The Heart of Your Refrigeration System: How Compressors Work

How do compressors work in a refrigerator is a fundamental question when understanding refrigeration technology. Here's a quick answer:

| Compressor Function | Description |

|---|---|

| Primary Role | Acts as the "heart" of the refrigeration system, pumping refrigerant through the cooling cycle |

| Basic Operation | Compresses low-pressure refrigerant gas into high-pressure, high-temperature gas |

| Working Principle | Uses mechanical energy to reduce gas volume, increasing pressure and temperature per Boyle's Law |

| Cycle Position | First stage of the refrigeration cycle, followed by condensation, expansion, and evaporation |

| Energy Impact | Consumes up to 80% of a refrigerator's total energy usage |

The refrigerator compressor is the workhorse of any cooling system, whether in your kitchen fridge or a mortuary cooler. It creates the pressure difference that drives the entire refrigeration cycle, allowing heat to be removed from inside the refrigerated space and expelled to the outside environment.

When you understand how do compressors work in a refrigerator, you can better diagnose issues, maintain efficiency, and make informed decisions about refrigeration equipment.

Why Your Fridge Needs a Compressor

Think of your refrigerator compressor as the heart of the system. Just as your heart pumps blood throughout your body, the compressor pumps refrigerant throughout the cooling system. Without this vital component, your refrigerator would be nothing more than an insulated box.

The compressor serves as both a motor and a pump, creating the necessary pressure differential that enables the refrigerant to flow through the system and undergo the phase changes essential for cooling. This pressure difference allows heat to be transferred from inside your refrigerator to the outside environment.

Temperature control in your refrigerator relies entirely on the compressor's ability to maintain this cycle. When the thermostat detects that the internal temperature has risen above the set point, it signals the compressor to start running, initiating the cooling process.

