Why Hydraulic Lift Tables Are Essential for Modern Workplaces

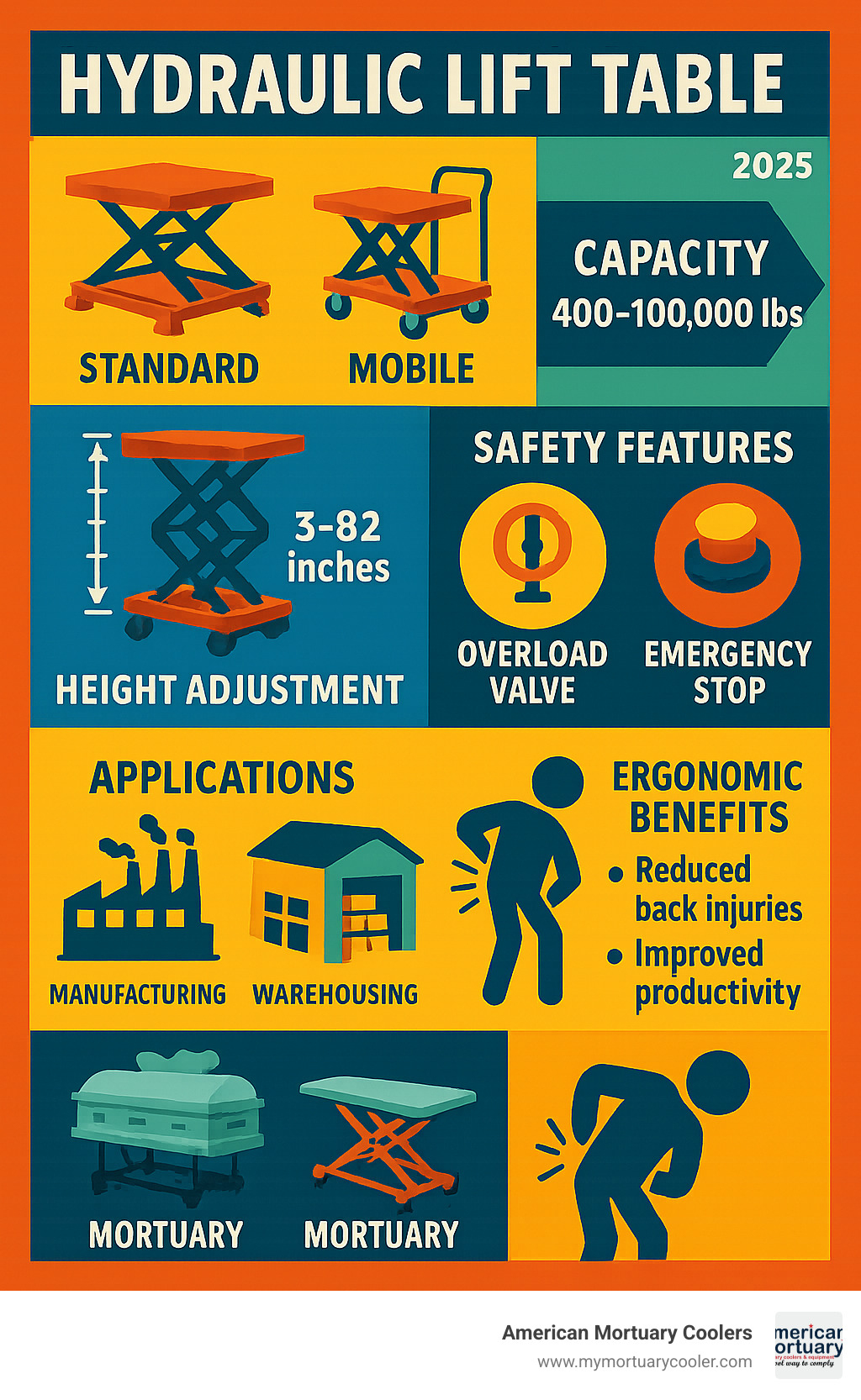

A hydraulic lift table is a mechanical platform that uses hydraulic power to raise and lower heavy loads, providing ergonomic positioning and reducing workplace injuries. These versatile lifting devices are essential tools across industries - from manufacturing floors to funeral homes - where workers need to handle heavy materials safely and efficiently.

