Why Walk-In Fridges Are Essential for Commercial Operations

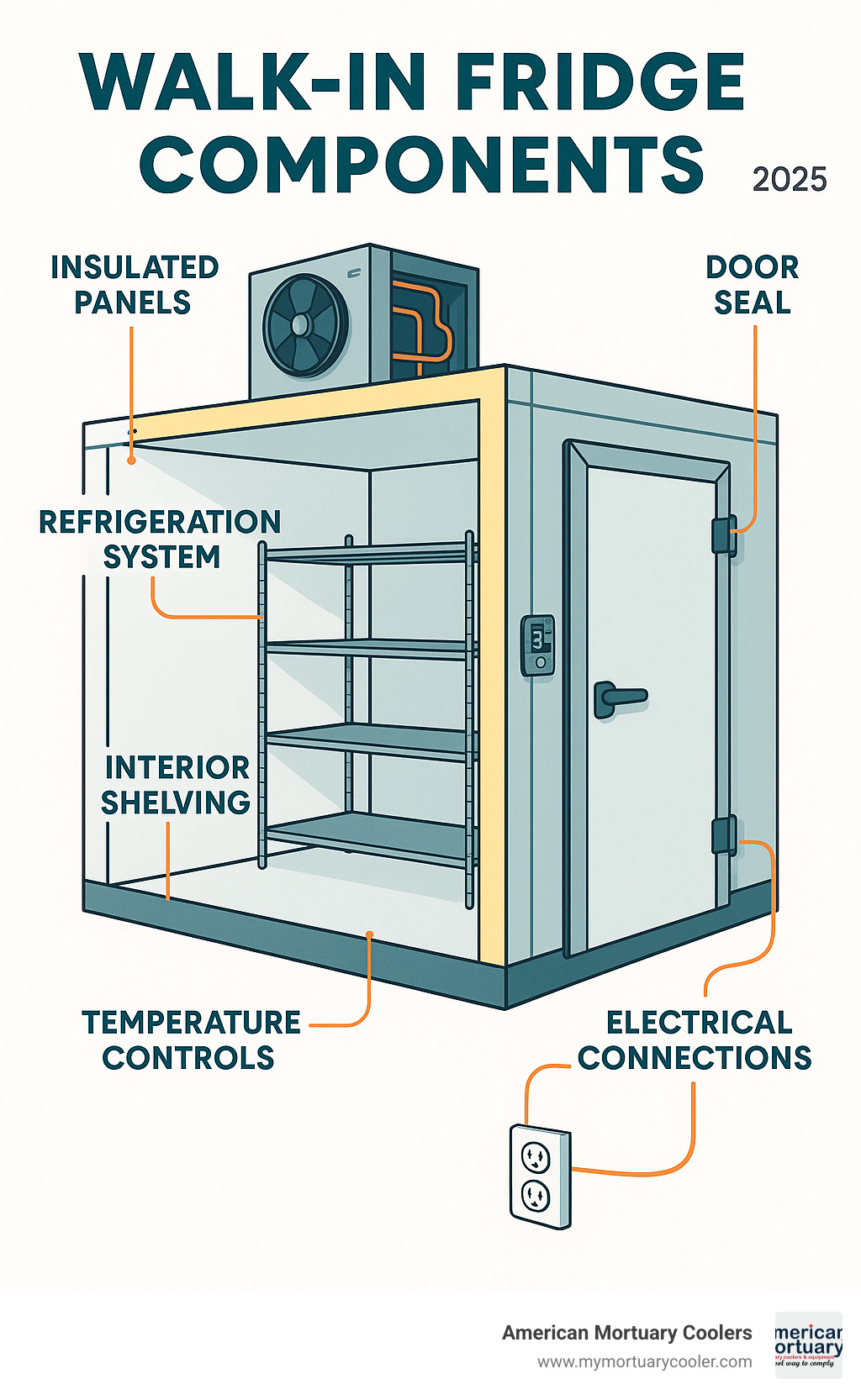

A walk-in fridge is a large-scale refrigerated storage unit that allows staff to enter and organize inventory inside the unit itself. These commercial-grade systems maintain precise temperatures between 32°F and 55°F, making them ideal for storing perishable goods in high-volume operations.

