Why Hydrau Lift Technology Powers Heavy-Duty Operations Across Industries

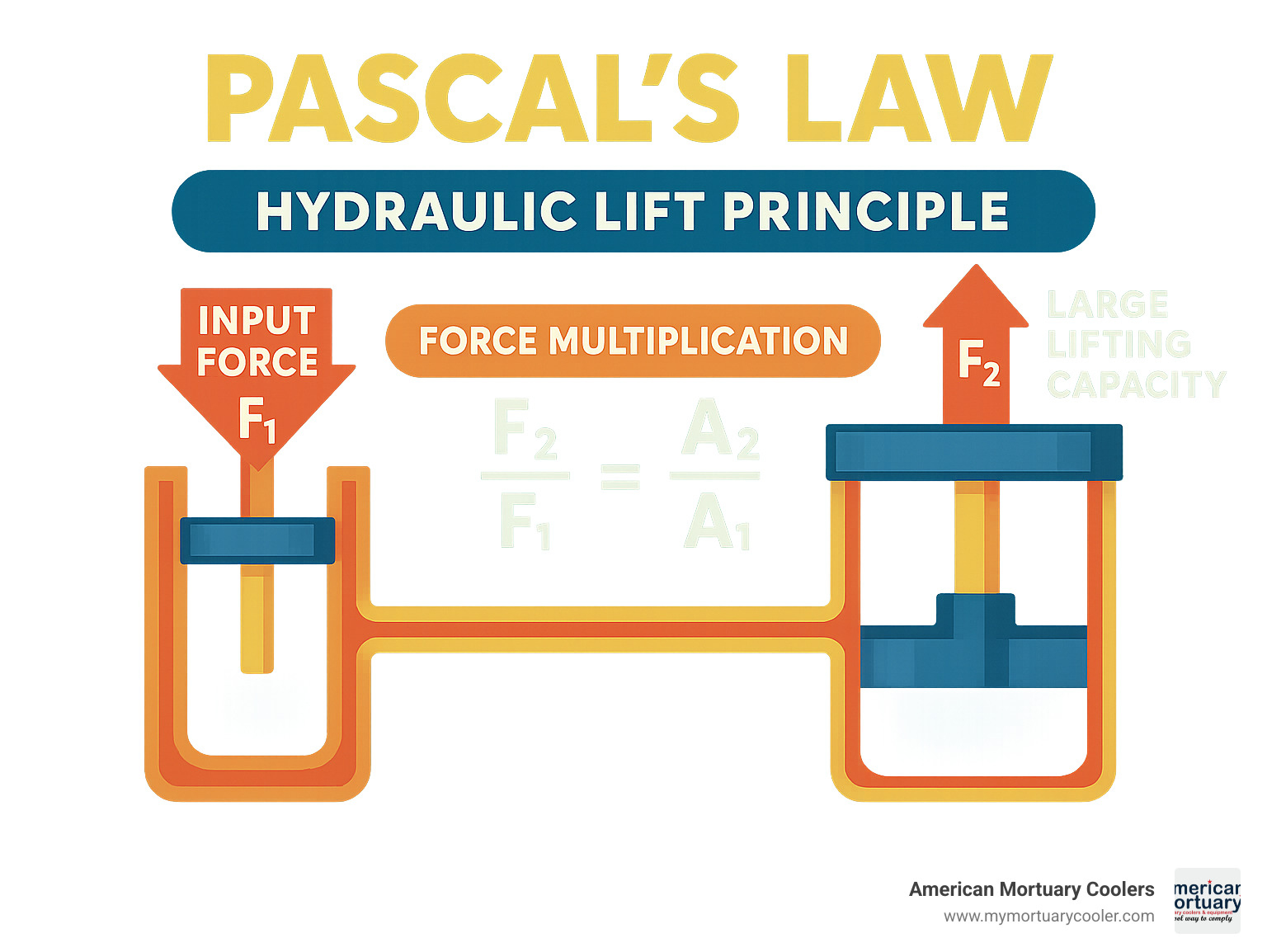

A hydrau lift uses pressurized fluid to raise, lower, and position heavy loads that would be impossible to move by hand. These systems rely on Pascal's law - where force applied to incompressible fluid multiplies through cylinders and pistons.

