Why Walk-In Cooler With Freezer Combos Are Essential for Modern Businesses

A walk in cooler with freezer is a dual-temperature refrigeration system that combines both cooling and freezing compartments in one integrated unit. This combo solution provides businesses with the ability to store both refrigerated items (typically 35-38°F) and frozen products (0°F to -10°F) while maximizing space efficiency and reducing equipment costs.

Key Benefits of Walk-In Cooler With Freezer Combos:

- Space savings - Single footprint houses both temperature zones

- Cost efficiency - Lower purchase price than two separate units

- Energy optimization - Shared insulation walls and refrigeration systems

- Simplified installation - One electrical connection and condensing unit

- Temperature flexibility - Independent controls for each compartment

According to industry data, over 90% of restaurants and hotels in Canada rely on walk-in refrigeration for storing the majority of food needed for service. Modern combo units feature advanced insulation with R-values of 32, meeting or exceeding federal energy standards while supporting floor loads up to 600 lbs per square foot.

Industries that benefit most from walk-in cooler with freezer combos include restaurants, hotels, convenience stores, medical facilities, floral shops, and catering operations. These businesses need reliable dual-temperature storage without dedicating excessive floor space to separate refrigeration units.

I'm Mortuary Cooler, a national level mortuary cooler supplier with extensive experience helping funeral homes and commercial facilities select the right walk in cooler with freezer solutions for their specific needs.

Simple walk in cooler with freezer glossary:

Why This Guide Matters

Choosing the right walk in cooler with freezer involves more than just picking a size and placing an order. This guide walks you through the entire buyer's journey, from understanding how combo units work to calculating your specific needs, evaluating energy efficiency, and planning for long-term maintenance.

The decision factors we'll cover include space planning, insulation requirements, refrigeration system options, regulatory compliance, installation considerations, and total cost of ownership.

What Is a Walk-In Cooler With Freezer Combo and Why Choose One?

A walk in cooler with freezer combo is essentially two temperature-controlled rooms that share a wall and work together as one smart system. The cooler side keeps your fresh items at 35-38°F, while the freezer side maintains 0°F to -10°F for frozen inventory and long-term storage.

Instead of buying two separate units that each need their own four walls, the combo shares one wall between compartments. That shared wall has the same heavy-duty insulation (usually R-32), but you're not paying for duplicate materials or eating up extra floor space.

Why choose a combo over standalone units? The footprint savings alone can be a game-changer. A combo unit can give you the same storage capacity as two separate units while using about 25% less floor space. Plus, you often need just one condensing unit to run both sides, which means simpler installation and potentially lower upfront costs.

The dual-zone setup makes perfect sense for businesses that need both temperature ranges daily. Each compartment has independent temperature controls, so you're not compromising on precision.

How It Works vs. Standalone Units

Each compartment gets its own evaporator coil - the cooler side uses a medium-temperature coil, while the freezer side gets a low-temperature coil with electric defrost capability. These independent evaporators can connect to separate condensing units or share a single unit with dual circuits.

That shared-wall insulation eliminates redundant materials. Instead of needing eight exterior walls for two standalone units, you only need seven total walls with the combo design. The shared wall uses the same high-R-value insulation as exterior walls, maintaining perfect temperature separation.

Space efficiency becomes obvious when you run the numbers. Two separate 8'×10' units would require 160 square feet plus clearance space. An equivalent combo unit might only need 120 square feet total, freeing up 40 square feet for other equipment.

For detailed technical specifications, check out our In-Depth Guide to Walk-In Cooler Freezer Combos: Compare Top Options.

Industries & Applications Benefiting Most

Foodservice operations are ideal for combo units. During dinner rush, cooks need quick access to both fresh herbs from the cooler and frozen proteins from the freezer. A walk in cooler with freezer combo positioned between kitchen and prep area means they can grab what they need from both temperature zones efficiently.

Breweries use combos for fresh kegs and draft beer in the cooler section, while storing specialty hops, yeast cultures, and experimental ingredients in the freezer.

Medical and pharmaceutical facilities often need both refrigerated vaccines and medications alongside frozen samples and specimens. The combo unit simplifies temperature monitoring and compliance documentation.

Event catering companies can load both fresh and frozen items for transport to venues, making logistics much easier.

Key Factors When Selecting Your Walk-In Cooler/Freezer

Choosing the right walk in cooler with freezer starts with evaluating your specific needs and operational requirements. Consider your capacity requirements - both current and future - along with construction specifications that match your environment.

Panel thickness and R-value directly affect your energy bills. Most quality units now come with R-32 insulation in 4-inch panels, which exceeds federal energy codes and provides excellent temperature stability.

Don't forget regulatory compliance during planning. Energy codes vary by location, but most areas now require compliance with EISA standards.

