Understanding Walk-In Refrigerator Costs in 2024

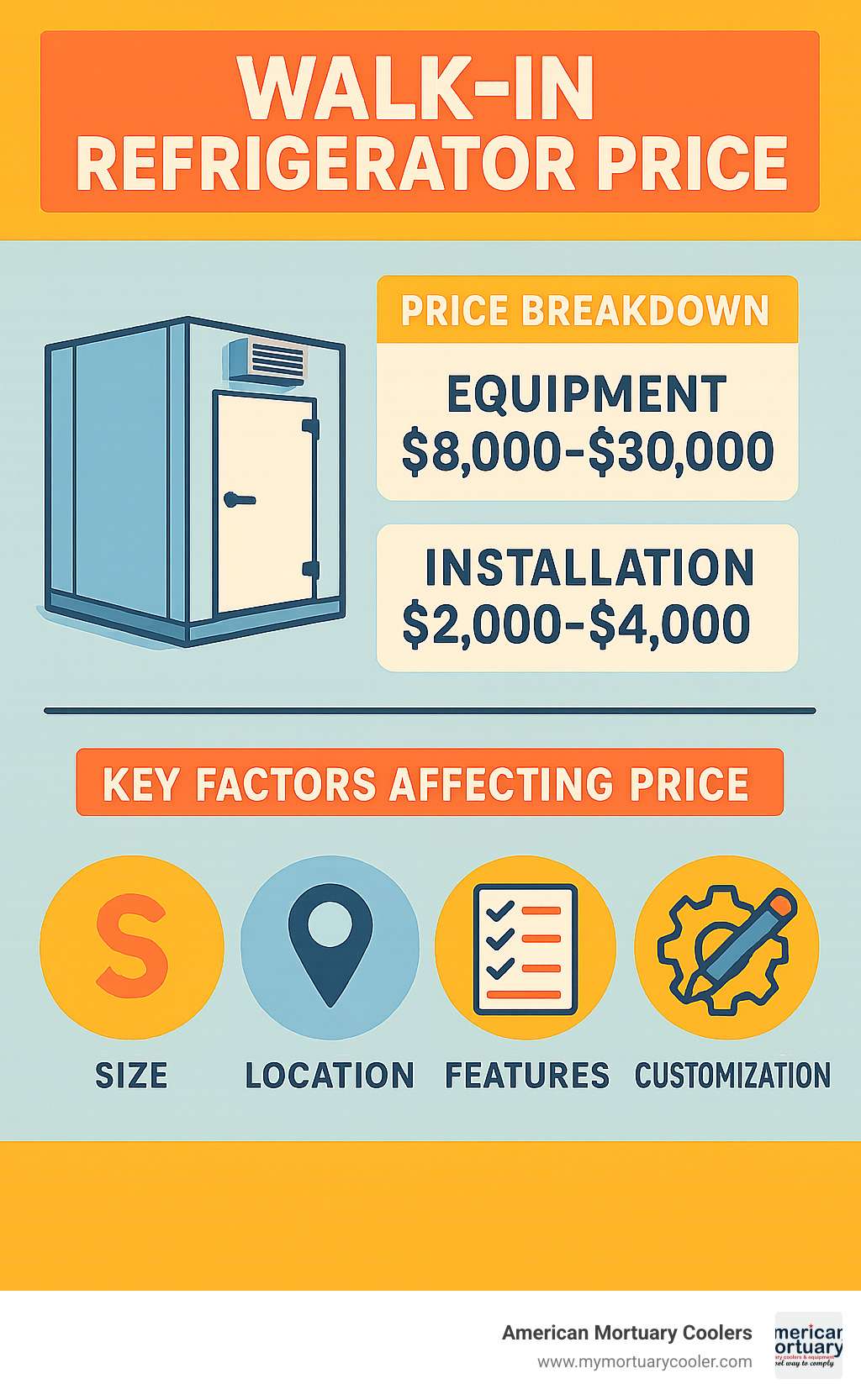

Walk in refrigerator price varies widely based on size, features, and installation requirements, but here's what you can expect to pay:

Quick Price Guide:

- Small units (6x6 ft): $8,000 - $15,000 installed

- Medium units (8x10 ft): $11,000 - $25,000 installed

- Large units (10x12+ ft): $15,000 - $40,000+ installed

- Used equipment: $400 - $10,000 (condition varies)

- Installation labor: $2,000 - $4,000 additional

Walk-in refrigerators are room-sized cooling units that maintain temperatures between 35°F and 41°F for storing large quantities of perishable items. These units use 4-inch insulated panels and commercial-grade refrigeration systems designed for heavy daily use.

