Understanding the Cycle of Refrigerant Fundamentals

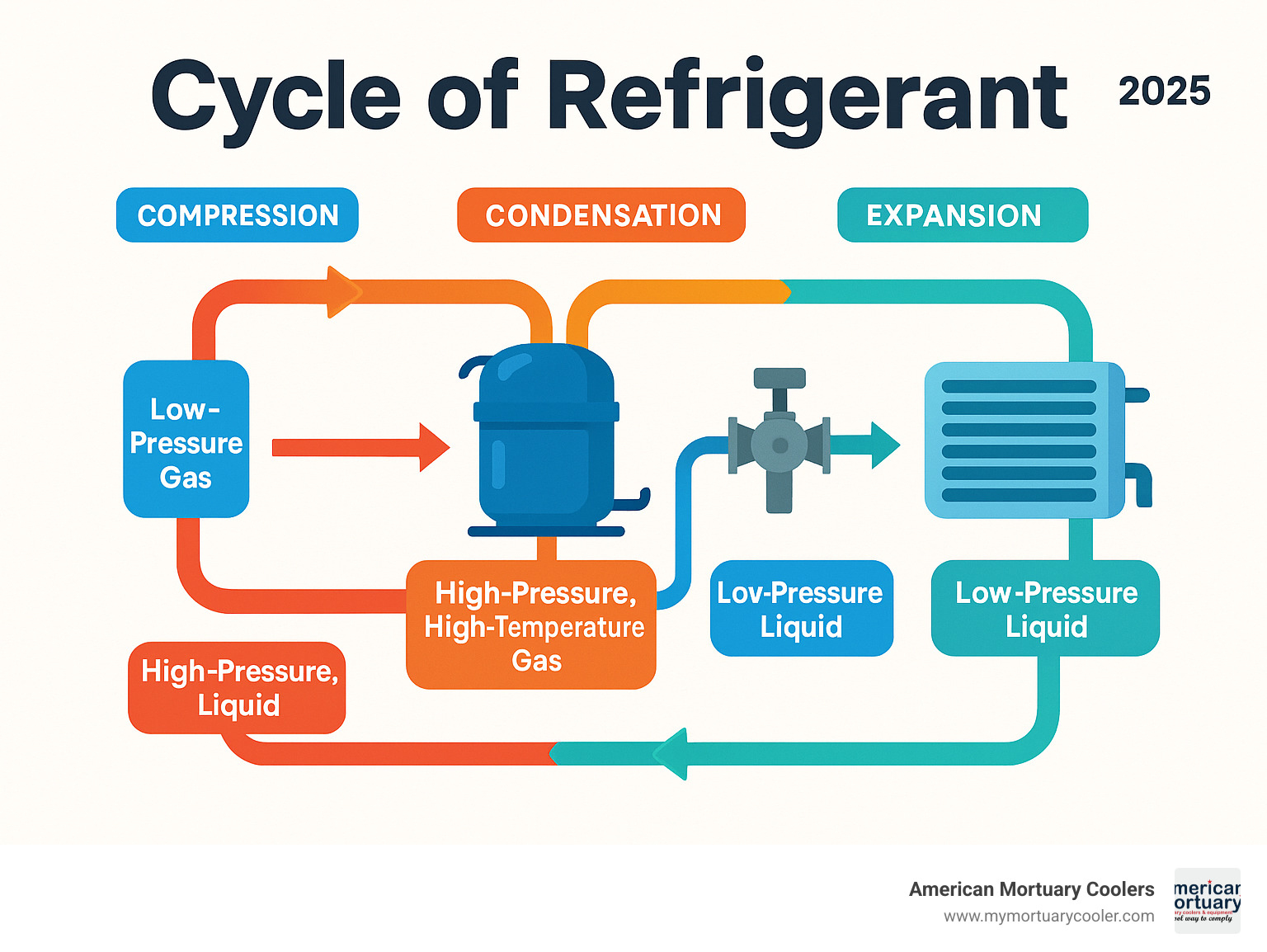

The cycle of refrigerant is a continuous thermodynamic process that moves heat from one location to another using a specialized fluid called refrigerant. This closed-loop system operates through four main stages that work together to create cooling or heating effects in everything from home air conditioners to mortuary coolers.

