Understanding the Cooler Bug Phenomenon Across Industries

Cooler bug issues affect everything from video game mechanics to commercial refrigeration systems, creating headaches for gamers, restaurant managers, and facility operators alike. Whether you're dealing with Pals that won't stay on cooling duty in Palworld or walk-in freezers that ice up overnight, these problems share common symptoms and solutions.

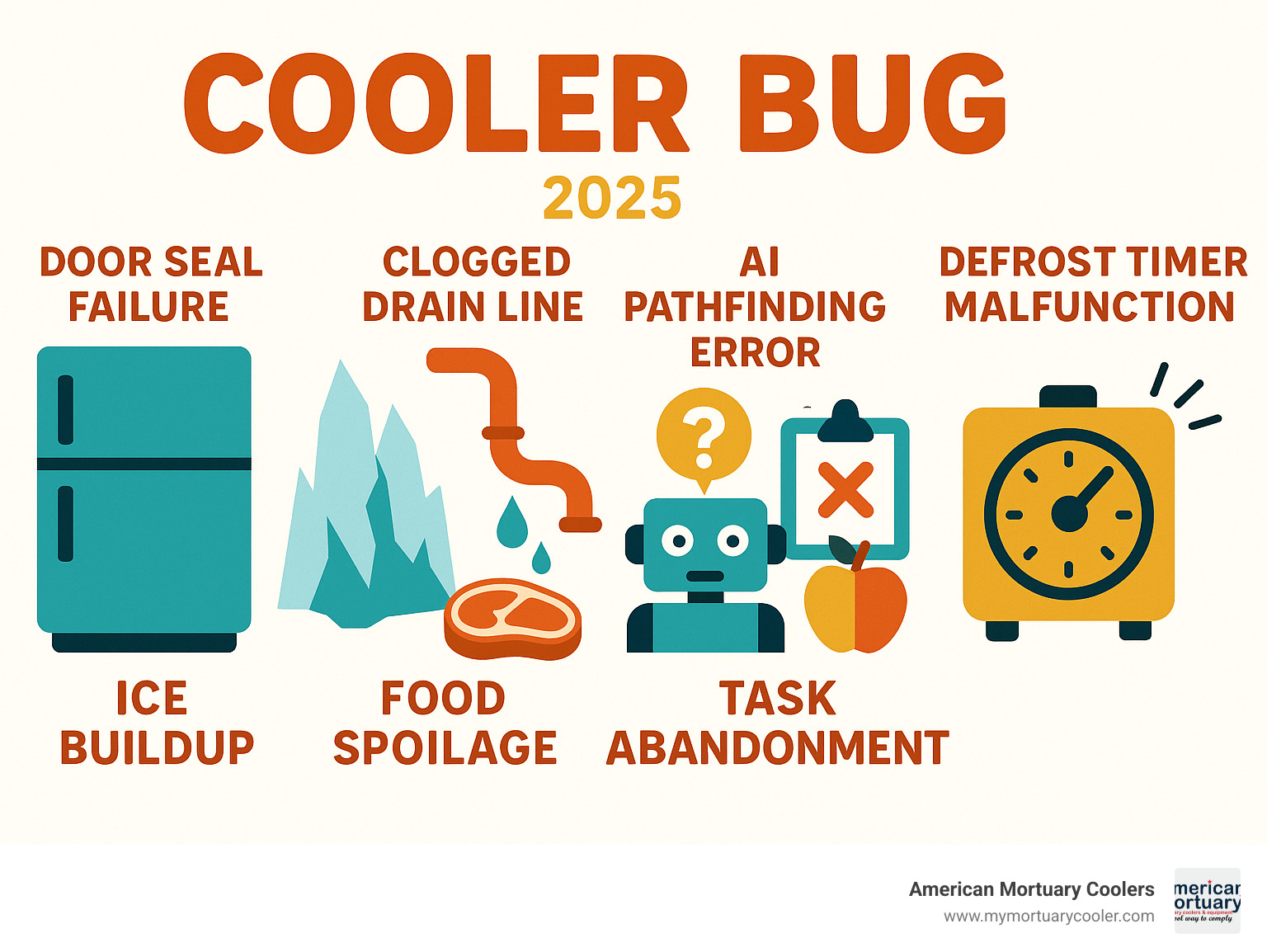

Quick Cooler Bug Reference:

- Gaming: AI characters abandon cooling tasks, food spoils despite assigned workers

- Commercial: Ice buildup, temperature fluctuations, compressor strain

- Pet Care: Feeder insects grow too fast in poorly controlled temperatures

- Common Fixes: Manual task assignment, gasket replacement, temperature monitoring

The research shows that over 60 user comments were generated on a single Palworld thread about cooler bugs, while multiple users report success with workarounds like manually throwing Pals onto coolers. In commercial settings, facility managers struggle with similar issues - door seals failing, defrost timers malfunctioning, and staff leaving doors open too long.

These problems cost money through spoiled inventory, higher energy bills, and frustrated customers. The good news? Most cooler bugs have straightforward fixes once you know what to look for.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with years of experience helping facilities solve temperature control challenges. Through working with funeral homes and commercial operators, I've seen how cooler bug issues can disrupt operations and learned which solutions actually work long-term.

What Exactly Is a Cooler Bug?

The term cooler bug might sound like tech jargon, but it's actually become the go-to phrase for describing when cooling systems just won't cooperate. Whether you're a gamer frustrated with AI characters who won't do their job, a restaurant manager dealing with a temperamental walk-in cooler, or a pet owner trying to keep feeder insects at the right temperature, you're probably dealing with the same basic problem.

In the gaming world, especially in Palworld, a cooler bug happens when your AI companions (called Pals) decide they have better things to do than keep your food cold. One player perfectly captured the frustration: "Pals abandon cooling duties to do other tasks because the game AI behaves like it has ADHD." Your carefully assigned cooling Pals will literally walk away from their posts, leaving your food to spoil while they go chase butterflies or whatever else catches their digital attention.

But step outside the gaming world, and you'll find the same term describes equally annoying real-world problems. Commercial refrigeration systems develop their own version of cooler bugs through hardware malfunctions that mess with temperature control. Door gaskets fail, drain lines get clogged, defrost timers go haywire, and compressors start acting up. A single loose door gasket can become "the biggest avoidable energy drain on a walk-in cooler," turning your efficient cooling system into an expensive ice-making machine.

Pet owners face their own cooler bug challenges when storing feeder insects like hornworms or crickets. Without proper temperature control, these little critters either grow too fast (expensive) or die too soon (also expensive). Community discussions show that temperature control problems pop up in at least 3 out of 5 reptile care forum posts about insect storage.

The latest community report from Palworld players shows just how widespread these cooling issues have become, affecting thousands of players who just want their digital food storage to work properly.

Cooler Bug 101: From Freezers to Video Games

Here's what makes the cooler bug phenomenon so interesting - it crosses industry lines because all cooling systems work on similar basic principles. Whether you're dealing with AI pathfinding in a video game or mechanical components in a commercial freezer, the failures usually trace back to the same root causes.

Task priority conflicts plague both digital and physical systems. In games, Pals ignore cooling duties when the system assigns higher priority scores to other tasks. In commercial settings, automatic defrost cycles might override temperature maintenance at the worst possible times.

Physical obstructions create problems everywhere. Blocked airflow, clogged drains, or damaged seals prevent proper operation in real coolers. Similarly, game environments with poor AI pathfinding create digital "obstructions" that prevent characters from reaching their assigned cooling stations.

Sensor failures cause chaos in both worlds. Faulty temperature readings trigger incorrect responses from automated systems, whether that's a malfunctioning thermostat in your walk-in cooler or buggy game code that can't properly detect when food needs cooling attention.

And let's be honest - human error plays a huge role too. Leaving doors open, improper loading, or skipping maintenance schedules cause real-world problems. In games, players often accidentally reassign Pals or place coolers in locations where AI can't properly access them.

