Why Morgue Refrigeration Doors Service Maintenance Is Critical for Your Facility

Morgue refiregeration doors service maintenance directly impacts facility safety, regulatory compliance, and operational costs. When these doors fail, the consequences go far beyond temperature fluctuations—they threaten preservation integrity, staff safety, and your facility's reputation.

Essential Morgue Door Maintenance Schedule:

- Daily: Visual seal inspection and temperature logging

- Weekly: Gasket cleaning and ice removal

- Monthly: Hinge lubrication and alignment checks

- Quarterly: Professional seal integrity tests and sensor calibration

- Annually: Complete door system overhaul and compliance audit

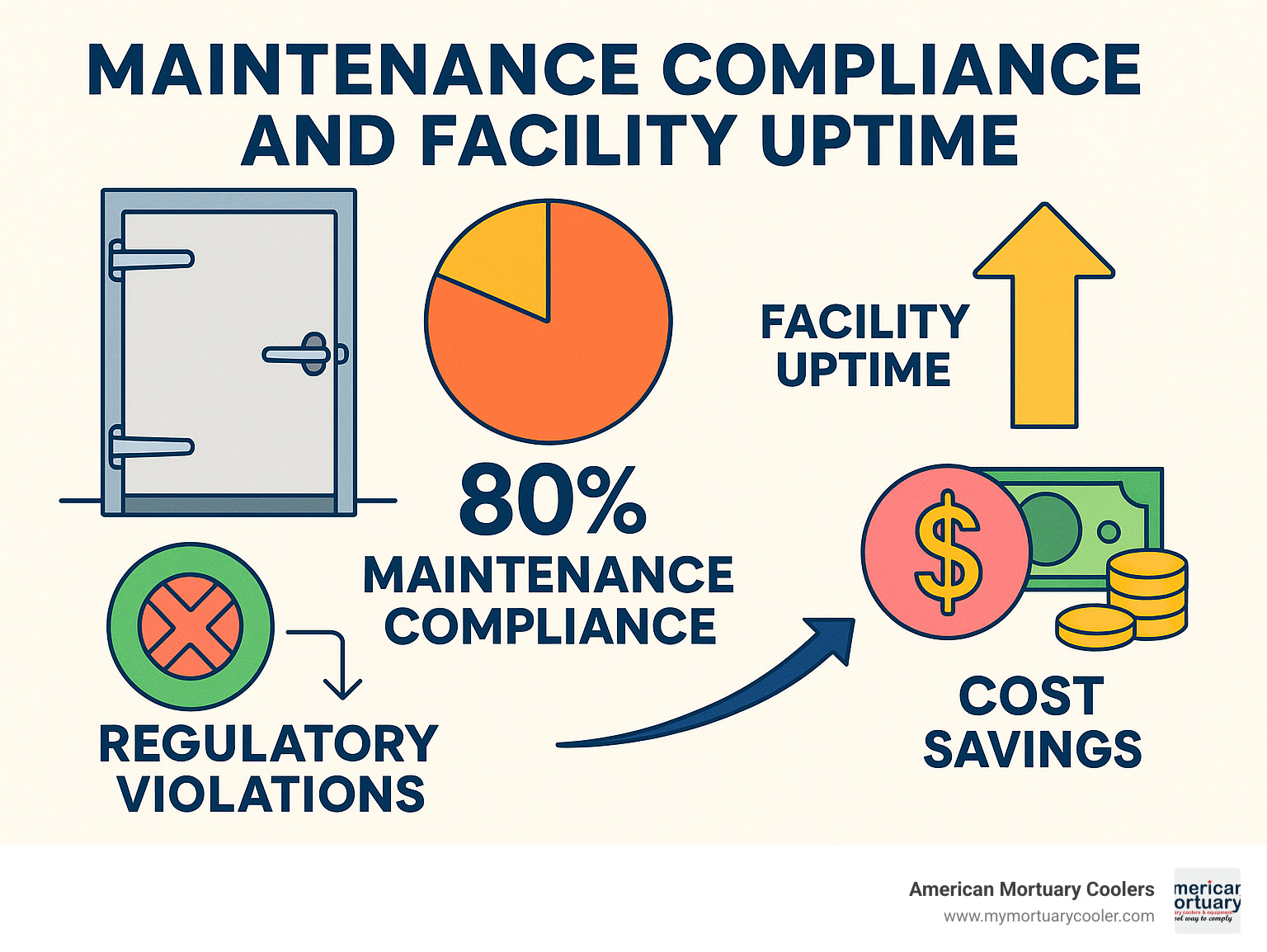

Research shows that regular maintenance can reduce morgue refrigerator failure risk by up to 80%, while compromised gasket seals cause 90% of temperature instability issues. Facilities following documented maintenance checklists report 50% fewer emergency repairs and extend door lifespan by 3-5 years.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral facilities implement effective morgue refiregeration doors service maintenance programs. My expertise stems from working directly with funeral directors nationwide to address their most pressing refrigeration challenges.

Learn more about morgue refiregeration doors service maintenance:

The High Stakes: Safety, Compliance & Cost

Picture this: It's 2 AM on a Saturday, and your morgue door just failed. Bodies need to be moved, families are waiting, and you're scrambling to find emergency service. This nightmare scenario happens when morgue refrigeration doors service maintenance gets neglected.

OSHA mandates interior release handles to prevent accidental entrapment. NFPA standards govern electrical safety in these hazardous environments, while CDC guidelines for biological containment directly impact how your morgue doors must function. These are legally binding requirements that can result in hefty fines and facility shutdowns.

The financial impact hits hard. Emergency repairs during off-hours cost 3-4 times normal rates. Temperature excursions can compromise entire inventories. We've seen facilities face over $50,000 in combined costs from a single door failure incident.

Energy overspend from compromised door seals forces refrigeration systems to work 25-40% harder, dramatically spiking utility bills. One Chicago medical examiner's office cut energy costs by 30% just by following proper door seal maintenance.

Scientific research on polyurethane insulation shows how proper insulation and sealing work together to maintain stable temperatures and prevent energy waste.