The total cost depends on unit size (ranging from 68 to 1,600+ square feet), indoor versus outdoor installation, refrigeration system power, and whether you choose a quick-ship model or custom build. Installation costs typically add $2,000 to $4,000 to the equipment price.

Regional pricing varies significantly - a 10-square-foot unit costs around $9,638 in New York compared to $5,577 in Denver. Custom units take 10-12 weeks to deliver, while quick-ship models arrive in 1-6 weeks.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes steer walk in refrigerator price considerations and equipment selection.

Explore more about walk in refrigerator price:

What Is a Walk-In Refrigerator & Why Temperature Matters

Walk-in refrigerators are room-sized cooling units that can hold hundreds of cubic feet of inventory - perfect for restaurants, funeral homes, and other businesses that need serious cold storage.

The construction uses 4-inch thick insulated panels with R-values ranging from R-25 to R-32. This heavy-duty build keeps temperatures rock-steady even when doors swing open constantly throughout busy service periods.

Temperature control is critical. The FDA sets the legal limit at 41°F or lower for commercial refrigeration, but smart operators aim for 38°F as their target temperature. This gives you a safety buffer while avoiding energy waste from over-cooling.

Spoilage accelerates rapidly once temperatures climb to 45°F and above, but drop below 35°F and you risk freezing delicate items like lettuce and fresh produce.

The cooling system works through a continuous cycle, pulling warm air to the condenser where a thermostat manages the compressor and fan cycles. When internal temperatures dip below 35°F, an automatic defrost cycle kicks in to prevent damaging ice buildup.

Indoor versus outdoor placement significantly affects both performance and walk in refrigerator price. Indoor units benefit from stable ambient temperatures but need proper ventilation. Outdoor units require weatherproof panels and concrete slab preparation, but can reduce your building's HVAC load.