The four stages of the refrigerant cycle are:

- Compression - Low-pressure gas is compressed into high-pressure, high-temperature gas

- Condensation - Hot gas releases heat and condenses into liquid form

- Expansion - High-pressure liquid drops in pressure and temperature through an expansion device

- Evaporation - Low-pressure liquid absorbs heat and turns back into gas

This process repeats continuously, with refrigerant completing 3-5 full cycles per hour in typical residential systems. The cycle works because liquids absorb heat when they evaporate and release heat when they condense - a fundamental principle that makes modern refrigeration possible.

Whether you're dealing with a walk-in cooler, mortuary freezer, or any cooling system, understanding how the refrigerant moves through these stages helps you troubleshoot problems, optimize performance, and ensure reliable operation. The same basic principles apply whether the system is cooling food, preserving bodies, or maintaining comfortable indoor temperatures.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigeration systems and the cycle of refrigerant processes that power mortuary cooling equipment. My background includes designing and supplying custom cooling solutions that rely on precisely tuned refrigerant cycles for optimal performance and reliability.

Cycle of refrigerant terms simplified:

The Science Behind the Cycle of Refrigerant

Think of the cycle of refrigerant as nature’s heat-shuttling trick. When liquids evaporate they absorb heat; when vapors condense they release it. Your body feels the same physics when sweat cools your skin.

Because the refrigerant is in a closed loop system, the same fluid keeps changing state over and over. Nothing is “used up”; we’re just moving heat.

