Why Walk-In Cooler Maintenance Keeps Your Investment Running Strong

Walk in cooler maintenance is the key to preventing costly breakdowns, extending equipment life, and protecting your stored products. More than 85% of food safety and product loss stems from walk-in cooler or freezer temperature issues, making regular upkeep essential for any business relying on cold storage.

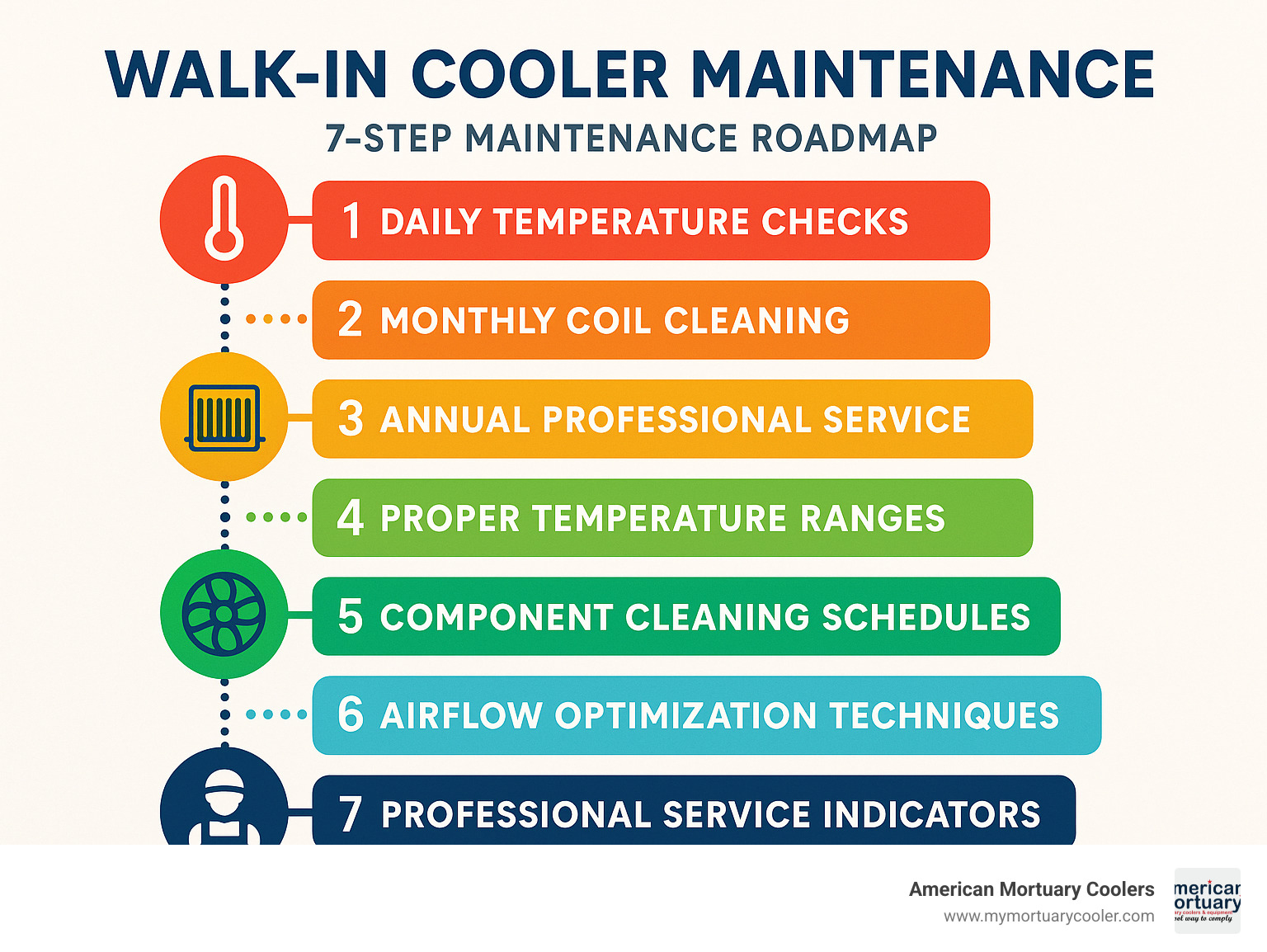

Essential walk-in cooler maintenance includes:

