Why 10x12 Walk-In Coolers Are the Perfect Mid-Size Storage Solution

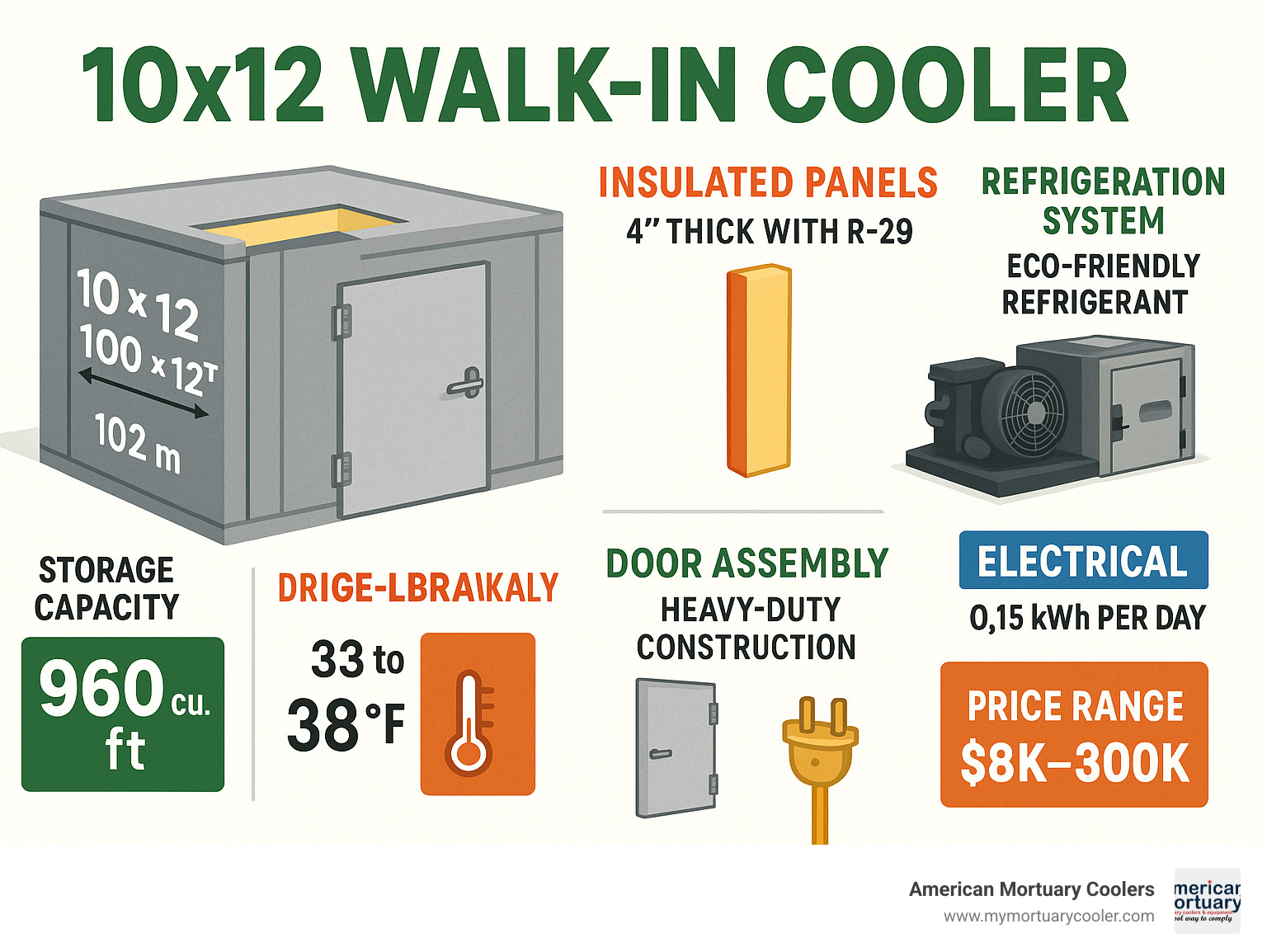

A 10x12 walk in cooler provides 960 cubic feet of storage space, making it ideal for businesses that need substantial refrigerated storage without the footprint of larger units. Here's what you need to know:

Key Specifications:

- Storage Capacity: 960 cubic feet of usable space

- Dimensions: 120" x 144" exterior footprint

- Temperature Range: 33°F to 38°F (FDA compliant)

- Insulation: 4" thick urethane panels with R-29 rating

- Price Range: $8,000 to $30,000 depending on features

Common Applications:

- Restaurants and commercial kitchens

- Funeral homes and mortuaries

- Floral shops and laboratories

- Bars and beverage storage facilities

The 10x12 size hits the sweet spot between capacity and cost. It's large enough to handle serious storage needs but won't break the budget like bigger units. Most models come with 20-year panel warranties and 5-year compressor coverage, giving you peace of mind on your investment.

These coolers maintain consistent temperatures between 33°F and 38°F, which keeps your products safe and meets FDA requirements. The modular panel design means you can assemble most units without specialized contractors, saving on installation costs.

Energy efficiency is another major benefit. Modern 10x12 units use only 0.1529 kWh per day and feature eco-friendly R448A refrigerant. Many models deliver 20% better efficiency than older traditional coolers.

I'm Mortuary Cooler, a national-level supplier specializing in commercial refrigeration solutions including 10x12 walk in cooler systems for funeral homes and other specialized facilities. With years of experience helping businesses choose the right cooling equipment, I've seen how the right 10x12 unit can transform operations while keeping costs manageable.

10x12 walk in cooler glossary:

Understanding the 10x12 Walk-In Cooler

Picture this: you need serious cold storage space, but you don't want to dedicate half your building to it. That's where a 10x12 walk in cooler shines. With its generous 960 cubic feet of interior space, it's like having a walk-in closet that keeps everything perfectly chilled.

The exterior footprint measures 120" x 144", but here's what really matters - you get a roomy interior with about 82 inches of height. That means you can stack shelving units high and still walk comfortably underneath without bumping your head (trust me, that matters more than you'd think after a long day).

What makes these coolers so effective at their job? It all comes down to those 4-inch thick urethane panels with their impressive R-29 insulation rating. Think of it as wrapping your valuables in the world's best winter coat. These panels maintain rock-solid temperatures between 33°F and 38°F, hitting that sweet spot where everything stays fresh without freezing.

Every quality unit meets NSF/ANSI 7 certification and DOE compliance standards. That's not just bureaucratic paperwork - it means your cooler is safe for food storage and won't send your electric bill through the roof.

The magic number here is 38°F - widely considered the goldilocks temperature for refrigeration. It's cold enough to keep the FDA happy (they require 41°F or lower), but warm enough that you won't accidentally turn your lettuce into ice sculptures.

Typical Applications for a 10x12 Walk-In Cooler

The beauty of a 10x12 walk in cooler lies in its versatility. Restaurants love them for bulk ingredient storage - imagine having all your produce, dairy, and proteins organized in one temperature-controlled space. Bars and pubs use them to keep their beer selection perfectly chilled, while cafés store everything from fresh pastries to sandwich ingredients.

But these coolers aren't just for the food world. Floral shops rely on them to keep arrangements looking fresh for days longer than room temperature storage would allow. Scientific laboratories need precise temperature control for sensitive samples and materials that could be ruined by temperature fluctuations.

At American Mortuary Coolers, we've seen how funeral homes benefit tremendously from these units. They provide the perfect environment for storing supplies and maintaining proper conditions for specialized needs. The space is large enough to be practical but manageable enough to fit in most facilities.

For funeral industry professionals who want to dive deeper into the specifics, our In-Depth Guide to Comparing 10 x 12 Mortuary Cooler Options covers the unique requirements and features that matter most in mortuary applications.

Core Specifications & Features

Modern 10x12 walk in cooler units come packed with thoughtful features that make daily use a breeze. The self-closing doors include heated frames - a brilliant solution that prevents frost buildup around the seals. No more chipping ice or dealing with doors that won't close properly because of frost.