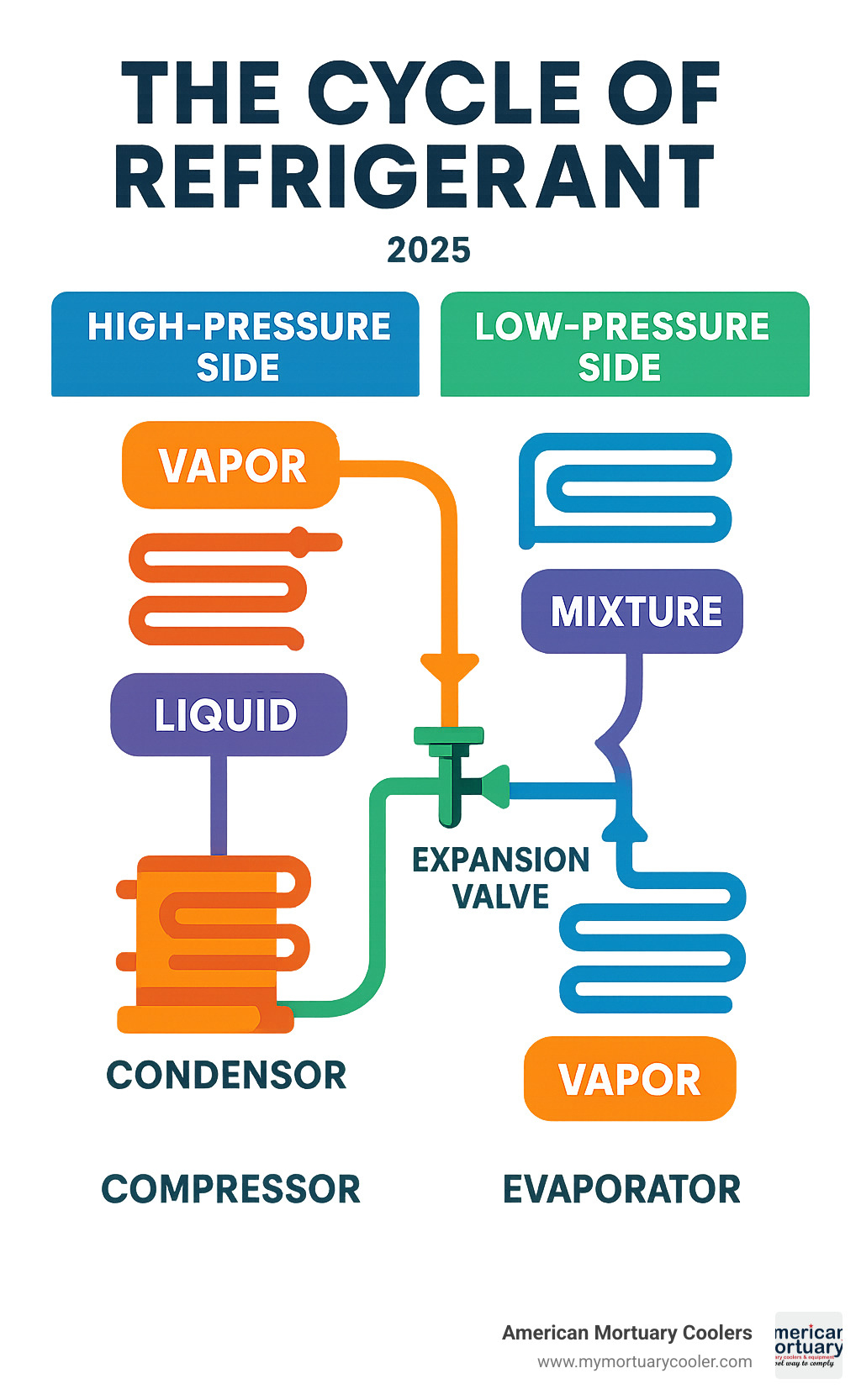

Pressure drives those phase changes. Compress a gas and, by the Ideal Gas Law, its temperature shoots up. Give it room to expand and it cools down. Systems simply alternate between a hot, high-pressure “reject heat” side and a cold, low-pressure “absorb heat” side:

| High Side (Condenser) | Low Side (Evaporator) |

|---|---|

| High pressure / temperature | Low pressure / temperature |

| Refrigerant releases heat | Refrigerant absorbs heat |

| Gas condenses to liquid | Liquid evaporates to gas |

Why does this matter? Every modern convenience—from safe food to air-conditioned offices—relies on that table. Data centers, vaccine freezers, and the mortuary coolers we build at American Mortuary Coolers all protect precious contents by controlling these pressures and temperatures.

Key principles that keep the loop orderly include:

- Ideal Gas Law – pressure ↔ temperature

- Boiling-point manipulation – refrigerants are chosen to boil at very low temps

- Phase equilibrium – knowing exactly when liquid turns to vapor lets technicians set targets and diagnose faults

For a deeper dive into heat-transfer basics, see this scientific research on heat transfer.

Core Components and Their Roles in the Cycle of Refrigerant

Every cycle of refrigerant relies on four core parts working like a relay team:

- Compressor – raises pressure and temperature

- Condenser – dumps heat to the surroundings

- Expansion device – drops pressure so cooling can occur

- Evaporator – absorbs heat and turns liquid back to vapor

Two operating “guardrails” keep the hand-off smooth: superheat (protects the compressor from liquid) and subcooling (guarantees solid liquid to the expansion device).

The Compressor: Heart of the System

Like a heart pumping blood, the compressor pushes refrigerant around the loop. Common styles include:

- Reciprocating – piston driven, rugged, economical, but noisy. Good for small to mid-size walk-ins. Reciprocating compressors

- Scroll – quiet, efficient spiral halves; popular in comfort cooling.

- Rotary/Screw – continuous flow for large commercial loads.

All do the same job: take low-pressure vapor from the evaporator and discharge high-pressure vapor into the condenser.

The Condenser: Heat Rejector

Air-cooled units blow outdoor air across refrigerant coils; water-cooled variants circulate water. Either way, the vapor first desuperheats, then condenses, then subcools before heading to the liquid line. Clean coils and good airflow keep head pressures in check.

Expansion Devices

These create the all-important pressure drop.

- Thermostatic expansion valves (TXVs) automatically meter flow.

- Capillary tubes are fixed-orifice workhorses for small fridges.

- Electronic expansion valves (EEVs) add micro-precision.

When high-pressure liquid hits the restriction, part of it “flashes” to vapor, chilling everything down for the evaporator. More info about 404 compressors

