Why the Refrigerator Compressor Cycle Powers Every Cooling System

The refrigerator compressor cycle is the heart of every cooling system, from your home fridge to mortuary coolers. This process moves heat from inside a cold space to the outside environment through a series of pressure and temperature changes.

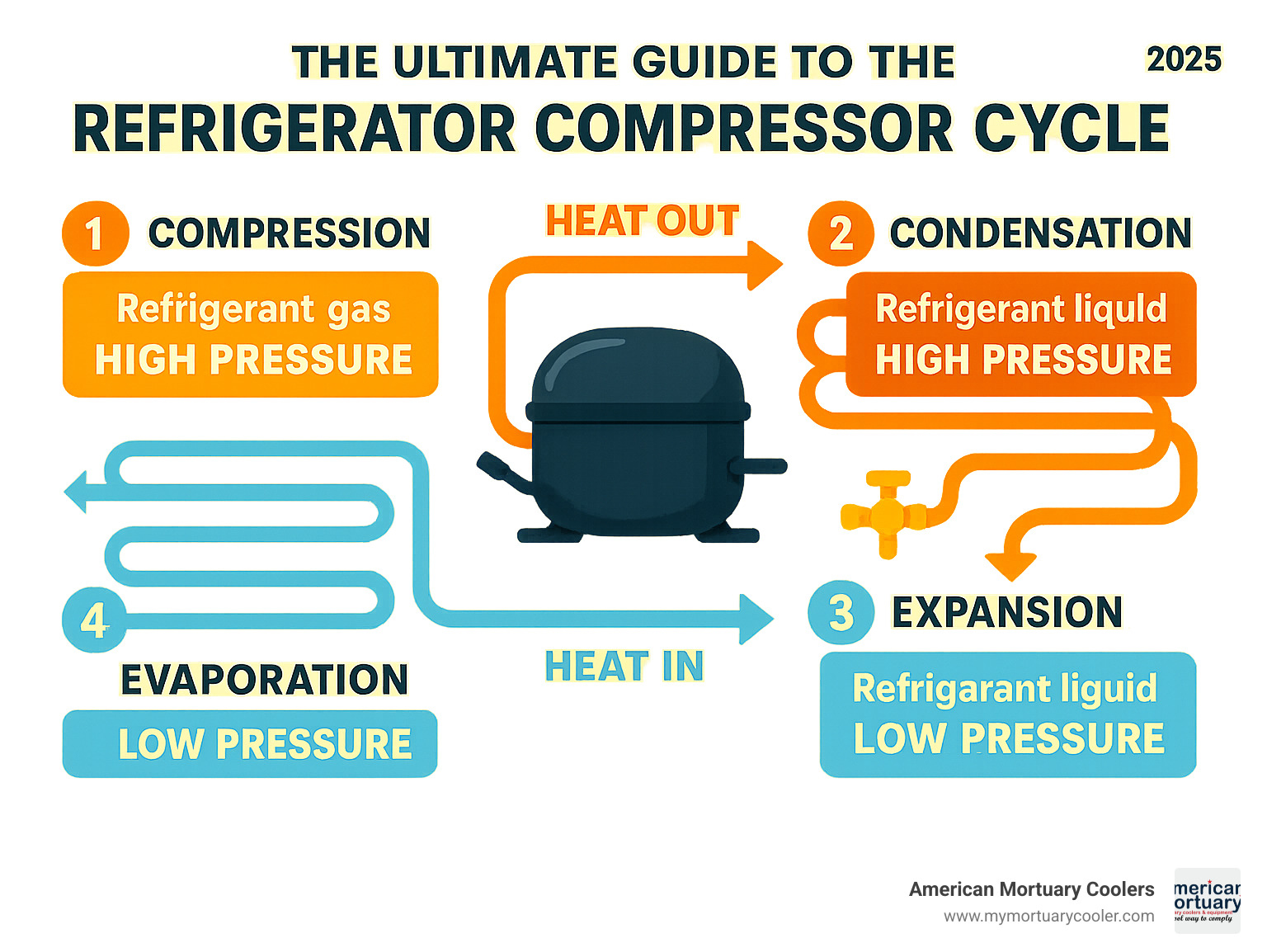

Quick Answer: The refrigerator compressor cycle works in 4 steps:

- Compression - Compressor squeezes refrigerant gas, making it hot and high-pressure

- Condensation - Hot gas releases heat and turns into liquid in the condenser coils

- Expansion - Liquid refrigerant expands through a valve, dropping pressure and temperature

- Evaporation - Cold liquid absorbs heat and turns back to gas in the evaporator coils

The cycle repeats every 10-20 minutes in a typical refrigerator, with properly functioning units running about 50% of the time (20 minutes on, 20 minutes off). This closed-loop system uses a special refrigerant that changes from liquid to gas and back again to move heat energy.

Understanding how this cycle works helps you spot problems early, reduce energy costs, and keep your cooling systems running efficiently. Whether you're dealing with a walk-in cooler that's running too often or a mortuary cooler that's not maintaining proper temperatures, the compressor cycle holds the answers.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigeration systems and vapor-compression technology. My expertise in the refrigerator compressor cycle comes from years of helping funeral homes maintain reliable cooling equipment for their specific needs.

Refrigerator compressor cycle terms explained:

Why Understanding Matters

When you understand the refrigerator compressor cycle, you gain control over three critical areas that affect your daily operations and bottom line.