- Daily tasks - Temperature logs, surface cleaning, spill cleanup

- Monthly tasks - Condenser coil cleaning, drain line flushing, gasket inspection

- Annual service - Professional refrigerant checks, electrical connections, oil sampling

- Temperature monitoring - 35°F-41°F for coolers, -10°F to 0°F for freezers

- Component cleaning - Evaporator coils, fan blades, drain lines with non-acid cleaners

- Airflow optimization - Proper shelving, strip curtains, LED lighting upgrades

- Professional support - Call technicians for persistent issues, refrigerant leaks, or compressor problems

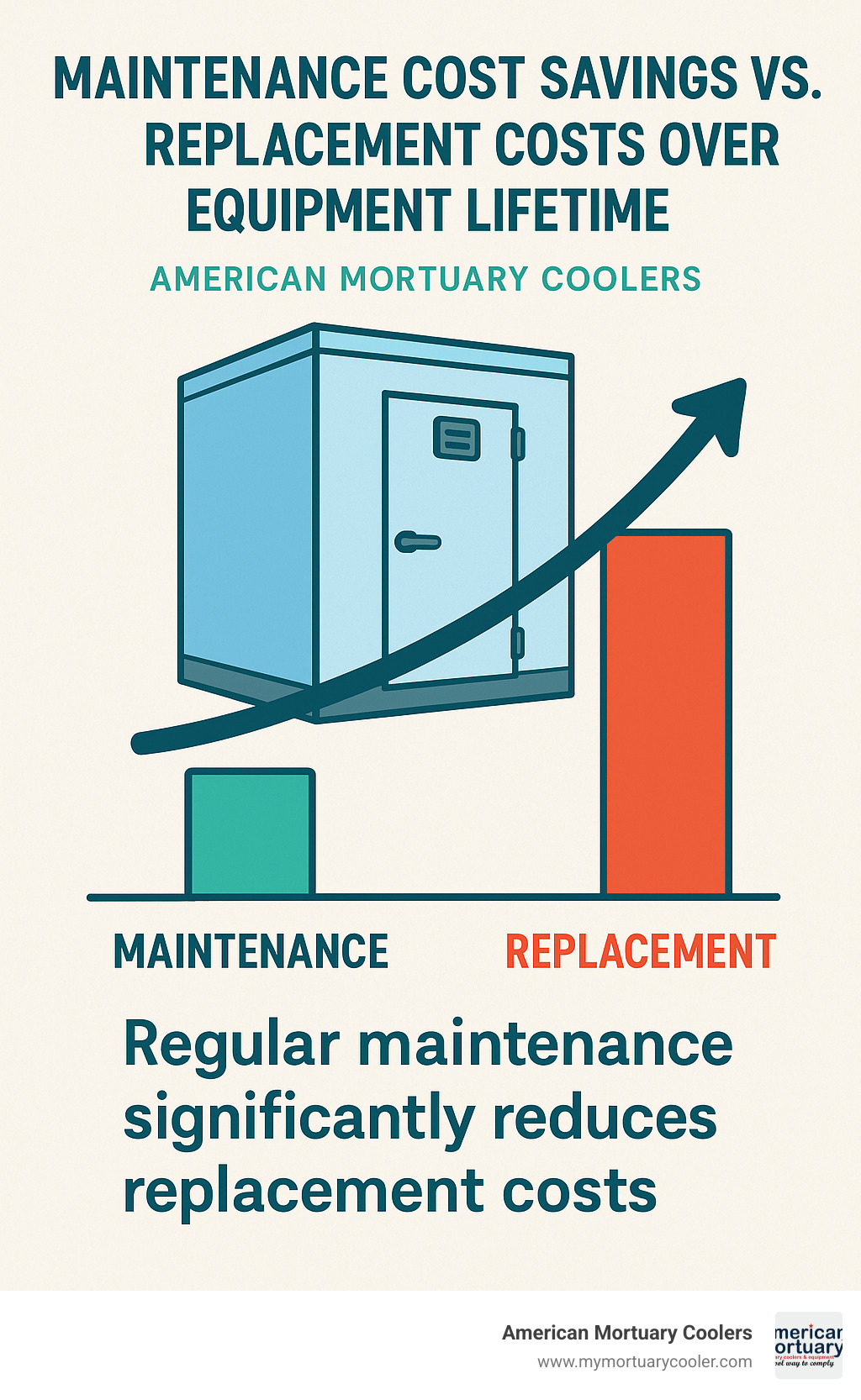

A well-maintained walk-in cooler can last 10-15 years, with some units operating efficiently for over 30 years. Regular cleaning and maintenance help avoid costly emergency repairs - compressor replacement alone ranges from $200 to over $700, not including labor costs.

The ideal maintenance approach combines simple daily checks with deeper monthly cleaning and annual professional tune-ups. Blocked condenser coils can cause compressor overheating and failure, while clean coils and proper airflow keep your system running efficiently and reduce energy costs.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in reliable cold storage solutions for funeral homes and healthcare facilities. My experience with walk in cooler maintenance spans decades of helping funeral directors maximize equipment lifespan while minimizing unexpected breakdowns that can compromise service quality.

Relevant articles related to walk in cooler maintenance:

Essential Walk-In Cooler Maintenance Checklist

Setting up a solid maintenance routine is what separates businesses that thrive from those dealing with constant headaches. Here's something that might surprise you: 85% of product spoilage happens because of temperature problems that could have been prevented with regular care.

Your walk-in cooler isn't just equipment - it's protecting thousands of dollars worth of inventory every single day. With proper walk in cooler maintenance, these workhorses can keep running strong for 15+ years. I've seen units still going after 30 years when they're treated right.

The energy savings alone make maintenance worth your time. Clean coils and proper airflow can cut your energy costs by 27%. That's real money back in your pocket every month.