How Faulty Doors Undermine Bio-Containment and Preservation

Temperature stability is everything in body preservation. Standard morgue refrigeration operates between 35.6°F and 39.2°F, but even small fluctuations accelerate decomposition. When door seals fail, temperature swings of 5-10 degrees become the norm.

Humidity control requires 85-95% humidity to prevent dehydration while avoiding moisture-driven decomposition. Faulty doors let humid outside air rush in, disrupting this balance and creating condensation that promotes bacterial growth.

Odor control becomes impossible with compromised seals. What should stay contained escapes into your facility, creating an unbearable work environment and potentially exposing staff to harmful pathogens.

Pathogen containment is the most serious concern. When doors don't seal properly, airborne contaminants escape, putting your staff and visitors at risk.

Legal & Financial Fallout of Neglected Maintenance

Regulatory citations carry immediate fines ranging from $5,000 to $50,000 per violation, plus increased scrutiny and potential license suspension. Lost business hurts most in the long run. When temperature failures compromise a viewing or service, that trust shatters permanently. Facilities that suffer major refrigeration failures lose 20-30% of their business within the first year.

Prevention costs pennies compared to the alternative. Regular maintenance protects your facility, reputation, and bottom line.

Morgue Refrigeration Doors Service Maintenance Checklist

Morgue refrigeration doors service maintenance works like caring for a high-performance vehicle—regular attention prevents breakdowns, but neglect leads to expensive emergencies. The most successful maintenance programs are built on consistent daily habits rather than sporadic intensive efforts.

Documentation isn't just bureaucratic work—it's your protection when inspectors arrive. Digital logs through a Computerized Maintenance Management System (CMMS) make tracking effortless while generating compliance reports. Facilities using documented maintenance schedules report 60% fewer emergency repairs.

More info about door gaskets explains why these components deserve special attention.

Daily & Weekly Morgue Refrigeration Doors Service Maintenance Tasks

Visual seal inspection takes less than a minute per door but catches most problems before they become critical. The paper test is brilliantly simple—close a piece of paper in the door seal and try to pull it out. If it slides out easily, your seal needs attention. This test catches about 90% of seal problems before they compromise your refrigeration system.