Food Safety comes first. Temperature fluctuations can spell disaster for funeral homes storing bodies or restaurants preserving food. A compressor that's short-cycling (running less than 10 minutes at a time) or running continuously signals problems that could lead to spoilage or health code violations. We've seen funeral homes face serious issues when their mortuary coolers failed to maintain proper temperatures due to compressor cycle problems.

Energy Bills represent your second biggest concern. A properly functioning refrigerator runs about 50% of the time, but newer units can run up to 90% during peak conditions. When your compressor cycle is off, energy costs skyrocket. For example, a system with a faulty temperature sensor might run continuously, doubling your electricity usage overnight.

Maintenance Prevention saves you thousands in emergency repairs. Understanding normal cycle patterns helps you spot problems before they become catastrophic failures. A compressor that suddenly changes from its normal 20-minute on/off pattern to running continuously often indicates refrigerant leaks, dirty coils, or failing components.

The Science Behind the Refrigerator Compressor Cycle

The refrigerator compressor cycle might seem like magic, but it's actually based on simple physics that's been around since the 1800s. Think of your refrigerator as a clever heat-moving machine rather than a "cold maker" - because that's exactly what it is.

Here's the beautiful part: your fridge doesn't create cold. Instead, it steals heat from inside and dumps it outside. It's like having a tiny bouncer that kicks unwanted heat out of your cooler and into your kitchen. This process follows the Carnot cycle principles, where we use the natural relationship between pressure and temperature to move thermal energy around.

The magic happens through something called latent heat - the energy needed to change a substance from liquid to gas (or vice versa). When water boils on your stove, it absorbs a massive amount of energy to turn into steam. The refrigerator compressor cycle uses this same principle, but with special refrigerants that boil and condense at much lower temperatures.

Modern systems achieve impressive efficiency ratings called coefficient of performance (COP) values. This means for every unit of electricity you put in, you get 2-4 units of cooling power out. That's like getting $4 worth of cooling for every $1 you spend on electricity. Scientific research on vapor-compression systems continues to improve these efficiency numbers.

Vapor-Compression Overview

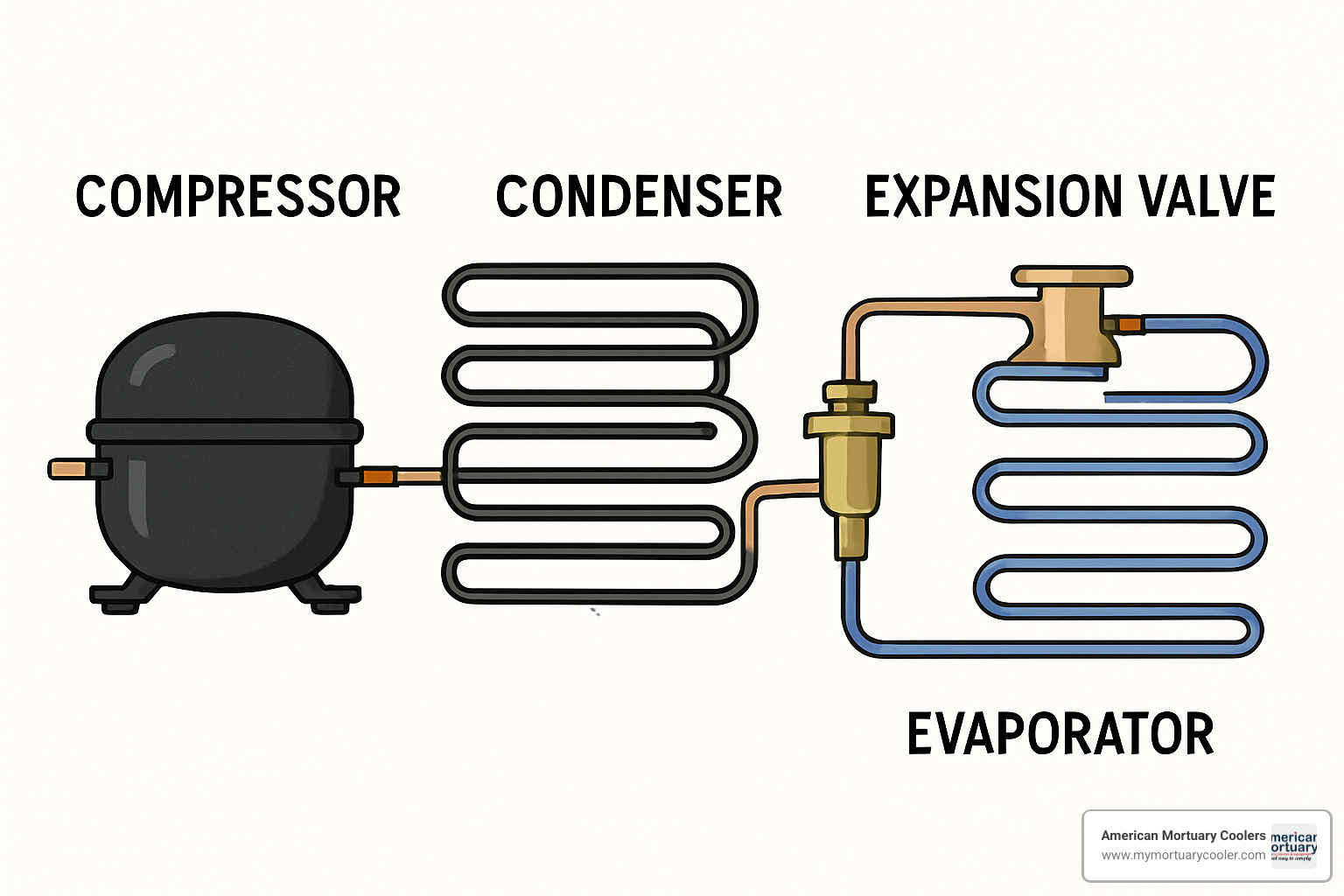

The vapor-compression system works like a closed-loop conveyor belt for heat energy. Your compressor does the heavy lifting work by squeezing refrigerant gas until it's hot and under high pressure. Next, the condenser acts as the heat rejection hub, releasing all that captured heat to the outside air while turning the hot gas back into liquid.

