Why Understanding Refrigeration Basics Matters for Your Business

Refrigeration is the process of removing heat from a space or substance to lower its temperature below the surrounding environment. Whether you're preserving food, storing medical supplies, or maintaining mortuary facilities, understanding how refrigeration works can save you thousands in energy costs and prevent costly equipment failures.

Quick Refrigeration Overview:

- Core Process: Heat removal and relocation using refrigerant phase changes

- Key Components: Compressor, condenser, evaporator, expansion valve

- Temperature Goals: 3-5°C (37-41°F) for coolers, 0°F (-18°C) for freezers

- Energy Impact: Accounts for 5-17% of commercial building electricity use

- Maintenance: Clean coils every 6 months, check door seals quarterly

The refrigeration industry has come a long way since the 1800s ice harvesting days. By 1940, over 50% of American households owned refrigerators, changing how we store food and conduct business. Today's systems are more efficient than ever, with some using natural refrigerants like R290 propane that can reduce energy consumption by up to 40%.

But here's the thing most people don't realize: refrigeration doesn't create cold - it removes heat. This fundamental principle drives everything from your walk-in cooler to industrial freezing systems. Understanding this concept helps you make better decisions about equipment selection, maintenance, and troubleshooting.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in custom refrigeration solutions across the United States. With years of experience in commercial and mortuary refrigeration systems, I've seen how proper understanding of refrigeration fundamentals can dramatically improve equipment performance and longevity.

Simple refrigaration word guide:

Refrigaration Fundamentals: How Cooling Really Works

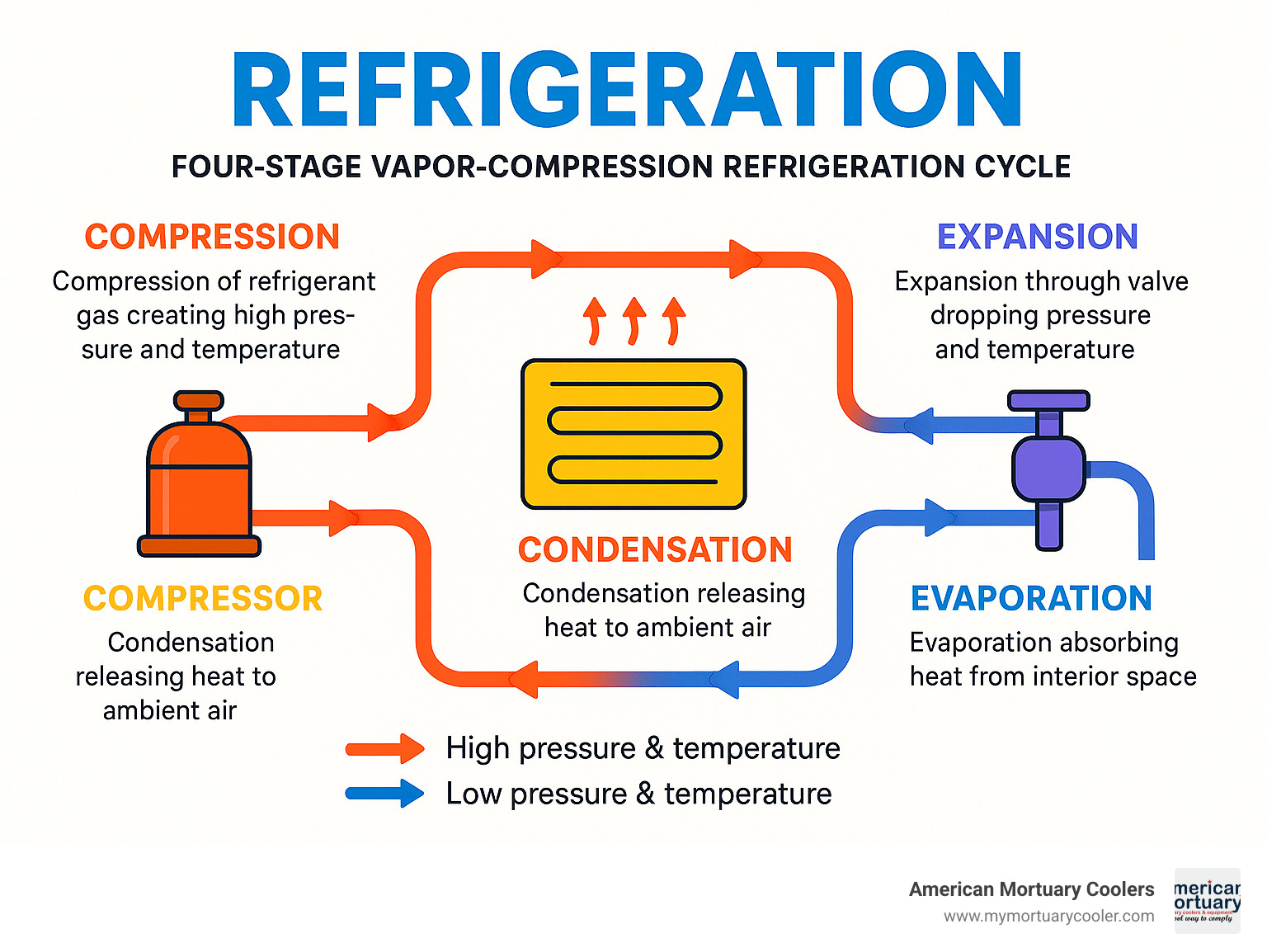

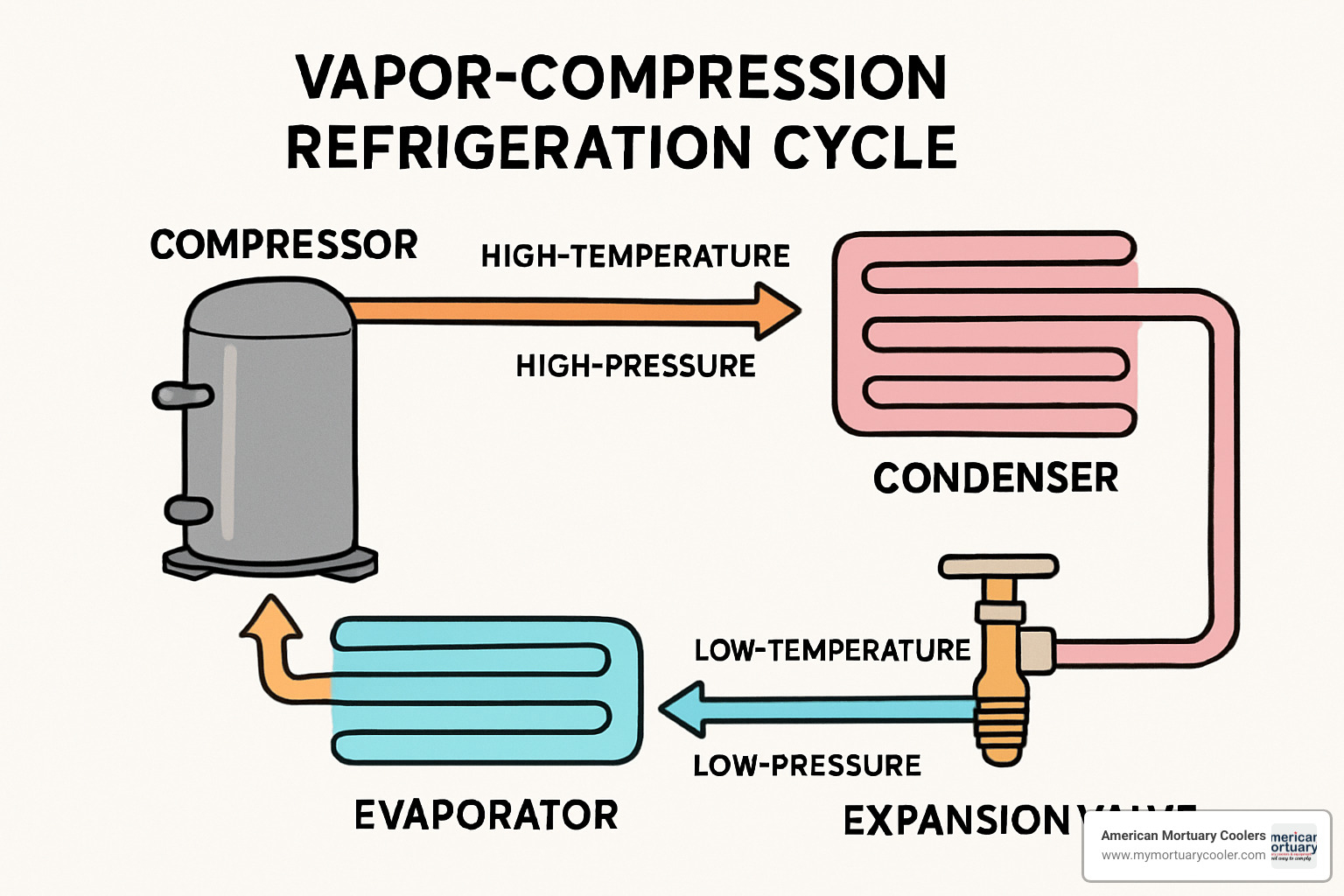

At its core, refrigeration operates on a simple principle: heat naturally flows from hot to cold. To make cooling happen where we want it, we manipulate this natural flow using the vapor-compression cycle, which uses a refrigerant that changes between liquid and gas states to absorb and release heat.

The process relies on latent heat - the energy required to change a substance's state without changing its temperature. Water requires 970 BTU per pound to change from liquid to vapor, making phase-change cooling incredibly effective.

According to ASHRAE terminology research, understanding these fundamental concepts is crucial for anyone working with refrigeration systems.

Key Components of a Refrigaration Cycle

Every vapor-compression refrigeration system has four essential components:

1. Compressor - The Heart of the System The compressor takes low-pressure refrigerant vapor and compresses it into high-pressure, high-temperature gas. Modern compressors include reciprocating (most common), scroll (quieter), screw (large commercial), and centrifugal (very large systems).

Learn more about compressor function to understand how different types affect performance.

2. Condenser - The Heat Ejector The condenser rejects heat from high-pressure refrigerant to the environment. As hot refrigerant gas flows through condenser coils, it releases heat and transforms back into liquid. Condensers can be air-cooled, water-cooled, or evaporative.

3. Evaporator - The Heat Absorber Inside your cooled space, the evaporator allows liquid refrigerant to expand and evaporate, absorbing heat from surrounding air. This is where actual cooling happens.

4. Expansion Device - The Pressure Dropper The expansion valve creates a pressure drop allowing high-pressure liquid refrigerant to expand rapidly, causing temperature to drop dramatically - sometimes 40-60°F instantly.

Refrigaration Capacity & Performance Metrics

Understanding refrigeration performance helps you select the right equipment:

BTU/hr and Tons of Refrigeration

- One ton of refrigeration = 12,000 BTU/hr

- Residential units: 1-5 tons

- Commercial systems: 50+ tons

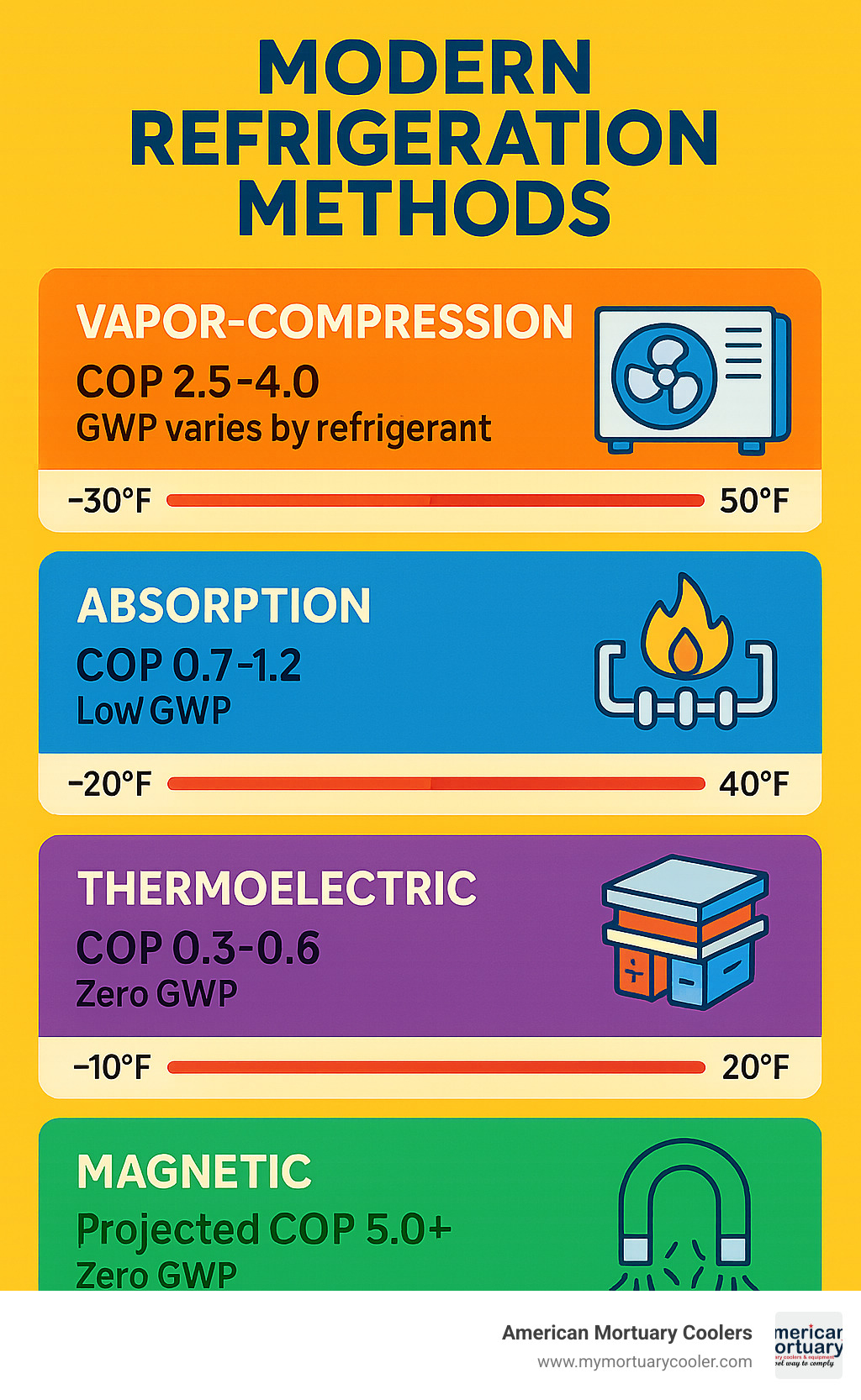

Coefficient of Performance (COP) COP measures cooling per unit of energy input:

- Air conditioning: 2.5-4.0

- Heat pumps: 3.0-5.0

- Commercial refrigeration: 1.5-3.0

| Metric | Good Range | Excellent Range |

|---|---|---|

| COP | 2.5-3.5 | 3.5+ |

| EER | 10-12 | 12+ |

| SEER | 14-16 | 16+ |

Superheat and Subcooling

- Superheat: Vapor temperature above saturation (typically 8-12°F)

- Subcooling: Liquid temperature below saturation (typically 8-15°F)

Proper superheat ensures complete evaporation without liquid returning to the compressor.

