Why Freezer Panels Are Critical for Temperature Control

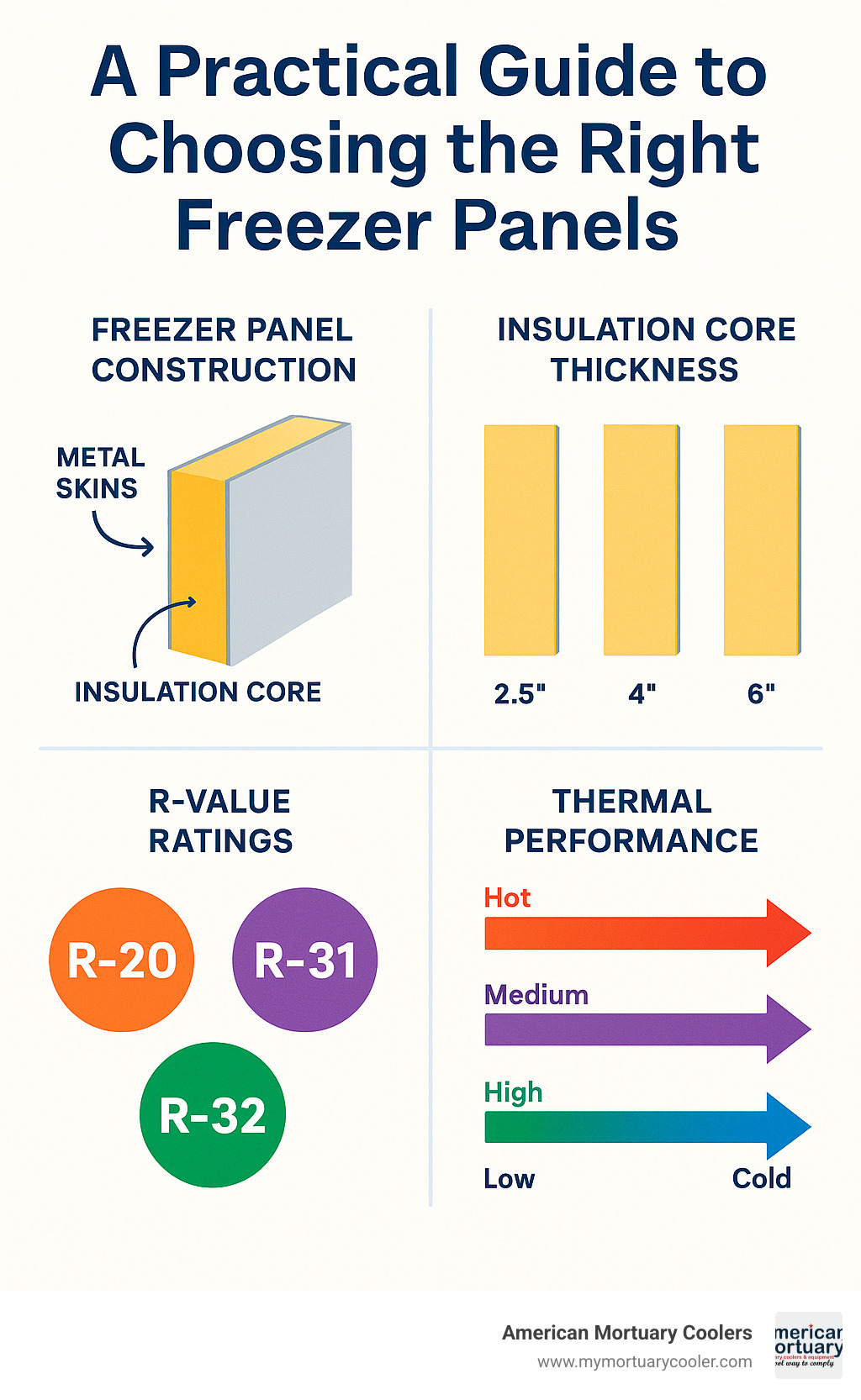

Freezer panels are insulated building components that form the walls, ceiling, and sometimes floors of walk-in freezers and cold storage rooms. These panels consist of a foam insulation core sandwiched between metal skins, designed to maintain consistent sub-zero temperatures while minimizing energy consumption.