Key Benefits of Hydraulic Lift Tables:

- Ergonomic Safety: Eliminates repetitive bending and lifting that causes back injuries

- Load Capacity Range: Handle anywhere from 400 lbs to 100,000 lbs depending on model

- Height Adjustment: Raise materials from floor level up to 82 inches for optimal work positioning

- Workplace Efficiency: Reduce manual handling time and improve productivity

- Injury Prevention: Significantly lower workers' compensation claims and lost time accidents

Standard lift tables typically handle 2,000-6,000 lbs with platform sizes ranging from 24" to 72" wide. Mobile versions can move loads up to 800 lbs while adjusting platform height from 15.5" to nearly 52". Low-profile models compress down to just 3 inches for pallet jack access, while heavy-duty units support massive 100,000 lb loads for industrial applications.

I’m part of the American Mortuary Coolers team, a national-level mortuary cooler supplier with extensive experience helping funeral professionals select the right hydraulic lift table solutions for body and casket handling applications. Our background in mortuary equipment has given us deep insights into how these lifting systems improve both safety and operational efficiency in sensitive workplace environments.

How a Hydraulic Lift Table Works

A hydraulic lift table operates through mechanical scissor arms that expand and contract in a diamond pattern, creating smooth vertical movement. When hydraulic cylinders push outward, the scissor legs spread apart and lift the platform. Release the pressure, and gravity brings everything back down.

The real beauty lies in how hydraulic cylinders multiply your effort. A gentle push on a foot pedal creates enormous lifting force through pressurized fluid. Whether you choose a foot-pump system or an electric motor, the basic physics remain the same - small input, massive output.

Lift capacity ranges from lightweight 400-pound units perfect for small parts up to industrial giants handling 100,000 pounds. The scissor design stays remarkably stable across this entire range, making hydraulic tables incredibly versatile.

Basic Anatomy of a Hydraulic Lift Table

Every hydraulic lift table contains five key components working in perfect harmony:

The platform deck serves as your workhorse surface. Most feature diamond-plate steel that grips loads securely while resisting wear. Sizes run from compact 24" x 24" squares up to massive 144" platforms for industrial applications.

Your base frame provides the rock-solid foundation. Heavy-duty steel construction keeps everything stable, even under maximum load. The base typically matches your platform size, creating a wide, stable footprint.

The scissor legs create that signature diamond lifting pattern. These precision-engineered arms feature lifetime-lubricated bearings at every pivot point. As they expand and contract, they multiply the hydraulic force while maintaining smooth motion.

Hydraulic cylinders provide the muscle. Single cylinders work beautifully for lighter loads, while heavy-duty tables use multiple cylinders for even force distribution. Chrome-plated surfaces resist corrosion and ensure smooth operation.

Finally, the powerpack serves as mission control. This compact unit houses your hydraulic pump, fluid reservoir, and all control valves. Manual tables use foot-operated pumps, while electric models feature motor-driven systems.

For deeper insights into workplace ergonomics and lifting equipment benefits, explore this Scientific research on workplace ergonomics.

Hydraulic Circuit & Physics

Pascal's law explains why hydraulic systems work so beautifully - pressure applied to confined fluid transmits equally in all directions. When you pump fluid into the cylinder, that pressure pushes against the piston with incredible force.

A small pump creating 1,000 PSI pressure in a 4-inch diameter cylinder generates over 12,500 pounds of lifting force. This explains why you can foot-pump a 2,000-pound load with minimal effort.

Flow control valves regulate how fast your table moves up and down. Most quality tables include down-speed valves that create smooth, safe lowering regardless of your load weight.

Manual vs Electric vs Air-Powered Hydraulic Lift Table

Foot-pump systems offer unbeatable reliability. No electricity required, minimal maintenance needs, and precise operator control. These excel for occasional use or locations without convenient power access.

Electric motor systems provide the fastest, most convenient operation available. Press a button and watch your table rise smoothly to any desired height. Three-phase power handles the heaviest industrial loads, while single-phase units work in most standard facilities.

Pneumatic air-powered tables use compressed air instead of hydraulic fluid. These provide exceptionally smooth lifting with excellent load distribution across the platform.

For detailed comparisons of manual lifting options, check out our Ultimate Guide to Comparing Manual Scissor Lifts.

Types & Real-World Applications

Every workplace has different lifting challenges, which is why hydraulic lift tables come in so many specialized designs. From compact units that fit in tight spaces to massive systems that handle truck-sized loads, there's a perfect match for your specific needs.

Standard & Low-Profile Tables

Standard hydraulic lift tables are the reliable workhorses you'll find in facilities everywhere. These units typically handle 2,000 to 6,000 lbs with their platforms lowering to about 7 inches when fully compressed. You can choose from compact 24" x 36" platforms for tight spaces or spacious 48" x 72" decks when you need room to work.