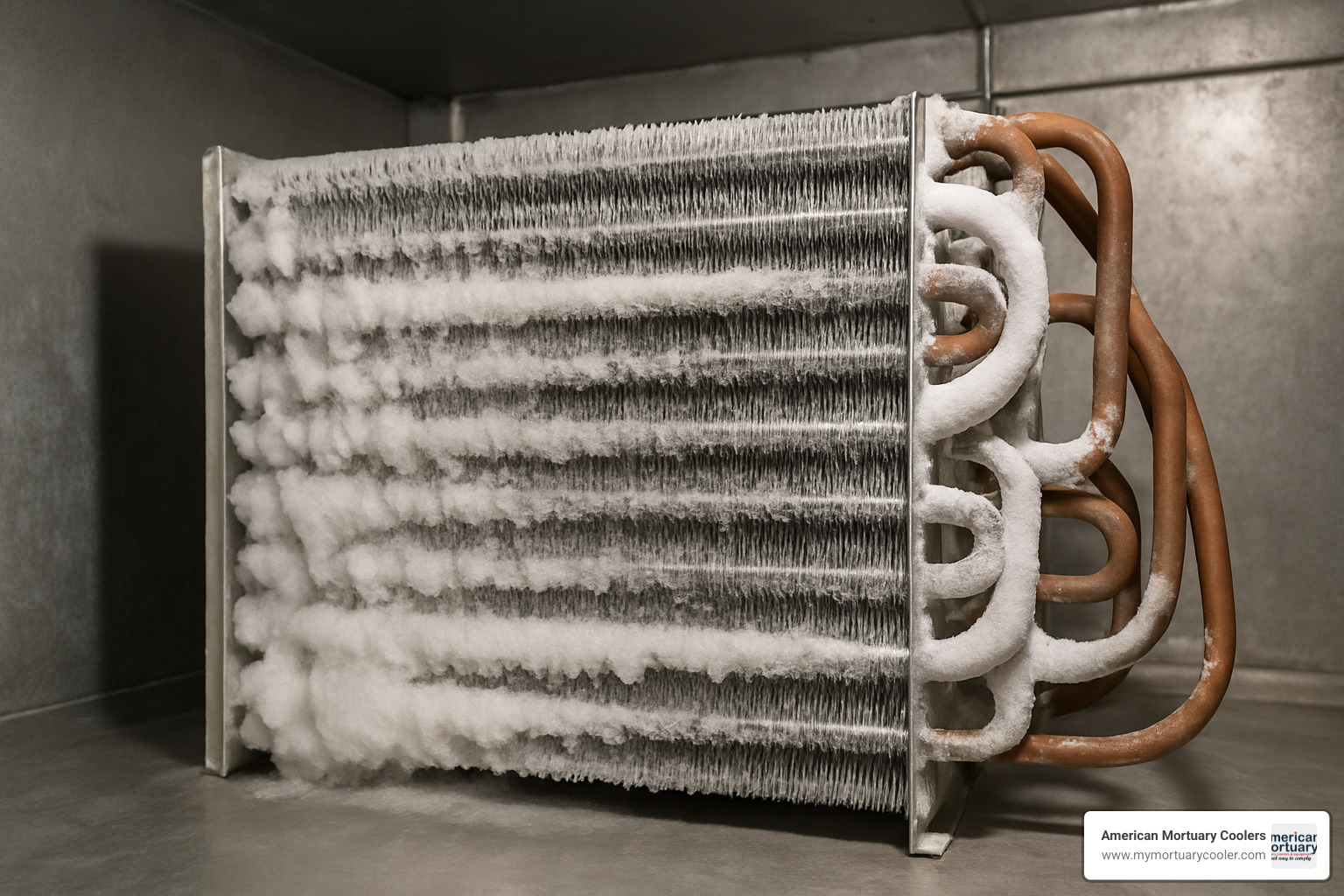

The Evaporator: Where Cooling Happens

Inside the walk-in, low-pressure liquid boils and soaks up heat. Fin spacing balances surface area against frost risk—wider fins suit mortuary units with frequent door openings. Proper defrost and 10-15 °F of superheat ensure only vapor heads back to the compressor.

Operating Phases: High Side vs Low Side in the Cycle of Refrigerant

Think of the cycle of refrigerant like a highway with two lanes - one for high-pressure traffic and one for low-pressure traffic. The compressor acts like a toll booth that separates these two sides, creating a pressure difference that makes the whole system work.

The high side includes everything from the compressor discharge through the condenser, liquid line, and right up to the expansion device. Here's where refrigerant lives the high-pressure life - typically running between 200-400 PSI depending on what type of refrigerant you're using and how hard the system is working. The refrigerant is hot and under pressure, which is exactly what we need to dump heat into the outside air.

On the flip side, the low side covers everything from the expansion device outlet through the evaporator, suction line, and back to the compressor inlet. This is the chill zone where refrigerant operates at much lower pressures - usually somewhere between 20-80 PSI. The lower pressure means lower temperature, which lets the refrigerant soak up heat from whatever you're trying to cool.

This pressure split isn't just clever engineering - it's absolutely essential. Heat always flows from hot to cold, so we need the high-pressure side to be hotter than the outside air to reject heat, while the low-pressure side must be colder than your walk-in cooler or mortuary unit to absorb heat effectively.