Key Walk-In Fridge Benefits:

- Storage capacity: One cubic foot accommodates approximately 28 lbs of food

- Temperature control: Coolers operate at 35°F, freezers at -10°F

- Durability: Average lifespan of 15 years with proper maintenance

- Energy efficiency: Modern units meet EISA standards with R-29+ insulation

- Versatility: Available in sizes from 6' to 60' length configurations

Walk-in refrigeration systems serve diverse industries beyond food service. Restaurants rely on them for bulk ingredient storage, while medical facilities use specialized versions for vaccine preservation at 35-38°F. Funeral homes require mortuary coolers that maintain consistent temperatures for body preservation, and breweries install keg coolers with glass doors for product display.

The commercial refrigeration market continues growing as businesses recognize the cost savings and operational benefits. With walk-in fridges representing 12.2% of all restaurant equipment repair calls but lasting 15 years on average, choosing the right system upfront matters significantly.

We're American Mortuary Coolers, a Tennessee-based company specializing in walk-in fridge solutions for funeral homes and specialized facilities. Our experience includes helping directors steer space constraints and compliance requirements while finding durable, American-made walk-in fridge systems that improve their operations.

Why a Roundup Now?

The commercial refrigeration market is experiencing significant growth as businesses recognize the long-term value of quality walk-in fridge systems. With an average lifespan of 15 years and walk-in units accounting for 12.2% of restaurant equipment repair calls, making the right choice upfront saves thousands in maintenance costs.

Recent trends show a shift toward seamless construction methods and energy-efficient designs. Manufacturers are moving away from traditional metal panel systems toward one-piece fiberglass construction that eliminates thermal bridging and reduces energy consumption by up to 30%.

Best Walk-In Fridge Options for Every Industry

Finding the right walk-in fridge can feel overwhelming with so many options available. The good news? Each type serves specific industries and needs, making your choice clearer once you understand what's out there.

From basic coolers that keep your produce crisp to specialized mortuary chambers, today's walk-in fridge systems cover every temperature requirement. You'll find standard coolers, freezers, dual-temperature units, outdoor installations, modular kits, self-contained pods, glass-door displays, pharmaceutical rooms, mortuary chambers, and beer chillers.

Let's break down the best options for different situations, so you can find exactly what works for your operation.

Top Outdoor Walk-in Fridge Picks

When indoor space is tight, outdoor walk-in fridge units become your best friend. These tough systems handle everything Mother Nature throws at them while keeping your products perfectly chilled.

Polar King's fiberglass construction leads the pack here. Their seamless shells don't just look good – they're built to last decades outdoors. The snow load capacity hits 100 pounds per square foot, so you won't worry about winter damage. Plus, they're UV resistant up to 175°F, which means scorching summer days won't crack or fade the exterior.

You've got two main installation choices: thru-wall or freestanding configurations. Thru-wall units are brilliant for expanding storage without adding building space. We've helped funeral homes install these systems to connect indoor prep areas with outdoor storage, creating seamless workflow without expensive construction projects.

The seamless fiberglass design eliminates those pesky moisture intrusion points that plague traditional metal panels. This isn't just about avoiding leaks – it's about energy savings too. These units achieve thermal conductivity of only 0.04 BTUs, making them far more efficient than aluminum or steel alternatives.

Dual-Temp Walk-in Fridge Systems

Sometimes you need flexibility more than anything else. Combo cooler/freezer systems give you the best of both worlds in one footprint, perfect for operations with changing storage needs.

Split-system reefer containers offer incredible versatility with temperature ranges from 0°F to +86°F. These units let you store frozen goods one day and switch to produce storage the next. The heavy-duty pallet-jack floors handle serious weight, so you can move inventory efficiently without damaging the system.

Twenty-foot reefer containers with Thermo King refrigeration systems exemplify this flexibility. You get professional-grade cooling power with the convenience of container mobility. The T-rail aluminum flooring supports forklifts and pallet jacks, making these units ideal for high-volume operations.

For permanent installations, traditional combo units feature separate cooler and freezer compartments. This setup works perfectly for restaurants needing both fresh and frozen storage or funeral homes requiring different temperature zones for various needs.

Compact Indoor Walk-in Fridge Cubes

Space constraints don't have to limit your cold storage options. Capsule-pak systems pack everything into self-contained units that install in just 20 minutes with a simple electrical connection.

These monoblock units integrate the condensing unit and evaporator in one assembly. No separate outdoor condenser, no refrigeration lines running through walls, no complicated installation. Just plug it in and start using it.

The floorless panel design adapts to your existing floor structure, eliminating expensive floor modifications. You only need 2 feet of ceiling clearance above the unit, making these perfect for retrofit installations in existing buildings.