Those diamond-plate kick plates on the doors aren't just for looks. They're your first line of defense against the inevitable bumps and scrapes that happen during busy days. LED lighting comes standard on quality units, giving you crystal-clear visibility while sipping energy like a hummingbird.

The digital temperature controllers put you in complete control. No more guessing games - you can see exactly what's happening inside your cooler and make adjustments on the fly. Most units run on 208/230 volts and come with refrigeration systems ranging from ¾ HP to 3 HP, depending on your cooling needs and how hard your environment makes the system work.

Here's something that matters for our planet: these systems typically use R448A refrigerant, which is much friendlier to the environment than older refrigerants. It's proof that you don't have to choose between performance and responsibility.

For those interested in our specialized solutions, take a look at our 10x12 Mortuary Refrigerator | Walk-In Cooler | USA to see features custom-designed for funeral industry needs.

Comparing Top 10x12 Walk-In Cooler Brands & Models

Shopping for a 10x12 walk in cooler can feel overwhelming with so many options out there. Let me break down the top brands and what makes each one special, so you can find the perfect fit for your needs.

Atosa stands out as the efficiency champion in this space. Their modular design delivers an impressive 20% greater efficiency than traditional models - that's real money saved on your electric bill every month. The AWC1012-TF model has a list price of $30,691, but you'll typically find it selling for around $19,616 with their powerful 3 HP refrigeration system included.

AWIC (American Walk-In Coolers) takes a different approach, focusing on value without sacrificing quality. Their units start around $8,281 for basic configurations, making them perfect for businesses watching their budget. What I love about AWIC is that they include free PVC strip curtains and LED lighting - those little extras add up quickly when you're pricing everything separately.

Barr has built their reputation on availability. If you need a 10x12 walk in cooler fast, they're your go-to option with ready-to-ship units often available for immediate delivery. Their competitive pricing makes them a solid choice when time is critical.

Mr. Winter specializes in quick-ship options too, understanding that businesses sometimes need cooling solutions yesterday, not next month. They've streamlined their process to get units out the door quickly without compromising on quality.