Here's the thing about coolers versus freezers - they need different attention schedules because freezers work harder and deal with more ice buildup:

| Task | Walk-In Cooler | Walk-In Freezer |

|---|---|---|

| Temperature Monitoring | Daily (35°F-41°F) | Daily (-10°F to 0°F) |

| Surface Cleaning | Daily | Daily |

| Condenser Coil Cleaning | Monthly | Monthly |

| Evaporator Coil Cleaning | Bi-monthly | Monthly (more ice buildup) |

| Drain Line Maintenance | Monthly | Bi-weekly (higher freeze risk) |

| Gasket Inspection | Monthly | Monthly |

| Professional Service | Annual | Bi-annual |

Daily Walk in Cooler Maintenance Routine

Daily maintenance isn't complicated. We're talking about 10-15 minutes that can save you from thousand-dollar disasters.

Temperature logging is your first line of defense. Those numbers tell a story about what's happening inside your cooler. Bacteria start partying when temperatures creep above 40°F, and some nasty bugs like Listeria can grow even in cold conditions.

Surface cleaning keeps things sanitary and helps you spot problems early. A quick wipe-down with mild soap and water does the trick. While you're at it, check those door gaskets - they're like the weatherstripping on your house. Cracked or dirty gaskets let warm air sneak in.

Spill cleanup can't wait until tomorrow. Even small spills create breeding grounds for bacteria and can cause slip hazards for your staff.

Make sure your doors close completely and aren't being propped open. I've seen too many businesses lose entire loads because someone left a door cracked open overnight.

Monthly Walk in Cooler Maintenance Tasks

Monthly maintenance is where you really extend your equipment's life. Plan on spending 1-2 hours once a month - it's way cheaper than emergency service calls.

Condenser coil cleaning is the big one. These coils are like the radiator in your car - when they get dirty, everything works harder. Use a vacuum first to get the loose stuff, then follow up with approved coil cleaner. Never use acid-based cleaners - they'll eat your coils alive.

Drain line maintenance prevents those awful overflow situations. Ice buildup in drain lines is especially common in freezers, so check these more often in colder units.

Door gasket inspection catches problems before they become expensive. Look for cracks, stiffness, or areas where the gasket isn't sealing tight. A dollar bill should stay put when you close the door on it - if it slides out easily, your gasket needs attention.