We've helped funeral homes install these systems in prep rooms without major renovations. The plug-and-play design means minimal downtime and lower installation costs compared to traditional split systems.

Specialty & Mortuary Options

Some industries need more than basic refrigeration. Specialized walk-in fridge applications require precise temperature control and unique features that standard units can't provide.

Cadaver coolers maintain optimal 35-40°F temperatures for body preservation while meeting strict health department requirements. These units feature stainless steel interiors with rounded corners for easy sanitization and specialized airflow patterns that ensure consistent temperatures throughout the space.

Morgue modules and blast chill tunnels serve funeral homes with high-volume needs. Blast chillers rapidly cool bodies to -30°F minimum when required, while standard morgue units provide reliable long-term storage.

Floral storage units maintain 33-35°F temperatures that keep cut flowers fresh for maximum display life. Vaccine storage requires even tighter control at 35-38°F with precise humidity monitoring for regulatory compliance.

Pharmaceutical cold rooms need data logging capabilities and alarm systems that alert staff immediately if temperatures drift outside acceptable ranges. These systems often include backup power connections and redundant cooling systems for critical applications.

Each specialty application demands specific design considerations. That's why we work closely with funeral directors to understand their exact needs before recommending solutions.

For comprehensive information about mortuary-specific options, check out our detailed guide: A comprehensive guide to walk-in mortuary cooler options.

How to Choose the Right Size, Configuration & Location

Getting the size right for your walk-in fridge can make or break your operation. Too small, and you're cramming inventory like a game of Tetris. Too large, and you're paying to cool empty space for the next 15 years.

The industry standard of 28 pounds per cubic foot gives you a solid starting point, but real life isn't quite that neat. Your actual needs depend on what you're storing, how often you turn inventory, and how you organize everything inside.

When planning your space, 40-inch aisles aren't just a suggestion – they're essential for moving carts and equipment safely. We've seen too many facilities squeeze into tight spaces only to struggle with daily operations. Always plan for 20-30% growth capacity because businesses rarely shrink over a walk-in's lifespan.

| Feature | Indoor Walk-In Fridge | Outdoor Walk-In Fridge |

|---|---|---|

| Installation | Requires indoor floor space | Freestanding or thru-wall |

| Insulation | Standard R-29 | Improved weatherproofing |

| Maintenance | Climate-controlled environment | Weather exposure considerations |

| Cost | Lower initial cost | Higher upfront, saves indoor space |

| Utility Access | Easy electrical/plumbing | Requires outdoor-rated connections |

Walk-In Fridge Footprint Calculator

Calculating your walk-in fridge footprint isn't rocket science, but it does require honest assessment of your workflow. Start with your total inventory weight, divide by 28 pounds per cubic foot, then add 40% for aisle space and workflow.

Here's where many people go wrong – they calculate for today's needs and forget about tomorrow. Your funeral home might handle 50 cases annually now, but what about five years from now? Adding that 25% growth factor upfront costs far less than replacing your entire system later.

Product turnover matters more than you might think. High-turnover items need prime real estate near the door, while long-term storage can occupy the back corners. This affects your layout and ultimately your footprint requirements.

For smart shelving strategies that maximize your space, check out our Complete Guide to Walk-In Cooler Shelving Options.

Site & Utility Checklist

Nothing kills a smooth installation faster than finding your concrete slab resembles a skateboard ramp. Your foundation needs to be level within ¼ inch per 10 feet – any more and you'll fight door alignment issues forever.

Most walk-in fridge systems need 208-230 volt, 3-phase power with 15-30 amp capacity. This trips up many funeral homes because residential-style electrical won't cut it. We always recommend coordinating with your electrician before ordering to avoid delivery day surprises.

Clearance requirements aren't just manufacturer suggestions – they're your lifeline when service calls happen. Cramming a unit into a tight corner might save floor space, but it'll cost you dearly when technicians need access to the condenser.

Don't forget about local permits and codes. Some areas have specific requirements for seismic and wind load resistance, especially for outdoor installations. Getting this right upfront prevents expensive modifications later.

Budget & Warranty Snapshot

The sticker price on your walk-in fridge tells only part of the story. Smart buyers look at total ownership costs over the unit's 15-year lifespan, including installation, energy consumption, and maintenance.

Purchase versus rental makes sense for some operations, especially if you're testing a new location or have seasonal needs. However, most funeral homes benefit from ownership given their stable, long-term operations.