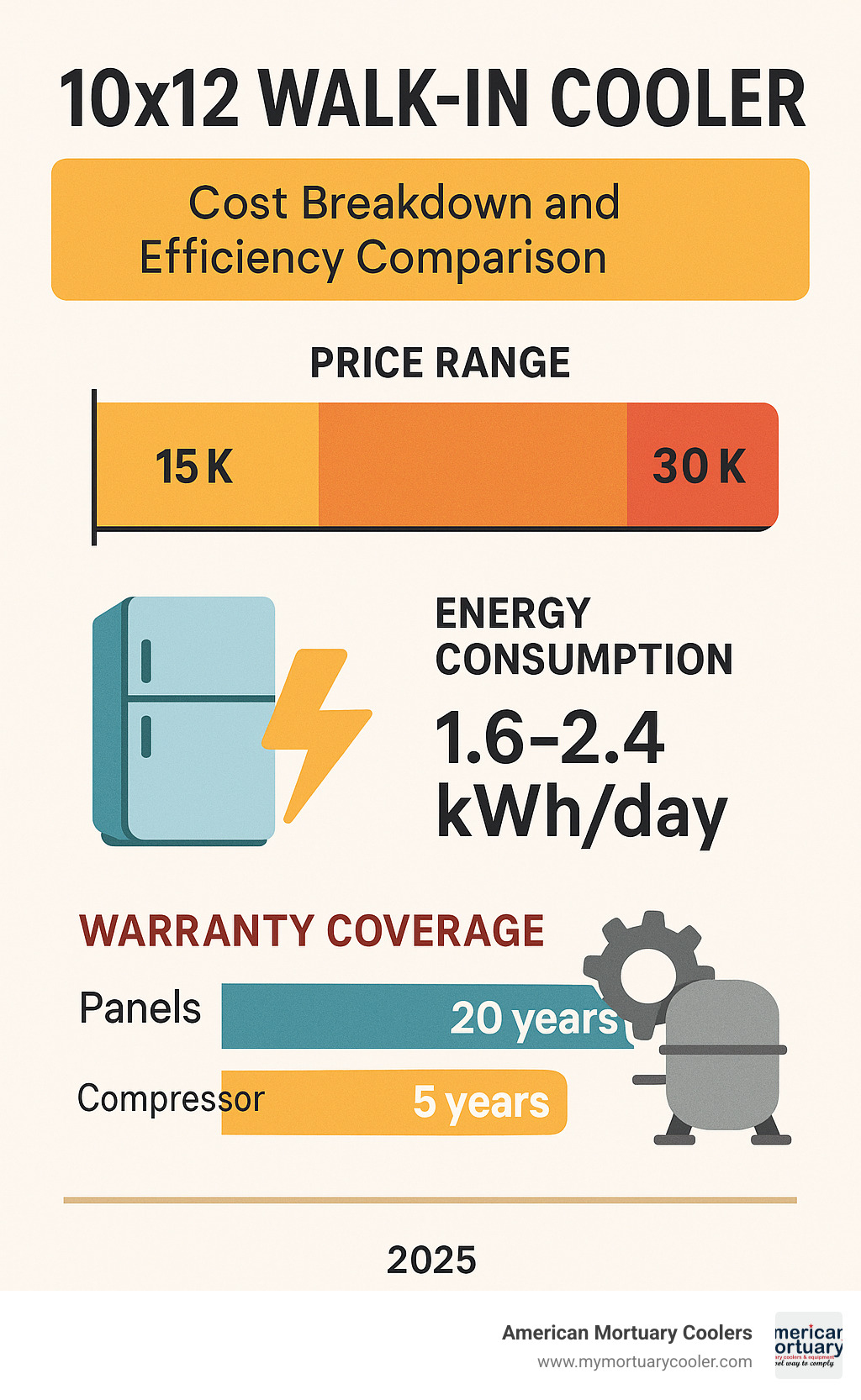

Across all these quality brands, you're looking at a price range from $8,000 to $30,000. The variation depends on features like refrigeration capacity, door configurations, and included accessories. Most manufacturers stick to similar warranty structures because they know what works: 20-year panel warranties, 5-year compressor coverage, and 1-year parts and labor protection.

Here's something that might surprise you - energy consumption is remarkably consistent across quality brands. Most units use approximately 0.1529 kWh per day, which translates to about $15-20 monthly in electricity costs.

| Brand | Starting Price | Key Features | Warranty |

|---|---|---|---|

| Atosa | $19,616 | 20% more efficient, 3 HP system | 20-yr panels, 5-yr compressor |

| AWIC | $8,281 | Free strip curtains, LED lighting | 20-yr panels, 5-yr compressor |

| Barr | Variable | Ready-to-ship availability | 20-yr panels, 5-yr compressor |

| Mr. Winter | Variable | Quick-ship specialization | 20-yr panels, 5-yr compressor |

Price & Warranty Breakdown

Let's talk about the real cost of owning a 10x12 walk in cooler - because the sticker price is just the beginning of the story.

That 20-year panel warranty isn't just marketing fluff. It reflects the genuine durability of modern urethane insulation panels. These panels maintain their R-29 insulation value throughout their entire lifespan, which means your energy costs stay predictable year after year. No nasty surprises when your cooling bills start creeping up because the insulation is failing.

The 5-year compressor warranty covers what's typically the most expensive component to replace. Quality compressors from manufacturers like Chandler often last well beyond the warranty period with proper maintenance. Think of it as insurance for your peace of mind.

Most suppliers include shipping to the lower 48 states in their pricing, which can save you $1,000 or more compared to paying freight charges separately. That's a significant chunk of change that you can put toward other features or just keep in your pocket.

Financing options are widely available, making it easier to spread the cost over time rather than taking a big hit to your cash flow. Upgrade costs for features like wider doors, heavy-duty floors, or improved refrigeration systems typically add $500 to $2,000 to the base price.