More info about walk-in refrigeration units

Typical Dimensions & Configurations

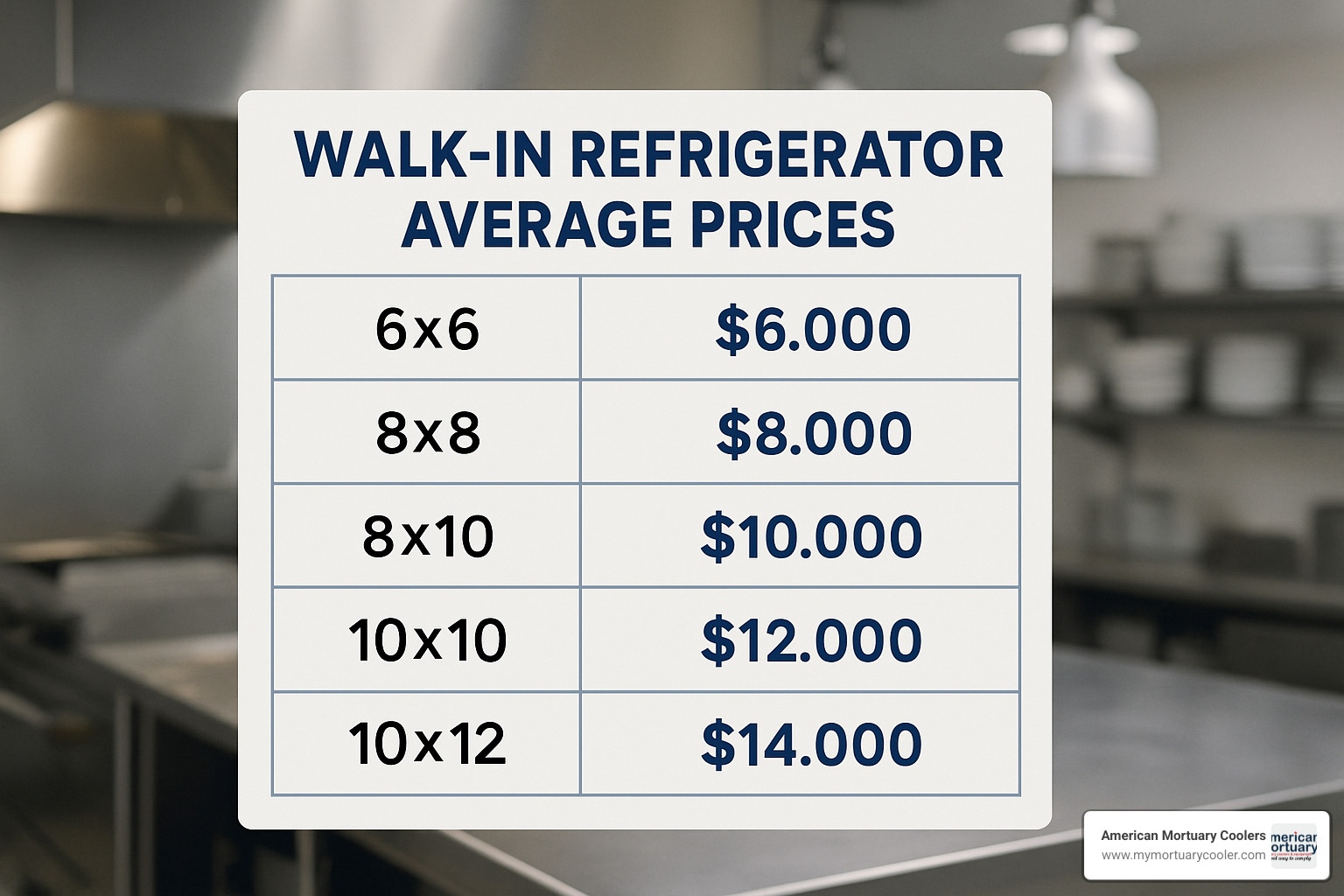

Walk-in refrigerators range from "cozy storage closet" to "small warehouse." Standard quick-ship models typically start at 4×6 feet and go up to 10×14 feet, with heights between 7'4" and 8'3".

The most popular sizes include 6×6 feet for small cafes, 8×8 feet for mid-sized restaurants, and 10×10 feet for larger operations. Hotels and major food service operations often go with 10×12 feet or larger.

4-inch thick insulation is standard, so your usable interior space will be about 8 inches smaller in each direction than the exterior dimensions.

Critical Temperature Zones

At 45°F and above, spoilage accelerates rapidly and creates real food safety risks. The 41°F FDA limit isn't just a suggestion - it's the law for commercial operations.

Most walk-in refrigerators can maintain temperatures from 28°F to 55°F, but the optimal range is much tighter. That 38°F sweet spot balances food safety with energy efficiency, while staying above the 35°F threshold where your automatic defrost system activates.

The key is consistency. Temperature swings hurt food quality and energy bills, which is why proper insulation and sizing matter for long-term operating costs.

Walk-In Refrigerator Price Breakdown for 2024

The walk in refrigerator price landscape has evolved significantly in 2024, with costs influenced by supply chain improvements, energy efficiency regulations, and increased demand across food service industries.

Equipment costs typically represent 60-70% of your total project budget, while installation and setup account for the remaining 30-40%.

Average Walk in Refrigerator Price Ranges

New Equipment Pricing:

- Quick-ship models: $8,000 - $30,000

- Custom builds: $10,000 - $40,000+

- Average across all sizes: $15,000

Used Equipment Pricing:

- Basic used units: $400 - $1,000 (often requiring significant refurbishment)

- Refurbished units: $2,000 - $10,000

- Nearly-new surplus: $5,000 - $15,000

For a standard 10 square foot walk-in cooler, expect total installed costs between $3,000 and $9,000, with the equipment itself ranging from $1,000 to $5,000 and installation labor adding $2,000 to $4,000.

The refrigeration system typically represents 30-40% of the total cooler cost.

Walk in Refrigerator Price by City & Region

Geographic location significantly impacts both equipment and installation costs. Labor rates, local building codes, and shipping distances all factor into regional pricing variations.

Major City Pricing (10 sq ft unit installed):

- New York, NY: $9,638

- Chicago, IL: $8,419

- Los Angeles, CA: $7,276

- Atlanta, GA: $6,465

- Seattle, WA: $5,839

- Phoenix, AZ: $5,884

- Miami, FL: $5,880

- Denver, CO: $5,577

At American Mortuary Coolers, we deliver across the contiguous 48 states from our Tennessee facility, with regional service centers in major markets to minimize shipping costs and delivery times.