Then comes the clever part - the expansion device creates controlled throttling, suddenly dropping the pressure so the liquid refrigerant gets ice-cold. Finally, the evaporator becomes the absorption center where this cold refrigerant soaks up heat from inside your cooler, turning back into gas and completing the loop.

This closed-loop system means the same refrigerant keeps circulating forever, picking up heat on one side and dropping it off on the other. It's thermodynamics in action - we can't destroy energy, but we can definitely move it where we want it to go.

Refrigerator Compressor Cycle Step-by-Step

Let's follow a molecule of refrigerant as it travels through the refrigerator compressor cycle. This journey happens thousands of times per day in your cooling system, creating the reliable temperatures you depend on.

The compression stage starts when low-pressure refrigerant vapor enters the compressor at around 32°F and 30 psi. Picture squeezing a balloon - the compressor does the same thing, crushing this vapor until it reaches 200+ psi and heats up to 140°F or higher. This creates what we call superheated vapor that's packed with thermal energy.

During condensation, this hot, angry vapor flows through the condenser coils where it meets cooler outside air. As it cools down, something beautiful happens - it condenses back into liquid at about 100°F. This phase change releases massive amounts of latent heat to the environment, which is exactly what we want.

The expansion process is where the real magic occurs. High-pressure liquid refrigerant squeezes through a tiny expansion device (like a capillary tube or valve), and the sudden pressure drop causes some of it to instantly flash into vapor. This creates a cold mixture at about 20°F - cold enough to freeze your fingers.

Finally, evaporation completes our heat-moving mission. The cold refrigerant mixture enters the evaporator coils inside your cooler, where warm air causes the remaining liquid to boil into vapor. This absorbs thermal energy and cools the surrounding air, then the now-warm vapor heads back to the compressor to start the whole process over again.

The entire refrigerator compressor cycle follows a clockwise flow pattern that you can track on a pressure-enthalpy (P-h) diagram. Each state change happens at specific pressure and temperature points, creating the predictable cooling performance that keeps your mortuary coolers running reliably day after day.

Key Components and Their Functions

The refrigerator compressor cycle relies on four main players working together like a well-rehearsed orchestra. When one component falls out of tune, the whole system suffers - and your energy bills remind you about it.

Think of these components as a relay team passing the refrigerant baton around a closed track. The compressor gives the initial push, the condenser cools things down, the expansion device creates the pressure drop, and the evaporator does the actual cooling work. Supporting players like accumulators and filter-driers keep everything running smoothly behind the scenes.

At American Mortuary Coolers, we see these components in action every day. A mortuary cooler that suddenly can't maintain 38°F usually has one of these four components crying for help. Understanding what each one does helps you spot problems before they become expensive emergencies.

For a visual journey through these components in real mortuary applications, our Inside Your Fridge: A Visual Tour of Refrigerator Anatomy guide shows exactly where everything lives inside your cooling system.

The Compressor – The System's Heart

Your compressor is literally the heart of the refrigerator compressor cycle - it pumps refrigerant through the system while adding the energy needed to make heat transfer happen. Stop the compressor, and everything else becomes expensive decoration.