When you factor in the energy savings and long warranty coverage, the total cost of ownership becomes very reasonable. You're not just buying a cooler - you're investing in years of reliable, efficient operation.

Energy Efficiency & Refrigeration Packages for 10x12 Walk-In Cooler

Modern 10x12 walk in cooler units are remarkably efficient, consuming just 0.1529 kWh per day. To put that in perspective, that's roughly $15-20 per month in electricity costs, depending on your local rates. Compare that to running an older unit, and you'll see why upgrading makes financial sense.

The 20% efficiency improvement of newer models like the Atosa units can save hundreds of dollars annually compared to older coolers. That's money back in your pocket every single month, month after month.

The industry has made a smart switch to R448A refrigerant, which improves both efficiency and environmental impact. This eco-friendly refrigerant works effectively in the temperature ranges these coolers maintain while reducing greenhouse gas potential. It's good for your business and good for the planet.

ECM (electronically commutated motor) fans in the evaporator units provide additional energy savings by automatically adjusting speed based on cooling demand. Instead of running at full blast all the time, they ramp up when needed and dial back when things are under control. It's like having a smart thermostat for your cooling system.

For technical details on how these refrigeration components work together to maximize efficiency, check out our A Comprehensive Guide to Walk-In Cooler Compressors and Evaporators. Understanding your system helps you get the most out of your investment.

Buying Guide: Selecting & Customizing Your 10x12 Walk-In Cooler

Selecting the perfect 10x12 walk in cooler doesn't have to be overwhelming. I've helped hundreds of businesses make this decision, and it really comes down to understanding your specific needs and environment.

The biggest decision you'll face is whether to go with a floor or floorless model. If you're installing outdoors or placing your cooler directly on concrete, you absolutely need an insulated floor. Without it, you'll battle condensation issues and watch your energy bills climb. For indoor installations on raised platforms, floorless models work fine and save money.

Location matters more than most people realize. Outdoor installations need weather-resistant components and typically require larger refrigeration systems to handle temperature swings. Your 3 HP system might struggle on a 95°F summer day if it's sitting outside. Indoor units can use smaller, more efficient systems but need proper ventilation around the condenser - don't stuff it in a corner and expect it to work miracles.

Door selection can make or break your daily operations. The standard 36" x 78" doors work for most situations, but upgrading to 49" pallet-wide doors makes sense if you're moving large items or using forklifts. Trust me, trying to maneuver a loaded pallet through a narrow door gets old fast.

Strip curtains are worth every penny if your door opens frequently. They maintain temperature while allowing easy access. Loading ramps eliminate the hassle of lifting heavy items over the door threshold. Temperature alarms can save you thousands in spoiled products - they're cheap insurance that pays for itself the first time they prevent a disaster.

Popular customization options include heavy-duty floors rated for 1,200+ pounds, upgraded LED lighting systems, and antimicrobial wall liners for improved sanitation. Each serves specific needs, so focus on what matters most for your operation.

Sizing & Layout Considerations for a 10x12 Walk-In Cooler

Getting the layout right in your 10x12 walk in cooler makes the difference between smooth operations and daily frustration. I always tell customers to plan for 36 inches of aisle width minimum - you need room to move comfortably with loaded carts. If forklifts or pallet jacks are part of your workflow, bump that up to 48 inches.

Shelving depth affects both storage capacity and airflow. Standard 18-inch deep shelving hits the sweet spot - maximizing storage while maintaining proper air circulation. Deeper shelving might seem like more storage, but it blocks airflow and creates hot spots that compromise your products.

Here's something most people miss: leave at least 6 inches of clearance around the evaporator unit. Block that airflow, and your cooler works harder while cooling less effectively. It's like putting a blanket over your air conditioner.

Think about future expansion when planning your layout. The modular panel construction makes expansion possible later, but it's easier and more cost-effective to size appropriately from the start. Consider your business growth over the next 5-10 years - that 10x12 walk in cooler that seems huge today might feel cramped in five years.