Quick hydrau lift overview:

- Capacity range: 100 lbs to 200,000+ lbs depending on system type

- Common types: Patient lifts, scissor tables, VRCs, boat lifts, automotive lifts, cadaver lifts

- Key advantage: Safe, controlled lifting with emergency descent protection

- Typical applications: Mortuary operations, healthcare, material handling, automotive service

- Maintenance: Monthly inspections, annual oil changes, 5-year hose replacement

The history of hydrau lift technology dates back to Joseph Bramah's hydraulic press patent in England, with the first hydraulic elevator entering service in New York City in 1870. Today's systems can support loads up to 6,000 lbs in standard industrial applications.

Modern hydrau lift systems excel in two-level applications up to 22 feet, operating at speeds up to 1 meter per second. They're limited to about 10 cycles per hour and 100 cycles per day, making them ideal for moderate-use scenarios where reliability matters more than speed.

Unlike mechanical lifts that use cables or chains, hydrau lift systems eliminate free-fall risks. When power fails, the descent is slow and controlled - a critical safety feature in mortuary, healthcare, and industrial settings.

Must-know hydrau lift terms:

Hydrau Lift Fundamentals: Pascal's Law in Action

Every hydrau lift is basically a physics lesson in action. The magic happens thanks to Pascal's law - when you push on incompressible fluid, that pressure spreads equally in all directions. This basic concept lets a compact hydraulic system lift loads that would otherwise require a small army.

Picture this: you apply 100 pounds of force to a small 2-inch piston. That pressure travels through hydraulic oil to a larger 6-inch cylinder, and suddenly you've got 900 pounds of lifting power. That's nine times what you put in! This force multiplication is why a relatively small hydrau lift can handle multi-ton loads without breaking a sweat.

The secret ingredient is that incompressible oil. Unlike air that squishes under pressure, hydraulic fluid keeps its volume constant. Every ounce of force you apply gets transmitted directly to where the lifting happens. Most systems use mineral oil or synthetic blends.

The beauty of a hydrau lift system lies in its simplicity. The pump and motor create initial pressure, while the reservoir stores your hydraulic fluid. Cylinders and pistons do the actual lifting work, valve controls manage flow and speed, and hoses and fittings move that pressurized fluid where it needs to go.

Safety is built right into the design. When power fails, you won't get the scary free-fall you might see with cable systems. Instead, the trapped hydraulic fluid provides controlled, safety descent - usually slow enough for safe evacuation or emergency procedures.

| Oil-Based Hydraulics | Water-Based Hydraulics |

|---|---|

| Higher viscosity, better lubrication | Lower viscosity, faster response |

| Temperature stable | Environmentally friendly |

| Longer component life | Fire-resistant properties |

| Standard for heavy-duty applications | Used in food/pharmaceutical settings |

How a hydrau lift raises and lowers loads

The lifting process starts when your electric pump kicks in, creating pressure build-up in the hydraulic fluid. This pressurized oil flows through hoses into the main cylinder, pushing the piston upward. As that piston rises, it carries your platform, carriage, or whatever load you're moving.

During the pump cycle, the system traps pressurized fluid in the cylinder to hold position. A pressure-compensated valve maintains this holding pressure automatically, so your load stays exactly where you put it - no annoying drift or settling.

When it's time to come down, gravity return takes over. You open the return valve, gravity pulls the load downward, and hydraulic fluid flows back to the reservoir. The flow control valve regulates this return speed, giving you smooth, predictable descent regardless of how heavy your load is.

Why hydrau lift speed is ideal for low-mid rise tasks

Hydrau lift systems typically max out around ≤1 m/s - slower than high-speed elevators but perfect for their intended jobs. This moderate speed is safer for operators, gentler on delicate loads, and allows for precise positioning.

The duty cycle works out to about 10 cycles per hour and 100 cycles per day. These numbers might sound limiting, but they're actually ideal for many real-world applications like mortuary operations, patient transfers, or material handling tasks.

