenance to prevent costlier emergency breakdowns.

For detailed costs and financing, see our guides on walk-in cooler financing options and walk-in cooler pricing.

Warranties & Expected Lifespan

With proper care, expect 15-20 years of reliable service from quality walk-in-coolers-.

Standard warranty coverage includes 1 year parts and labor for complete systems, 5 years on compressors, 25 years on foam insulation, and 12-year warranties on structural components.

Quality installation, consistent maintenance, and proper operating environment affect lifespan. Refurbishment can extend useful life when replacement seems premature.

Emerging Technology Trends

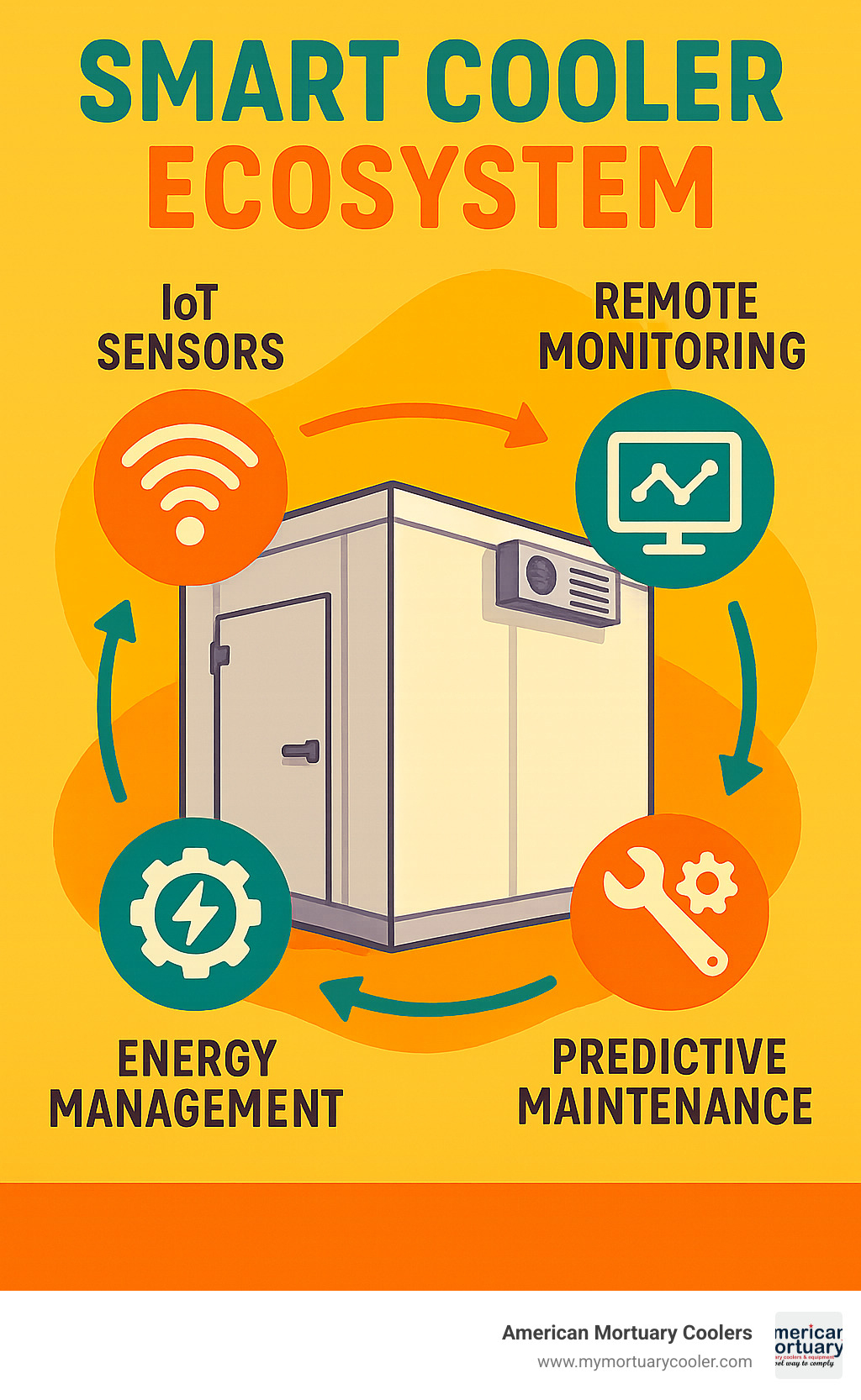

Smart monitoring systems represent the biggest advancement. IoT sensors track temperature, humidity, energy consumption, and performance around the clock, providing smartphone alerts and predictive maintenance.