Custom Features & Add-Ons

Modern 10x12 walk in cooler units offer impressive customization options. LED strip lighting provides better illumination than standard fixtures while using less energy. Smart monitoring systems can send alerts to your phone if temperatures rise - preventing costly product loss while you're away.

Heavy-duty floors become essential for operations storing heavy items or using forklifts. These floors support 1,200+ pounds per square foot versus 300-500 pounds for standard floors. Antimicrobial wall liners help maintain sanitary conditions and prove particularly valuable in food service and medical applications.

The key is matching features to your actual needs. A floral shop might prioritize humidity control, while a restaurant focuses on heavy-duty doors and ramps. Don't pay for features you won't use, but don't skimp on ones that matter to your operation.

For comprehensive information on available options, see our Best Walk-In Cooler Options Available guide.

Installation, Maintenance & Compliance Essentials

Setting up your 10x12 walk in cooler doesn't have to be overwhelming. The cam-lock panel system makes installation surprisingly straightforward - these panels literally snap together without requiring special tools or professional contractors. Think of it like building with grown-up Legos, except these pieces create airtight seals that keep your cooler running efficiently for decades.

Before your cooler arrives, you'll need to prepare the installation site properly. Site preparation includes ensuring you have adequate electrical service - most units require 208/230V power. Your floor needs to be level and well-drained. Don't forget to check local building codes for seismic, wind, and snow load requirements. Some areas require engineered drawings or special anchoring systems, which can add time and cost to your project.

The refrigeration system needs room to breathe. Plan for adequate clearance around the condenser for airflow and future service access. Your technician will thank you later when they can easily reach all components for maintenance.

Once your cooler is running, regular maintenance becomes your best friend for keeping energy costs down and avoiding expensive repairs. Monthly condenser coil cleaning maintains efficiency and prevents premature compressor failure. Quarterly door seal inspections catch problems before they waste energy or cause temperature fluctuations. Temperature logs help you spot potential issues before they become costly failures.

For detailed cost information about professional installation services, check out our guide on walk-in cooler installation costs.

Step-By-Step Assembly and Delivery Process

Your 10x12 walk in cooler typically arrives via truck with lift-gate delivery service included. The panels, refrigeration system, and accessories usually ship on one or two pallets. Standard curb delivery means the driver will place your shipment at the curb - some suppliers offer inside delivery for an additional fee, which can be worth it for heavier components.

Assembly follows a logical sequence that takes about 4-6 hours with two people. Start with floor panels if your unit includes them, then erect the walls and ceiling panels. The cam-lock system makes this process straightforward, but following the manufacturer's instructions carefully ensures proper sealing between panels.

The refrigeration system connects last and requires basic electrical knowledge. If you're not comfortable with electrical connections, hiring a qualified technician for this step is a smart investment. Most suppliers provide detailed assembly instructions and phone support during installation, with some offering helpful video guides.

Plan for a full day to complete installation, testing, and initial temperature stabilization. Your cooler will need several hours to reach its target temperature range after startup.

Routine Maintenance to Keep Your 10x12 Walk-In Cooler Efficient

Keeping your 10x12 walk in cooler running efficiently doesn't require a degree in refrigeration, but it does need consistent attention. Monthly maintenance should include cleaning the condenser coils, checking refrigerant levels, and inspecting door seals. Clean coils are crucial - dirty coils make your compressor work harder and can lead to premature failure.

Quarterly tasks include deep cleaning the interior, checking defrost system operation, and calibrating temperature controls. Annual professional service helps identify potential problems before they cause expensive failures. Keep detailed maintenance logs to track performance and identify trends that might signal developing issues.

Door seal inspection deserves special attention. Damaged seals waste energy and can cause dangerous temperature fluctuations. The magnetic gasket seals used on quality units typically last 3-5 years with proper care. Replace them promptly when they show wear or lose their magnetic grip - it's much cheaper than replacing spoiled inventory.

Cleaning schedules should include weekly interior sanitizing, monthly coil cleaning, and quarterly gasket care. The defrost cycles run automatically, but monitor them to ensure they're completing properly.