Key freezer panel components:

- Metal skins - Stainless steel, galvanized steel, or aluminum exterior

- Insulation core - Polyurethane foam, EPS, or polyisocyanurate

- Joint systems - Tongue-and-groove or cam-lock connections

- Thickness options - 2.5" to 5+ inches for different applications

- R-values - Thermal resistance ratings from R-20 to R-32+

Standard walk-in freezer panels are typically 4 inches thick and provide an R-value of 31, meeting EISA energy efficiency requirements. The modular design allows for rapid assembly using tongue-and-groove construction with cam-locks, creating an airtight seal that prevents air infiltration.

Common applications include:

- Restaurant walk-in freezers

- Food processing facilities

- Pharmaceutical cold storage

- Mortuary body storage

- Floral preservation rooms

- Agricultural produce storage

Energy-efficient freezer panels can help businesses save up to 30% on refrigeration-related electricity costs compared to poorly insulated alternatives.

As Mortuary Cooler with years of experience as a national mortuary cooler supplier, I've seen how the right freezer panels can make the difference between reliable temperature control and costly equipment failures.

Simple guide to freezer panels terms:

Understanding Freezer Panels: Anatomy, Materials & Thermal Science

Freezer panels are sophisticated engineered structures that stand between your valuable inventory and temperature swings. Each panel is a carefully crafted sandwich with two metal skins and a high-performance insulation core that blocks heat transfer while providing structural strength.

The modular construction approach allows a typical 42" x 8' panel to be installed by just two people in under 10 minutes. The cam-lock system with tongue-and-groove edges creates minimal thermal bridging.

What Are Freezer Panels?

Freezer panels are specialized modular building components designed for sub-zero storage. The modular construction offers flexibility with panels manufactured up to 9500mm long. The cam-lock system uses gasketed fasteners creating airtight seals, while the tongue-and-groove design minimizes heat loss by reducing thermal bridging.

Insulation & R-Value Explained

R-value measures how well a material resists heat transfer. Higher R-value means better insulation and lower energy costs.

Most freezer panels range from 2.5" to 5" thick, with 4" being optimal for most applications. A standard 4" polyurethane panel delivers an R-value of 31, meeting the EISA R-32 mandate.

Polyurethane foam delivers R-7.0-8.0 per inch and bonds exceptionally well to metal skins. EPS (Expanded Polystyrene) offers R-4.0 per inch with good moisture resistance. Polyisocyanurate (PIR) provides R-6.0-7.0 per inch with good fire resistance.

For detailed panel selection guidance, see our Walk-In Cooler Panels guide.

Types of Freezer Panels by Joint & Finish

Tongue-and-groove joints feature interlocking edges that create excellent thermal seals while being self-aligning. Barrier strip connectors use external strips for easier panel replacement.

Stainless steel offers superior corrosion resistance and NSF approval. Galvanized steel provides good corrosion resistance at lower cost. Embossed finishes hide imperfections and resist traffic damage. FRP (Fiber Reinforced Plastic) brings excellent chemical resistance for easy cleaning.

Choosing the Right Freezer Panels for Your Application

Picking the perfect freezer panels requires matching your specific needs. A restaurant in Florida has different requirements than a mortuary in Minnesota.