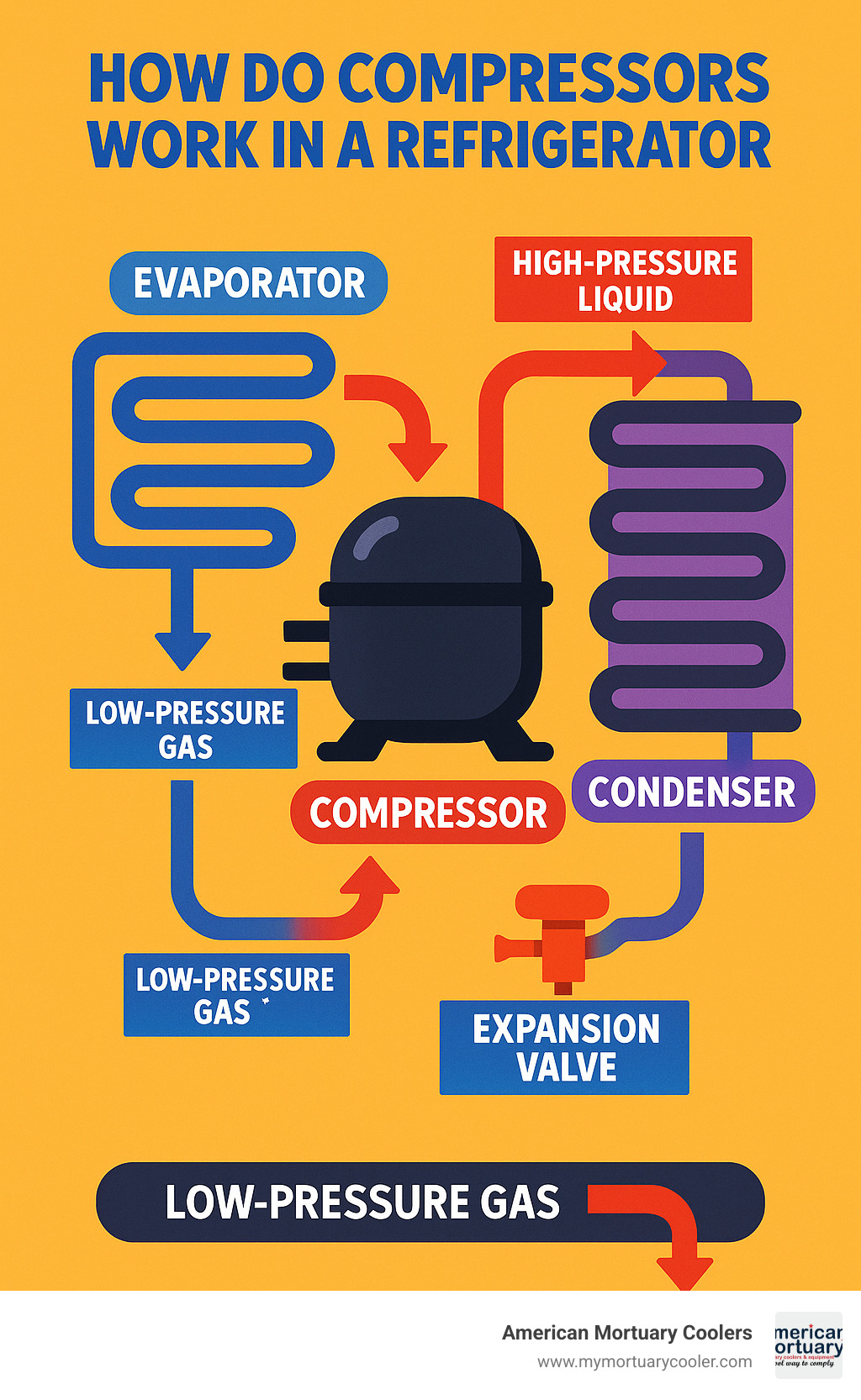

The Four-Stage Cycle in 30 Seconds

The refrigeration cycle consists of four distinct stages, with the compressor playing the starring role in the first:

Compression: The compressor draws in low-pressure refrigerant gas and compresses it, raising both its pressure and temperature.

Condensation: The hot, high-pressure gas flows to the condenser (those coils typically at the back of your fridge), where it releases heat to the surrounding air and condenses into a high-pressure liquid.

Expansion: The high-pressure liquid passes through an expansion valve or capillary tube, which causes a sudden drop in pressure and temperature.

Evaporation: The cold, low-pressure liquid enters the evaporator coils inside your refrigerator, absorbs heat from the interior, and evaporates back into a gas.

This continuous cycle repeats as long as cooling is needed, with the compressor driving the entire process.

How Do Compressors Work in a Refrigerator?

Ever wondered what's really happening inside that humming box in your kitchen? Let's explain how do compressors work in a refrigerator by exploring the fascinating physics that keeps your food fresh.

At heart, a refrigerator compressor is all about pressure manipulation. It takes the low-pressure refrigerant vapor that's absorbed heat from inside your fridge and transforms it into high-pressure, high-temperature gas. This pressure difference is the magic that makes refrigeration possible.

Remember blowing up balloons as a kid? The physics behind your refrigerator compressor follows the same principle – Boyle's Law. This law tells us that when you squeeze a gas into a smaller space, its pressure goes up. Your compressor does exactly this, mechanically squeezing refrigerant gas to dramatically increase both its pressure and temperature.

When your refrigerator's internal temperature rises above your set point, the thermostat sends an electrical signal to the compressor. This starts the suction and discharge cycle – like a mechanical heartbeat pumping refrigerant through your cooling system.

During this process, the refrigerant becomes "superheated" – heated well above its boiling point while remaining in gas form. This superheating is essential for efficient refrigeration cycles.

Step-by-Step: How Do Compressors Work in a Refrigerator

Let me walk you through what's happening inside your fridge compressor:

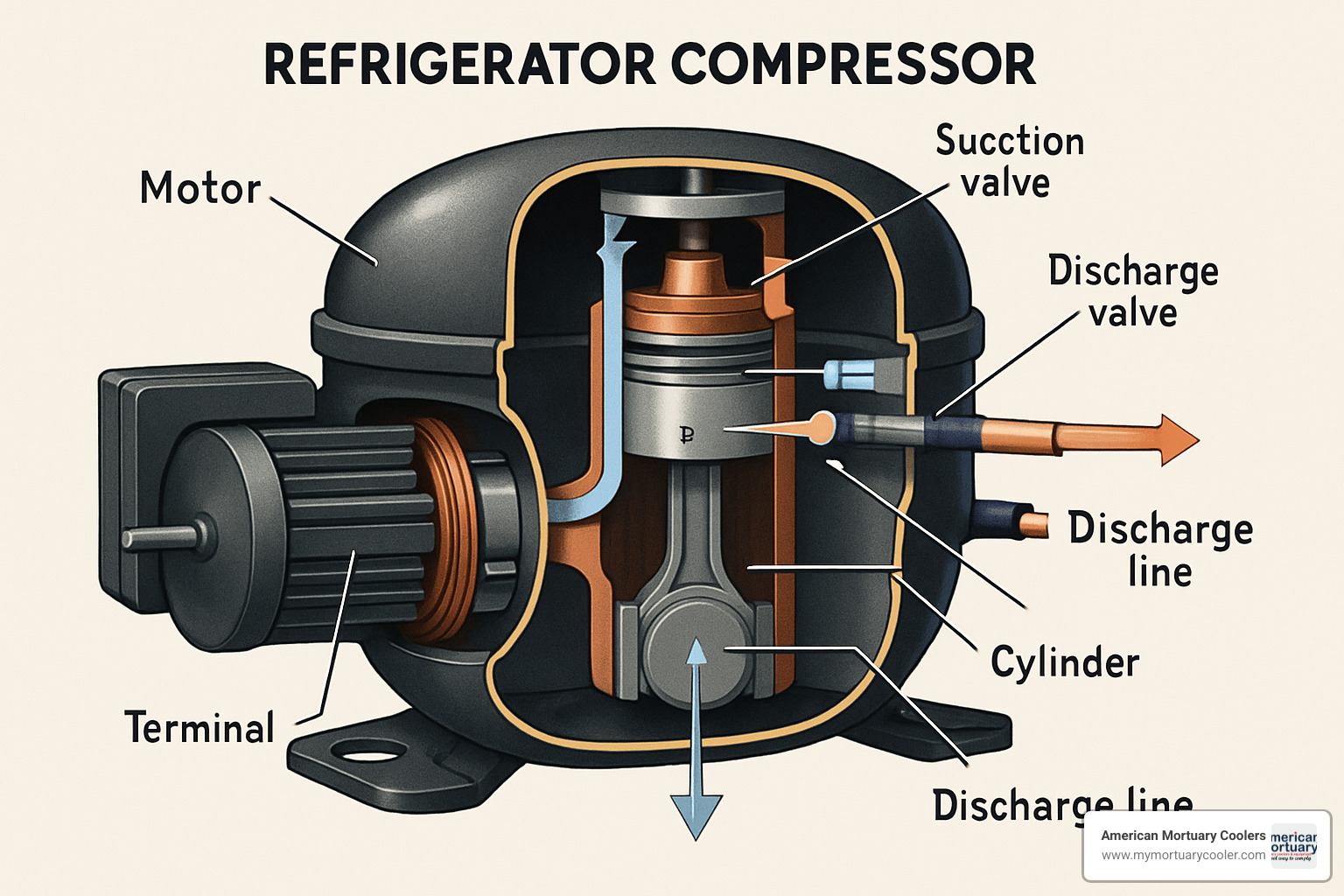

First comes the low-pressure intake. The compressor's suction valve opens, drawing in cool, low-pressure refrigerant vapor from inside your refrigerator's evaporator coils.

Next is the mechanical squeeze – the heart of compression. Depending on your fridge model, this might happen via a piston pumping in a cylinder or through rotating mechanisms that trap and compress the gas.

This compression creates the high-pressure output. As the gas gets squeezed, both pressure and temperature spike dramatically. The discharge valve opens, and this hot, high-pressure gas rushes toward the condenser coils.

This process forms a continuous loop that repeats as long as cooling is needed. Your typical home refrigerator compressor will cycle on and off roughly 3-8 times every hour, depending on usage patterns.

Thermodynamics 101: How Do Compressors Work in a Refrigerator

To truly grasp how do compressors work in a refrigerator, we need to touch on some basic physics principles:

The Ideal Gas Law (PV = nRT) describes the relationship between pressure, volume, and temperature. When your compressor squeezes the refrigerant into a smaller space, both pressure and temperature naturally increase.

Latent heat is the energy absorbed or released during phase changes. Think about how sweating cools you down – as moisture evaporates from your skin, it takes heat with it. Your refrigerator uses this same principle in a controlled cycle.

Energy conservation is the foundation of refrigeration. Your compressor adds energy to the system, which allows heat to move from a cold area (inside your fridge) to a warm area (your kitchen).

For more detailed information about the science behind refrigeration cycles, check out MIT's comprehensive explanation of compression refrigeration systems.