More info about coil cleaning methods walks you through different techniques for various situations.

Annual Professional Service Tune-Up

Some things need a trained eye and specialized tools. Annual professional service catches the sneaky problems that can turn into major failures.

A good technician will check refrigerant levels and pressures, making sure your system has the right amount of coolant. They'll tighten electrical connections that vibration loosens over time - loose connections create heat and can cause fires.

Oil sampling is like getting blood work for your compressor. The oil tells a story about what's happening inside - acid levels, moisture, and metal particles all signal different problems before they become catastrophic.

Scientific research on preventive maintenance shows how oil analysis can predict failures months before they happen. That's the difference between planned maintenance and emergency disasters.

The bottom line? Walk in cooler maintenance isn't glamorous, but it's what keeps your business running smoothly and your products safe.

Deep-Cleaning Critical Components

When it comes to walk in cooler maintenance, deep cleaning your critical components is where the real magic happens. Think of it as giving your cooler a spa day - it takes more time and effort than your daily routine, but the results are worth every minute.

Safety should always come first. Before you touch anything electrical, disconnect the power completely. Grab your safety glasses, slip on some gloves, and make sure you're wearing non-slip shoes. Keep your workspace well-ventilated too - those cleaning chemicals need somewhere to go.

The three main players in your cooler's performance are the condenser coils, evaporator coils, and drain lines. Each one has its own personality and cleaning needs, but they all work together to keep your temperatures steady and your products safe.

How to Clean Condenser Coils Safely

Your condenser coils are the workhorses of your refrigeration system. They're busy converting high-pressure refrigerant gas into liquid while releasing heat - basically doing the heavy lifting that keeps everything cold. When these coils get dirty, your compressor has to work overtime, and that's when expensive problems start.

Start by powering down completely - this isn't optional. Remove any toe guards or panels that are blocking your access to the coils.

Begin with a good vacuum using a narrow attachment to pull out all the loose debris. You'd be amazed what accumulates in there - dust, hair, food particles, and sometimes things you can't quite identify.

Apply your approved coil cleaner according to the label directions - and please, stick to non-acid cleaners only. Use a long-handled brush to work the cleaner into those coil fins, being gentle but thorough. The fins are delicate, so don't go at them like you're scrubbing a grill.

Rinse everything thoroughly until there's no cleaning residue left behind. Give it a final vacuum to remove any remaining debris and moisture, then reassemble your guards and restore power. The whole process usually takes about an hour, but clean coils can improve your energy efficiency significantly.

More info about easy coil cleaning covers some advanced techniques if you're dealing with particularly stubborn buildup.

Evaporator Coil & Fan Maintenance

Evaporator coils are the gentler cousins of condenser coils. They're busy absorbing heat from inside your walk-in, turning liquid refrigerant back into gas. These coils need a softer touch during cleaning - think massage therapist, not construction worker.

Power off your unit and wait for complete defrosting before you start. This is crucial because you can't properly clean ice-covered coils. Remove the fan guards and take a good look at your fan blades while you're at it.

Clean those coil fins with a soft brush and mild detergent, being extra gentle. These fins bend easily, and bent fins restrict airflow. Rinse thoroughly and let everything air dry completely before reassembling.

While you're in there, check your defrost settings. This is also the perfect time to play detective with ice patterns. Ice forming on only one side usually means your fan motor is struggling. Ice extending all the way to the compressor suggests low refrigerant charge.

Scientific research on mold growth shows that mold can actually grow even in cold environments, especially around sugary or salty substances. Regular coil cleaning prevents this mold buildup from contaminating your stored products.

Drain Line Clearing & Sanitizing

Drain lines might not seem glamorous, but they're absolutely critical for removing condensate water from your evaporator coils. When they get clogged, you're looking at ice buildup, water damage, and a whole lot of headaches.

Start by locating your drain pan and giving it a thorough inspection. Look for clogs, ice, or any signs of backup. Clear any blockages you find, but avoid using sharp objects that might damage the lines.

Flush the lines with warm water and mild detergent, working from the inside out. If you're dealing with a freezer application, make sure your drain line heaters are installed and working properly.