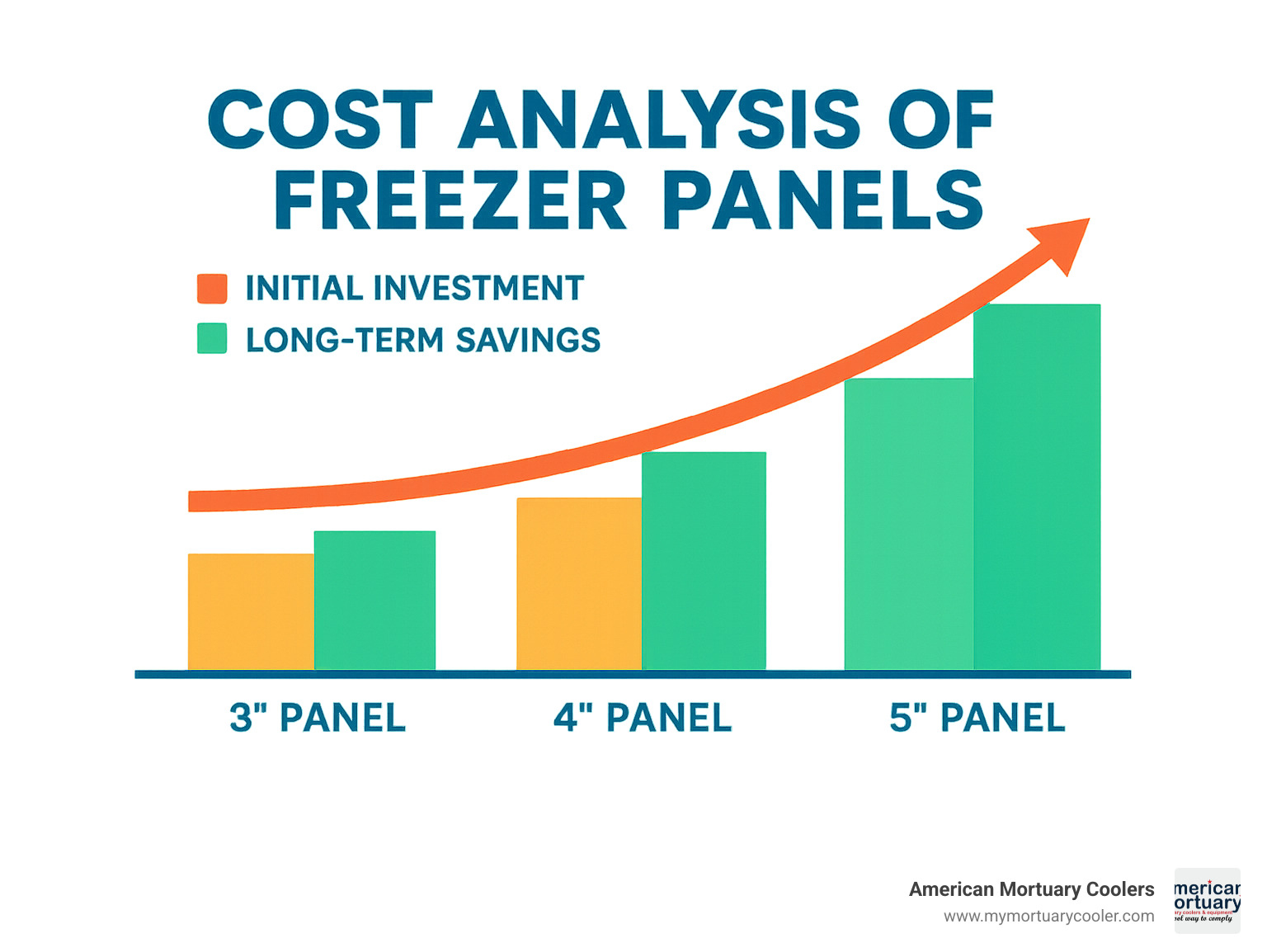

Key factors include operating temperature range, indoor versus outdoor installation, local climate conditions, and budget constraints. Energy savings from premium panels typically pay for themselves within two to three years.

For detailed purchasing guidance, check our Definitive Guide to Buying Freezer Panels for Sale.

Freezer Panels Thickness & Performance

Standard 4-inch panels with R-value around 31 meet EISA requirements and handle most commercial freezer applications between 0°F and -10°F, offering the best cost-to-performance ratio.

Panels 5 inches and thicker achieve R-values of 35+ and become essential for sub-zero applications below -10°F and outdoor installations in harsh climates. Upgrading from 3-inch to 4-inch panels typically reduces energy consumption by 15-20%. Moving to 5-inch panels can deliver energy savings up to 30%.

Industry-Specific Needs & Typical Uses

Food service needs NSF/ANSI 7 certification and easy-clean surfaces. Pharmaceutical storage demands precise temperature control with stainless steel finishes. Agriculture operations prioritize cost-effectiveness with galvanized steel. Mortuary applications require sub-zero temperatures, sanitation standards, and 5-inch-plus thickness. Cold storage warehouses need structural loading capability and long-term durability.

Selecting Doors, Floors & Accessories

Hinged doors are most reliable, while sliding doors save space. Glass doors work for display applications. Aluminum flooring provides slip-resistance, while stainless steel flooring offers premium cleanability. Essential accessories include ramps, gaskets, shelving systems, and door frame heaters.

Installation, Accessories & Compliance Essentials

Proper freezer panels installation is critical - every gap becomes a pathway for heat infiltration, leading to energy waste and equipment failures.

Pre-Install Checklist for Freezer Panels

Site preparation requires a level concrete slab and proper vapor barrier. Complete electrical rough-in and HVAC planning before panels arrive. Layout planning using panel drawings prevents corner and access problems.

Step-by-Step Panel Assembly with Camlocks

Start with corners - get them plumb and square as everything builds from there. Panel alignment must be perfect with each new panel. Cam-lock engagement requires proper torque specifications - over-tightening damages panels while under-tightening prevents sealing. Sealant application needs continuous lines at all joints.