Core Components & Physical Principles

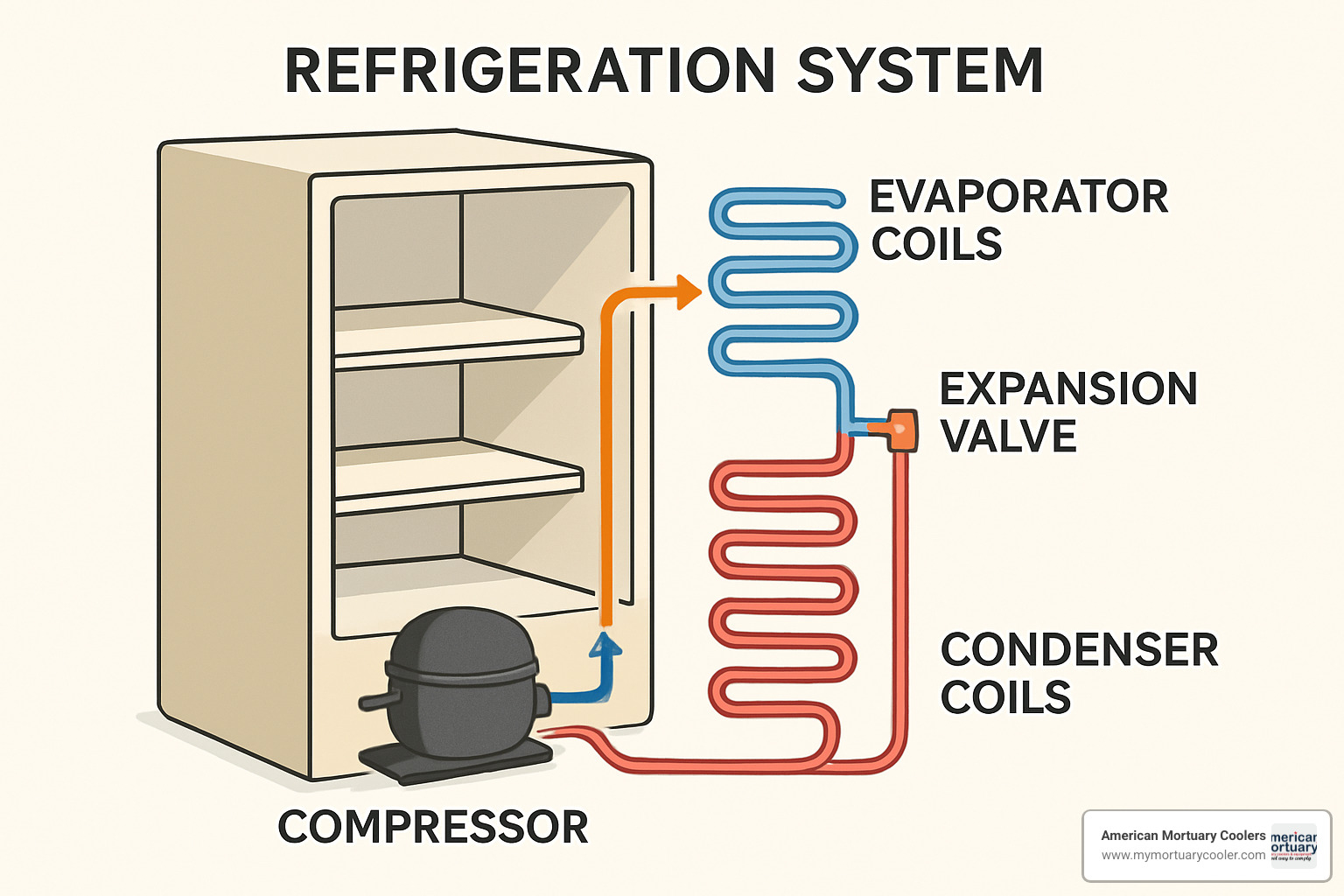

Understanding how do compressors work in a refrigerator means getting familiar with the four main components that make up the refrigeration system.

Your refrigerator's cooling system is like a relay race with four runners. First is the compressor – the heart of the system that pumps refrigerant and creates the pressure differences that drive everything else. Next comes the condenser – those coils usually at the back or bottom of your fridge where hot gas releases heat and turns into liquid. Third is the expansion valve or capillary tube – a narrow passage that creates a sudden pressure drop. Finally, the evaporator coils inside your fridge absorb heat from your food.

Supporting these main components are temperature sensors, thermostats, and fans that help keep everything running smoothly. Together, they don't actually "create cold" – they move heat from inside your fridge to your kitchen.

Stage 1 – Compression

The journey begins with compression. Inside your refrigerator's compressor, you'll find an electric motor providing the muscle, all sealed inside a hermetic shell that prevents refrigerant leaks, with oil lubrication keeping everything running smoothly.

Most home refrigerators use reciprocating compressors with pistons that move back and forth. This workhorse transforms the refrigerant from a low-pressure gas (about 1-2 bar) into a high-pressure gas (8-12 bar). This pressure boost allows the refrigerant to later condense at room temperature.

Stage 2 – Condensation

After leaving the compressor, our hot, high-pressure refrigerant gas (typically 80-110°C/176-230°F) flows into the condenser coils where it cools down and transforms from gas to liquid.