Size & Configuration Planning

Most walk in cooler with freezer combos fall into standard footprints that work well for typical commercial applications. The sweet spot for many businesses is the 8'×10' or 10'×12' range - large enough for serious storage capacity but still manageable for installation.

Standard footprints start with compact 6'×8' units perfect for small cafes. Mid-range 8'×12' configurations work well for restaurants and medium-sized operations, while large 12'×20' systems handle high-volume facilities like institutional kitchens.

Custom footprints work when you're dealing with unusual spaces or specific workflow needs. The key is matching the unit's shape to your space rather than forcing a standard size into an awkward location.

Here's a practical calculation method: multiply length × width × height to get total cubic feet, then subtract about 30% for shelving, air circulation, and access space. A 10'×12'×8' combo gives you roughly 670 cubic feet of actual usable storage when properly configured.

| Layout | Cooler Size | Freezer Size | Total Footprint | Best For |

|---|---|---|---|---|

| 6×8 Combo | 6×4 | 6×4 | 48 sq ft | Small restaurants, cafes |

| 8×10 Combo | 8×6 | 8×4 | 80 sq ft | Mid-size operations |

| 10×12 Combo | 10×8 | 10×4 | 120 sq ft | Large kitchens, institutions |

Construction & Insulation Essentials

Polyurethane insulation has become the gold standard because it delivers superior thermal performance while resisting moisture infiltration. Quality panels using polyurethane foam achieve R-values of 32 with just 4-inch thickness, exceeding federal energy standards.

Fiberglass construction offers advantages for outdoor installations where weather resistance is critical. These units withstand roof snow loads of up to 100 pounds per square foot without requiring additional steel framing.

Fire-rated panels have become mandatory in many jurisdictions. CAN/ULC-S138 approved panels provide the fire resistance required by most commercial building codes.

For comprehensive information about construction options, visit our More info about cooler features guide. You can also verify fire-rated certification at the Intertek fire-rated certification database.

Refrigeration System Choices

Self-contained systems mount the condensing unit directly on top of the walk-in unit, creating a complete plug-and-play installation. Remote systems locate the condensing unit away from the walk-in box, typically outdoors, which reduces noise and allows better heat rejection.

Modern refrigerants like R-448A provide better environmental performance while maintaining excellent cooling capacity. Microchannel coils and dual-speed EC motors represent the latest advances in energy efficiency, often cutting energy usage by 30-50%.

Energy Efficiency & Regulatory Compliance

EISA and DOE regulations establish minimum insulation requirements. Current standards specify R-29 for cooler applications and R-32 for freezer applications.

EC motors provide significant energy savings compared to traditional motors by automatically adjusting speed based on cooling demand. LED lighting has become standard because of its low heat output and minimal energy consumption.

For thermal performance information, see this resource on thermal conductivity.

Installation, Customization, and Lifecycle Costs

Getting your walk in cooler with freezer installed properly makes the difference between decades of reliable service and constant headaches. The foundation needs to be rock solid - your concrete slab must be level within a quarter inch over 10 feet.

Electrical planning often catches people off guard. You'll typically need 208/230V three-phase power for the refrigeration system, plus standard 115V for lights and controls. Plan on dedicated circuits with 30-60 amp capacity depending on your unit size.

The flooring choice depends on usage. Standard aluminum diamond plate works for most applications, but heavy-duty reinforced options are needed for forklifts. The freezer side always needs an insulated floor to prevent ground heat infiltration.

Accessibility compliance requires ramps to handle the 4-6 inch step up into the unit, making product movement much easier.

Warranty coverage varies between manufacturers. Look for 15-20 year panel warranties, 5-year door and compressor coverage, and at least 1-year parts and labor.

Financing options can transform a major capital expense into manageable monthly payments, often preserving working capital for other business needs.

Indoor vs. Outdoor Setup

Indoor installations need adequate breathing room. Self-contained units need at least 24 inches of clearance above the condensing unit and 12 inches on the sides for proper airflow.

Outdoor installations face tougher challenges but offer advantages like not heating up your building. You'll need weatherproof construction and structural reinforcement for wind and snow loads.

Snow loading becomes critical in northern climates. Units must handle local snow loads ranging from 20 to over 100 pounds per square foot. Membrane roofing protects outdoor units while maintaining insulation continuity.

For detailed cost information, check our Walk-In Cooler Installation Cost guide.

Custom Options & Add-Ons

Glass doors transform your walk in cooler with freezer into a merchandising tool. Customers can see products without opening doors, saving energy and creating impulse purchases.

Strip curtains provide economical solutions for high-traffic situations, creating air barriers that reduce temperature loss when doors open frequently.

Temperature monitoring systems protect your investment by catching problems early. Modern alarm systems send alerts via phone, email, or text when temperatures drift outside safe ranges.