For detailed construction guidance, see this Step-by-Step Guide to Constructing a Walk-in Freezer.

Regulatory & Safety Considerations for Freezer Panels

Fire safety requirements include CAN/ULC-S138 approval and ASTM E84 flame spread ratings. Food safety certifications like NSF/ANSI 7 are mandatory for food contact surfaces. USDA approval is essential for meat processing, while FDA compliance is needed for pharmaceutical applications.

Building codes require structural loading calculations and proper anchoring. Seismic anchoring is mandatory in earthquake zones. Worker safety requires proper PPE and confined space protocols.

For fire-rated panel specifications, see Scientific research on fire-rated panels.

Maximizing Performance: Maintenance, Innovations & Cost Savings

Proper maintenance makes freezer panels last 20+ years, while neglect causes expensive failures within 5 years.

Routine Care to Extend Freezer Panels' Life

Daily checks include door seals, temperature monitoring, and ice buildup inspection. Weekly cleaning covers interior surfaces and gasket lubrication. Monthly inspections measure gasket compression and check cam-lock hardware. Quarterly maintenance involves professional cleaning and thermal imaging. Annual overhauls include complete system inspection and gasket replacement.

For gasket maintenance procedures, see our Practical Guide to Finding Replacement Gaskets for Walk-In Coolers.

Latest Trends in Freezer Panels Technology

Vacuum insulated panels achieve R-values exceeding 50 per inch for space-constrained applications. Phase-change material liners add thermal mass, reducing compressor cycling and delivering 10-15% energy savings. Antimicrobial coatings using silver-ion treatments reduce cleaning requirements. Smart panel integration brings IoT monitoring with embedded sensors and predictive maintenance alerts.

Cost Breakdown & ROI of Freezer Panels

Initial investment includes panels at $15-40 per square foot, installation labor at $5-15 per square foot, and accessories adding 10-20%. Operating expenses center on energy consumption, often exceeding initial panel cost within 3-5 years.

Energy payback shows quality 4-inch versus 3-inch panels pay for themselves in 2-4 years. Upgrading to 5-inch panels takes 4-7 years but delivers substantial savings in extreme applications. Incentives include utility rebates, tax credits, and USDA grants.

For comprehensive cost analysis, see All About the Cost of Walk-In Freezers.

Frequently Asked Questions about Freezer Panels

How do freezer panels maintain sub-zero temperatures without icing up?

The secret lies in moisture control through proper vapor barrier design. The closed-cell polyurethane foam core doesn't absorb moisture, while metal skins create continuous vapor barriers preventing humid air from reaching cold surfaces.

Ice problems typically stem from air leakage from worn gaskets, thermal bridging from poor installation, or excessive moisture load from frequent door openings. Regular gasket maintenance prevents 90% of icing problems.

What certifications should my freezer panels carry?

For food service, you need NSF/ANSI 7 certification and UL 471 listing. ASTM E84 flame spread ratings are increasingly required by fire codes. Mortuary applications often need USDA approval and FDA compliance for pharmaceutical storage. CAN/ULC-S138 certification may be required for fire-rated applications.

Always verify local requirements before ordering - codes vary dramatically between jurisdictions.

How often should gasket seals be replaced on freezer panels?

High-traffic installations need replacement every 12-18 months. Moderate-traffic applications typically get 2-3 years from gaskets. Low-traffic applications can go 3-5 years.

Inspection matters more than schedule - look for cracking, hard material, gaps, ice formation, or increased energy consumption. A failing gasket costs hundreds monthly in wasted energy versus $200 for replacement.

Conclusion & Next Steps

Choosing the right freezer panels is about investing in your operation's reliability and efficiency. Focus on matching panel thickness to temperature requirements - 4-inch standard works for most commercial freezers, while sub-zero applications need extra insulation. Energy savings often justify the investment within just a few years.

At American Mortuary Coolers, we understand every application is unique. Our Tennessee-based team delivers custom installations nationwide, taking time to understand your specific needs before recommending solutions.

Key factors to remember: proper insulation thickness, quality installation eliminating thermal bridges, and maintenance plans keeping gaskets in good condition. Quality panels properly installed provide years of reliable service.

Ready to explore your options? Our team brings decades of cold storage experience, delivering across all 48 contiguous states. Every project starts with understanding your requirements, operating conditions, and budget.

For additional insights, check our comprehensive resources at More info about our practical guides.