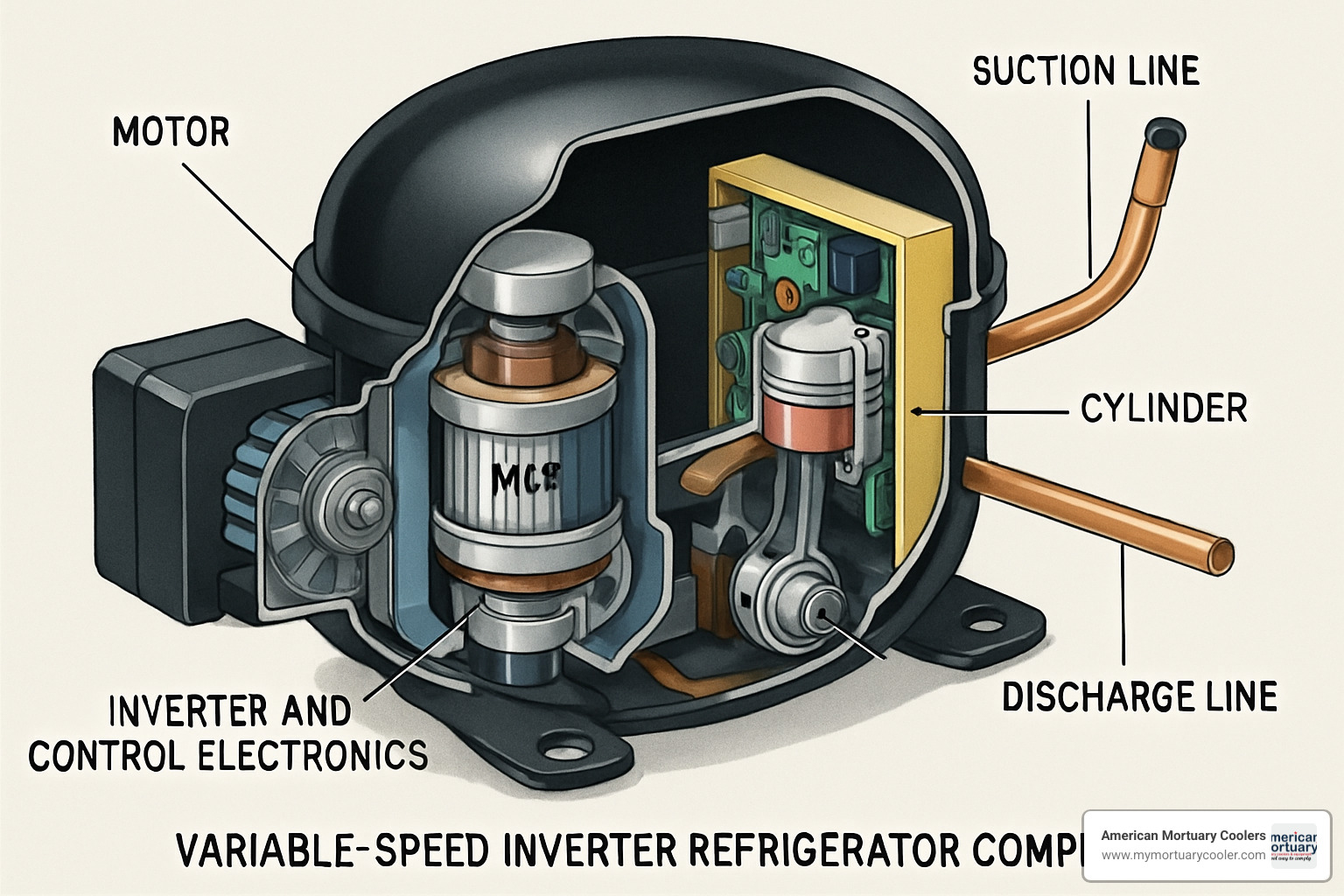

Reciprocating compressors work like tiny car engines with pistons pumping up and down in cylinders. They're the workhorses of the refrigeration world - reliable, fixable, and they don't mind getting their hands dirty. The downside? They sound like it too. These make sense when you need dependable cooling and don't mind a little background noise.

Scroll compressors use a more neat approach with two spiral-shaped pieces - one sits still while the other orbits around it, squeezing refrigerant toward the center. They run quieter and sip less electricity than their piston-powered cousins. Most commercial funeral homes prefer scroll compressors because nobody wants equipment noise during services.

Rotary compressors spin their way to compression using a rotating mechanism that's compact and whisper-quiet. You'll find these in modern residential units and smaller commercial systems where space and noise matter more than raw power.

Here's something that catches many people off-guard: compressor oil management. The oil that lubricates your compressor's moving parts needs to stay in the compressor, not take a vacation through your refrigerant lines. When oil gets stuck somewhere else in the system, your compressor can seize up faster than you can say "expensive repair bill."

The Condenser – Heat Rejection Hub

The condenser handles the hot and sweaty job of dumping heat from your refrigerant into the outside world. It's where the magic of phase change happens - hot refrigerant vapor comes in, and cooler liquid refrigerant goes out.

Air-cooled condensers are the most common setup you'll see. They use fans to blow ambient air across coil surfaces, kind of like a car radiator. Simple to install and maintain, but they struggle when summer temperatures soar. The refrigerant typically needs to condense at temperatures 25-30°F higher than the surrounding air. So on a 90°F day, your condenser is working at around 120°F - no wonder your electric bill jumps in summer.

Water-cooled condensers take a different approach by using water flow to carry away heat. They're more efficient than air-cooled units because water absorbs heat better than air. The refrigerant only needs to run about 10°F warmer than the leaving water temperature. The catch? You need reliable water supply, treatment, and disposal - not always practical for every location.

Subcooling happens in the condenser's final stretch, where liquid refrigerant cools below its saturation temperature. This ensures you're sending pure liquid to the expansion device instead of a bubbly mixture. Proper subcooling typically runs 8-15°F and directly impacts your system's capacity and efficiency.

Expansion Devices – Metering the Flow

The expansion device might be small, but it controls the entire refrigerator compressor cycle by creating the pressure drop that lets refrigerant absorb heat in the evaporator. Think of it as the system's traffic cop, deciding how much refrigerant flows where and when.

Capillary tubes win the prize for simplicity - just a long, skinny copper tube that restricts flow through friction. No moving parts, no sensors, no drama. They work great in small systems with steady loads, like household refrigerators. The downside? They can't adapt when conditions change, so they're pretty much one-trick ponies.

Thermostatic Expansion Valves (TXV) bring intelligence to the party by automatically adjusting refrigerant flow based on evaporator superheat. They sense temperature and pressure changes, then open or close to maintain consistent superheat levels. This protects your compressor while maximizing cooling capacity. TXVs shine in systems where loads vary throughout the day.

Electronic Expansion Valves (EEV) represent the high-tech solution with electronic controls that precisely meter refrigerant flow. They offer the best performance and efficiency but cost more upfront than mechanical alternatives. Modern commercial systems increasingly choose EEVs for their surgical precision in controlling refrigerant flow.