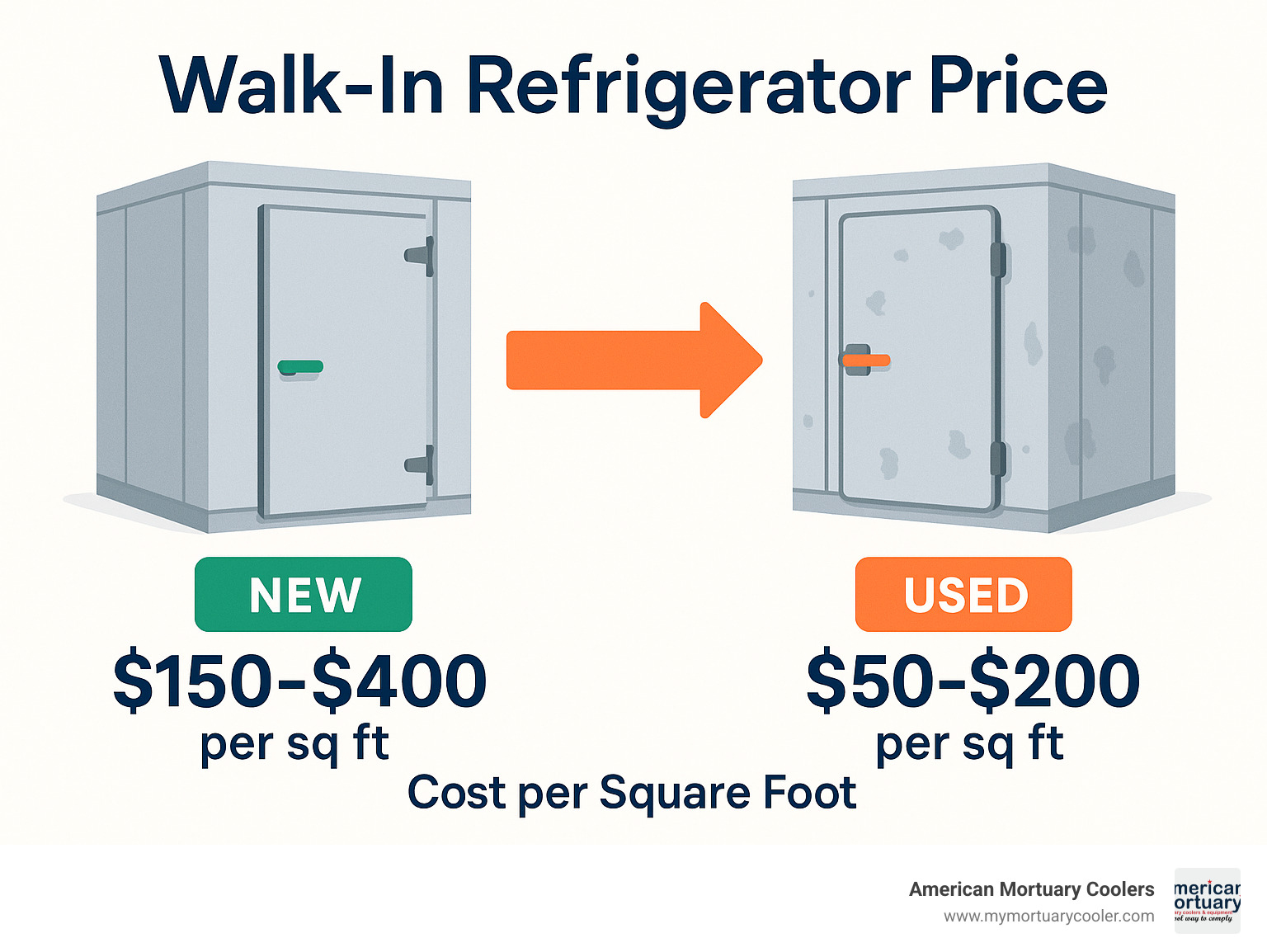

New vs Used: Pros, Cons & Hidden Costs

New Equipment Advantages:

- Full manufacturer warranty (typically 1-5 years on components, up to 20 years on panels)

- Latest energy efficiency features

- Customization options for exact space requirements

- Compliance with current safety standards

Used Equipment Considerations:

- Significant upfront savings (often 50-70% less than new)

- Potential for costly repairs and retrofits

- Limited or no warranty coverage

- May not meet current energy efficiency standards

- Unknown maintenance history

Hidden Costs in Used Equipment:

- Refrigerant system updates to meet environmental regulations

- Electrical upgrades for older units

- Panel replacement due to wear or damage

- Higher ongoing energy costs from older, less efficient systems

We often see customers who initially save money on used equipment end up spending more long-term due to maintenance issues and higher operating costs.