Think about how water droplets form on a cold glass on a hot day. The condenser works in reverse – the refrigerant is hot, and your kitchen air is cool. As room temperature air passes over these coils (often helped by a small fan), heat transfers from the hot gas to the cooler air.

The condenser coils have fins that increase surface area and help transfer heat more efficiently. As the refrigerant releases heat, it condenses into a liquid while maintaining high pressure.

Stage 3 – Expansion

Now comes the magic moment. Our high-pressure liquid refrigerant creates the cooling effect through expansion. This happens when the refrigerant passes through either a capillary tube (in most home refrigerators) or an expansion valve (in larger systems).

Have you ever noticed how an aerosol can gets cold when you spray it? That's the same principle at work here. As the refrigerant squeezes through this narrow passage, it experiences a sudden pressure drop, which creates a corresponding temperature drop.

Stage 4 – Evaporation

The final stage happens in the evaporator, where the actual cooling takes place. The cold, low-pressure liquid refrigerant enters the evaporator coils inside your refrigerator and absorbs heat from your food.

This absorbed heat causes the refrigerant to boil and evaporate into a gas – even though it's cold. A fan circulates air over these cold evaporator coils, which is why you feel that cool breeze when you open the refrigerator door.

As the refrigerant changes from liquid to gas, it absorbs a significant amount of heat, effectively removing warmth from inside your refrigerator. After completing its job, the refrigerant returns to the compressor as a low-pressure gas, ready to begin the journey again.

For more detailed information about fridge compressor function, check out our complete guide to fridge compressor function and operation.