Shelving systems maximize storage capacity. Adjustable wire shelving adapts to different product sizes, while specialized racks handle specific items.

Budgeting, Financing, and ROI

Base pricing for combo units typically starts around $12,000-15,000 for smaller configurations. Larger custom units can reach $25,000-30,000 or more depending on features.

Lead times vary based on customization. Quick-ship models arrive within 2-10 days, while custom units require 4-8 weeks.

100% financing programs eliminate upfront cash requirements and spread payments over 3-7 years. Monthly payments often cost less than energy savings compared to older equipment.

Energy rebates from utilities can offset 10-30% of purchase price for high-efficiency units. Payback periods typically range from 2-5 years when replacing older equipment.

Operating & Maintaining Your Walk-In Cooler With Freezer

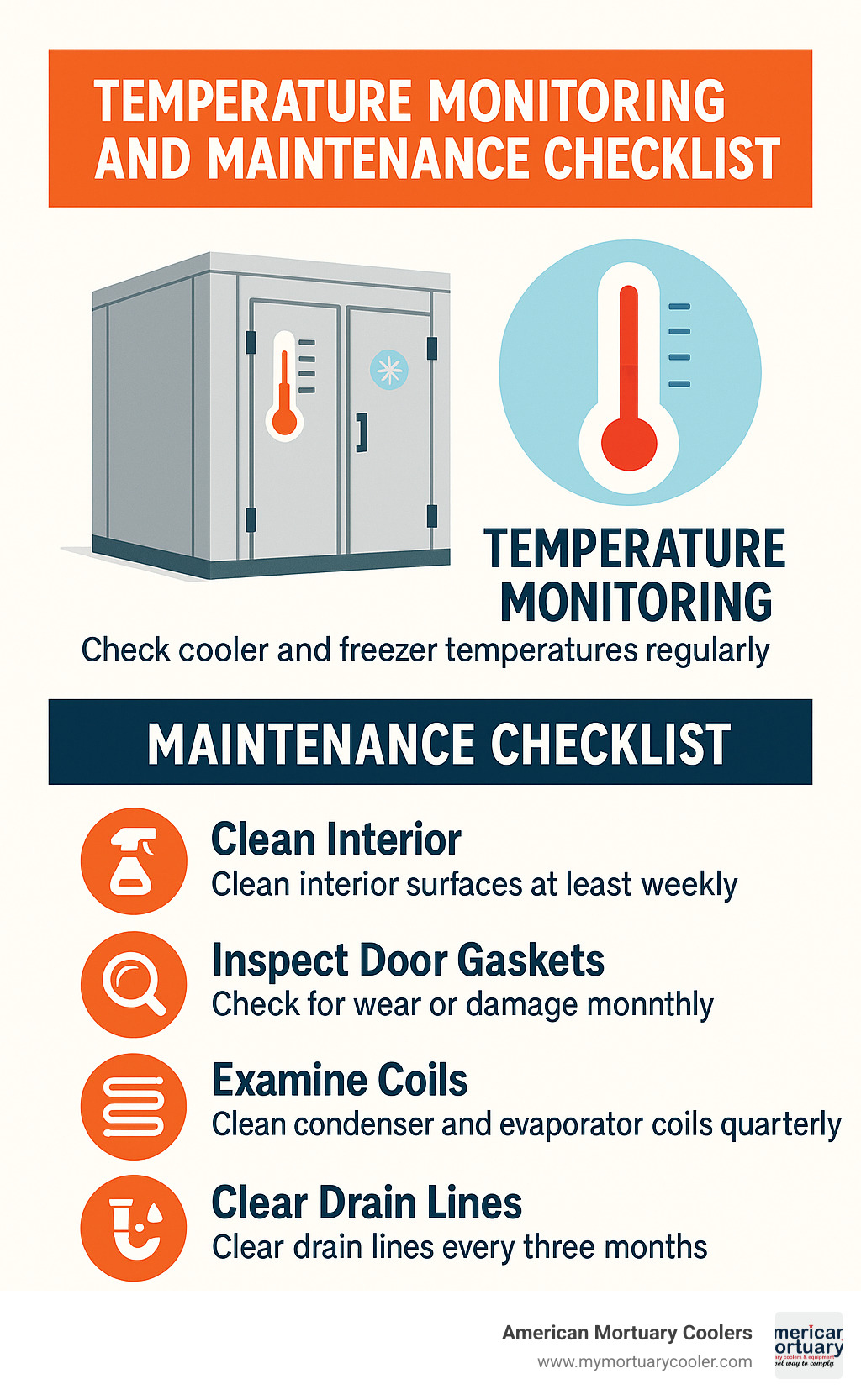

Once your walk in cooler with freezer is running, proper daily operation protects your investment and keeps products safe. Temperature monitoring should become routine - check both compartments at least twice daily. Your cooler should stay between 35-38°F, while the freezer needs 0°F to -10°F.