For buildings in the 2-8 floors range, hydrau lift systems hit the sweet spot of cost-effectiveness and performance. Beyond about 22 feet of travel, the cylinder requirements get impractical, and that's when traction systems usually make more sense.

Core Components & Types of Hydrau Lift Systems

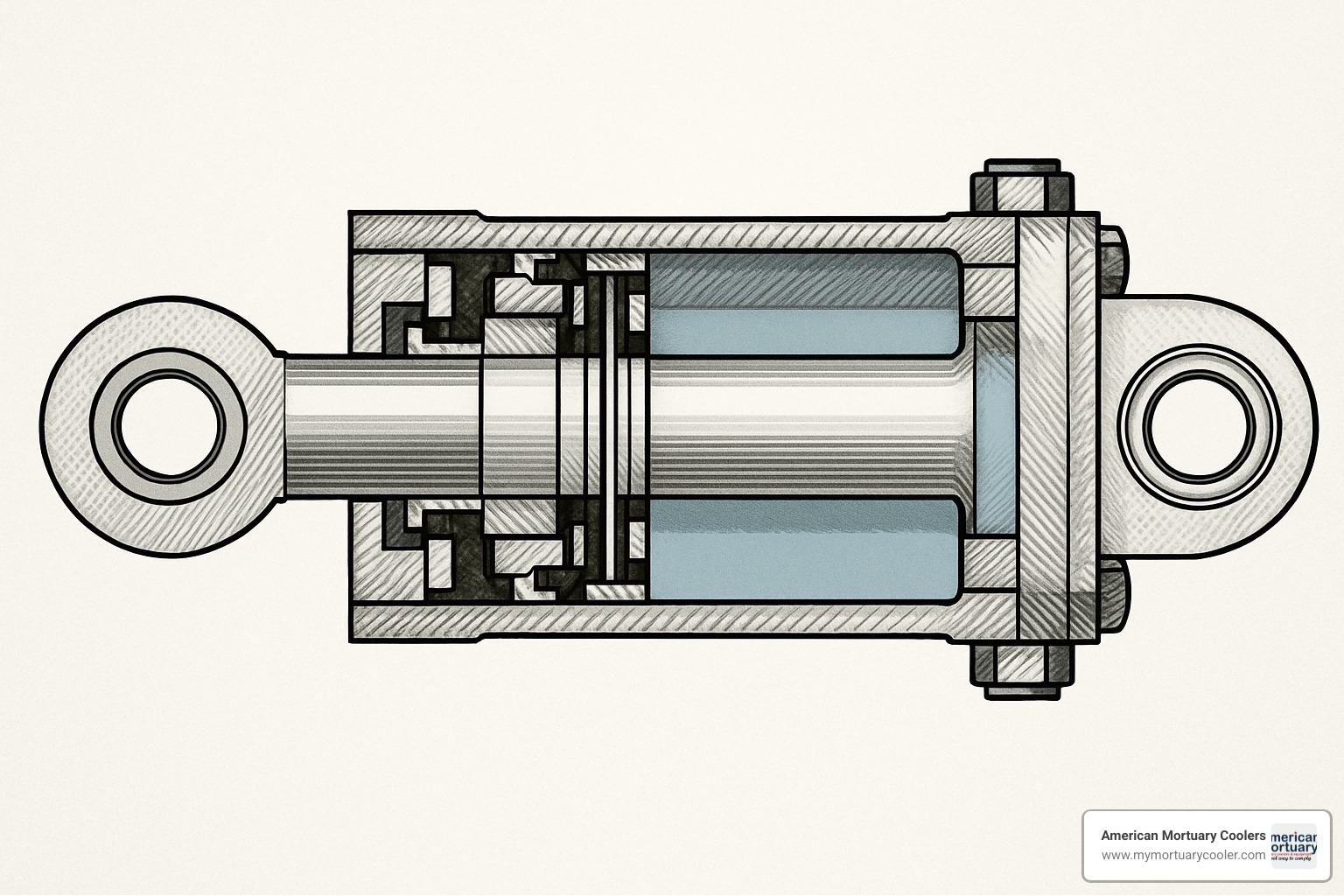

Think of a hydrau lift like a giant syringe - but instead of medicine, you're pushing hydraulic fluid to create incredible lifting power. The ram cylinder is the muscle of the system, where all that pressurized fluid gets converted into the force that actually lifts your load.