Cost Factors: Size, Features, Installation & More

When shopping for a walk-in refrigerator, the walk in refrigerator price depends on several key factors that work together to determine your final investment.

Size drives everything else. A 6×6 foot unit needs a smaller compressor and fewer panels than a 10×12 foot unit. We typically see horsepower requirements ranging from 0.5 HP for small units up to 4+ HP for large installations.

Your choice of brand matters significantly. Premium manufacturers like Nor-Lake and Amerikooler command higher prices because they use better materials and offer stronger warranties. Generic brands cost less upfront but may require more maintenance.

Door specifications can surprise people with their cost impact. A basic swing door comes standard, but upgrading to glass doors adds 15-25% to your total cost.

Floor requirements represent another major decision point. You can install your unit on an existing concrete slab or add insulated floor panels. Floor panels cost more initially but provide better temperature control.

The refrigeration system type significantly affects both price and installation complexity. Self-contained units cost less and install easier, while remote systems offer quieter operation and better energy efficiency for larger installations.

If you're planning an outdoor installation, budget an extra 10-15% for weatherproof panels and protective features. You'll also need proper concrete slab preparation, typically costing $500-$2,000.

Don't forget about permits and inspections. Most jurisdictions require permits for commercial refrigeration installations, typically costing $200-$1,000.

More info about walk-in cooler design

Equipment Upgrades That Add 5-40%

Optional features can transform a basic walk-in refrigerator into a sophisticated food storage system, but each upgrade affects your bottom line.

Glass doors represent one of the most popular upgrades, adding 15-25% to your total cost. They're especially valuable for display applications where customers need to see products without opening the door.

Automatic door closers add just 5-10% to your investment but provide excellent value. They ensure doors close completely every time, preventing temperature fluctuations and reducing energy costs.

Digital temperature controls cost 10-15% more than basic thermostats but offer precise temperature management and better monitoring capabilities. Many digital systems include alarm functions that alert you to temperature deviations.

Smart monitoring systems represent the premium upgrade option, adding 20-30% to your total cost. These systems provide remote alerts, data logging, and smartphone connectivity.

Premium finishes like stainless steel can add 10-40% depending on your specifications. Stainless steel looks professional and resists corrosion.

Energy-saving features cost more upfront but reduce operating expenses. EC motors use 20-30% less electricity than standard motors, while LED lighting systems provide better illumination using less power.

Indoor vs Outdoor Placement

Where you install your walk-in refrigerator affects both the walk in refrigerator price and long-term performance.

Indoor installations typically represent baseline pricing since they don't require special weatherproofing. However, indoor placement means the refrigeration system dumps heat into your building, potentially increasing your HVAC costs.

Outdoor installations add 10-15% to your equipment cost for weatherproof panels and protective features. You'll also need proper site preparation, including a level concrete slab. Concrete work typically runs $500-$2,000 depending on size and site conditions.

Outdoor placement offers significant advantages despite higher upfront costs. You free up valuable interior space, and heat rejection doesn't affect your building's HVAC system.

At American Mortuary Coolers, we help you evaluate these factors based on your specific facility and climate conditions.

Installation, Operating & Maintenance Costs

When budgeting for a walk-in refrigerator, the sticker price is just the beginning. Installation, daily operation, and maintenance create ongoing costs that significantly impact your total investment over the unit's 15-20 year lifespan.

Professional installation isn't optional - it's absolutely essential. Installation costs typically add $2,000 to $4,000 to your equipment purchase, though complex projects can push this higher.

The installation process usually takes one to three days depending on unit size and complexity. Most installers work systematically: site preparation and panel delivery, panel assembly and refrigeration system installation, then electrical connections and system testing.

Remember those regional price differences? Labor costs drive much of that variation. The same installation that costs $4,000 in New York might only cost $2,500 in Denver.

Latest research on installation costs

More info about comparing quotes

What's Included in Professional Installation

A proper installation covers far more than just assembling panels and plugging in the unit. Professional installers handle every detail to ensure your walk-in refrigerator operates safely and efficiently from day one.

Site surveys kick off the process, with technicians verifying dimensions, checking electrical capacity, and planning access routes for equipment delivery.

Panel assembly looks straightforward with modern cam-lock systems, but proper alignment and sealing require experience. Poor assembly creates air leaks that waste energy and compromise temperature control.