Historical Milestones & Societal Impact

Before mechanical cooling, people used root cellars, salt preservation, and elaborate ice storage systems. The wealthy could afford shipped ice, but most ate only fresh, local food.

From Ice Harvesting to Mechanical Refrigaration

Ancient civilizations mastered early cooling techniques. In 220 B.C., Chinese Emperor Shih Huang Ti used underground terracotta rings for ice storage. Ancient Persians built "yakhchāl" - dome-shaped ice houses that kept ice frozen in desert heat.

The 1800s ice trade became massive business. New York City's ice consumption jumped from 12,000 tons in 1843 to 100,000 tons by 1856. Workers cut massive ice blocks from frozen lakes, packed them in sawdust, and shipped them worldwide.

Scientific breakthroughs began with William Cullen's artificial ice demonstration in 1748. Benjamin Franklin and John Hadley cooled a thermometer to -14°C, with Franklin noting "the possibility of freezing a man to death on a warm summer's day."

Jacob Perkins patented the first complete vapor-compression refrigeration cycle in 1834 - the same principle we use today. Carl von Linde developed practical ammonia refrigeration in 1876, and Freon (R-12) made home refrigerators safe by the 1930s.

How Refrigaration Changed Food, Health, and Cities

Mechanical refrigeration transformed society completely. Research shows refrigeration contributed 5.1% to increased adult height through better nutrition. After the 1890s, dairy consumption increased 1.7% yearly, and protein intake rose 1.25% annually.

Cities grew in new ways as refrigerated rail cars enabled western settlement while maintaining fresh food access. The "cold chain" made seasonal eating nearly extinct in developed countries.

Farming transformed dramatically. In 1935, 6.8 million farms fed 127 million Americans. By 2007, less than 1% of 310 million people worked in farming. This consolidation happened because refrigeration enabled centralized production and long-distance distribution.

The dairy boom deserves special mention. Before refrigeration, you needed to live near cows for fresh milk. Refrigerated transport turned dairy from local luxury into national industry.

By 1940, over 50% of American households owned refrigerators, marking the shift from luxury to necessity and enabling modern supermarkets.