Daily logs help spot problems before they become disasters. Digital thermometers with min/max memory show highest and lowest temperatures since your last check.

HACCP requirements mandate continuous temperature monitoring for food storage operations. These logs protect both your products and business from liability issues.

Cleaning intervals depend on usage, but weekly deep cleaning of interior surfaces keeps things sanitary. Monthly attention to door gaskets and hinges prevents wear, while quarterly cleaning of evaporator coils maintains efficiency.

Daily Use & Food Safety

Smart temp monitoring means taking extra readings during busy periods when staff are constantly in and out. Cross-contamination prevention starts with smart organization - store raw meats on lower shelves and maintain good air circulation.

Loading practices make a huge difference. Never pack compartments beyond 70% capacity - your unit needs air circulation to work properly. Let hot foods cool to room temperature before storage.

Essential food safety practices:

- Never store anything directly on the floor

- Rotate stock using first-in, first-out principles

- Label everything with dates and contents

- Keep six inches clearance around evaporator coils

- Train staff to minimize door opening time

- Clean spills immediately

- Check door gaskets weekly

Preventive Maintenance & Warranty Coverage

Quality manufacturers back their walk in cooler with freezer units with substantial warranties. Panel warranties typically run 15-20 years, covering insulation degradation and structural failures.

Compressor warranties usually provide 5-year coverage on the sealed refrigeration system. Door warranties cover 5 years for hinges, gaskets, latches, and structural parts.

After-sales support varies dramatically between suppliers. Look for companies with local service networks who stock common parts and provide technical support.

Frequently Asked Questions about Walk-In Cooler/Freezer Combos

How do I calculate the right size for my business?

Start by taking inventory of what you're storing currently. Measure how much space your refrigerated and frozen items actually take up, including busy holiday periods.

Here's a simple rule: refrigerated items need about 1.5 to 2 times their actual volume because of packaging and air circulation. Frozen items typically need about 1.2 to 1.5 times their volume since you can stack them more efficiently.

Your delivery schedule makes a huge difference. Weekly deliveries require more walk in cooler with freezer capacity than daily deliveries. Add at least 25-30% extra capacity for business growth and seasonal peaks.

Can I install a combo unit outdoors in extreme climates?

Absolutely, but outdoor installations in harsh climates need extra planning. Choose units specifically engineered for your local weather conditions. Fiberglass construction often handles extreme weather better than metal because it resists corrosion and temperature swings.

Your unit needs engineering for maximum snow loads (over 100 pounds per square foot in some areas), wind resistance, and temperature swings. Proper drainage prevents ice buildup, and membrane roof systems add protection.

What ongoing costs should I expect beyond the purchase price?

Electricity will be your biggest expense, typically running $200-800 monthly depending on unit size and local rates. Energy-efficient units with EC motors and LED lighting cut these costs significantly.

Routine maintenance supplies run about $50-100 yearly. Professional service calls cost $150-300 per visit. Plan for major component replacements every 10-15 years - compressor replacement typically costs $2,000-4,000.

A well-maintained walk in cooler with freezer easily lasts 15-20 years, and energy savings from modern units often offset operating costs compared to older equipment.

Conclusion & Next Steps

Choosing the right walk in cooler with freezer becomes straightforward when you understand the essential factors - proper sizing, quality construction, energy efficiency, and reliable service support.

At American Mortuary Coolers, we specialize in crafting custom solutions for funeral homes and commercial facilities across all 48 contiguous states. Our direct delivery model means your equipment arrives ready for installation, complete with comprehensive warranties and ongoing support.

The advantages of combo units are clear: reduced footprint means more operational space, lower initial costs protect your budget, simplified installation gets you running faster, and improved energy efficiency keeps monthly bills reasonable. Modern units with R-32 insulation, EC motors, and LED lighting deliver excellent performance while exceeding current energy codes.

Ready to move forward? Start by calculating your specific storage needs for both temperature zones, including seasonal peaks and growth plans. Evaluate your facility's capabilities - electrical system capacity and floor strength. Obtain quotes from reputable manufacturers with strong service networks in your area.

Plan for proper installation and staff training because even the best equipment needs knowledgeable operators. Establish maintenance protocols from day one to protect your investment and ensure reliable service.

Whether replacing aging equipment or planning a new facility, the right combo unit becomes the reliable backbone of your cold storage operations. Take time to consider everything we've covered, and remember that experienced suppliers can guide you through complex decisions.

For comprehensive specifications and additional resources, check out our The Complete Guide to Walk-In Cooler Features and Prices. You'll find detailed information to help make the best decision for your specific situation.