Compressor Types, Mounting Styles & Efficiency

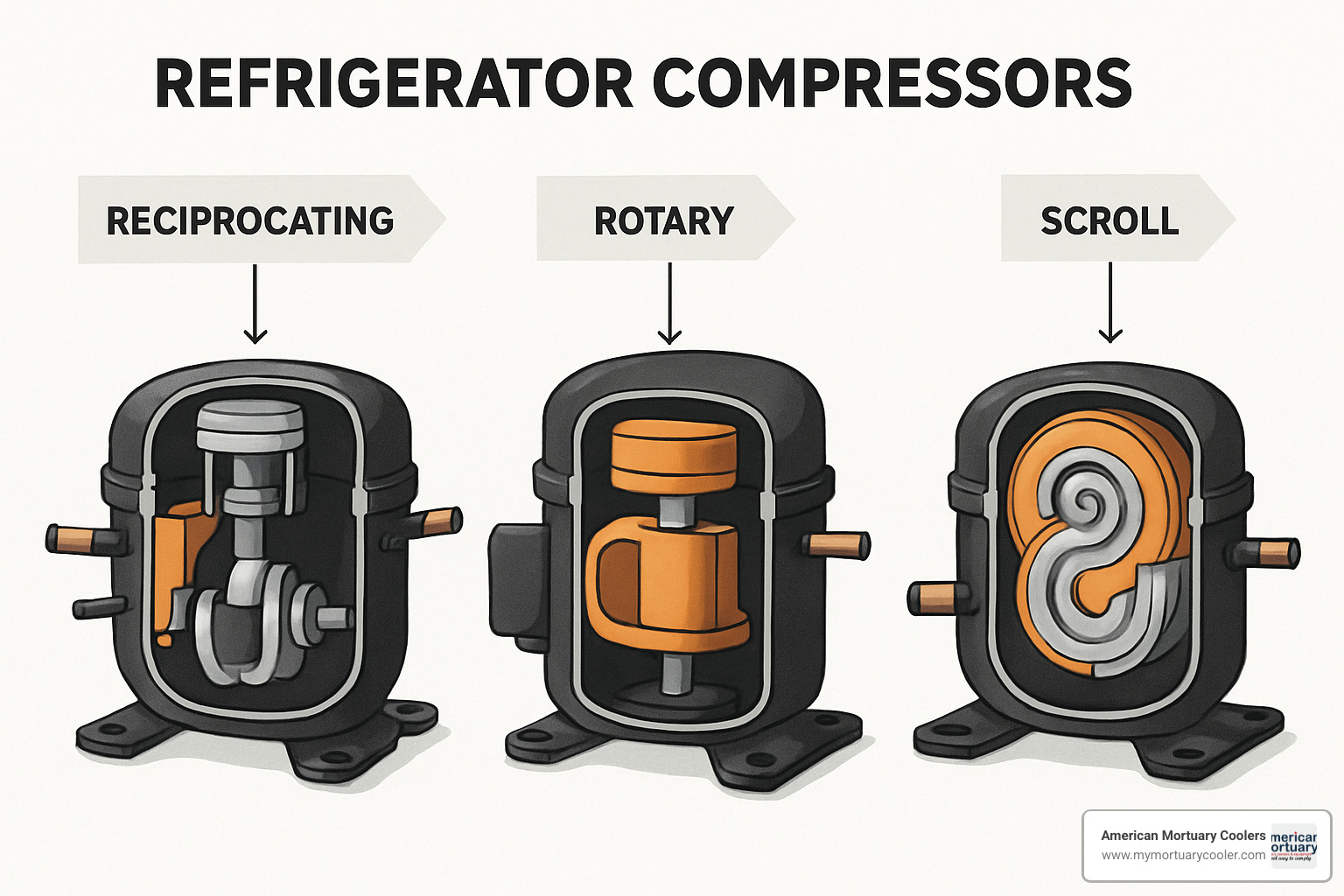

When exploring how do compressors work in a refrigerator, you'll quickly find that not all compressors are created equal. Think of compressors like car engines – they come in different designs, each with unique advantages.

Your typical household refrigerator likely uses a reciprocating compressor, which works like a car piston, moving up and down to compress refrigerant. These workhorses are common because they're reliable and cost-effective, though they can be a bit noisy.

For something quieter, many modern refrigerators feature rotary compressors, which use a spinning motion to compress refrigerant. If you've noticed a newer fridge that hums along more quietly than your old one, it might have a rotary compressor inside.

In commercial settings, you might find scroll compressors with their interlocking spiral design. Their larger cousins – screw compressors with rotating helical screws and centrifugal compressors with high-speed impellers – typically show up in industrial-scale cooling systems.