Modern Methods & Technologies

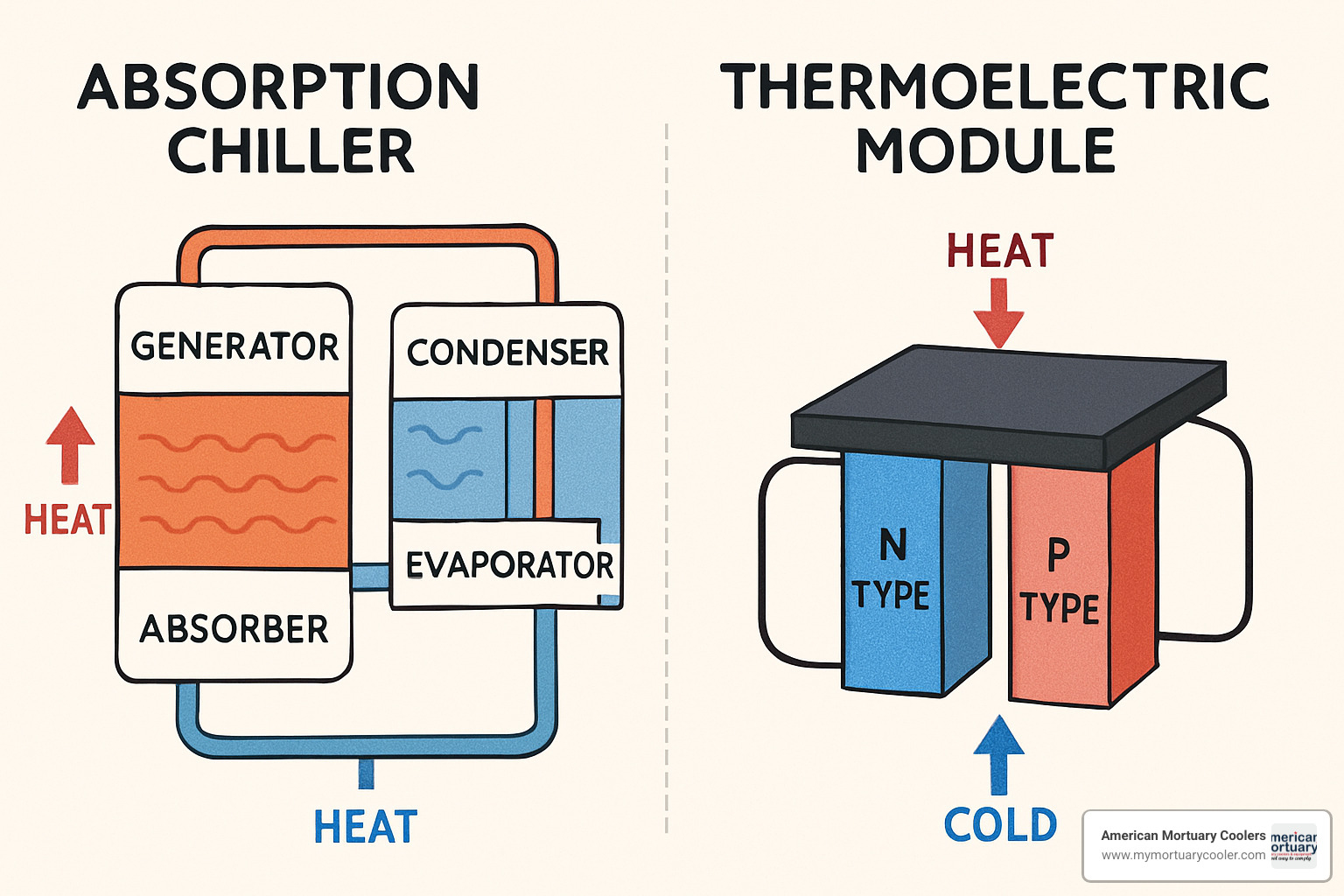

Refrigeration has expanded beyond traditional vapor-compression systems. Absorption refrigeration uses heat instead of electricity, perfect for RVs and remote locations. Thermoelectric cooling uses the Peltier effect for silent operation in wine coolers and electronics. Magnetic refrigeration exploits the magnetocaloric effect for ultra-high efficiency.

Sustainable Refrigerants & Energy Efficiency

The refrigeration industry is experiencing its biggest change since Freon's invention. We're moving toward environmentally friendly refrigerants that are often more efficient.

R290 propane offers up to 40% energy savings with a global warming potential of just 3, though it requires special handling due to flammability. CO₂ refrigeration (R744) has zero environmental impact but operates at higher pressures. Ammonia (R717) serves industrial applications with incredible efficiency and zero GWP.

Synthetic options include R454B (GWP 466), R32 (GWP 675), and R1234yf (GWP 4). Variable-speed compressors and electronic expansion valves provide precise control and energy savings.

Advanced insulation delivers 20-30% energy reductions. Adding doors to open merchandiser cases cuts energy use by 40%.

Learn more about refrigerated cooling for efficiency improvements.

Emerging Solid-State Refrigaration Innovations

Thermoelectric systems using bismuth telluride offer silent operation and precise control. Magnetocaloric materials like gadolinium achieve efficiencies rivaling traditional systems. Elastocaloric cooling using nickel-titanium provides compact solutions.

IoT controls revolutionize monitoring and optimization. Remote monitoring enables anywhere access with predictive maintenance algorithms that prevent breakdowns before they occur.