Walk-in coolers develop ice build-up when warm, humid air sneaks in through damaged seals or when defrost cycles malfunction. Game coolers fail when AI characters can't steer to their assigned positions or when the task assignment system glitches out completely.

Top Signs You Have a Cooler Bug

Catching cooler bug symptoms early saves you money, time, and a lot of frustration. The warning signs are surprisingly similar whether you're dealing with pixels or real refrigeration equipment.

In gaming, watch for food spoilage despite having assigned cooling Pals. This is the classic sign that your AI workers are slacking off. You might also notice AI characters standing around near coolers without actually doing anything useful, or getting "no work available" error messages when your coolers clearly need attention. The most maddening symptom is watching Pals abandon their cooling duties to go do something completely unrelated.

Commercial refrigeration problems start with thin frost appearing on interior surfaces - this is your early warning system. Don't ignore it. Temperature fluctuations outside the 35-41°F range for coolers mean trouble is brewing. Ice buildup around evaporator coils or drain areas indicates your system is working overtime to fight humidity infiltration. Unusual compressor cycling or continuous operation suggests your equipment is struggling, and higher than normal energy bills often show up before you notice the physical symptoms.

For pet care storage, the signs include feeder insects growing faster than expected (they're too warm), premature insect mortality in storage containers (temperature stress), condensation inside containers (humidity control problems), and temperature readings above 50-60°F in areas meant for insect storage.

The golden rule across all applications: address these symptoms immediately. Even in commercial settings, just 5-10 minutes of an open door allows enough humid air inside to create freeze-up problems that take hours to resolve.

7 Best Products to Beat the Cooler Bug Today

After years of helping facilities solve temperature control challenges, I've learned that the right tools make all the difference in beating cooler bug problems. Whether you're dealing with AI characters that won't stay put in Palworld or walk-in freezers that build up ice overnight, these products address the root causes rather than just treating symptoms.

The beauty of tackling cooler bugs is that many solutions work across different industries. A good temperature monitor helps both restaurant managers and reptile owners maintain proper conditions. Smart thermostats prevent the temperature swings that cause problems in everything from gaming to commercial refrigeration.

Digital Defenders: Software & Sensor Picks

Smart thermostat controllers have revolutionized how we handle temperature control. These devices maintain precise temperatures with programmable cycles that prevent the wild swings that trigger most cooler bug issues. The best models offer accuracy within 0.1°F and let you monitor conditions from anywhere.

I've seen facilities cut their service calls in half just by installing remote temperature monitors with smartphone alerts. These devices catch problems while they're still small - before that slightly warm milk becomes a cooler full of spoiled inventory. Look for units that track both temperature and humidity, since keeping relative humidity between 50-60% prevents many common issues.

For gamers dealing with Palworld's notorious cooling problems, the community has developed some clever pathfinding fixes and assignment scripts. While these aren't commercial products, they often work better than waiting for official patches. The most reliable workaround involves manually throwing Pals onto coolers to force proper task assignment - it sounds odd, but multiple users report success with this method.

More info about temperature control walks you through setting up digital monitoring systems that prevent problems before they start.

Heavy-Duty Hardware: Commercial Cooler Solutions

Nothing beats a quality door gasket for preventing commercial cooler bugs. I've seen facilities struggle with ice buildup and high energy bills for months, only to solve everything with a simple gasket replacement. Premium gaskets with magnetic strips create proper seals that last for years, while cheap alternatives fail within months and cost more in the long run.

Heavy-duty vinyl strip curtains work wonders in busy kitchens where doors open constantly. These curtains can reduce ice buildup by 70% in high-traffic areas by blocking humid air from entering the cooler. Choose strips with proper overlap coverage and temperature ratings that match your application.

Regular maintenance prevents most mechanical failures, and professional coil cleaning brushes make this job much easier. Monthly coil cleaning removes the debris that causes compressor strain and temperature fluctuations. It's one of those simple tasks that prevents expensive repairs down the road.