For deeper insights into how compressors and expansion devices work together, check out our Complete Guide to Fridge Compressor Function and Operation.

The Evaporator – Where Cooling Happens

The evaporator is where your refrigerator compressor cycle finally delivers on its promise - actual cooling. This is where liquid refrigerant absorbs heat from the space and boils into vapor, creating the cold temperatures you need.

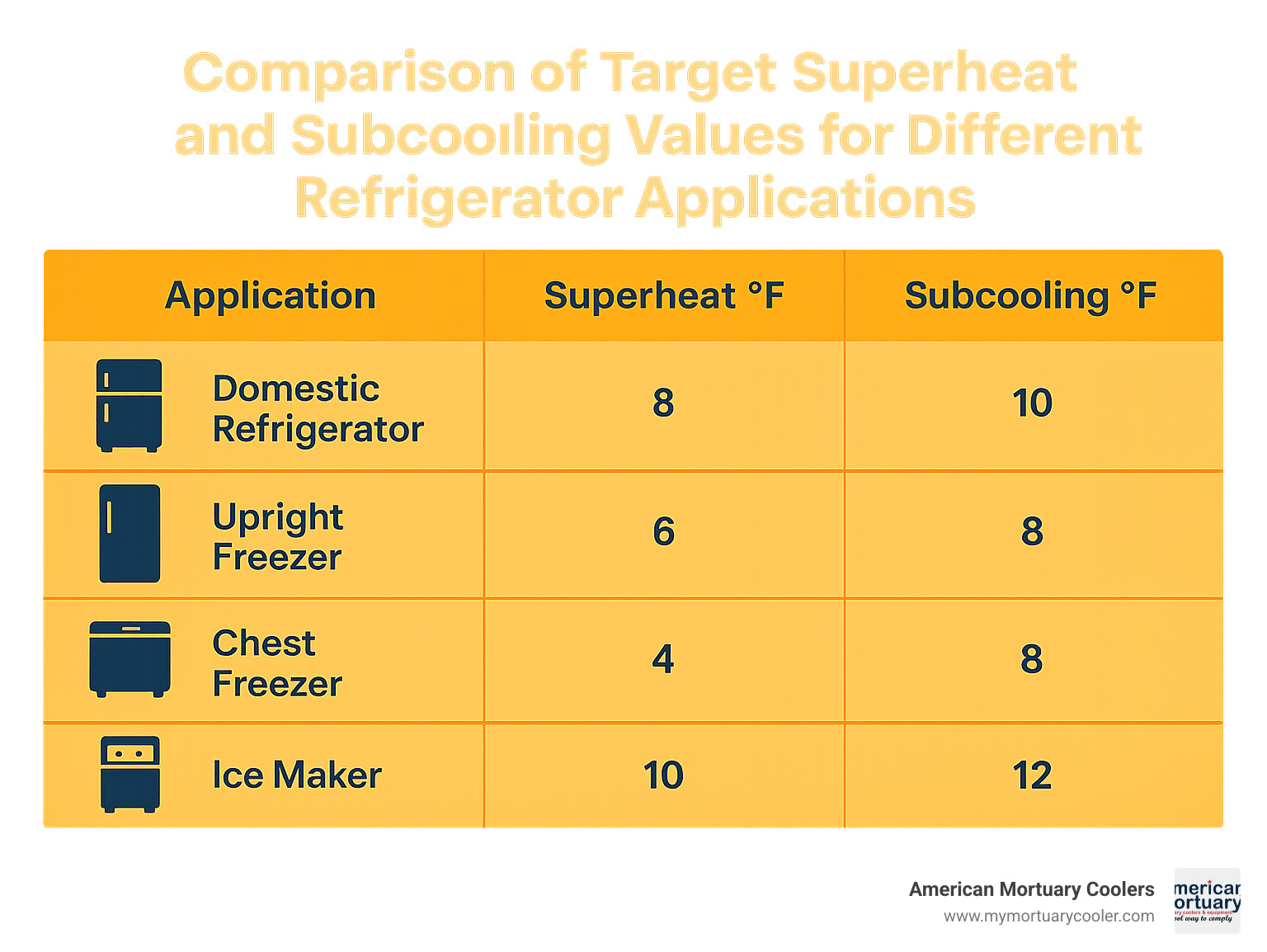

Superheat occurs in the evaporator's final section where refrigerant vapor heats above its saturation temperature. This might sound counterproductive, but it's actually critical protection for your compressor. Superheat ensures only vapor returns to the compressor, preventing liquid slugging that can destroy compressor valves in seconds. Most systems target 8-12°F of superheat for optimal protection and performance.

Frost control becomes a real challenge in low-temperature applications. When evaporator surfaces drop below 32°F, moisture in the air freezes directly onto the coils. This ice buildup acts like a winter coat, insulating the coils and blocking heat transfer. Your compressor works harder and harder trying to maintain temperature while the ice keeps building up. Automatic defrost systems solve this by periodically melting accumulated ice, keeping your system running efficiently even in demanding conditions.

Pressure, Temperature, Superheat & Subcooling Essentials

Think of the refrigerator compressor cycle as having two neighborhoods with different atmospheric pressures. Just like mountain towns have lower air pressure than coastal cities, your cooling system operates with distinct pressure zones that make the magic happen.

The low side runs from where refrigerant exits the expansion device, through the evaporator, and back to the compressor inlet. Here, pressures typically hover between 20-40 psi for medium-temperature applications like your standard walk-in cooler at 35°F. For mortuary coolers running colder at -10°F, you'll see pressures drop to 0-15 psi.