Best Practices for Safe, Efficient Use

Getting the most from your refrigeration system requires attention to detail. Most problems are preventable with proper maintenance and temperature control.

Setting the Right Temperature & Humidity

The sweet spot for refrigerated storage is 3-5°C (37-41°F), but products have specific needs. Meat and poultry prefer 30-38°F, dairy handles 38-46°F, and fruits/vegetables need 44-50°F to avoid chilling damage.

Bacterial growth doubles every 20 minutes at room temperature, but even a 5°F increase can cut food shelf life in half. Use calibrated thermometers in warmest spots and log temperatures twice daily. For freezers, maintain 0°F (-18°C) or below.

Routine Maintenance Checklist

Monthly: Inspect door seals for air leaks, cracks, or tears. A worn seal increases energy costs by 25%. Clean interior surfaces and drain pans.

Quarterly: Clean condenser coils - dirty coils reduce efficiency by 30%. Check fan operation and listen for unusual noises.

Semi-annually: Professional inspection including refrigerant levels and leak detection.

Annually: Review energy consumption trends and update maintenance records.

Warning signs requiring immediate attention: unusual noises, ice buildup, temperature fluctuations, higher energy bills, or refrigerant leak signs.

More information about commercial cooler repair helps determine when to call professionals.

Choosing the Right System for Your Walk-In or Mortuary Cooler

Remote systems work best when you can't dump heat inside buildings - quieter and more efficient but complex installation. Self-contained units offer easier installation in one package.

Insulation thickness significantly affects operating costs. We recommend 4-6 inches for coolers and 6-8 inches for freezers with vapor barriers preventing moisture infiltration.

At American Mortuary Coolers, custom solutions custom to specific needs always outperform generic installations. We design and deliver systems across all 48 contiguous states with direct delivery and custom panels ensuring perfect fit and optimal performance.

Learn more about walk-in refrigeration units to understand your options.

Frequently Asked Questions about Refrigaration

Why does my refrigaration system need both subcooling and superheat checks?

Think of subcooling and superheat as your refrigaration system's vital signs. Just like a doctor checks your blood pressure and heart rate, these two measurements tell you everything about your system's health.

Superheat measures how much hotter the refrigerant vapor is compared to its boiling point. You want this around 8-12°F. It's like making sure steam coming out of a kettle is actually steam, not water droplets. If liquid refrigerant gets back to your compressor, it's like trying to compress water - something's going to break, and it won't be cheap to fix.

Subcooling tells you how much cooler your liquid refrigerant is below its condensing temperature. The sweet spot is usually 8-15°F. This ensures you're getting pure liquid into your expansion valve, not a mix of liquid and vapor that reduces efficiency.

Here's what these numbers reveal about your system: Low superheat with low subcooling usually means you're overcharged with refrigerant. High superheat with high subcooling? You're probably running low. When superheat is low but subcooling is high, your expansion valve might be acting up.

These simple checks can save you thousands in repairs and keep your system running efficiently for years longer.

How often should I service a walk-in cooler to maintain optimal refrigaration performance?

The honest answer? It depends on how hard you're working your system and what kind of environment it's living in.

For most refrigaration applications, we recommend professional service every 3-6 months. But that's just the starting point. A busy restaurant kitchen with grease in the air needs attention every 2-3 months. A clean office break room might go 6 months between services.

At American Mortuary Coolers, we've learned that mortuary and medical applications need monthly inspections because there's zero tolerance for failure. When you're preserving human remains or life-saving medications, you can't afford to wait until something goes wrong.

Environmental factors make a huge difference. If your condenser coils are outside in a dusty area, they'll need cleaning more often. High-traffic areas with constant door openings put extra stress on the system. Extreme temperatures - whether blazing summer heat or freezing winter cold - also increase service needs.

Don't wait for your system to tell you it needs help. Rising energy bills, longer run times, or unusual noises are all signs you've already waited too long. More info about commercial cooler repair can help you spot problems before they become expensive disasters.