Leak-proof storage containers might seem basic, but they prevent the cross-contamination and moisture issues that trigger many cooler bugs. Invest in containers with secure sealing mechanisms and clear visibility - you'll thank yourself during busy inventory periods.

More info about walk-in maintenance covers the maintenance strategies that keep commercial units running smoothly.

Pet-Care Champs: Insect Storage Coolers

Portable 6-pack electric coolers have become the go-to solution for reptile owners storing feeder insects. These units maintain the 50-60°F temperatures needed to slow hornworm growth rates, and they cost under $40. Remove the internal shelves to accommodate different container sizes, and you have a perfect insect storage system.

Programmable timer outlets provide precise temperature cycling without expensive thermostats. Set them for 5 hours on, 1 hour off cycles to maintain target temperatures without overcooling. This simple solution works with any electric cooler and prevents the temperature swings that kill feeder insects.

Humidity control pads solve the moisture problems that plague insect storage. These reusable pads prevent both desiccation and mold growth, keeping your feeder insects healthy until feeding time. Pair them with ventilated container organization systems that allow proper airflow while preventing escapes.

Gamer Fix Kits: Beat the In-Game Cooler Bug

Frost Pal figurines might seem like novelty items, but they represent something important - community knowledge about which creatures work reliably for cooling tasks. Experienced players have learned that dedicated frost Pals like Chillet work better than dual-function creatures that get distracted by other activities.

Assignment strategy guides compiled by the gaming community provide step-by-step instructions for avoiding cooler bug issues. These guides teach you how to manipulate AI behavior and prevent cooling task abandonment through proper Pal selection and base layout.

Task priority modification tools help players understand why their cooling systems fail. These include save file editors and game mods that adjust priority scores for different activities, ensuring your cooling Pals stay focused on their jobs.

External guide offers community-tested solutions that actually work for persistent cooler bugs in survival games.

Troubleshooting & Quick Fixes

When a cooler bug hits, you need solutions that work fast. After handling thousands of service calls, we've learned that most problems have simple fixes if you know where to look first.

The key is staying calm and working through issues systematically. Start with the easiest solutions before moving to more complex repairs. Most cooler bug problems stem from just a few common causes, and fixing them doesn't require advanced technical skills.

Gaming troubles often resolve with basic resets. If your Pals are ignoring the cooler, try fast traveling away from your base and coming back. This refreshes the AI pathfinding and usually gets them back to work. When that doesn't work, manually throw your Pals directly onto the cooler units - it forces them to engage with the task.

Sometimes the problem isn't the Pals at all. Sorting your storage containers can reset food spoilage timers as a temporary fix. For long-term success, assign frost-only creatures like Chillet to cooling duties. They won't get distracted by other tasks like multi-purpose Pals do.

Commercial cooler issues usually start with the door seals. Run your hand around the gasket edges feeling for air leaks or cold spots. Even small gaps let humid air in, causing ice buildup and temperature swings. You can often fix minor seal problems by cleaning debris from the gasket channels or adjusting the door hinges.

Coil cleaning solves about 90% of temperature control problems. Dirty evaporator coils can't absorb heat properly, while dirty condenser coils can't release it. Use soft brushes and avoid harsh chemicals that damage the fins. Clean coils mean better performance and lower energy bills.

Drain line problems cause water backup and ice formation around the evaporator. Flush the lines with warm water to clear clogs. If water doesn't drain freely, you've found your problem. Most drain issues come from food particles or debris blocking the line.

Timer cycling issues affect defrost operations. If your cooler isn't defrosting properly, try manually spinning the fan blades to check for obstructions. Sometimes a simple power cycle - shutting down for 15 minutes then restarting - resets electronic controls and fixes timing problems.