The high side covers everything from the compressor outlet through the condenser to the expansion device inlet. These pressures pack more punch, usually ranging from 150-300 psi depending on how hot it is outside and what type of refrigerant you're using.

Here's where it gets interesting - every pressure has a corresponding saturation temperature. It's like a secret code written in PT charts. For example, R-134a refrigerant at 30 psi always has a saturation temperature of 32°F. This relationship helps technicians predict what temperatures they should find throughout the system.

Safety becomes critical when working with these pressures. Always wear safety glasses and use proper gauge sets. High-pressure refrigerant can cause serious injury if released unexpectedly.

Why Only Vapor Should Return to the Compressor

Imagine trying to squeeze a marble with your bare hands - that's what happens when liquid refrigerant reaches your compressor. The results aren't pretty, and they're definitely not cheap to fix.

Liquid slugging destroys compressors faster than almost any other problem. When liquid refrigerant hits the compression chamber, it can't be squeezed down like vapor can. Instead, it creates hydraulic pressure that cracks cylinder heads, bends connecting rods, or destroys valve plates in seconds.

Your compressor was born to be a vapor pump, not a liquid pump. Its internal parts - whether pistons, scrolls, or rotors - expect to compress gas that squishes into smaller spaces. Liquid refrigerant has virtually no give to it, so it acts like trying to compress a steel ball bearing.

We've seen funeral homes face thousands in repair costs when liquid slugging destroys their mortuary cooler compressors. The damage usually happens so fast that by the time you hear unusual noises, it's already too late.

Prevention means keeping proper superheat throughout the refrigerator compressor cycle. Your expansion device and evaporator need to be sized correctly so all liquid turns to vapor before heading back to the compressor. Suction accumulators act like insurance policies, catching any liquid that might sneak through during system hiccups.

Measuring & Adjusting Superheat in the Refrigerator Compressor Cycle

Getting superheat right protects your compressor while keeping efficiency high. The process requires two temperature readings, but don't worry - it's simpler than it sounds.

You need the actual refrigerant temperature and the saturation temperature that matches your suction pressure. The difference between these numbers equals your superheat.

Start by attaching a thermometer or temperature probe to the suction line near where it leaves the evaporator. Wrap some insulation around the probe to get accurate readings - you want the refrigerant temperature, not the air temperature.

Next, connect your manifold gauge set to measure suction pressure. Use a PT chart to find what saturation temperature matches this pressure reading. Most technicians keep PT charts on their phones these days.

Now for the math - subtract the saturation temperature from the actual temperature. If your suction line reads 40°F and the saturation temperature is 32°F, you've got 8°F of superheat. That's right in the sweet spot for most applications.

Adjustments depend on what you find. Superheat below 5°F means you're flirting with liquid slugging danger. Close the expansion valve slightly or reduce the TXV setting to cut refrigerant flow. Superheat above 15°F means you're starving the evaporator. Open the valve or increase the TXV setting to boost refrigerant flow.

The refrigerator compressor cycle runs most efficiently with superheat between 8-12°F in typical applications. Mortuary coolers might run slightly different targets depending on their specific temperature requirements, but the measurement process stays the same.

Duty Cycle, Efficiency & Troubleshooting

Your refrigerator's refrigerator compressor cycle should run about 50% of the time under normal conditions - that's roughly 20 minutes on, followed by 20 minutes off. This rhythm tells you that your system has enough cooling power for the job without wasting energy.

Think of it like your heart rate. A steady, predictable pattern means everything's working as it should. When that pattern changes dramatically, it's time to pay attention.

Modern inverter technology has changed this traditional on-off dance. Instead of cycling completely off, these smart systems slow down or speed up the compressor as needed. They might run continuously but at reduced power, often delivering better efficiency and more stable temperatures than the old-school cycling approach.

Your energy bills directly reflect how often your compressor runs. A system operating normally at 50% duty cycle and drawing 10 amps uses an average of 5 amps. But if problems force that duty cycle up to 90%, your average power consumption jumps to 9 amps - nearly doubling your electricity costs overnight.

We see this pattern frequently with mortuary coolers that develop refrigerant leaks or dirty condensers. The compressor works harder and longer trying to maintain proper temperatures, and energy costs spiral upward until the underlying problem gets fixed.

Typical Compressor Duty Cycles Explained

Real-world testing shows that a typical 23.3 cubic foot refrigerator operates with a 45% duty cycle (18 minutes on, 22 minutes off) when everything's running smoothly. Newer, more efficient units can run up to 90% of the time during extreme conditions, but they should settle back into normal cycling once temperatures stabilize.

Ambient temperature plays a huge role in how often your compressor runs. Every 10°F increase in room temperature can boost compressor runtime by 15-20%. A unit that cycles perfectly at 70°F might run non-stop when the room hits 95°F - and that's actually normal behavior.

Door openings throw a wrench into normal cycling patterns. Each time someone opens the door, warm, humid air rushes in. The compressor has to work extra hard to remove that added heat and moisture. Busy funeral homes with frequent cooler access often see doubled compressor runtime during peak activity periods.

Load factors like how full your cooler is and the temperature of items going in also affect cycling. An empty refrigerator actually cycles more frequently than a full one because there's less thermal mass to help maintain stable temperatures. It's like the difference between heating a small pot of water versus a large one.