Refurbishment paths can extend your unit's life significantly. Quality manufacturers design their systems for component replacement – new doors, seals, and refrigeration equipment can add another decade of service.

Warranty coverage varies dramatically between manufacturers. Look for 12-25 year structural warranties that cover the foam core and panel construction. The best manufacturers offer 25 years on internal structure, 12 years structural coverage, and 5 years on compressors.

For detailed cost breakdowns and financing options, our Walk-In Cooler Pricing 101: Compare Walk-In Cooler Prices guide covers everything you need to make an informed decision.

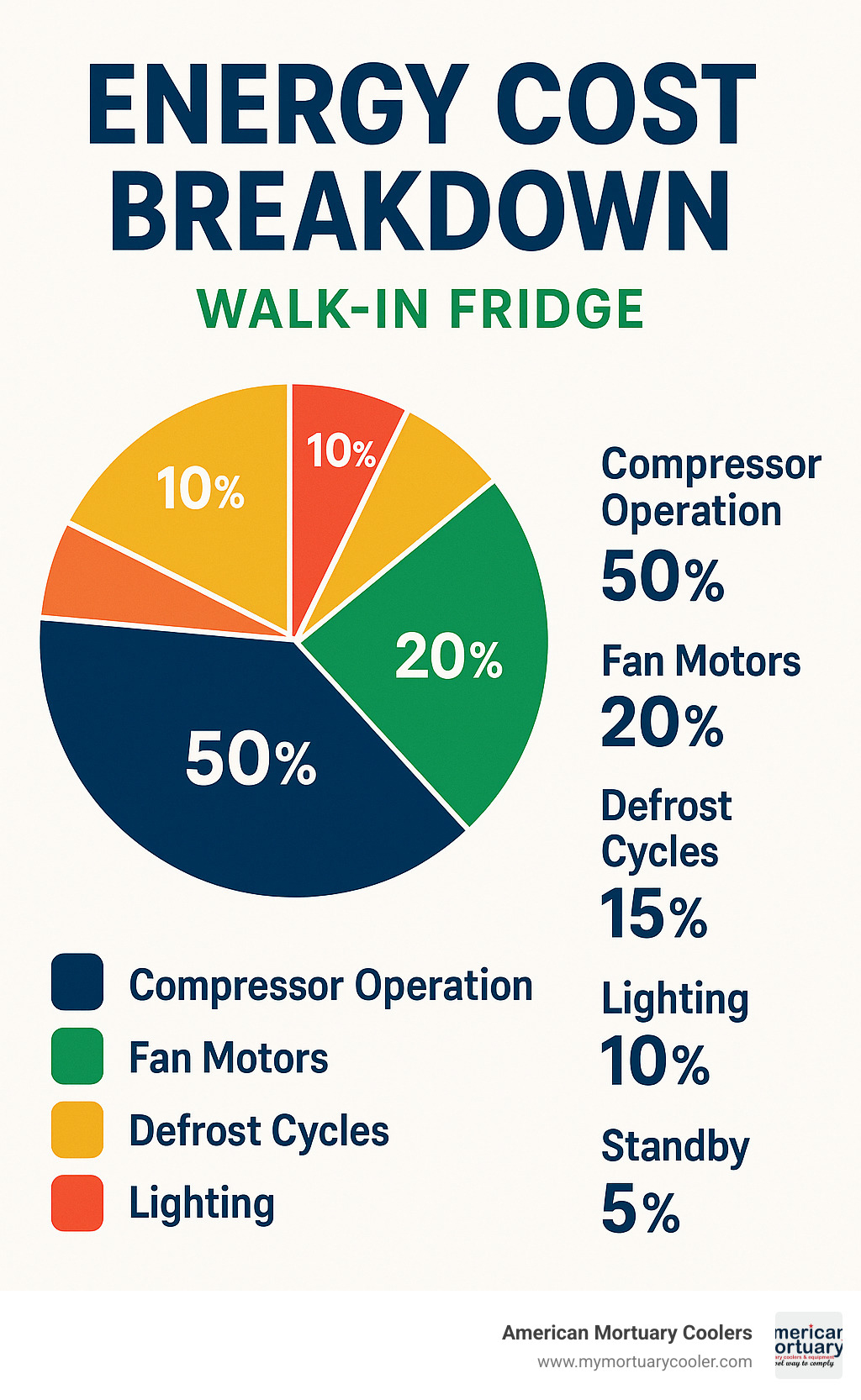

Energy Efficiency & Smart Features

Today's walk-in fridge systems are like the hybrid cars of commercial refrigeration - they're designed to work smarter, not harder. With energy costs climbing and environmental regulations tightening, manufacturers have responded with impressive innovations that can cut your operating costs by thousands of dollars annually.