Low-profile tables solve one of the most common complaints: "How do I get my pallet onto this thing without building a ramp?" These clever designs compress down to just 3 inches when lowered, so your standard pallet jack can roll loads right onto the platform.

The trade-off with low-profile models is usually lower capacity - most max out around 3,000 lbs - and they cost more due to the specialized engineering.

Mobile & Rotating Tables

Mobile lift tables are like having a lifting device that comes to you instead of the other way around. Four sturdy polyurethane casters let you roll these units anywhere in your facility. Most handle 400 to 2,000 lbs while adjusting from about 15 inches up to 52 inches high.

The real game-changer is adding 360-degree rotation to mobile tables. You load parts on one side of your assembly line, then spin the platform so workers on the other side can reach everything comfortably.

For more insights on selecting the right system for your needs, check out Scissor Lift Secrets: Choosing the Perfect Hydraulic Lift.

High-Capacity & Tandem Tables

When regular hydraulic lift tables just aren't enough, heavy-duty models step up to handle truly massive loads. Units rated for 8,000 to 10,000 lbs feature extra-thick scissor arms and large, low-pressure cylinders. The absolute heaviest systems can handle up to 100,000 lbs - enough to lift loaded truck trailers!

Tandem systems use multiple synchronized cylinders with extended platforms for long or unusually shaped loads. The engineering challenge is keeping all cylinders perfectly synchronized to prevent binding or dangerous tipping.

Industry Spotlight: Manufacturing, Warehousing, Mortuary

Manufacturing facilities use hydraulic lift tables to create ergonomic workstations that reduce fatigue and improve quality. Warehousing operations benefit from dock-height lift tables that eliminate loading ramps while providing flexible height adjustment.

Mortuary applications are where our expertise at American Mortuary Coolers really shows. Funeral homes need specialized hydraulic lift tables for respectful, safe handling of caskets and remains. Battery-powered units provide quiet, smooth operation during services.

Mortuary work has unique requirements - stainless steel construction for easy cleaning, quiet operation during services, and absolute reliability when it matters most.

Choosing the Right Hydraulic Lift Table

Finding the perfect hydraulic lift table doesn't have to feel overwhelming. You need to know what you're hauling, where you're going, and what features matter most for your daily work.

Load Capacity & Platform Size

Calculating the right capacity starts with your heaviest load, but you can't just look at total weight - you need to think about how that weight sits on the platform. A 2,000-pound pallet spread evenly across the deck is completely different from a 1,500-pound machine sitting in one corner.

The magic term here is UDL - uniformly distributed load. This is the weight your table can handle when it's spread evenly across the entire platform. Concentrate that same weight in one spot, and you might damage the scissor mechanism.

Smart platform sizing means giving yourself breathing room. If your typical pallet measures 40" x 48", don't buy a 40" x 48" platform. You'll spend frustrating minutes trying to center loads perfectly.

| Capacity | Platform Size | Lowered Height | Raised Height | Typical Applications |

|---|---|---|---|---|

| 2,000 lbs | 36" x 48" | 7" | 48" | Light manufacturing, assembly |

| 4,000 lbs | 48" x 48" | 8" | 60" | Warehouse pallets, heavy parts |

| 6,000 lbs | 48" x 72" | 9" | 72" | Heavy manufacturing, automotive |

Mobility & Power Options

Choosing between manual push and electric drive often comes down to how much you'll actually move the table. Battery-powered mobility gives you the best of both worlds - no power cords to trip over, but effortless movement even with heavy loads.

Power options for the lifting mechanism depend on your facility's electrical service. Single-phase power handles most applications up to about 4,000 lbs capacity. Three-phase power efficiently handles the heaviest loads but requires appropriate electrical service.

For detailed comparisons of different electric systems, check out our Comprehensive Guide to Electric Scissor Lift Options.

Accessories & Customization

Accordion skirting serves a crucial safety function - those expanding metal guards protect fingers and clothing from getting caught in the scissor mechanism.

Turntables transform a simple lift into a positioning system. Instead of workers reaching around large parts, they can rotate the entire load for comfortable access from any angle.

Tilt tops address how to access materials in boxes without bending over. These platforms can angle up to 90 degrees, bringing the work up to comfortable eye level.

Integral scales eliminate the "lift it, weigh it, lift it again" workflow. The scale weighs your load automatically as it rises, with digital displays showing real-time weight.

Stainless steel construction costs more upfront but becomes essential in environments where cleanliness matters. Food processing, pharmaceutical manufacturing, and mortuary applications all benefit from stainless steel's corrosion resistance and easy cleaning properties.