Quick Diagnostics When Cycles Seem Off

When your compressor starts behaving differently - running constantly, short-cycling, or never turning on - systematic troubleshooting helps you catch problems before they turn into expensive emergencies.

Temperature probe accuracy often causes cycling headaches. A faulty sensor might tell the system it's too warm when temperatures are actually fine, leading to excessive compressor runtime. We've seen mortuary coolers run continuously because a $20 temperature sensor was reading 10 degrees high. Always test sensors with a calibrated thermometer before assuming bigger problems.

Amp draw measurements reveal what's really happening inside your compressor. Use a clamp-on ammeter to measure current draw during operation. A compressor pulling significantly more current than its nameplate rating signals mechanical problems, system restrictions, or refrigerant issues that need immediate attention.

Ice buildup on evaporator coils acts like a thick winter coat, insulating the heat transfer surfaces and forcing longer run times. Check that defrost systems are working properly and ensure nothing's blocking airflow across the evaporator. Even a small amount of ice can dramatically reduce cooling efficiency.

Dirty condenser coils cause similar problems on the high-pressure side. When dust and debris coat the condenser, it can't reject heat effectively. The compressor works harder and longer trying to achieve proper pressures and temperatures.

For comprehensive troubleshooting guidance specific to mortuary applications, check out our Compressor Conundrum: American Mortuary Coolers Has You Covered article. It covers the most common issues we encounter when servicing funeral home cooling equipment, along with practical solutions that work in real-world situations.

Understanding these refrigerator compressor cycle patterns helps you spot problems early, keep energy costs under control, and ensure your cooling equipment provides reliable service when you need it most. The Targeting Refrigerators for Repair or Replacement research provides additional insights into when repair makes sense versus replacement for aging systems.

Modern Innovations & Environmental Considerations

The refrigeration industry is experiencing its biggest change in decades, and the refrigerator compressor cycle sits at the center of these exciting changes. We're seeing innovations that not only make systems more efficient but also help funeral homes and other businesses meet increasingly strict environmental regulations.

The push for change comes from two directions - rising energy costs and environmental concerns. Funeral directors tell us they're looking for cooling solutions that run quieter, cost less to operate, and won't face regulatory restrictions down the road. The good news is that modern technology delivers on all these fronts.

Inverter compressors have revolutionized how we think about the refrigerator compressor cycle. Instead of the traditional on-off cycling pattern, these smart units adjust their speed to match exactly what's needed. Think of it like cruise control for your car - instead of constantly hitting the gas and brakes, the system maintains steady performance with much less energy waste.

The benefits are impressive. Inverter systems run 30-50% more efficiently than traditional compressors while providing better temperature stability. For a mortuary cooler that needs to maintain precise temperatures, this technology eliminates the temperature swings that can occur with standard cycling systems.

Electronic expansion valves work hand-in-hand with inverter compressors to optimize refrigerant flow. These valves can make thousands of tiny adjustments per hour, something impossible with mechanical expansion devices. The result is a system that adapts to changing conditions automatically.

Smart sensors throughout modern systems create what we call "intelligent cooling." Temperature sensors, pressure transducers, and humidity monitors feed real-time data to controllers that make split-second decisions about system operation. We've installed systems that alert facility managers to potential problems before they affect operations.

The environmental side of the equation focuses on refrigerants. Traditional refrigerants like R-404A and R-134a face phase-out schedules under EPA regulations that get stricter each year. The AIM Act requires significant reductions in hydrofluorocarbon (HFC) production and consumption.

Low-GWP refrigerants offer the solution. R-600a (isobutane) works excellently in smaller systems, while R-744 (carbon dioxide) handles larger commercial applications. These natural refrigerants have global warming potentials near zero compared to hundreds or thousands for traditional HFCs.

We've been working with these newer refrigerants for several years now, and the performance often surprises people. R-600a systems typically use 40% less energy than R-134a systems while providing better temperature control. The main consideration is that these refrigerants require different safety procedures during installation and service.

Control Systems That Optimize the Refrigerator Compressor Cycle

Modern control systems transform the refrigerator compressor cycle from a simple thermostat operation into something that resembles the sophisticated engine management in today's cars. These systems constantly monitor, adjust, and optimize performance in ways that were impossible just a few years ago.

IoT monitoring connects your cooling systems to the internet, enabling remote oversight that can prevent problems and reduce service calls. We install systems that send alerts to your phone when temperatures drift outside acceptable ranges or when maintenance is due. Facility managers can check system status from home or adjust settings while traveling.

The data these systems collect helps optimize operations over time. We've seen funeral homes reduce energy costs by 25% simply by implementing smart scheduling that pre-cools spaces during off-peak electricity hours.

Adaptive defrost represents another major efficiency gain. Traditional systems run defrost cycles on fixed schedules, often when no defrost is needed. Smart systems monitor actual ice buildup using sensors and run defrost only when necessary. This saves energy and reduces temperature fluctuations that can affect product quality.

Load-based controls learn your facility's patterns and adjust accordingly. If your mortuary cooler typically gets heavy use on Monday mornings, the system can pre-cool on Sunday night to handle the increased load more efficiently. These predictive capabilities help maintain stable temperatures while minimizing energy consumption.

The integration of all these technologies creates cooling systems that practically manage themselves. Modern refrigerator compressor cycles adapt to weather changes, usage patterns, and equipment aging automatically. For funeral homes that need reliable cooling without constant attention, these advances represent a significant step forward in both performance and peace of mind.