The reservoir is your system's fuel tank, storing hydraulic fluid when everything's at rest. Bigger reservoirs help keep everything cooler and make your hydraulic fluid last longer. Smart systems include built-in filtration that keeps dirt and debris out, which can save you thousands in repairs down the road.

Your power unit combines the electric motor with the hydraulic pump. Variable-speed pumps give you silky-smooth control (perfect for delicate mortuary work), while fixed-speed units keep things simple and affordable.

Don't overlook the hoses and fittings - these are the arteries of your hydrau lift system. High-pressure hydraulic hoses need to meet strict safety standards, and those fittings require regular inspection. We always tell our customers to budget for hose replacement every five years.

Seals throughout the system are what keep everything contained and working properly. Modern seal materials can handle different hydraulic fluids and temperature ranges, but they do wear out over time.

Holed vs Hole-less Hydrau Lift Designs

Holed systems put that hydraulic cylinder underground in a drilled hole or excavated pit. Need a 20-foot lift? You're digging a 20-foot deep hole. The upside is you can go as high as your building structure allows, and you get rock-solid stability. The downside? You're dealing with excavation permits, soil analysis, and waterproofing - all expensive headaches.

Hole-less systems keep everything above ground using telescoping rams or side-mounted cylinders. You're limited to about 20-30 feet of travel height, but you skip all that underground work. For existing funeral homes, this is often the only practical option.

In my experience with mortuary installations, hole-less systems win most of the time. They're easier to install in existing buildings, and 20-30 feet of travel handles most funeral home needs perfectly.

Hydrau lift variations for every need

Patient lifts handle up to 400 pounds with the gentle touch needed for healthcare settings. These systems include safety features like 360-degree spreader bars and emergency lowering.

Scissor table lifts give you stable platforms for material handling, with capacities ranging from 330 pounds all the way up to several tons. The scissor mechanism multiplies your hydraulic cylinder's travel distance, so you get more lift height without a massive installation.

For moving materials between floors, vertical reciprocating conveyors (VRCs) are the workhorses of industry. These hydrau lift systems handle everything from small parts to full pallets, with safety gates and interlocks that keep OSHA inspectors happy.

Boat lifts prove that hydraulic power works anywhere - even in marine environments. These systems use corrosion-resistant materials and free-standing designs that don't need permanent pilings.

In automotive service bays, auto lifts rely on hydraulic power for safety and reliability. Whether it's post lifts, scissor lifts, or alignment lifts, they all use that same dependable hydrau lift technology.

For our mortuary customers, cadaver lifts provide essential ergonomic benefits. These specialized systems reduce physical strain on funeral home staff while ensuring dignified handling of remains.

Emerging hydrau lift hybrids and MRL setups

Machine-room-less (MRL) systems eliminate the need for separate hydraulic equipment rooms by tucking components right into the lift shaft. This saves valuable building space.

Battery-powered systems keep working when the power goes out. Modern battery technology offers hours of operation on a single charge, with automatic charging during normal use.

Solar-charged systems combine environmental responsibility with practical operation. These hydrau lift installations work great for remote locations or facilities looking to reduce energy costs.

Real-World Applications & Advantages of Hydrau Lift Technology

When you walk into a modern funeral home, hospital, or industrial facility, you're likely seeing hydrau lift technology at work - even if you don't realize it. These systems quietly handle the heavy lifting that keeps operations running smoothly and safely.

The beauty of hydrau lift systems lies in their versatility. In warehouses, they eliminate the back-breaking work of manually positioning heavy pallets and parts. Healthcare facilities have acceptd hydrau lift technology as an essential tool for patient care. Marine environments showcase just how tough hydrau lift systems can be. Construction and automotive shops rely on hydrau lift systems for safe vehicle service.