Refrigeration system work must be handled by licensed HVAC technicians. They mount condensing units, run refrigerant lines, install evaporators, and charge systems with the correct refrigerant type and quantity.

Electrical connections involve more than just plugging into a wall outlet. Most units need 208/230V single-phase or three-phase power, plus separate circuits for lighting and controls.

System commissioning wraps up the installation with comprehensive testing. Technicians verify temperature control accuracy, test door seals, check automatic defrost cycles, and calibrate all controls.

Ongoing Bills: Electricity, Repairs, Compliance

The walk in refrigerator price extends well beyond purchase and installation into daily operating costs that continue for decades.

Energy consumption has improved dramatically with modern units. A typical 8×10 foot walk-in cooler uses approximately 0.15 kWh per day, translating to just $15-30 monthly electricity costs depending on your local rates.

Routine maintenance keeps your unit running reliably and efficiently. Annual service contracts typically cost $500-$1,500 and include cleaning condenser coils, checking refrigerant levels, testing door seals, calibrating temperature controls, and inspecting electrical connections.

Component replacement happens gradually over your unit's lifetime. Door gaskets need replacement every 2-3 years at $100-$300 per set. Compressors may need service or replacement after 10-15 years, costing $2,000-$5,000.

Compliance and inspections vary by location and application. Food service operations need health department inspections - some jurisdictions require annual inspections costing $100-$500.

At American Mortuary Coolers, we've seen customers operate our units for decades with minimal maintenance costs. Quality construction and proper installation create the foundation for years of reliable, cost-effective operation.

Buying Guide: Brands, Models, DIY vs Pro

Navigating the walk-in refrigerator market can feel overwhelming with so many brands and options available. Your walk in refrigerator price will vary significantly between brands, but you'll generally get what you pay for in terms of quality and support.

Nor-Lake stands as the industry heavyweight, known for exceptional durability and endless customization options. Amerikooler offers a sweet spot of quality and value, providing both quick-ship models and custom solutions.

For larger installations and outdoor applications, Polar King has built a solid reputation. Mr. Winter focuses on getting you up and running quickly with their quick-ship models and competitive warranties.

If budget is your primary concern, Atosa and various regional manufacturers provide basic functionality at lower price points. Just remember that cutting corners on quality often leads to higher maintenance costs.

The quick-ship versus custom decision comes down to timing and specific needs. Quick-ship models arrive in 1-6 weeks and cost less, but you're limited to standard sizes and features. Custom builds take 10-12 weeks but accommodate tricky space requirements.

Leasing options deserve serious consideration, especially for newer businesses. Monthly payments typically range from $200-$800 depending on unit size.

More info about choosing a supplier

Is DIY Ever Worth It?

Walk-in refrigerator installation is never a DIY project. I've seen too many business owners learn this lesson the expensive way.

HVAC licensing requirements make this a non-starter in most areas. Refrigeration work requires specific licenses, and getting caught doing unlicensed work can result in hefty fines and insurance nightmares.

Here's the real kicker: most manufacturers void warranties for improper installation. Since the refrigeration system represents 30-40% of your total investment, protecting that warranty is absolutely crucial.

An experienced HVAC engineer recently told me that even using all used parts, building a walk-in cooler would cost over $3,000 in materials alone. Factor in the specialized tools, time, and expertise required, and professional installation becomes the obvious choice.

Safety concerns make DIY installation downright dangerous. Improper refrigerant handling poses serious health risks, and commercial electrical systems require specific knowledge to work safely.

Where to Shop & How to Compare Quotes

Direct manufacturer purchases often provide the best pricing and warranty support, especially for custom applications. Restaurant supply dealers offer the advantage of local relationships and can provide multiple brand options.

Surplus dealers excel for used and refurbished equipment, but make sure they provide detailed maintenance histories and realistic warranty coverage. Online marketplaces give you the widest selection but often lack local service support.

When comparing quotes, make sure you're comparing apples to apples. Panel thickness and insulation values vary between manufacturers. Refrigeration system capacity and efficiency directly impact both performance and operating costs.

Warranty terms deserve careful attention. Some manufacturers offer comprehensive coverage while others exclude key components. Installation scope should be clearly defined.

Watch out for quotes significantly below market averages, as they often indicate inferior components or hidden costs.

At American Mortuary Coolers, we believe in transparent pricing with detailed specifications and clear warranty terms. Our nationwide service network means you'll have support regardless of your location.