Safety, Maintenance & Compliance

When you're working with a hydraulic lift table, safety isn't just a nice-to-have feature - it's absolutely essential. Modern lift tables come packed with safety features that protect both your workers and your equipment investment.

Essential Safety Features

Emergency stops are your first line of defense. Those big red mushroom-shaped buttons should be within easy reach from anywhere you might be operating the table. When you hit one, everything stops immediately.

Safety bars and toe guards solve one of the scariest scenarios - someone getting caught underneath a lowering platform. These protective barriers extend around the platform's edge and gently compress as the table lowers. If they encounter any resistance, the motion stops instantly.

Overload valves act like a built-in bouncer - they simply won't let the table lift more weight than it's designed to handle. Velocity fuses constantly monitor fluid flow, and if they detect rapid fluid loss that indicates a broken hydraulic line, they instantly seal the system.

Routine Maintenance Checklist

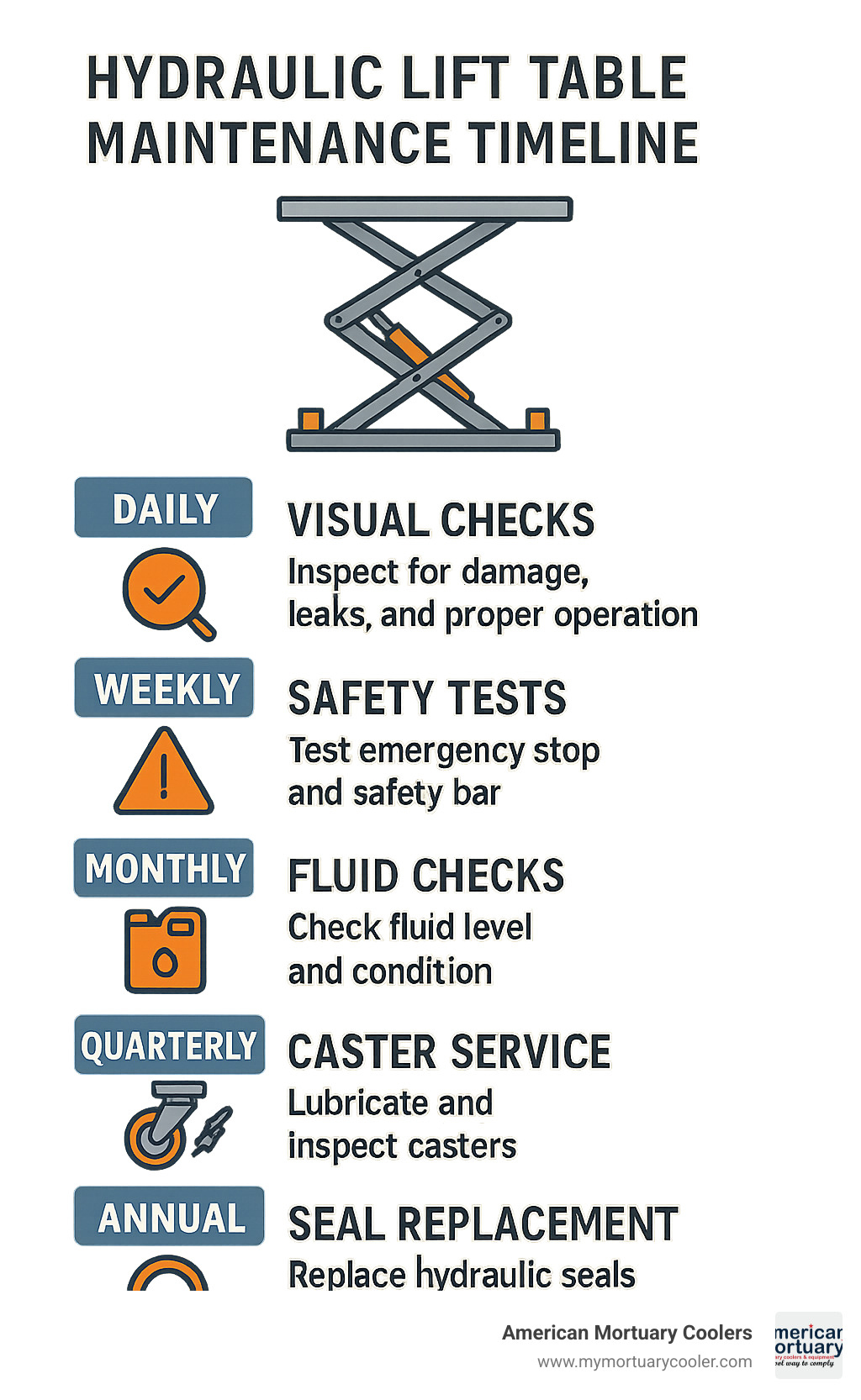

Daily visual inspections take just a few minutes but can save you thousands in repair costs. Walk around your table and look for fluid puddles underneath, bent or cracked parts, loose bolts rattling around.