Refrigerant checks require looking for obvious signs like oil stains or frost patterns that suggest leaks. Low refrigerant causes temperature fluctuations and compressor strain. This usually needs professional attention, but identifying it early prevents major damage.

| Quick Fix | Time Required | Success Rate | Long-term Solution |

|---|---|---|---|

| Manual Pal Assignment | 2 minutes | 85% | Build dedicated cooling area |

| Door Gasket Adjustment | 10 minutes | 70% | Replace gasket completely |

| Coil Cleaning | 30 minutes | 90% | Monthly maintenance schedule |

| Defrost Timer Reset | 5 minutes | 60% | Timer replacement |

The most effective approach follows a simple pattern: identify what's wrong, test the easiest fix first, then move to component replacement if needed. Document what works so you can handle similar problems faster next time.

How to Fix Commercial Fridge Problems walks through detailed repair procedures for complex cooler bug situations that need professional help.

Quick fixes buy you time, but addressing root causes prevents future problems. A properly maintained cooler rarely develops bugs in the first place.

Preventative Maintenance & Buying Guide

Preventing cooler bug problems costs far less than fixing them after failure. Our maintenance protocols, developed through years of working with funeral homes and commercial facilities, focus on high-impact activities that prevent the most common failure modes.

Daily Prevention Tasks:

- Visual Inspection: Check for frost buildup, unusual sounds, or temperature display errors

- Door Discipline: Train staff to minimize door-open times and ensure complete closure

- Surface Cleaning: Wipe down door handles, gaskets, and interior surfaces with mild soap

- Load Management: Maintain 75-90% capacity for optimal airflow without overloading

Weekly Maintenance:

- Temperature Logging: Record actual temperatures and compare to thermostat settings

- Gasket Inspection: Check door seals for damage, debris, or poor contact

- Drain Monitoring: Verify drain lines flow freely without backup or standing water

- Inventory Rotation: Practice FIFO (First In, First Out) to prevent product spoilage

Monthly Deep Maintenance:

- Coil Cleaning: Clean evaporator and condenser coils with appropriate brushes and solutions

- Fan Inspection: Check fan blades for damage, debris, or bearing wear

- Defrost System Test: Verify defrost cycles activate and complete properly

- Humidity Control: Monitor and adjust relative humidity to 50-60% range

Gaming-Specific Prevention:

- Dedicated Cooling Areas: Build coolers on isolated 2x2 foundations to prevent pathfinding conflicts

- Frost-Only Assignments: Use Pals with single cooling abilities rather than multi-function creatures

- Task Priority Management: Understand AI behavior patterns to predict and prevent task abandonment

Buying Guide Priorities:

- Reliability Over Features: Choose proven designs over complex systems with more failure points

- Service Network Access: Ensure local technician availability for major repairs

- Energy Efficiency: Calculate long-term operating costs, not just purchase price

- Scalability: Select systems that can grow with changing needs

Service contracts provide peace of mind but evaluate coverage carefully. The best contracts include preventative maintenance, emergency response, and parts coverage with guaranteed response times. We recommend bi-annual professional inspections at minimum.

How to Fix Evaporator Freeze Up explains advanced prevention techniques for the most damaging type of cooler bug.

Energy savings from proper maintenance often exceed service contract costs. A well-maintained cooler uses 15-20% less energy than one with dirty coils, worn gaskets, and improper loading practices.

Frequently Asked Questions about Cooler Bugs

Why does my food still spoil even with a working cooler bug fix?

This frustrating situation happens more often than you'd think, and there's usually a good reason behind it. When your cooler bug fix doesn't seem to work, you're likely dealing with what we call "surface fixes" - solutions that address the obvious symptoms while the real problem keeps running in the background.

In gaming situations, that inventory sorting trick that resets spoilage timers? It's like putting a band-aid on a broken pipe. It stops the immediate problem, but your AI characters are still wandering off to do other tasks instead of keeping your food cold. The underlying pathfinding issues haven't been solved.

Commercial coolers present similar challenges. You might replace a door gasket and think you're all set, but if the door frame itself is warped, that new gasket won't seal properly. Or maybe you cleaned those coils until they sparkled, but low refrigerant levels are still causing temperature swings that spoil your inventory.

The real eye-opener comes when you install continuous temperature monitoring. Many "fixed" coolers still experience those sneaky temperature fluctuations that compromise food safety, even when the average temperature looks fine on your display.