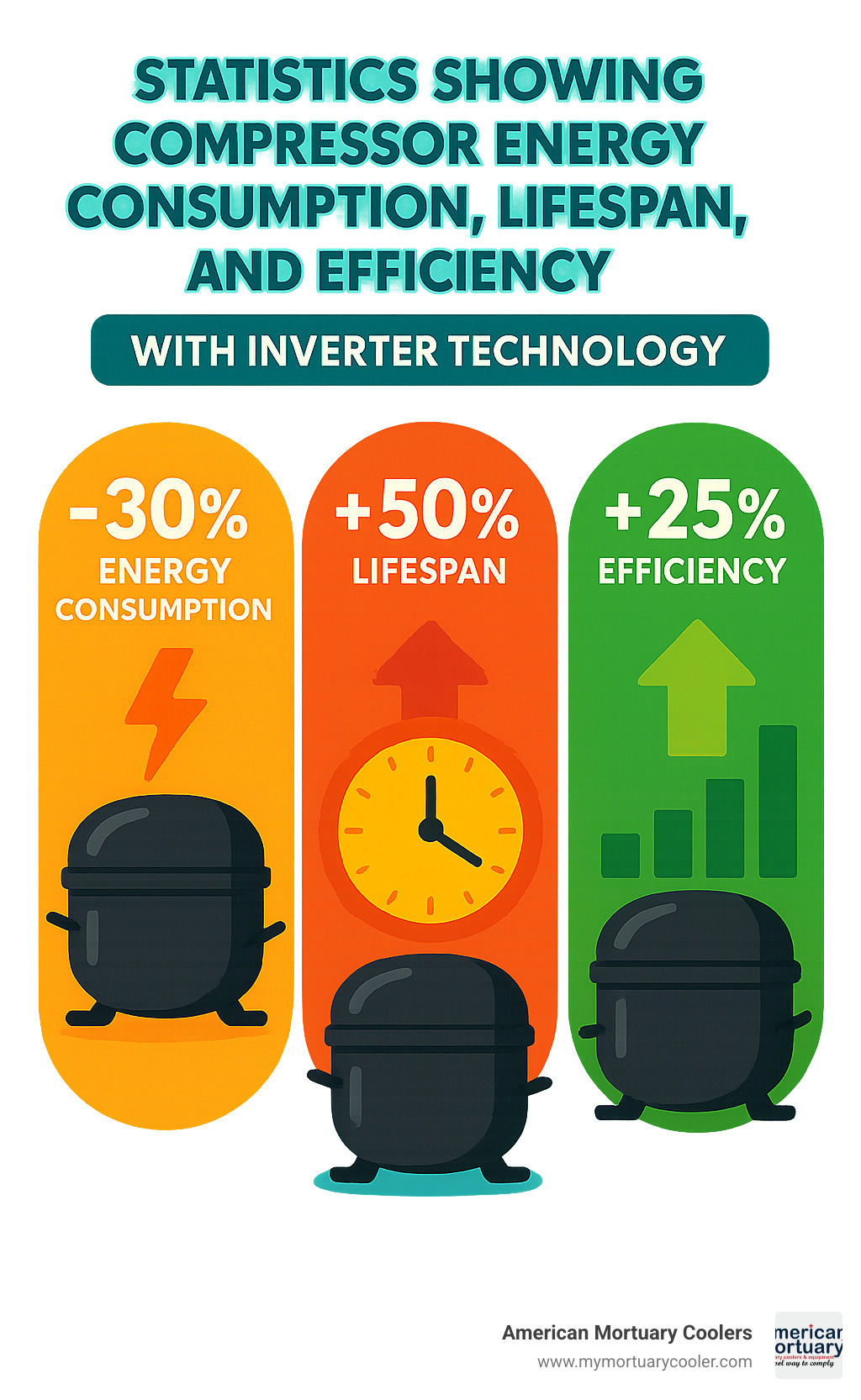

The latest technology making waves is inverter technology, which allows compressors to run at variable speeds instead of just on or off. It's like having a car with cruise control that can smoothly adjust to hills rather than constantly stepping on and off the gas pedal.

Where your compressor sits matters too. Here's a straightforward comparison:

| Feature | Top-Mounted Compressor | Bottom-Mounted Compressor |

|---|---|---|

| Energy Efficiency | Better in cool environments | Better in hot environments |

| Service Access | More difficult to access | Easier to access and service |

| Cleanliness | Stays cleaner, fewer service calls | Gets dirtier more quickly |

| Space Utilization | Doesn't take up storage space | Takes up some back storage space |

| Best Environment | Dry storage areas | Hot kitchens, line cook applications |

Reciprocating vs Rotary

Reciprocating compressors are like reliable old pickup trucks of the cooling world. They use a piston moving back and forth in a cylinder to compress refrigerant. While they're often more affordable upfront, they do have more moving parts, which can mean more noise and potentially more maintenance over time.

Rotary compressors are the smooth operators of the refrigeration world. Using rotating mechanisms instead of back-and-forth motion, they typically run quieter. They also tend to be more energy-efficient and often last longer since they have fewer moving parts to wear out.

Fixed-Speed vs Inverter

Think of a fixed-speed compressor as an old light switch – it's either fully on or fully off. When your refrigerator needs cooling, the compressor kicks on at full power, runs until the temperature drops enough, then shuts off completely until needed again.

Inverter compressors work more like a dimmer switch. They can run at various speeds depending on how much cooling is needed. When just a little cooling is required, they run slowly and quietly. When more cooling power is needed, they ramp up accordingly.

This smarter approach leads to more stable temperatures and can reduce energy consumption by up to 30% compared to traditional fixed-speed compressors.

Placement Matters

Top-mounted compressors tend to shine in cooler, drier environments. Because they're positioned up high, they stay cleaner and typically require fewer service calls over their lifetime. This placement also keeps them from taking up valuable storage space inside the unit.

Bottom-mounted compressors have their own advantages, particularly in hot kitchen environments where heat rises. They're much easier to access for maintenance and cleaning. However, being closer to the floor means they're more likely to collect dust and dirt, which can affect performance over time.

Maintenance, Troubleshooting & Energy Tips

Now that you understand how do compressors work in a refrigerator, let's talk about keeping your cooling system running smoothly.

One of the most important maintenance tasks is cleaning those condenser coils at least twice a year. When dust and debris build up on these coils, they can't release heat efficiently, forcing your compressor to work overtime.

Your refrigerator also needs room to breathe! Ensure adequate airflow around your unit, especially near the condenser. That beautiful built-in look might be tempting, but cramming your fridge into a tight space with no ventilation is asking for trouble.

Those rubber door seals (or gaskets) might not seem connected to your compressor, but they absolutely are. When seals fail, warm air sneaks in, and your compressor has to run longer to maintain temperature. Here's a quick test: close the door on a dollar bill and try to pull it out. If it slides out easily, your seal might need replacing.

Pay attention to how often your compressor turns on and off. A healthy compressor typically cycles 3-8 times per hour. If yours runs constantly or clicks on every few minutes, something's not right.

DIY Health Check

You don't need to be a technician to perform a basic compressor health check. When your refrigerator kicks on, listen for clicks followed by a low hum. That initial click is the start relay activating, and the hum is your compressor running. If you hear repeated clicking without the hum, your start relay might be failing.

Next, while the compressor is running, feel the condenser warmth (usually at the back or underneath your fridge). It should feel warm – that's normal heat rejection. If it's cold, your compressor might not be running; if it's burning hot, there could be airflow or refrigerant issues.