Don't forget to insulate any exposed drain lines - this prevents freezing and keeps everything flowing smoothly. Test your water flow after cleaning to make sure everything's working as it should.

More info about iced evaporator fix provides detailed troubleshooting if you're dealing with persistent ice problems in your drain system.

Temperature, Airflow & Organization Strategies

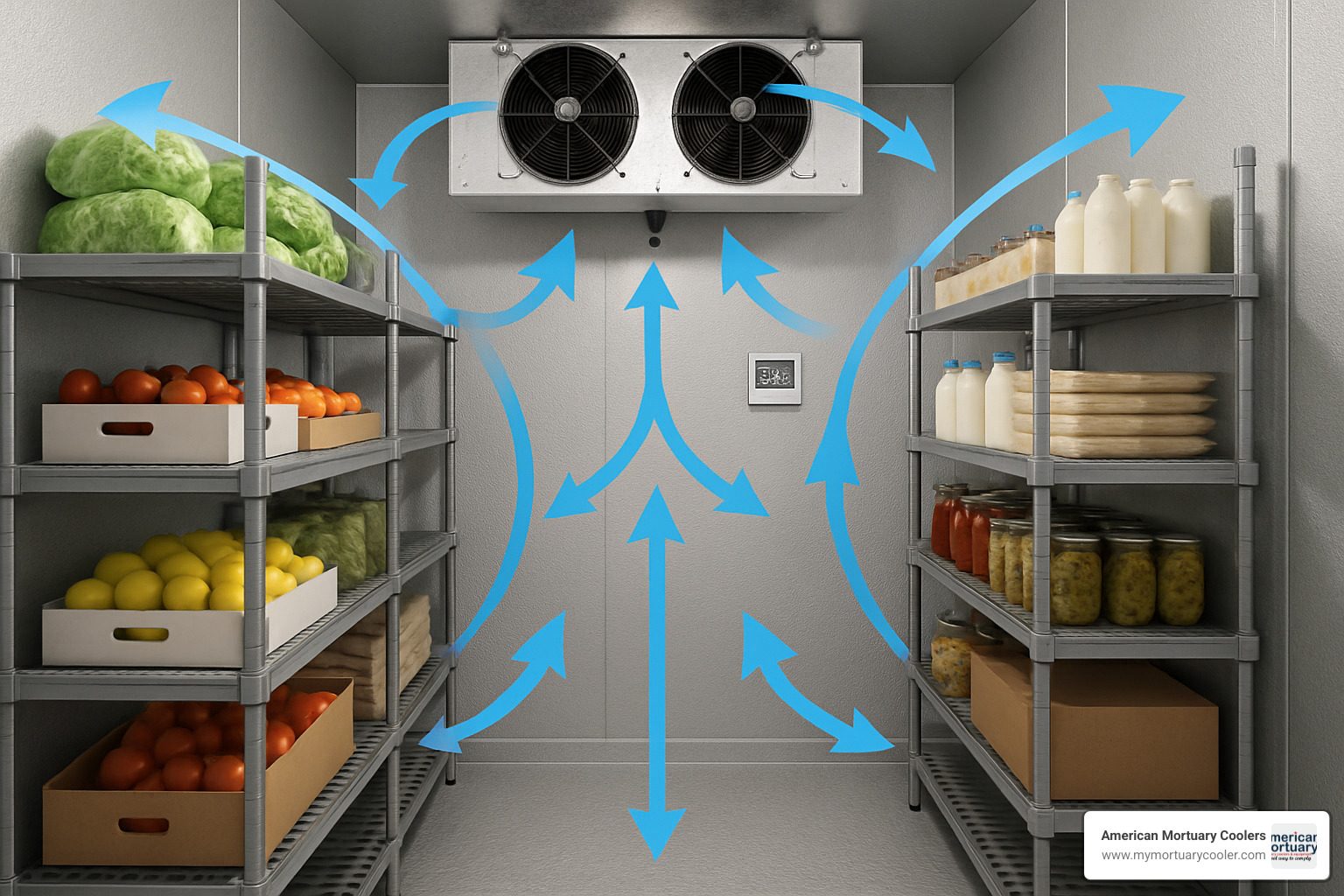

Getting your temperature and airflow right is where walk in cooler maintenance really pays off. Think of your walk-in as a carefully balanced ecosystem - everything needs to work together smoothly.