For professional insights on optimizing your hydraulic systems, check out Lift Like a Pro with These Hydraulic Pump Essentials.

Hydrau lift in funeral & mortuary operations

Having worked with funeral homes across the country through American Mortuary Coolers, I've seen how hydrau lift systems transform daily operations. These aren't just pieces of equipment - they're essential tools that protect staff while maintaining the dignity that's so important in funeral service.

The physical demands of funeral work are often underestimated. Body and casket lifts eliminate the strain of manual lifting, handling loads from 650 to over 1,000 pounds with ease. The smooth, controlled operation maintains the reverence essential to funeral service while protecting staff from career-ending injuries.

Scissor table lifts have revolutionized preparation room work. Staff can adjust working heights to comfortable levels, reducing back strain and improving the quality of their work. The stainless steel construction meets strict hygiene requirements while standing up to daily use and frequent cleaning.

OSHA compliance isn't optional in funeral homes, and professional hydrau lift systems are designed with this in mind. Built-in safety features like emergency stops, overload protection, and safety gates keep operations compliant while protecting workers.

Power outages don't respect funeral schedules, which is why battery-powered systems are increasingly popular. Modern battery technology provides hours of operation with quick recharging, ensuring services can continue even during emergencies.

For detailed specifications and options, our Essential Guide to American Mortuary Coolers Scissor Lifts covers everything you need to know about selecting the right system for your facility.

Hydrau lift for industrial material flow

Vertical reciprocating conveyors (VRCs) represent one of the smartest applications of hydrau lift technology. These systems solve the age-old problem of moving materials between floors without the expense and complexity of freight elevators.

Mezzanine applications are where VRCs really shine. Warehouses can maximize their vertical space without breaking the budget on traditional elevator systems. These hydrau lift units handle everything from small parts to full pallets, with standard capacities up to 6,000 pounds.

Pallet transfer systems streamline warehouse operations in ways that immediately impact the bottom line. Workers load pallets at ground level, then use the hydrau lift system to move them efficiently to upper storage levels.

Hydrau lift for patient care & mobility

Healthcare applications demand the highest safety standards, making hydrau lift systems invaluable for patient care. These systems support up to 400 pounds while providing the gentle, controlled transfers that protect both patients and caregivers from injury.

The gentle transfer operation isn't just about comfort - it's about safety and dignity. Hydrau lift systems provide smooth acceleration and deceleration that eliminates jarring movements. The controlled descent feature ensures safety even during power failures.

Sling compatibility makes these systems incredibly versatile. Six-point, four-point, and two-point slings accommodate different patient needs and transfer requirements. ADA compliance makes hydrau lift systems essential for accessibility.

Selecting, Operating & Maintaining Your Hydrau Lift

Choosing the right hydrau lift system requires careful analysis of your specific needs. Load capacity calculation goes beyond simple weight - you must consider load distribution, lifting frequency, and safety factors. We recommend sizing systems at least 20% above maximum expected loads.

Duty cycle analysis determines whether hydrau lift technology fits your application. With limitations of 10 cycles per hour and 100 cycles per day, these systems work best for moderate-use applications.

Fluid choice affects performance, maintenance, and environmental impact. Mineral oil provides excellent performance and cost-effectiveness for most applications. Synthetic fluids offer extended temperature ranges and longer service life.

Hydraulic Lift Manufacturers | Market overview provides additional resources for system selection and vendor evaluation.

Buyer checklist for the best hydrau lift fit

Load type analysis goes beyond weight to consider size, shape, and center of gravity. A 1,000-pound compact load behaves differently than a 1,000-pound long, flexible load. Hydrau lift systems handle concentrated loads better than distributed loads.

Lift height requirements determine system configuration. Heights up to 15 feet work well with hole-less systems, while greater heights may require holed configurations.

Space constraints often drive system selection. Hole-less systems need floor space for cylinders and equipment, while holed systems require underground clearance.

Budget analysis should include lifecycle costs, not just initial purchase price. Hydrau lift systems typically cost less initially than mechanical alternatives but may have higher maintenance costs.