Temperature logging is your early warning system. Record internal temperatures at least twice daily, noting any unusual fluctuations. Ice removal around seals, hinges, and drains prevents bigger problems down the road.

Weekly gasket deep cleaning requires EPA-approved disinfectants designed specifically for mortuary use. Never use bleach on rubber seals—it makes gaskets brittle and prone to cracking. Door surface cleaning prevents residue buildup that interferes with proper operation.

Monthly & Quarterly Morgue Refrigeration Doors Service Maintenance Procedures

Hinge alignment and lubrication prevents binding and uneven wear that stresses seals and wastes energy. Use only food-safe lubricants approved for low-temperature applications. Latch adjustment ensures doors close securely and stay closed.

Magnetic seal strength testing uses standardized pull tests to identify weakening magnets before they fail completely.

Quarterly professional inspections bring expert eyes to your maintenance program, including refrigerant leak testing, precision sensor calibration, and detailed gasket evaluations.

| Maintenance Frequency | Failure Risk Reduction | Cost Savings |

|---|---|---|

| No Regular Maintenance | Baseline (100%) | $0 |

| Monthly Only | 40% reduction | 25% cost savings |

| Weekly + Monthly | 65% reduction | 45% cost savings |

| Daily + Weekly + Monthly | 80% reduction | 60% cost savings |

Annual Professional Inspection & Compliance Audit

Annual comprehensive inspections are essential for maintaining warranty coverage and regulatory compliance. Complete refrigerant system leak testing uses electronic detectors to find tiny leaks before they become major failures. Full gasket replacement with upgraded materials extends door life and improves energy efficiency.

The detailed audit reports with photographic documentation provide evidence of proper maintenance for regulatory inspections.

More info about walk-in cooler door care provides additional professional maintenance insights.

Diagnosing & Fixing Common Door Problems

Gasket issues cause 70% of our service calls. These rubber seals work 24/7 in challenging conditions, expanding and contracting with temperature changes while maintaining an airtight seal. The remaining problems split between mechanical issues like worn hinges and failed latches (20%) and electrical problems such as heater strip failures and sensor drift (10%).

Gasket problems show up as tears and cracks from normal aging, or weakening magnetic strength over time. Door misalignment stresses gaskets and causes premature failure.

Mechanical issues develop gradually. Hinges wear out and cause doors to sag, making them harder to close properly. Latch mechanisms can fail, leaving doors that won't stay securely shut.

Electrical problems are less common but tricky to diagnose. Door heater strips prevent ice formation, but when they fail, you'll notice ice buildup around seals.

Early-Warning Signs Your Morgue Refrigeration Doors Service Maintenance Is Due

The gap light test is one of the most reliable indicators. If you can see light around a closed door, you've got seal problems that need immediate attention.

Rising energy bills without increased usage often signal door seal issues. Watch for condensation or "sweating" on door frames—this usually means warm, humid air is infiltrating your cooler space. If you hear an audible hiss when doors close, that's air escaping through damaged seals.

Temperature alarms becoming more frequent is another red flag. Don't ignore these early warnings.

DIY Troubleshooting vs. Calling a Pro

You can safely handle basic cleaning and sanitizing, simple gasket adjustments, ice removal, and drainage clearing. Always call professionals for refrigerant system work, electrical repairs, complete gasket replacement, and major hinge or latch adjustments.

Lockout-tagout procedures aren't optional—follow them religiously when performing any maintenance work. Keep detailed service logs with photos of problems and repairs.

Scientific research on green refrigerants shows how modern refrigeration systems require specialized knowledge for safe servicing.

Pro Support & Future-Proof Innovations

Smart sensors are revolutionizing morgue refrigeration monitoring. These devices track temperature, humidity, and door status 24/7, sending real-time updates to your smartphone. Remote monitoring systems have reduced unnoticed failures by up to 70% in facilities using them.

Door-ajar alarms catch moments when staff get distracted and doors get left open. Self-closing hinges automatically close doors even when staff forget. Antimicrobial gaskets resist bacterial growth while lasting longer than traditional materials.

Modular panel designs offer incredible flexibility for expanding capacity or reconfiguring layouts. The real innovation is predictive analytics—IoT sensors analyze patterns to predict when components might fail, allowing scheduled maintenance before problems occur.