Your cooler should stay between 35°F and 41°F, while freezers need to maintain -10°F to 0°F. These aren't just random numbers - they're the sweet spot where your products stay safe and your compressor doesn't work overtime. Keep humidity around 50-60% and you'll prevent that nasty mold growth that can ruin everything.

The secret to efficiency is keeping your unit 75-90% full. Too empty and the compressor cycles too often. Too packed and air can't circulate properly. It's like Goldilocks - you want it just right.

LED lighting is a game-changer that many people overlook. Those old fluorescent bulbs pump out heat all day long, making your compressor work harder. LEDs stay cool and last forever, plus they make everything look better when you're trying to find that one item in the back corner.

Proper shelving makes all the difference. Keep everything at least 6 inches away from walls and coils - your evaporator fan needs room to breathe. Stack items too close and you'll create dead air zones where temperatures can climb dangerously high.

Using Sensors & Remote Monitoring

Modern monitoring systems are like having a dedicated technician watching your cooler 24/7. KE2therm controllers and GlacierGrid alarm systems can save you from those middle-of-the-night disasters when something goes wrong.

These smart systems track more than just temperature. They monitor airflow patterns, fluid levels, and even tell you when it's time to clean your evaporator coils based on performance data. Some can store 10+ years of operational history, which becomes invaluable when diagnosing those tricky intermittent problems.

The smartphone integration is brilliant - you get high and low temperature alerts sent directly to your phone. No more finding spoiled products on Monday morning because something failed over the weekend.

Scientific research on bacterial growth shows that certain bacteria like Listeria can multiply even in cold temperatures, making continuous monitoring essential for safety compliance.

Prevent Warm-Air Infiltration

Door gaskets are your first line of defense against warm air sneaking into your cooler. Even tiny cracks can cost you serious money in energy bills and create perfect conditions for mold growth.

Monthly gasket inspections should be part of your routine. Look for cracks, brittleness, or areas where the seal doesn't make full contact. Clean them with mild detergent and hot water - you'd be amazed how much grime builds up and prevents proper sealing.

Strip curtains are the budget-friendly option for reducing infiltration. They're cheap, easy to install, and work surprisingly well. Air curtains cost more upfront but can reduce compressor runtime by 27% - that's real money back in your pocket every month.

Door alignment matters more than most people realize. If your hinges are sagging or the door doesn't close properly, all the gaskets in the world won't help. A simple adjustment can make the difference between efficient operation and constant temperature swings.

Time-based door alarms are worth considering if you have staff who tend to leave doors open while working. A gentle reminder after 30 seconds can prevent hours of recovery time and wasted energy.

Troubleshooting & When to Call a Pro

Even the best-maintained walk-ins will need attention occasionally. The budget-saver is knowing what you can fix in minutes and what demands a licensed technician.

Typical symptoms and quick reads

- Warm interior – often a mis-set thermostat or boxes blocking airflow, not a dying compressor.

- Frozen evaporator coils – defrost timer failure, clogged drain, or humid air sneaking through bad gaskets.

- Loud compressor – grinding or squealing signals worn bearings or loose mounts.

- Sweet chemical odor – usually a refrigerant leak that requires EPA-certified service.

Ignore these and costs climb fast. Compressor replacement runs $200-$700 for parts alone, so early action matters.

Quick DIY Checks Before Dialing Tech

- Thermostat test – set to the coldest point; a click confirms it’s sending power.

- Breaker panel – reset one time only; a second trip means call a pro.

- Defrost timer – manually advance through a cycle to be sure the compressor restarts.

- Door seal – close on a dollar bill; easy removal = gasket trouble.

- Clear airflow – move boxes and vacuum obvious dust on coils.

More info about temperature control dives deeper into thermostat calibration.

When to Bring in a Technician

- Temperatures stay high after the checks above.

- Ice extends from evaporator to compressor.

