Why Steel Prep Tables Are Essential for Professional Workspaces

A steel prep table is a durable work surface made from stainless steel that provides a hygienic, easy-to-clean workspace for food preparation, medical procedures, and industrial tasks. Here's what you need to know:

Key Features:

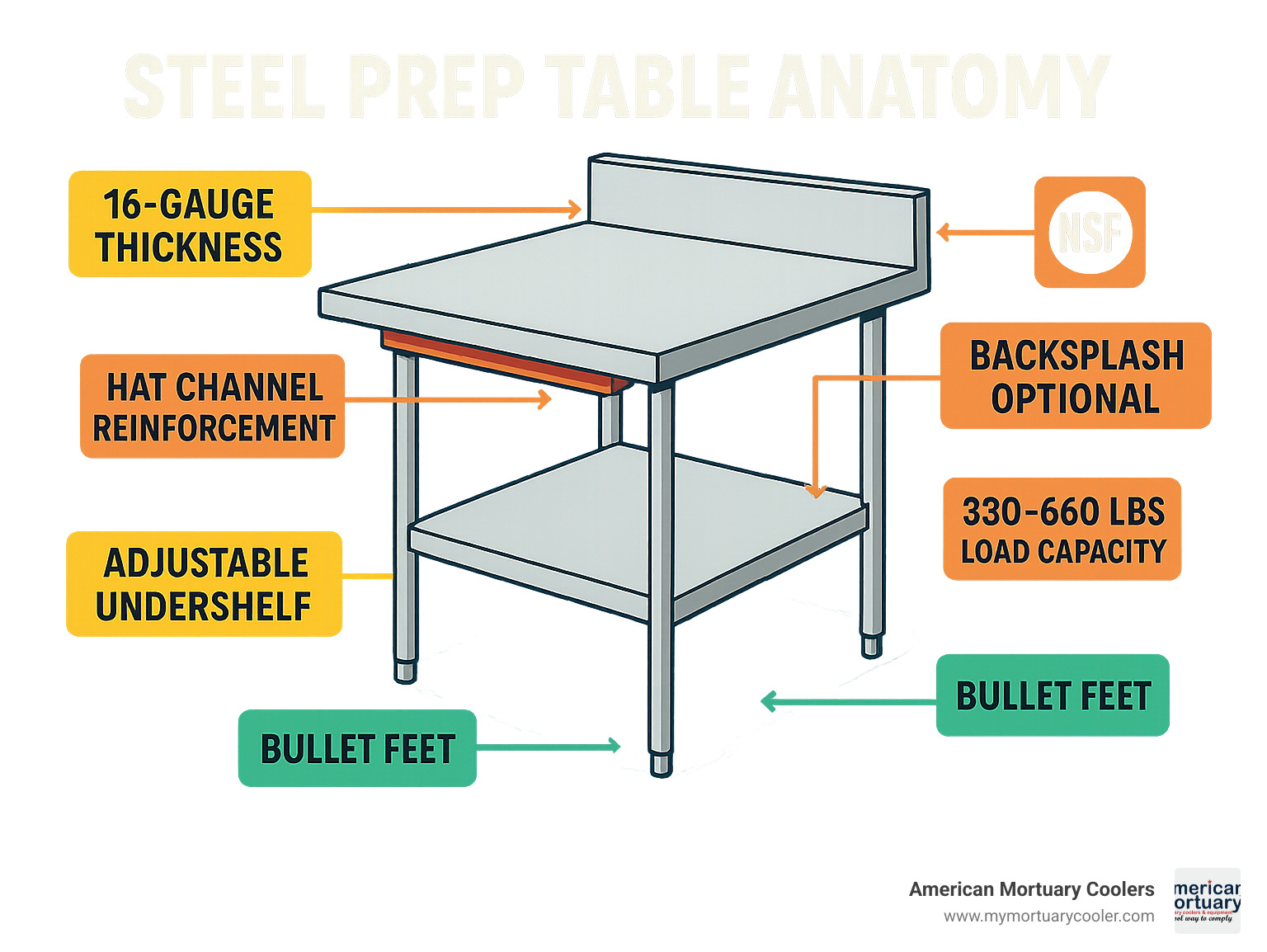

- Material: 14-18 gauge stainless steel (304 or 430 grade)

- Sizes: Range from 12"×24" to 72"×30"

- Capacity: Support 330-660 lbs evenly distributed

- Certifications: NSF-listed for food safety compliance

- Price Range: $90-$1,500 depending on size and features

Common Types:

- Open base tables with adjustable undershelves

- Tables with backsplash (1¼" to 10" height)

- Mobile units with locking casters

- Specialty models with sinks or refrigerated wells

Steel prep tables have become the backbone of professional kitchens, medical facilities, and industrial workspaces because they resist corrosion, clean easily, and handle heavy daily use. Whether you're outfitting a restaurant kitchen, hospital prep area, or funeral home embalming room, choosing the right steel prep table involves understanding gauge thickness, stainless steel grades, size requirements, and compliance certifications.