Operating a hydrau lift safely every day

Training requirements ensure safe operation of hydrau lift systems. Operators must understand system limitations, emergency procedures, and proper loading techniques. OSHA-certified training programs provide comprehensive safety education.

Lock-out procedures prevent accidents during maintenance or repairs. Every hydrau lift system needs clearly marked isolation points and procedures for safely disabling the system.

Emergency lowering capabilities provide safety during power failures or system malfunctions. Manual lowering valves allow controlled descent even when normal controls fail.

ANSI standards provide comprehensive safety guidelines for hydrau lift operations. Standards A92 and A10 cover aerial platforms and construction applications.

Maintenance roadmap to extend hydrau lift life

Daily inspection routines catch problems before they become failures. Check for fluid leaks, unusual noises, and proper operation of all controls.

Annual oil changes maintain system performance and prevent component damage. Hydraulic fluid degrades over time, losing its lubricating properties and accumulating contaminants.

Hose replacement every five years prevents catastrophic failures. Hydraulic hoses deteriorate from the inside out, making visual inspection inadequate.

The Ultimate Guide to Choosing the Best Hydraulic Lift Cart offers additional maintenance insights for mobile applications.

Cost, Installation & Environmental Considerations

When you're planning a hydrau lift installation, the upfront costs usually look pretty attractive compared to mechanical alternatives. That's one reason why so many of our funeral home customers choose hydraulic systems - they fit tighter budgets while delivering reliable performance.

But you need to look beyond that initial price tag. The real story comes from lifecycle costs, which include regular maintenance, energy bills, and eventually replacing worn components. Hydrau lift systems typically need oil changes every year and hose replacements every five years.

Site preparation is where costs can really surprise you. If you're going with a holed system, you're looking at excavation work that includes soil analysis, digging a pit as deep as your lift travels, and proper waterproofing. That's why we often recommend hole-less systems for existing funeral homes.

Power supply requirements are refreshingly straightforward with most hydrau lift systems. They typically run on standard 208-240V three-phase power, and the electrical demands are manageable for most buildings.

Machine room space used to be a bigger concern, but modern MRL (machine-room-less) systems have changed the game. These clever designs integrate all the hydraulic equipment right into the lift structure, which can save you valuable square footage in cramped funeral home layouts.

One thing our customers really appreciate about hydrau lift systems is how quiet they operate. The smooth hydraulic action doesn't create the mechanical noise you get with cables and gears, making them perfect for funeral homes where a peaceful atmosphere matters.

Environmental considerations are becoming increasingly important, and hydrau lift systems offer some real advantages here. Oil recycling programs make it easy to dispose of used hydraulic fluid responsibly. Eco-friendly hydraulic fluids are worth considering if environmental impact is a priority for your facility.

The bottom line? Hydrau lift systems offer excellent value when you match them to the right application. They're particularly cost-effective for funeral homes that need reliable, gentle lifting without the complexity and expense of high-speed mechanical systems.

Frequently Asked Questions about Hydrau Lift Systems

I get these questions all the time from funeral directors and facility managers looking to add hydrau lift systems to their operations. Let me share the answers that matter most when you're making this important decision.

What weight capacities and lift ranges are typical?

The beauty of hydrau lift systems is their incredible range of capacities. For most industrial applications, you're looking at systems that handle up to 6,000 pounds reliably. But here's where it gets interesting - specialized systems can go way beyond that depending on your needs.

In our mortuary work, we typically see lifts rated for 650 to 1,000+ pounds. That's perfect for casket handling and preparation room tasks. Patient lifts in healthcare settings usually max out around 400 pounds, which covers the vast majority of transfer needs safely.

Lift height depends on your system choice. Hole-less systems - the ones we often recommend for existing funeral homes - give you about 20 to 30 feet of travel. That's plenty for most two-story operations. If you need more height, holed systems can match your building requirements, though they require that underground cylinder installation.

Here's a pro tip from years of sizing these systems: always go 20% above your maximum expected load. Real-world conditions, load variations, and safety margins demand this extra capacity. I've seen too many facilities regret cutting it close on capacity calculations.

How does a hydrau lift compare to mechanical or traction lifts on cost & efficiency?