The foundation of energy efficiency starts with superior insulation. Federal EISA requirements mandate minimum R-values of R-29 for coolers and R-32 for freezers, but premium units blow past these standards. Polyisocyanurate foam insulation outperforms traditional EPS foam significantly, while seamless fiberglass construction eliminates the thermal bridging that wastes energy in panel-joint systems.

Companies like Polar King have perfected seamless fiberglass shells with thermal conductivity of just 0.04 BTU - that's remarkably low. This construction method can slash energy consumption by 25-40% compared to conventional metal panel systems. When you're running a walk-in fridge 24/7 for 15 years, those savings really add up.

Modern systems also feature ECM fan motors with variable-speed operation that automatically adjust to actual cooling needs. Instead of running at full blast constantly, these smart motors ramp up and down based on temperature requirements. Combined with LED lighting that produces minimal heat, these upgrades create a more efficient overall system.

Smart controls take efficiency even further. Data loggers track energy usage patterns, while humidity control systems prevent excess moisture that forces the refrigeration system to work overtime. According to scientific research on thermal conductivity, proper moisture management can improve system efficiency by up to 15%.

Greener Walk-in Fridge Upgrades

Environmental consciousness isn't just good for the planet - it's good for your bottom line. The latest green technology upgrades deliver impressive energy savings while reducing your facility's environmental footprint.

Variable-speed compressors represent a major breakthrough in refrigeration efficiency. Instead of cycling on and off like traditional compressors, these units match their capacity to actual cooling demands. During lighter load periods, they run at reduced speed, consuming significantly less energy.

Improved Vapor Injection (EVI) scroll compressors excel in freezer applications where traditional systems struggle. These advanced compressors maintain high efficiency even at -40°F, making them perfect for blast freezer operations. We've seen funeral homes reduce their freezer energy costs by 30% after upgrading to EVI technology.

Low-GWP (Global Warming Potential) refrigerants are becoming the industry standard. These environmentally friendly refrigerants deliver the same cooling performance while dramatically reducing environmental impact if leaks occur. Night curtains provide another simple upgrade - these vinyl barriers minimize energy loss during off-hours when the walk-in fridge isn't being accessed frequently.

Some forward-thinking facilities are even exploring solar assist systems that supplement grid power with renewable energy. While the initial investment is higher, the long-term savings can be substantial, especially in sunny climates.

Monitoring & Compliance Tech

Compliance used to mean someone walking around with a clipboard and thermometer twice a day. Modern walk-in fridge systems have transformed this tedious process into automated precision that actually improves food safety and regulatory compliance.

IoT sensors continuously monitor temperature and humidity, transmitting real-time data to cloud-based systems. The FDA's 40°F rule for food storage becomes effortless to maintain when your system automatically alerts you to any temperature excursions before they become problems.

Automated alerts can reach you via text, email, or phone call within minutes of a temperature deviation. This rapid response capability prevents product loss and ensures continuous compliance. For funeral homes, this technology provides crucial documentation during health department inspections.

HACCP logging happens automatically in the background, generating detailed reports that satisfy regulatory requirements without manual data entry. These systems can store years of temperature data, providing the documentation trail that inspectors expect to see.

Remote monitoring capabilities mean you can check your walk-in fridge status from anywhere with internet access. Whether you're at home on the weekend or traveling for business, you'll know immediately if something needs attention.

At American Mortuary Coolers, we've helped many funeral directors implement these smart monitoring systems. The peace of mind alone is worth the investment - knowing your mortuary cooler is maintaining proper temperatures around the clock eliminates those middle-of-the-night worries about equipment failures.

Frequently Asked Questions about Walk-In Fridges

Let's tackle the most common questions we hear from customers considering a walk-in fridge purchase. These answers come from years of helping funeral directors and business owners find the right refrigeration solutions.

What temperature should my walk-in fridge run?

The right temperature for your walk-in fridge depends entirely on what you're storing inside. We get this question almost daily, and the answer isn't always as straightforward as you might think.

For general food storage, walk-in coolers run at 35°F, while walk-in freezers operate at -10°F. But here's where it gets interesting - different industries have their own specific requirements that can vary quite a bit from these standards.