I'm Mortuary Cooler, a national-level supplier specializing in professional-grade equipment including steel prep table solutions for funeral homes and medical facilities. With years of experience helping facilities choose durable, compliant work surfaces, I'll guide you through everything you need to know to make the right steel prep table investment.

Easy steel prep table word list:

What Is a Steel Prep Table? Primary Uses and Types

A steel prep table is a flat stainless steel workspace built on a sturdy frame, designed for places where cleanliness can't be compromised. The non-porous stainless steel surface resists bacteria and wipes clean with ease - which is why you'll find these tables everywhere from busy restaurant kitchens to hospital prep rooms.

These tables show up in unexpected places. Restaurants and bakeries rely on them for food prep, but we've also delivered them to hospitals for medical equipment staging, garages for automotive work, and funeral homes where hygiene and durability are critical.

Most tables use 14-gauge or 18-gauge stainless steel for the top (thicker gauge means more durability). Nearly all include an adjustable undershelf - usually galvanized steel to keep costs reasonable while providing crucial storage space underneath.

Many models come with a backsplash that ranges from a simple 1¼-inch lip to a full 10-inch wall. For facilities that need NSF certification (restaurants, hospitals, food service), these tables meet all requirements for commercial food handling. The heavy-duty capacity typically ranges from 330 to 660 pounds evenly distributed.

Choosing the Right Steel Prep Table for Your Space

Start by mapping out your workflow zones. Where will you handle raw ingredients versus finished products? How will you prevent cross-contamination between different tasks? These aren't just good practices - they're often required for health department compliance.

Task separation is crucial. A bakery kneading dough has different needs than a restaurant prepping vegetables. If you're running mobile catering setups, tables with locking casters become game-changers. More info about choosing sink tables can help when considering models with integrated sinks.

Popular Steel Prep Table Sub-categories

Open base models feature an exposed frame with adjustable undershelves, giving maximum flexibility for storage bins and equipment while keeping everything accessible for cleaning.

Enclosed cabinet styles add hinged doors or drawers for secure storage. Refrigerated prep tables combine cold storage wells right in the work surface with refrigerated cabinet storage below.

Mobile models with locking casters let you reconfigure your workspace on demand, invaluable for facilities that need flexibility or thorough cleaning access.

Key Features to Evaluate Before You Buy

When shopping for a steel prep table, understanding gauge thickness becomes your first line of defense against buyer's remorse. Lower numbers mean thicker, stronger metal. A 14-gauge table gives you serious durability and can handle the heaviest kitchen equipment, while 18-gauge works perfectly for lighter tasks and keeps more money in your pocket.

Our heavy-duty tables can support up to 660 pounds evenly distributed on the top shelf and 330 pounds on the undershelf.

The stainless steel grade you choose makes a bigger difference than most people realize. Type 304 stainless steel stands up to everything - salt, acids, daily cleaning chemicals - without showing its age. Type 430 costs less upfront but doesn't have the same corrosion-fighting power.

Hat channels and cross-bracing underneath your table keep your tabletop from turning into a trampoline when you're working. Quality tables have these reinforcements welded right to the underside.

Gussets at the leg connections add rock-solid stability that lasts for years. Your adjustable undershelf should move smoothly without requiring tools. This adjustability is essential for meeting health department clearance requirements.

If you're considering a mobile table with casters, don't settle for cheap wheels. Heavy-duty swivel casters with reliable locks make the difference between a useful mobile workstation and a runaway table.

Rounded edges are huge for safety and cleaning. Sharp corners hurt when you bump into them, plus they create cleaning nightmares where bacteria can hide.

NSF certification isn't optional if you're in foodservice - it's the gold standard that proves your table meets strict public health requirements.

Steel Prep Table Maintenance Checklist

Daily care starts with a good wipe-down using food-safe cleaners and microfiber cloths. Skip the chlorine-based cleaners - they'll slowly damage your stainless steel. Stick with pH-neutral soaps or specialized stainless steel cleaners.

Weekly polishing keeps your table looking professional and prevents scratching. Always follow the grain direction of the steel. Don't forget to check and adjust those bullet feet regularly.