For comprehensive maintenance guidance, our A Practical Guide to Understanding Walk-In Coolers covers everything you need to know about keeping your investment running smoothly.

Frequently Asked Questions about 10x12 Walk-In Coolers

What temperature range is ideal for a 10x12 walk-in cooler?

The sweet spot for your 10x12 walk in cooler is 36-38°F. This temperature range keeps everything fresh while staying comfortably within the FDA's requirement of staying below 41°F for commercial food storage.

Most operators find that 38°F works perfectly for their needs. It's cold enough to preserve perishables but won't freeze delicate items like lettuce or flowers that can get damaged below 35°F. The automatic defrost system kicks in if temperatures drop too low, preventing the whole system from freezing up.

This temperature range works well whether you're storing restaurant ingredients, floral arrangements, or specialized items for funeral homes. The consistent temperature control helps maintain quality and extends the shelf life of whatever you're storing.

How much does a 10x12 walk-in cooler cost including installation?

You're looking at $11,000 to $25,000 for a complete 10x12 walk in cooler setup, including installation. The final price depends on several factors that can add up quickly.

Insulated floors add $1,000-2,000 to your total but are essential for outdoor installations or heavy storage needs. Higher horsepower refrigeration systems can add another $500-1,500, especially if you're in a hot climate or need faster recovery times.

Most suppliers include freight costs to the lower 48 states, which saves you money. Professional installation typically runs $500-1,500, though many businesses save by doing the assembly themselves using the cam-lock panel system.

Basic units start around $8,281, while fully-loaded models with premium features can reach $30,000. The middle range around $15,000-18,000 gives you a solid unit with good features for most applications.

Do I need an insulated floor in my 10x12 walk-in cooler?

You definitely need an insulated floor if your cooler will handle loads over 500 pounds, be placed outdoors, or if humidity control is critical for your operation.

Insulated floors prevent condensation from forming underneath your cooler, which can cause structural problems and increase energy costs. They also provide the structural support needed for heavy storage - standard floors only handle 300-500 pounds per square foot, while heavy-duty insulated floors can support over 1,200 pounds per square foot.

For outdoor installations, insulated floors are absolutely essential. They protect against ground moisture and temperature fluctuations that can make your refrigeration system work much harder. If you're placing your 10x12 walk in cooler on a concrete pad, an insulated floor is highly recommended even for indoor use.

The extra cost is worth it for the energy savings and peace of mind, especially if you're storing valuable inventory or running a high-volume operation.

Conclusion

Choosing the right 10x12 walk in cooler can transform how your business handles cold storage. With 960 cubic feet of space, these units hit that sweet spot between having enough room for serious storage needs and keeping costs manageable. They're not too big, not too small - just right for restaurants, funeral homes, labs, and countless other businesses that need reliable refrigeration.

The numbers speak for themselves: 20-year panel warranties and 5-year compressor coverage give you peace of mind, while energy consumption of just 0.1529 kWh per day keeps your electric bills reasonable. Modern features like eco-friendly R448A refrigerant, bright LED lighting, and precise digital controls make these units a joy to work with compared to older models that were energy hogs.

At American Mortuary Coolers, we've been helping businesses across the country find the perfect cold storage solutions. From our home base in Tennessee, we deliver customized 10x12 walk in cooler systems to all 48 contiguous states. Our specialty is mortuary applications, but we understand that great refrigeration principles apply whether you're storing flowers, food, or anything else that needs to stay cold.

What makes these coolers such a smart investment is their durability and energy savings. With proper care - and it's really not much work - these units will keep humming along for decades. The modular design means you can even expand later if your business grows. That's the kind of flexibility that makes financial sense.

Whether you need a basic setup for general storage or something specialized for mortuary work, a quality 10x12 walk in cooler pays for itself over time. The combination of reliable performance, low operating costs, and long warranties makes it one of the smartest equipment purchases you can make for your business.

Ready to learn more? Our A Comprehensive Guide to Walk-In Coolers has all the details you need to make the best choice for your specific situation.