Frequently Asked Questions about Refrigerator Compressors

Let's tackle the most common questions we hear from customers about the refrigerator compressor cycle. These answers come from real-world experience with mortuary coolers and commercial refrigeration systems.

How often does the refrigerant complete a full refrigerator compressor cycle?

The refrigerant makes its complete journey through all four components and back to the compressor every 10 to 20 minutes in most systems. That's roughly 3-5 complete cycles every hour.

Here's what's important to understand - this circulation time is different from the compressor's on/off cycling. While your compressor might run for 20 minutes then rest for 20 minutes, the refrigerant is constantly moving through the system whenever the compressor operates.

System size matters when it comes to circulation speed. A small household refrigerator moves refrigerant faster than a large walk-in mortuary cooler with long refrigerant lines. The refrigerant in our custom mortuary units might take 15-25 minutes for complete circulation due to their larger capacity and longer piping runs.

Operating conditions also affect circulation time. Hot ambient temperatures or heavy cooling loads can slow refrigerant movement slightly, while optimal conditions keep things moving at peak efficiency.

What superheat value should I see on my fridge?

You want to see 8-12°F of superheat at the evaporator outlet in most refrigeration applications. This sweet spot ensures your refrigerant completely vaporizes while still providing excellent cooling capacity.

Too little superheat (under 5°F) creates a dangerous situation where liquid refrigerant might return to the compressor. We've seen this destroy compressors in expensive mortuary coolers within hours. The compressor simply can't handle liquid - it's designed to compress vapor, not incompressible liquid.

Too much superheat (over 15°F) means you're not getting enough refrigerant flow. Your system works harder but cools less efficiently. It's like trying to cool a room with a fan that's barely running.

Different applications need slightly different superheat levels. Freezer systems often run 10-15°F superheat because they operate at lower temperatures. Medium-temperature applications like mortuary coolers typically work best with 6-10°F superheat.

Is a 60% duty cycle a sign of a problem?

A 60% duty cycle isn't automatically bad news, but it does mean your system is working harder than the typical 50% we consider normal. Before you panic, consider what's been happening around your equipment.

Normal reasons for higher duty cycles include hot weather pushing your condenser harder, frequent door openings letting warm air in, or heavy product loading after a busy period. We often see mortuary coolers run 60-70% duty cycles during summer months, then return to normal patterns when temperatures drop.

When to worry is if your system suddenly jumps from its normal pattern to 60% or higher without an obvious cause. This could signal dirty condenser coils, refrigerant leaks, or failing components that need attention.

The danger zone starts around 80% duty cycle. If your refrigerator compressor cycle is running continuously or nearly so, you've got either undersized equipment for your load or a system problem that needs immediate attention. We've helped many funeral homes avoid costly breakdowns by catching these issues early.

Consistent patterns matter more than occasional spikes. A system that normally runs 45% but hits 65% during a heat wave is probably fine. One that suddenly changes its normal pattern without explanation needs professional diagnosis.

Conclusion & Next Steps

The refrigerator compressor cycle might seem complex at first glance, but once you grasp those four fundamental stages - compression, condensation, expansion, and evaporation - you hold the key to understanding every cooling system in your facility. Whether you're keeping a mortuary cooler at precise temperatures or troubleshooting a walk-in freezer that's running too often, these same principles apply.

At American Mortuary Coolers, we've watched countless funeral directors transform from frustrated equipment owners into confident operators simply by understanding how their cooling systems work. When you know why your compressor cycles on and off, you can spot problems before they become emergencies. When you understand superheat and subcooling, you can have meaningful conversations with service technicians instead of feeling lost in technical jargon.

A maintenance mindset changes everything about equipment ownership. Instead of waiting for breakdowns, you start listening to your systems. That compressor that used to run 20 minutes on, 20 minutes off? When it starts running continuously, you know something's wrong. Those condenser coils that used to be clean? When they're clogged with dust, you understand why your energy bills jumped.

The funeral industry demands reliability above all else. Families trust you with their most precious moments, and equipment failure isn't an option. Understanding the refrigerator compressor cycle gives you the confidence that comes from knowledge - you're not just hoping your coolers work, you know how to keep them working.

Energy savings follow naturally when you optimize compressor cycles. We've seen funeral homes cut their cooling costs by 25% just by cleaning coils regularly and maintaining proper refrigerant levels. One client in Georgia reduced their monthly electric bill by $400 simply by fixing a faulty temperature sensor that was causing their compressor to run continuously.

Modern innovations like inverter compressors and smart controls offer exciting possibilities for upgrading older systems. But here's the thing - these advanced technologies still follow the same basic cycle principles you've learned. The physics haven't changed, just the precision of control.

For deeper insights into practical temperature management, check out The Easiest Way to Master Cooler Temperature Control, where we apply these cycle principles to real-world cooling challenges that funeral directors face every day.

Your next steps depend on your current situation. If you're dealing with an aging cooling system, use your new knowledge to evaluate whether repairs make sense or if replacement offers better long-term value. If you're planning new construction, consider how modern compressor technologies can provide better efficiency and reliability.

Ready to put this knowledge to work? American Mortuary Coolers specializes in custom solutions that incorporate the latest compressor technologies while maintaining the reliability you need. Our team understands both the science behind the refrigerator compressor cycle and the practical demands of funeral service. We deliver custom mortuary coolers across all 48 contiguous states, bringing decades of refrigeration expertise directly to your door.

Contact us to explore how understanding compressor cycles can help you choose the perfect cooling solution for your facility's unique needs.