Monthly deep maintenance involves checking all nuts and bolts. Daily use creates constant small vibrations that gradually loosen fasteners. For mobile tables with casters, regular wheel cleaning prevents debris buildup that can jam steering or lock mechanisms.

Comparing Materials, Gauges, and Alternate Work-Top Options

When shopping for a steel prep table, understanding material differences can save you hundreds of dollars - or cost you thousands if you choose wrong.

Type 304 stainless steel is the workhorse of commercial kitchens and medical facilities. It contains higher levels of chromium and nickel, making it practically bulletproof against corrosion. I've seen 304 tables in busy funeral homes that still look pristine after 15 years of daily embalming chemical exposure.

Type 430 stainless steel offers a middle ground that works well for lighter applications. It has good corrosion resistance and costs significantly less than 304. However, in high-chemical environments or heavy-use situations, you'll see wear patterns and potential corrosion issues that 304 simply doesn't develop.

Many manufacturers use galvanized steel support structures for legs and undershelves while keeping the work surface stainless. This hybrid approach makes sense - you get corrosion resistance where moisture and chemicals matter most, while controlling costs on structural components.

Wood butcher block tops have their place, especially in bakeries. Wood provides better grip for kneading dough and doesn't conduct heat like metal. But wood requires careful maintenance and isn't suitable for environments requiring frequent chemical sanitization.

The cost versus durability equation is straightforward: 14-gauge 304 stainless costs the most initially but lasts decades. 18-gauge 430 stainless offers good value for moderate use. When you factor in replacement costs and downtime, stainless steel usually wins the long-term value game.

Steel Prep Table vs Wood & Plastic

Knife marks tell an interesting story. Stainless steel will show cut marks over time, but these are surface scratches that don't create bacterial harboring spots. Plastic cutting boards develop deep grooves that can trap food particles and bacteria. Wood shows knife marks too, but properly maintained wood has natural antimicrobial properties.

Thermal resistance is where stainless steel really shines. You can set hot pans directly on the surface without worry - something that will melt plastic and can char wood.

Sanitation scores overwhelmingly favor stainless steel in commercial applications. The surface cleans easily with standard sanitizers and doesn't absorb liquids or odors.

The upfront price comparison usually favors wood and plastic, but that's where the savings end. A quality steel prep table can serve you for decades with basic maintenance, while facilities using alternatives often face replacement costs every 3-5 years.

Stainless Steel Prep Tables | TRINITY showcases how different materials and configurations affect both price and performance.

Sizes, Accessories, Customization & Price Ranges

Steel prep table sizes range from compact 12"×24" units perfect for small spaces to massive 72"×30" spec line tables that can handle industrial-level prep work. The most popular sizes fall in the 48"×24" to 60"×24" range.

Standard height runs 34-36 inches, designed for comfortable standing work. Custom heights are available for specific applications or ergonomic requirements.

Overshelves add valuable storage without consuming floor space, perfect for frequently used items. Double-overshelf configurations can nearly triple your storage capacity while maintaining the same footprint.

Drawers integrate seamlessly into many table designs, providing secure storage for utensils, small equipment, or ingredients. Sinks can be integrated into tabletops, creating all-in-one prep and wash stations.

Marine edges cut down on spillage and drips, featuring a raised lip around the table perimeter. Backsplash heights range from 1¼" to 10", with most applications falling in the 4-6" range.

Custom cutouts accommodate sinks, equipment, or specialized tools. Logo etching adds a professional touch for facilities wanting to brand their equipment.

Price tiers break down roughly as follows:

- Economy 18-gauge models: $90-$300

- Standard 16-gauge tables: $200-$600

- Heavy-duty 14-gauge units: $400-$1,000

- Specialty configurations: $800-$1,500+

Bulk discounts often apply for multiple unit orders. More info about embalming table options shows how specialized applications can benefit from custom features.

Add-On Accessories That Boost Productivity

Ingredient drawers transform prep tables into complete workstations, keeping frequently used items at fingertip level. Overshelves don't just add storage - they create organized zones that speed up prep work.

Foldable legs allow tables to collapse for storage or transport, perfect for catering operations. Casters with brakes provide mobility when needed and stability when working.

Cleaning, Compliance, and Longevity Tips

Keeping your steel prep table in top condition isn't rocket science, but doing it right makes all the difference between a table that lasts decades and one that looks worn out after a few years.

Our three-step cleaning process works for everything from light daily maintenance to deep sanitizing. Start by clearing away all debris and food particles. Next, wash with appropriate cleaners using smooth, even strokes. Finally, apply approved sanitizers and let them work according to label directions.