More info about selecting freezer doors provides detailed guidance on choosing the right door technology.

When to Schedule Professional Morgue Refrigeration Doors Service Maintenance

Call immediately when you notice temperature swings greater than 2 degrees from your setpoint or repeated temperature alarms despite troubleshooting efforts. Door binding or requiring excessive force to operate indicates hinge problems or frame warping.

Any refrigerant odors or visible leaks require immediate professional service—these are safety hazards that can affect staff health and violate environmental regulations.

Surge events like power outages or extreme weather can stress door systems in ways that aren't immediately obvious. We recommend professional inspections after any major electrical or weather events.

Training Staff for Routine Care

Hands-on training works much better than just handing someone a manual. Our checklist orientation walks staff through every task, showing them exactly what to look for and how to document findings.

SOP signoff ensures everyone understands their responsibilities. Refresher courses keep long-term staff current with new technologies. Safety drills practice emergency procedures like lockout-tagout and refrigerant leak response.

The key is making maintenance feel like a normal part of daily operations, not an extra burden.

Frequently Asked Questions About Morgue Refrigeration Doors Service Maintenance

How often should doors be professionally serviced?

Quarterly professional inspections work well for most locations. High-traffic facilities handling more than 20 cases monthly should consider monthly professional maintenance. Smaller facilities can often maintain safety and compliance with quarterly service, especially when staff follow daily and weekly maintenance routines.

Environmental factors matter too. Facilities in humid climates or areas with temperature extremes may need more frequent professional attention.

What cleaning agents are safe for gaskets and stainless steel?

Never use bleach on rubber gaskets—it makes them brittle and causes premature cracking. For gaskets, use EPA-approved disinfectants specifically designed for mortuary applications. Start with mild detergent solutions, then follow with approved sanitizers.

Stainless steel surfaces need specialized cleaners that won't leave residue or cause corrosion. Avoid abrasive cleaners, steel wool, or anything with harsh chemicals.

How do I document maintenance to satisfy inspectors?

Digital logging systems provide the best documentation, but you need both electronic and paper backups. Include photos of any problems and their repairs. Temperature records should show consistent monitoring with dates and signatures from qualified personnel.

Keep records for at least three years, longer if local regulations require it. Good documentation satisfies regulatory requirements and helps you run a better facility.

Conclusion

Taking care of your morgue refrigeration doors service maintenance protects what matters most. Every family trusts you with their precious memories during their darkest hours. When your refrigeration systems work flawlessly, you can focus on providing compassionate care and dignity when it's needed most.

Facilities that follow proper maintenance schedules see 80% fewer emergency breakdowns and extend their equipment life by 3-5 years. More importantly, they avoid the heartbreak of compromised services and the financial devastation of regulatory violations and emergency repairs.

At American Mortuary Coolers, we understand these challenges because we live and breathe the funeral industry every day. Our custom walk-in coolers, crafted right here in Tennessee, reflect our commitment to quality and reliability. But even the finest equipment needs proper care to perform when you need it most.

We've built a nationwide support network spanning from our regional offices in Atlanta and Chicago to Dallas, Los Angeles, New York, and Pittsburgh. Our factory-trained technicians don't just fix problems—they help prevent them through comprehensive maintenance programs custom to your facility's unique needs.

The choice is simple: invest in proactive morgue refrigeration doors service maintenance now, or pay exponentially more later when systems fail at the worst possible moment. We've helped hundreds of facilities across the contiguous 48 states avoid this scenario through proper planning and regular care.

Your families deserve the assurance that their loved ones are preserved with dignity and respect. Your staff deserves a safe, compliant work environment. Your business deserves the cost savings and peace of mind that come from reliable equipment.

Don't wait for warning signs to become emergencies. Whether you need guidance on implementing a maintenance program, emergency repairs, or a completely new custom cooling solution, we're here to help.

More info about maintenance and cleaning offers additional resources to help you develop a comprehensive facility maintenance program.

In the funeral industry, reliability means everything. When families entrust you with their final farewells, proper morgue refrigeration doors service maintenance becomes more than just equipment care—it becomes a sacred responsibility to honor those we serve and support those who grieve.