In our mortuary work, we typically recommend 35-40°F for body preservation. Floral businesses need their units running slightly cooler at 33-35°F to extend cut flower life. Pharmaceutical storage requires the tightest control at 35-38°F with continuous monitoring to meet regulatory requirements.

The FDA sets the baseline for food storage at 40°F maximum to prevent harmful bacteria growth. You can find the complete federal guidelines at the FDA cold storage guidelines if you need the official documentation.

Here's something many people don't realize: temperature consistency matters more than hitting an exact number. A unit that fluctuates between 32°F and 38°F actually stresses your products more than one that holds steady at 36°F. Those temperature swings also make your compressor work harder, driving up energy costs.

How long does a walk-in fridge last?

Most walk-in fridge systems give you about 15 years of reliable service, but we've seen quality units run strong for 20-25 years with proper care. The key word there is "proper care" - regular maintenance makes all the difference.

Construction quality plays a huge role in longevity. Seamless fiberglass designs typically outlast traditional panel systems because they don't have joints that can fail over time. We've seen 30-year-old Polar King units still running like champs, while some panel systems start having issues after just 10 years.

Your usage patterns matter too. A busy restaurant's walk-in fridge that gets opened 50 times a day will wear differently than a funeral home unit that might only be accessed a few times weekly. Outdoor units face additional challenges from weather, but quality construction handles these stresses well.

Don't write off an older unit too quickly though. Refurbishment can extend life significantly when the basic structure remains sound. Replacing doors, seals, or even the entire refrigeration system costs far less than buying new. We've helped customers get another decade of service from units that seemed ready for retirement.

How do I stop mold and frost build-up?

Moisture is the enemy of any walk-in fridge, causing both unsightly mold growth and energy-wasting frost buildup. The good news? Most moisture problems are completely preventable with the right approach.

Door gaskets are your first line of defense - worn seals let humid air infiltrate constantly. We recommend checking gaskets monthly and replacing them at the first sign of cracking or poor sealing. It's a small investment that prevents big problems.

Staff training makes a surprising difference. Every time someone opens the door, humid air rushes in. Minimizing door-open times and organizing storage for quick access reduces moisture infiltration dramatically. Some of our busiest customers install vinyl strip curtains as an extra barrier - they're especially effective in high-humidity environments like busy kitchens.

Regular coil cleaning keeps airflow and drainage working properly. Dirty coils can't remove moisture effectively, leading to ice buildup that blocks airflow and forces the system to work harder. Clean drain lines are equally important - standing water becomes a breeding ground for mold and bacteria.

Age plays a role too. Insulation panels lose R-value after 10+ years, creating cold spots where condensation forms. If you're seeing persistent moisture issues in an older unit, the insulation might be telling you it's time for an upgrade.

For a deep dive into mold prevention, check out our comprehensive guide: How to Get Rid of Mold in a Walk-In Fridge Forever. It covers everything from daily maintenance to professional remediation techniques.

Conclusion & Next Steps

Finding the perfect walk-in fridge doesn't have to feel overwhelming. Throughout this guide, we've covered everything from outdoor fiberglass units that laugh in the face of harsh weather to compact indoor systems that install in just 20 minutes. The key is matching your specific needs with the right construction quality and features.

Think of your walk-in fridge as a 15-year investment partner. Those seamless fiberglass designs might cost more upfront, but they'll save you thousands in energy bills and repair calls over their lifetime. Smart monitoring systems keep you compliant with health regulations while giving you peace of mind that your products stay at the perfect temperature, even when you're not there.

We've seen funeral directors transform their operations with the right cooling solution. One client in Kentucky went from constantly worrying about temperature fluctuations to having a system so reliable they barely think about it anymore. That's the kind of confidence quality equipment brings to your business.

At American Mortuary Coolers, we understand that every facility has unique challenges. Maybe you're dealing with limited space, specific temperature requirements, or strict compliance standards. Our Tennessee-based team has helped hundreds of funeral homes steer these exact situations across all 48 contiguous states.

The beauty of working with specialists is that we speak your language. We know what health inspectors look for, understand the importance of reliable temperature control for your families' peace of mind, and can recommend solutions that fit both your space and budget constraints.

Ready to move forward? Reach out for a custom quote that addresses your specific situation. We'll walk you through sizing calculations, discuss site requirements, and make sure you understand exactly what's involved before any equipment leaves our facility.

For deeper technical details and industry insights, our comprehensive resource covers everything: Everything You Need to Know About Walk-In Refrigeration Units. Whether you're planning now or just exploring options for the future, having the right information makes all the difference.