Frequently Asked Questions about Walk-In Refrigerator Price

What is the cheapest walk-in refrigerator price I can expect?

If you're looking for rock-bottom pricing, used equipment starts around $400-$1,000 for basic units. But these bargain-basement prices usually mean you're buying just the shell without a working refrigeration system, and they often need serious refurbishment work.

For a complete, functional used unit that actually keeps things cold, you're realistically looking at $2,000-$5,000 minimum. Even then, you're rolling the dice on reliability and longevity.

New equipment starts around $8,000 for small quick-ship models with basic refrigeration systems included. This doesn't include installation costs, which will add another $2,000-$4,000 to your total bill.

The most cost-effective approach is often a quality quick-ship model from a reputable manufacturer. While you'll pay more upfront than used equipment, you get warranty protection, modern energy efficiency, and reliability that typically makes it the cheaper choice over time.

How much does installation add to the final bill?

Installation typically adds $2,000-$4,000 to your equipment costs, which represents about 30-40% of your total project budget. This covers panel assembly and proper sealing, complete refrigeration system installation and commissioning, electrical connections and control setup, plus thorough testing and startup procedures.

Complex installations can push costs higher. If you need electrical upgrades, have difficult access to your installation site, or require concrete work for outdoor units, expect to pay more. Outdoor installations requiring concrete slabs typically add $500-$2,000 just for site preparation.

Location makes a huge difference too. The same installation work might cost $2,000 in Denver but $4,000 in New York due to regional labor rate differences.

Do I really save money buying used equipment?

Used equipment offers tempting upfront savings - often 50-70% less than new - but it's a bit like buying a used car from someone you don't know. You might get lucky, or you might inherit someone else's problems.

The potential savings are real: lower purchase price, immediate availability, and sometimes the previous owner throws in accessories or shelving.

But the hidden costs and risks are substantial. You get no warranty protection, which means any repairs come straight out of your pocket. You don't know the maintenance history. Older refrigeration systems often have issues and consume significantly more energy than modern units.

We've seen this scenario play out countless times: customers save $5,000 upfront on used equipment, then spend $3,000-$8,000 on repairs and upgrades within the first few years. Unless you have refrigeration expertise in-house or you're working with a very tight budget, new equipment typically provides better long-term value.

At American Mortuary Coolers, we always recommend being honest about your total budget and timeline. Sometimes a quality used unit makes sense, but more often, investing in new equipment pays off through reliability, efficiency, and warranty protection.

Conclusion

Making the right choice about walk in refrigerator price goes far beyond comparing sticker prices. Yes, you'll pay anywhere from $8,000 for a basic new unit to $40,000+ for large custom installations, but the real story unfolds over the 15-20 year lifespan of your equipment.

The smartest buyers think like marathon runners, not sprinters. They budget for total installed cost rather than just equipment price, knowing that installation adds another $2,000-$4,000 to the final bill. They consider how much electricity will cost over two decades and choose energy-efficient models that might cost more upfront but save thousands in operating expenses.

Regional pricing variations can be dramatic - remember that $4,000 difference between New York and Denver installations? Factor this into your planning, especially if you're expanding to multiple locations. And while used equipment might seem tempting at 50-70% savings, most buyers without refrigeration expertise find themselves spending those savings on repairs and upgrades within just a few years.

Here's what separates successful purchases from costly mistakes: choosing reputable manufacturers with strong warranty support. When your livelihood depends on consistent refrigeration, that warranty coverage becomes invaluable peace of mind.

At American Mortuary Coolers, we understand that funeral homes face unique challenges. Temperature control isn't just about efficiency - it's about dignity and respect for families during their most difficult moments. That's why we've built our reputation on durable, custom cooling solutions delivered directly from our Tennessee facility to anywhere in the contiguous 48 states.

Our approach differs from typical commercial refrigeration suppliers. We don't just sell equipment; we partner with funeral directors to create solutions that fit your specific space, budget, and operational needs. Whether you need a standard quick-ship model for immediate installation or a custom solution for challenging architectural requirements, we provide transparent pricing and detailed specifications upfront.

Every quote includes comprehensive warranty coverage and access to our regional service network. Because when families are counting on you, your equipment needs to work flawlessly - every single time.

Ready to move forward with confidence? Contact us today for a personalized quote that considers your specific needs, location, and budget requirements. Let's build something that serves your community for decades to come.