Which coolers are most prone to the cooler bug?

After years of working with cooling systems across different industries, we've noticed some clear patterns in which units struggle most with cooler bug issues.

In the gaming world, complex systems with multiple AI coordination requirements fail far more often than simple setups. Palworld's cooler boxes are notorious for problems because they require precise coordination between different game systems - and when one part glitches, everything falls apart.

Commercial walk-in coolers top our problem list, and it's not really their fault. These workhorses handle heavy daily use, multiple access points, and complex mechanical systems. Every door represents a potential failure point, and high-traffic environments constantly stress seals while introducing humid air that causes ice buildup.

Age plays a huge role too. Units over 10 years old start experiencing compound failures where small issues snowball into major problems. The insulation loses effectiveness gradually, seals become brittle, and components wear out at different rates.

Budget coolers with minimal insulation and basic components definitely fail more frequently than commercial-grade units. But here's something interesting we've learned - over-engineered systems with fancy digital controls can actually create more failure points than necessary. Sometimes simpler really is better.

How often should I service a cooler to avoid another cooler bug?

The honest answer is: it depends on how hard you're working your cooler and where it's located. But we've developed some practical guidelines based on thousands of service calls across our coverage areas.

High-use commercial applications like restaurants, hospitals, and funeral homes need the most attention. These units work around the clock under demanding conditions. Daily visual inspections catch problems early, while weekly temperature logging reveals developing issues before they become expensive failures. Monthly coil cleaning and quarterly professional inspections keep everything running smoothly.

Moderate-use applications in small offices or retail settings can stretch those intervals a bit. Weekly basic inspections, monthly temperature monitoring, and quarterly maintenance usually prevent most cooler bug problems from developing.

Light-use applications like home units or pet care storage need the least intensive schedules. Monthly inspections and quarterly cleaning, with annual professional service if needed, typically keep things running well.

Here's what we've learned from our service experience: well-maintained units typically operate 5-7 years between major repairs, while neglected systems often need emergency service annually. The math is pretty clear - preventative maintenance costs far less than emergency repairs.

Conclusion

Cooler bug problems don't have to be the bane of your existence. Whether you're battling AI pathfinding issues in Palworld, dealing with walk-in freezer ice buildup, or trying to keep your bearded dragon's hornworms from growing too fast, these frustrating problems actually have more in common than you might think.

After years of helping facilities across the country solve temperature-control challenges, we've found something interesting: most cooler bugs follow predictable patterns. The gaming community's "throw the Pal at the cooler" fix isn't that different from a technician manually resetting a defrost timer. Both solutions work around system failures that stem from similar root causes.

The real game-changer is prevention over reaction. Gaming communities figured this out when they started building dedicated cooling areas with frost-only Pals. Commercial operators learned it through expensive emergency service calls that could have been avoided with monthly coil cleaning. Pet owners finded it when their first batch of expensive feeder insects died from temperature swings.

Reliability matters more than fancy features. A simple thermostat that works consistently beats a smart system that glitches when you need it most. Safety comes from understanding your equipment and catching problems early, not from hoping they won't happen. The user experience improves dramatically when you stop fighting constant failures and start enjoying smooth operation.

At American Mortuary Coolers, we've built our reputation on understanding that cooling systems need to work when lives depend on them. Our custom mortuary coolers incorporate decades of lessons learned from installations across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania. When funeral directors trust us with their most critical equipment, we deliver solutions that eliminate cooler bugs through superior engineering and proven reliability.

The trust our customers place in us drives everything we do. Whether you're running a busy funeral home, managing a restaurant walk-in, or just trying to keep your pet's food fresh, you deserve equipment that works without constant babysitting.

Don't let another cooler bug ruin your day, spoil your inventory, or crash your game session. Take control with the maintenance strategies and solutions we've shared. Your future self will thank you when everything just works the way it should.

More info about cooler collections showcases our complete range of professional cooling solutions designed to eliminate cooler bugs through superior engineering and proven reliability.