What refrigerant is safest and most energy-efficient for modern refrigaration units?

This is probably the most important question in refrigaration today. The industry is going through massive changes, and choosing the wrong refrigerant now could cost you big money later.

R744 (CO₂) wins the safety award hands down. It's what we breathe out every day, so it's completely non-toxic and non-flammable. The global warming potential is essentially zero - literally a 1 on the GWP scale. The catch? It operates at much higher pressures than traditional refrigerants, so you need specialized equipment.

For pure efficiency, R290 (propane) is hard to beat. We're talking up to 40% energy savings compared to older refrigerants. The environmental impact is minimal with a GWP of just 3. The downside is it's flammable, so you need proper safety measures and trained technicians.

R454B offers the best of both worlds for many applications. It's a direct drop-in replacement for R410A in most systems, cuts global warming potential by 78%, and performs almost identically to what you're used to. It's mildly flammable (A2L classification), but much safer than propane.

The writing's on the wall - high-GWP refrigerants are being phased out. New EPA regulations are making traditional refrigerants more expensive and harder to get. Choosing a future-proof refrigerant now saves you from costly conversions later.

At American Mortuary Coolers, we help our clients across all 48 states steer these changes. What works in Tennessee might not be the best choice for a facility in Arizona or Minnesota. We consider your local climate, regulations, and service availability when recommending refrigerants for custom installations.

Conclusion

Understanding refrigeration fundamentals isn't just academic knowledge - it's practical information that can save you thousands of dollars, prevent costly equipment failures, and ensure your products stay properly preserved. Whether you're running a small funeral home or managing a large commercial facility, knowing how these systems work makes all the difference.

From the basic vapor-compression cycle we explored to the exciting solid-state cooling technologies on the horizon, the refrigeration field keeps evolving toward greater efficiency and environmental responsibility. The days of energy-wasting, environmentally harmful systems are numbered, and that's good news for everyone.

Here's what really matters for optimal refrigaration performance: temperature control is absolutely critical - maintain that 3-5°C sweet spot for coolers and 0°F for freezers. Regular maintenance truly pays off in the long run, so clean those coils every 6 months and check door seals quarterly. Choose your refrigerant wisely by considering both efficiency and environmental impact, because what you pick today affects your costs tomorrow.

Proper sizing matters more than most people realize. Oversized or undersized systems don't just waste energy - they actually reduce equipment lifespan and create headaches you don't need. And please, monitor your system's performance by tracking temperatures, energy use, and maintenance needs. Your future self will thank you.

The refrigeration industry's future looks genuinely bright. Natural refrigerants like R290 propane are offering up to 40% energy savings right now, and emerging technologies promise even greater efficiency down the road. As regulations continue pushing toward lower-GWP refrigerants, staying informed about these changes helps you make smarter equipment decisions that won't become obsolete in five years.

At American Mortuary Coolers, we've been helping businesses across the United States implement effective refrigeration solutions for years. From our home base in Tennessee to facilities in major markets like Atlanta, Chicago, Dallas, Los Angeles, and New York, we've seen how proper system design and maintenance separate smooth operations from costly disasters.

We understand that every application is unique - no two funeral homes have identical needs, and cookie-cutter solutions rarely work perfectly. That's why we offer custom solutions with direct delivery across all 48 contiguous states and work closely with each customer to design systems that meet their specific requirements. From the humid Southeast to the dry Southwest, from small funeral homes to large commercial facilities, we've learned that one size definitely doesn't fit all.

Learn more about refrigerated cooling to explore how modern refrigeration technology can benefit your specific application.

Remember this: good refrigeration isn't just about keeping things cold. It's about maintaining precise conditions efficiently, safely, and reliably. With the right knowledge and equipment, you can achieve all three while minimizing environmental impact and operating costs. And honestly, that's a win-win situation we can all feel good about.