Here's where many people go wrong: avoid chlorine-based cleaners at all costs. Chlorine causes permanent damage that can't be reversed. Instead, stick with pH-neutral soaps or cleaners specifically designed for stainless steel.

Microfiber cloths are your best friend for daily cleaning. They grab grease and grime without scratching, unlike paper towels. Always wipe following the grain direction of the steel - this prevents scratching and keeps your table looking professional.

The polishing step that most people skip actually creates a protective barrier against stains and fingerprints. Use stainless steel polish sparingly and work it in following the grain direction.

OSHA slip safety requirements mean keeping floors around your prep tables clean and dry. Spills happen, but letting them sit creates liability issues and safety hazards.

NSF audits examine both your equipment and your cleaning procedures. Inspectors want to see documentation of cleaning schedules and evidence that you're using approved sanitizers.

Steel Prep Table Safety & Regulatory Must-Knows

NSF certification isn't optional for commercial food operations - it's typically required by law. This certification means your table has been tested for cleanability, material safety, and structural integrity.

California Proposition 65 warnings appear on many stainless steel products because of trace amounts of lead and nickel used in manufacturing. This doesn't affect the safety of the finished product during normal use.

Load limits must be respected to prevent both structural failure and serious injuries. Even our heaviest-duty tables have limits - typically 660 pounds evenly distributed on the top surface and 330 pounds on undershelves. The key word is "evenly" - concentrated loads can cause failure even within these limits.

Edge-radius ergonomics matter more than you might think. Sharp edges create pressure points that cause fatigue during extended use. Properly rounded edges distribute pressure evenly, reducing strain on wrists and arms.

Frequently Asked Questions about Steel Prep Tables

How does 304 stainless differ from 430 in real kitchens?

Type 304 stainless steel is like the reliable workhorse that keeps going year after year, while Type 430 is the budget-friendly option that gets the job done but might show its age sooner.

In real-world use, 304 stainless steel handles acidic substances, salt exposure, and aggressive cleaning chemicals without breaking a sweat. We've visited funeral homes where 304 tables still look pristine after 20 years of daily embalming chemical exposure. Meanwhile, 430 tables in the same environment might start showing pitting or discoloration after just a few years.

The secret lies in the higher nickel content in 304 - it's what gives the steel that extra resistance to rust and staining. For high-volume operations or anywhere you use strong disinfectants regularly, that extra upfront cost for 304 pays for itself in longevity and appearance retention.

What weight can a typical steel prep table support safely?

Most commercial-grade steel prep tables can handle 650-660 pounds evenly distributed on the top surface, with undershelves safely supporting around 330 pounds. But these ratings assume you're spreading that weight around evenly.

Placing a heavy piece of equipment in one spot creates stress concentrations that can cause problems even if you're well under the total weight limit. We've seen tables damaged by placing a 150-pound mixer on one corner, even though the table could theoretically handle 650 pounds total. Always distribute weight evenly across the surface.

Can I retrofit casters or overshelves after purchase?

This is one of our most common questions, and the answer is usually yes - but it depends on how your original steel prep table was built.

Tables with threaded leg inserts are the easiest to work with. You can usually swap out the feet for caster stems without any major modifications.

Solid leg tables require more creativity. Sometimes you'll need to drill mounting holes or make other modifications.

Overshelves present a bigger challenge because they need proper mounting points that basic tables might not have. Many manufacturers offer retrofit kits designed specifically for their table lines.

Our advice? Start by checking with your original manufacturer first. They'll know exactly what works with your specific table model.

Conclusion

Finding the perfect steel prep table doesn't have to be overwhelming when you focus on what really matters for your workspace. The fundamentals are straightforward: match the gauge thickness to your workload, choose the right stainless steel grade for your environment, size it properly for your space, and add the accessories that make your daily tasks smoother.

Here at American Mortuary Coolers, we've been helping professionals across the country make these decisions for years. From our base in Tennessee, we've shipped quality equipment to facilities throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions - and we've learned that the right prep table setup makes all the difference in how smoothly your operation runs.

The truth is, a quality steel prep table pays for itself over time. You'll spend less on maintenance, work more efficiently, and stay compliant with health and safety regulations without the headaches that come with inferior equipment.

Think of it this way: your prep table is like the foundation of a house. You want it solid, reliable, and built to last. Cutting corners here affects everything else you do on top of it.

Whether you're setting up a new facility or upgrading existing equipment, we're here to help you make the right choice. A well-chosen steel prep table becomes the backbone of efficient, safe operations that serve you reliably for decades to come.

Ready to explore more professional-grade solutions? Check out our complete range of equipment at More info about mortuary cooler solutions, where we bring the same commitment to quality and durability to everything we build.