Advanced refrigeration technology includes variable-speed compressors that adjust capacity to match demands, low Global Warming Potential refrigerants meeting environmental regulations, and improved heat exchanger designs extracting more cooling from less energy.

Construction innovations focus on eliminating energy waste through seamless fiberglass construction, advanced insulation materials achieving higher R-values, and self-healing door gaskets.

Environmental considerations drive innovations using eco-friendly refrigerants with zero ozone depletion potential. Energy recovery systems capture waste heat for water warming or space heating.

Today's walk-in-coolers- offer better value through improved efficiency, longer lifespans, and smart technology preventing costly problems.

Frequently Asked Questions about Walk-In Coolers

What size walk-in cooler do I need?

Finding the right size walk-in-coolers- requires understanding your storage needs and business operations. Start with the 28 pounds per cubic foot rule - a 10×10 foot cooler provides about 22,400 pounds of storage capacity.

Consider your busiest periods and peak inventory levels. Do you receive large weekly deliveries or smaller daily shipments? How quickly does inventory turn over?

Don't forget workflow and accessibility. You need clear aisles for safe movement, space around equipment for maintenance, and room for shelving systems.

Think about future growth plans. It's more cost-effective to install a slightly larger unit now than replace it in five years. Most clients find sizing up one increment provides valuable flexibility without breaking budgets.

How long does a fully stocked unit take to cool down?

A fully loaded walk-in-coolers- typically needs 12 to 24 hours to reach optimal temperatures after stocking with warm products.

Timing depends on what you're cooling. Room-temperature products need less time than warm items from processing or delivery.

Smart loading practices cut cooling time significantly. Load gradually over several hours rather than all at once. Keep clear pathways around evaporator coils for air circulation. Resist opening doors frequently to check progress.

Plan deliveries around cooler capacity. Use existing inventory before large shipments to give your refrigeration system the best chance to maintain proper temperatures.

How can I boost energy efficiency without replacing my cooler?

Several upgrades can improve existing walk-in-coolers- efficiency by 20-40 percent without major capital investments.

Quick wins include upgrading to LED lighting with motion sensors, eliminating major heat sources while cutting electricity use by 75 percent.

Door management makes huge differences. Installing vinyl strip curtains reduces air exchange by 80 percent. Add automatic door closers and alarms to prevent accidental openings.

Basic maintenance like cleaning condenser coils monthly and checking door gaskets costs almost nothing but delivers immediate results. Dirty coils can reduce efficiency by 30 percent or more.

Medium-term upgrades include variable-speed evaporator fans and programmable thermostats that prevent unnecessary cycling.

Smart monitoring systems track energy consumption, identify wasteful patterns, and alert you to problems before expensive repairs become necessary.

Conclusion

Choosing the right walk-in-coolers- can transform how your business handles temperature-controlled storage. These systems aren't just big refrigerators - they're the backbone of operations that depend on keeping products at exactly the right temperature, whether you're storing fresh produce for tomorrow's dinner service or maintaining proper conditions for sensitive applications.

At American Mortuary Coolers, we've spent years helping businesses across the country find cooling solutions that actually work for their specific needs. From our home base in Tennessee, we've shipped custom units to funeral homes in Chicago winters and restaurants in Los Angeles heat waves. What we've learned is that every business is different, and cookie-cutter solutions rarely deliver the results people need.

The investment in quality walk-in cooling pays off in ways you might not expect. You'll save money on energy bills with modern efficient systems. Yes, proper maintenance keeps expensive repairs at bay. But the real value comes from knowing your products are protected, your staff can work efficiently, and regulatory inspectors will find everything exactly as it should be.

Modern walk-in coolers offer remarkable flexibility. You can start with a basic 8×10 unit and expand with modular panels as your business grows. Smart monitoring systems let you check temperatures from your phone. Energy-efficient features can cut operating costs by 30% or more compared to older systems. And with proper care, these units keep running reliably for 15-20 years.

Whether you're planning your first walk-in-coolers- installation or replacing equipment that's seen better days, the key is matching the system to your actual needs. Consider your peak storage requirements, think about how your team will use the space daily, and don't forget about future growth plans.

For funeral home directors and other specialized applications, we understand that standard solutions often fall short. That's why we focus on custom builds that meet your exact specifications, delivered directly to your location anywhere in the contiguous 48 states. Our approach eliminates the guesswork and ensures you get equipment designed for your specific challenges.

The cooling industry keeps evolving with better refrigerants, smarter controls, and more efficient designs. But the fundamentals remain the same - proper sizing, quality installation, and consistent maintenance create systems that serve businesses reliably for decades.

Ready to explore your options? Visit our mortuary coolers page to see how our custom approach can solve your specific cooling challenges. We're here to help you find solutions that work, not just sell you equipment.