- Any hint of refrigerant odor.

- Repeated alarms or short-cycling.

- Electrical arcing, burning smells, or motors that won’t start.

American Mortuary Coolers supports facilities across Tennessee, Georgia, Illinois, and the rest of the contiguous U.S. Calling early turns potential disasters into quick repairs.

Frequently Asked Questions about Walk-In Cooler Maintenance

What is the recommended temperature range for coolers and freezers?

Walk-in coolers should stay between 35°F-41°F, with 35°F being ideal for most applications. This range keeps your products from freezing while staying safely below the dangerous 40°F mark where harmful bacteria start multiplying rapidly.

Walk-in freezers need much colder temperatures of -10°F to 0°F, with -10°F being the sweet spot for most frozen goods. If you're storing ice cream or other premium frozen products, you'll want to go even colder - around -18°F to -20°F.

These aren't just suggestions - they're based on FDA requirements and NSF/ANSI Standard 7 for commercial refrigeration. Getting the temperature right isn't just about walk in cooler maintenance, it's about keeping your products safe and staying compliant with health regulations.

Here's something many people don't realize: even a few degrees can make a huge difference. At 42°F, you're already in the danger zone where bacteria like Salmonella can start growing. At 32°F, your products might freeze and lose quality. That narrow window is why consistent monitoring matters so much.

How often should coils and drain lines be cleaned?

Condenser coils need attention monthly if you're in a dusty environment, but you can stretch it to quarterly cleaning in cleaner conditions. Think about where your unit sits - if it's near a busy loading dock or in an area with lots of foot traffic, dust and debris accumulate faster.

Evaporator coils should be cleaned every 2-3 months for coolers and monthly for freezers. Freezers build up ice faster, which means more work for those coils and more frequent cleaning needs.

Drain lines require monthly inspection and cleaning, but bump that up to bi-weekly if you're running a freezer. Ice formation in drain lines is sneaky - it starts small but can quickly block the entire system, leading to water backup and potential damage.

Professional technicians should give your drain lines a thorough inspection annually. They'll check electrical connections and test those drain line heaters that keep freezer drains from icing up. It's one of those tasks that looks simple but benefits from experienced hands.

How do I know it's time to replace my walk-in?

This is the question nobody wants to face, but sometimes replacement makes more financial sense than continued repairs. Consider replacement when repair costs hit 50% of what a new unit would cost, or when your walk-in is over 15 years old and breaking down frequently.

Watch for these red flags: your unit can't maintain proper temperatures despite professional repairs, your energy bills keep climbing compared to newer models, or you're dealing with repeated compressor failures and refrigerant leaks. Structural problems with panels or insulation are also serious warning signs.

Sometimes the decision gets made for you - if your unit uses obsolete refrigerant that requires expensive conversion, replacement might be your only practical option.

Here's the encouraging news: a well-maintained walk-in cooler can last 10-15 years easily, and we've seen some units operate effectively for over 30 years. The key is that regular maintenance - it's what separates the units that last decades from those that fail after just a few years.

At American Mortuary Coolers, we've helped funeral homes across Tennessee and surrounding states make these tough decisions. Sometimes a repair makes sense, sometimes replacement is the smarter long-term investment. The difference usually comes down to how well the unit has been maintained throughout its life.

Conclusion

Proper walk in cooler maintenance turns cold storage from a liability into a long-term asset. By following the seven tactics in this guide—daily logs, monthly coil and drain cleaning, yearly professional tune-ups, tight temperature control, component care, smart airflow, and timely service calls—funeral homes and healthcare facilities cut energy use, avoid product loss, and dramatically extend equipment life.

A well-kept unit stays between 35 °F-41 °F (coolers) or -10 °F-0 °F (freezers), runs up to 27 % more efficiently, and can serve reliably for 30 years instead of the usual 10-15. Catching issues early also avoids big-ticket repairs like a $700 compressor swap.

Maintenance pays back every day through lower utility bills and fewer emergencies. Pick one action—start that temperature log or schedule next month’s coil cleaning—and build from there. Your future self (and your budget) will be grateful.

More info about cooler services connects you with parts and professional support from American Mortuary Coolers.