Monthly hydraulic fluid checks are crucial because fluid is the lifeblood of your system. Clean hydraulic fluid looks clear and bright. If it's turned dark, cloudy, or has particles floating in it, that's contamination that will destroy expensive hydraulic components.

Annual seal replacement prevents small leaks from turning into major fluid losses. Don't forget about caster lubrication if you have a mobile unit - those wheels and bearings work hard, especially when rolling heavy loads.

Regulatory Standards & Ergonomic ROI

OSHA 1910.178 covers powered industrial trucks and material handling equipment, including lift tables. ANSI MH29.1 gets more specific about scissor lift tables, covering everything from design requirements to operational procedures.

Back injuries alone cost employers an average of $50,000 per incident when you factor in medical costs, lost time, and training replacement workers. Companies that implement comprehensive ergonomic lifting solutions typically see 50-80% reductions in lifting-related injuries.

The productivity gains are equally impressive. Workers operating at comfortable heights make fewer errors, work more efficiently, and stay fresher throughout their shifts.

For additional guidance on selecting the right equipment, check out The Complete Guide to Choosing the Right Scissor Lift Table.

Frequently Asked Questions about Hydraulic Lift Tables

How do I calculate the correct lift capacity?

Start with your heaviest load and add 25% safety margin. If your heaviest item weighs 2,000 pounds, you need at least a 2,500-pound capacity table. This buffer protects against unexpected overloads.

Load distribution matters just as much as total weight. A 2,000-pound engine block concentrated in one corner can actually tip a 4,000-pound capacity table if it extends beyond the platform's stability zone.

If you handle various load sizes throughout the day, size your table for the biggest items. It's better to have extra capacity you don't always need than to struggle with an undersized table.

What safety checks should I perform before each use?

Walk around the table looking for obvious problems - bent scissor arms, hydraulic fluid puddles, or loose bolts that weren't there yesterday.

Test all safety devices before handling any loads. Press the emergency stop button and make sure it actually stops all motion. Check that warning beepers sound when the table moves.

Clear the work area of people and obstacles before starting any lifting operation. Start with a light test load to check normal operation. Listen for unusual noises or watch for jerky motion.

Can I retrofit my existing table with power drive or tilt?

Many hydraulic lift tables can be upgraded with additional features, but proper retrofits require manufacturer-approved components and qualified installation to maintain safety and warranty coverage.

Power drive conversions are the most common retrofit, replacing manual foot pumps with electric motor systems. Mobile base retrofits add casters and steering mechanisms to stationary tables.

Always work with the original manufacturer or authorized service providers for any modifications. Improper retrofits can void warranties, create safety hazards, and potentially violate OSHA requirements.

Conclusion

Hydraulic lift tables are game-changers for workplace safety and efficiency. These remarkable machines transform back-breaking manual lifting into smooth, controlled operations that protect your workers and boost productivity.

The beauty of hydraulic lifting technology lies in its versatility. Whether you're handling delicate electronics components on a compact 400-pound table or positioning massive steel beams with a 100,000-pound industrial giant, there's a perfect solution waiting for your specific needs.

Success comes down to smart selection. You need the right capacity for your heaviest loads, adequate platform space for your largest items, and the power source that matches your workflow.

Here at American Mortuary Coolers, we've learned that cookie-cutter solutions rarely work for unique challenges. Our experience designing custom mortuary equipment across Tennessee has shown us that the best results come from understanding exactly what you need, then building the perfect solution around those requirements.

The financial benefits speak for themselves. When you eliminate lifting-related injuries, workers' compensation costs plummet. Productivity jumps when people work at comfortable heights instead of bending and straining all day.

From our Tennessee workshop, we've delivered custom ergonomic solutions across all 48 contiguous states. Whether you need a standard warehouse hydraulic lift table or a specialized stainless steel unit for sensitive applications, we understand that your operation is unique.

Ready to transform your material handling operations? Our team specializes in analyzing your specific requirements and recommending solutions that fit perfectly. We've seen how the right lifting equipment protects workers, improves efficiency, and delivers measurable results that make the investment worthwhile.

For specialized automotive applications, check out our Detailed Guide to Choosing the Best Scissor Car Lift for Your Garage for additional insights into hydraulic lifting solutions.