For those comfortable with tools, an amp-draw test using a multimeter with an amp clamp can tell you if your compressor is drawing the right amount of current. Compare the reading to the specifications on the compressor label.

When to Call a Pro

While DIY maintenance is great, some symptoms signal it's time to bring in reinforcements. An overheating shell is a red flag – if the compressor feels too hot to touch comfortably, internal issues might be brewing. Similarly, if you notice an oil burn smell around your compressor area, something serious is happening inside.

Start relay failures (that clicking-without-starting scenario) typically require professional attention, as do unusual noises like grinding, knocking, or buzzing from the compressor.

If you suspect a refrigerant leak – perhaps your fridge isn't cooling properly, or you notice oily residue around connections – call a pro immediately. Refrigerant requires special handling and equipment, and it's actually illegal for non-certified individuals to handle it in many places.

With proper care, a good refrigerator compressor can serve faithfully for 10-20 years. Our technicians have seen well-maintained units last even longer, especially when owners follow our 5 Easy Changes to Fix an Iced Evaporator and other preventive maintenance tips.

Frequently Asked Questions about Refrigerator Compressors

Why is the compressor called the "heart" of the system?

You know how your heart keeps you alive by pumping blood throughout your body? That's exactly what a compressor does for your refrigerator! It pumps refrigerant through the entire cooling system, creating the pressure and energy that makes everything work. Without this vital component, your fridge would just be an insulated box with no cooling ability.

When you load up your fridge with warm leftovers or keep opening the door while deciding what snack to grab, your compressor kicks into high gear to restore the cool temperature – just like your heart beats faster during exercise to meet increased demands.

How long should a household compressor last?

Most household refrigerator compressors should give you about 10 to 20 years of reliable service with proper care. Several factors affect this lifespan:

Quality matters - Higher-quality compressors typically outlast budget models.

Usage patterns affect lifespan dramatically. If your refrigerator door is constantly opening and closing, or if it's in a warm garage, your compressor works overtime.

Regular maintenance makes a huge difference. Simply cleaning those condenser coils twice a year and ensuring good airflow around your fridge can add years to your compressor's life.

Power issues like voltage fluctuations and surges can silently damage your compressor over time.

Environment matters too. Compressors in hot kitchens work much harder than those in cooler spaces.

Can I replace a fixed-speed unit with an inverter model?

Yes, you can upgrade from a fixed-speed compressor to a modern inverter model in many cases – but there's more to consider than just swapping parts.

Compatibility is crucial. Your new inverter compressor needs to work with your existing refrigerant type, match the cooling capacity requirements, and connect properly to your electrical system.

The control systems are different too. Inverter compressors need more sophisticated controls than their fixed-speed cousins. This often means replacing control boards and other electronic components.

Then there's the cost-benefit question. While inverter technology can slash your energy consumption by up to 30%, you'll need to weigh the upfront investment against those long-term savings.

This is definitely not a DIY weekend project for most people. Professional installation ensures proper system integration and safe handling of refrigerants.

Conclusion

Understanding how do compressors work in a refrigerator is like having a backstage pass to the magic show of cooling technology. We've journeyed from the basic compression of refrigerant gas to the neat thermodynamic dance that makes your refrigerator hum quietly in your kitchen.

Your refrigerator's compressor truly is the hardworking heart of the entire operation. It's not just a mechanical component – it's the driving force behind keeping your food fresh or, in our specialized world of mortuary coolers, providing the essential preservation that funeral homes depend on.

When you consider that the compressor accounts for up to 80% of your refrigerator's energy consumption, you can see why choosing the right type matters so much. Whether it's a reciprocating workhorse or an energy-sipping inverter model, the right compressor can significantly reduce your energy bills while improving reliability.

Here at American Mortuary Coolers, we take these refrigeration principles and apply them with precision to our specialized cooling systems. We're passionate about creating solutions that meet the unique needs of the funeral industry, where temperature stability isn't just about convenience – it's essential for dignified preservation.

Based in Tennessee, we're proud to provide durable, custom cooling solutions with direct delivery across the contiguous 48 states. Our regional centers in Atlanta, Chicago, Dallas, Los Angeles, New York and beyond ensure we can support funeral professionals wherever they serve their communities.

Whether you're trying to figure out why your kitchen fridge is making that strange noise or you're selecting a commercial cooling system for professional use, understanding the compressor's function empowers you to make better decisions.

For those seeking more information about mortuary coolers and specialized refrigeration systems, I invite you to explore our resources or reach out to our team. We're always happy to help you select the right cooling solution for your specific needs.