This is where hydrau lift systems really shine for the right applications. Initial costs are typically lower - sometimes significantly so - especially for low-rise installations like most funeral homes need. You're not dealing with complex gear systems, cables, or counterweights.

Installation costs favor hydraulic systems too. The structural requirements are simpler, and there are fewer moving parts to align and adjust. For a funeral home adding a lift to an existing building, this can save thousands in construction costs.

Energy efficiency is excellent for moderate-use applications. Your hydrau lift only uses power during the actual lifting cycle. Once it's holding position, energy consumption drops to nearly zero. Compare that to some mechanical systems that maintain continuous power draw.

The trade-off comes in maintenance costs and duty cycle limitations. Hydraulic systems need regular fluid changes, seal replacements, and hose maintenance. But here's the thing - the simpler mechanical design often means longer overall system life and fewer catastrophic failures.

Those speed and cycle limitations I mentioned earlier - 10 cycles per hour, 100 per day - make hydraulic systems perfect for funeral homes but less suitable for high-frequency applications like busy freight elevators.

What safety features are mandatory under OSHA/ANSI codes?

Safety isn't optional with hydrau lift systems, and frankly, that's a good thing. OSHA Standard 1926.451 requires specific safety features that protect your staff and comply with regulations.

Interlocked safety gates are mandatory at all loading points. These gates prevent anyone from accessing the lift area while the system is operating. It's basic protection that prevents accidents and keeps inspectors happy.

ANSI A92 standards cover the structural and operational requirements for lifting equipment. These standards specify everything from control system design to emergency procedures. Following these standards isn't just about compliance - it's about protecting your people.

Emergency lowering capability is required for most installations. Your hydrau lift must provide manual lowering even when power fails or controls malfunction. We test these systems regularly during maintenance visits to ensure they work when needed.

Overload protection prevents both equipment damage and injuries. Pressure relief valves and load monitoring systems stop operation if loads exceed safe limits. Modern systems include both visual and audible warnings to alert operators to unsafe conditions.

Operator training is mandatory under OSHA requirements. Everyone using your hydrau lift system needs proper training on operation, emergency procedures, and hazard recognition. We always recommend OSHA-certified training programs and regular refresher sessions to maintain safety awareness.

The bottom line? These safety features aren't burdens - they're protections that keep your facility running safely and legally. When you're handling the responsibilities that come with funeral service, having systems you can trust completely makes all the difference.

Conclusion

When you're looking for reliable lifting solutions that won't let you down, hydrau lift technology delivers exactly what you need. These systems have proven themselves across countless applications - from the gentle care required in patient transfers to the heavy-duty demands of industrial operations.

After years of working with funeral homes across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, I've seen how the right hydrau lift system can transform daily operations. Every facility has its own unique challenges, whether it's tight spaces in an older funeral home or specific capacity requirements for modern crematory operations.

What impresses me most about quality hydrau lift systems is their incredible durability. When you invest in a well-built system and take care of it properly, you're looking at decades of dependable service.

The safety features built into today's hydrau lift systems give you real peace of mind. Whether it's the controlled descent during power outages or the overload protection that prevents accidents, these systems are designed to keep your staff safe while they focus on serving families during difficult times.

Our nationwide delivery network means you can get the hydrau lift solution you need, no matter where you're located. We understand that funeral service doesn't stop for equipment delays, which is why we've built relationships across all 48 contiguous states to ensure prompt delivery and local support when you need it.

Whether you're considering a patient lift for your preparation room, a scissor table for your embalming area, or a specialized mortuary lift for your crematory, the right hydrau lift system will make your work safer and more efficient. It's not just about moving heavy loads - it's about protecting your most valuable asset: your team.

Maximize Safety with American Mortuary's Durable Crematory and Mortuary Lift Solutions provides additional resources for professional applications requiring the highest standards of safety and reliability.

The innovations we're seeing in hydrau lift technology show that this proven technology will continue serving our industry for generations to come. When you choose hydraulic lifting solutions, you're investing in technology that grows with your needs while maintaining the reliability that funeral service demands.