Heat Absorption & Rejection Sequence

The beauty of the cycle of refrigerant lies in its perfectly choreographed heat transfer dance. Each phase builds on the previous one, creating a continuous loop that never misses a beat.

Compression kicks off the show by taking lazy, low-pressure refrigerant vapor and giving it a serious energy boost. The compressor doesn't just increase pressure - it pumps real energy into the refrigerant, making it both high-pressure and high-temperature. This energy input is what powers the entire cycle.

During condensation, that hot, energized refrigerant vapor meets its match - ambient air or cooling water. As it releases heat to the environment, the vapor condenses back into liquid form. The condenser actually handles more heat than the evaporator absorbs because it has to reject both the heat picked up from your cooled space plus all that extra energy the compressor added.

The expansion phase is where things get really interesting. When high-pressure liquid refrigerant hits the expansion device, it's like opening a champagne bottle - the sudden pressure drop causes some of the liquid to instantly flash into vapor. This flashing process cools down the remaining liquid, preparing it perfectly for the next phase.

Evaporation is where the magic happens for your cooling needs. The cold, low-pressure liquid refrigerant eagerly absorbs heat from your mortuary cooler or walk-in, causing it to boil and turn back into vapor. This vapor then travels back to the compressor, and the whole beautiful process starts over again.

Superheating & Subcooling Significance

If you want your cycle of refrigerant to run smoothly and efficiently, you need to understand superheat and subcooling. These aren't just technical terms - they're your system's insurance policies against damage and poor performance.

Superheat is like adding a safety buffer to your refrigerant vapor. It means heating the vapor above its normal boiling point before it reaches the compressor. This extra heat ensures that only vapor - never liquid - enters the compressor. Why does this matter? Because liquid refrigerant hitting compressor pistons is like throwing rocks into a blender. It can crack valves, bend connecting rods, or destroy pistons entirely.

But superheat isn't just about protection - it's about getting every ounce of cooling capacity from your evaporator. Too little superheat means you're wasting evaporator space with liquid that isn't absorbing heat. Too much superheat means you're starving the evaporator of refrigerant. Most systems run happiest with about 10-15°F of superheat at the evaporator outlet.

Subcooling works on the high side to ensure you get a solid column of liquid refrigerant to your expansion device. It means cooling the liquid refrigerant below its condensing temperature. Without proper subcooling, you might get vapor bubbles in your liquid line, causing the expansion device to act erratically.

More info about R404 PT chart shows exactly how these temperature and pressure relationships work together in real-world applications.

Every degree of subcooling typically boosts your system capacity by 0.5-1%. In our mortuary cooler applications at American Mortuary Coolers, this extra capacity helps maintain rock-solid temperatures even when funeral directors are opening doors frequently or adding multiple bodies during busy periods.

Variations, Applications, and Troubleshooting

While the basic cycle of refrigerant remains consistent, different applications require variations in components and operation. Vapor-compression cycles are most common, but absorption cycles use heat instead of mechanical compression. Heat pumps use the same refrigerant cycle but can reverse operation to provide heating instead of cooling.

Walk-in coolers and freezers, like those we manufacture at American Mortuary Coolers, represent specialized applications of the cycle of refrigerant. These systems must maintain precise temperatures while handling frequent door openings, high humidity loads, and varying product loads. Scientific research on scroll compressors shows how different compressor types perform in these applications.

Mortuary coolers present unique challenges requiring specialized refrigeration cycle design. They must maintain consistent temperatures for extended periods, handle the thermal mass of bodies, and operate reliably 24/7. Our experience across regions from Tennessee to California has shown us how ambient conditions affect cycle performance.

Choosing the Right Compressor & Expansion Device

Selecting appropriate components for the cycle of refrigerant depends on several factors including capacity requirements, efficiency goals, noise constraints, and reliability needs. Compressor selection particularly impacts overall system performance and operating costs.

For smaller systems, reciprocating compressors offer good value and reliability. They're available in wide capacity ranges and can handle varying loads well. However, they're noisier than other types and may require more maintenance.

Scroll compressors provide quieter operation and higher efficiency, making them ideal for applications where noise is a concern. They have fewer moving parts than reciprocating types, potentially offering better reliability. However, they're more expensive initially.

Expansion device selection affects both capacity and efficiency. TXVs provide the best control and efficiency but cost more than capillary tubes. EEVs offer the most precise control and can adapt to varying loads, but they're the most expensive option and require electronic controls.

Practical Uses in Everyday Life & Industry

The cycle of refrigerant touches virtually every aspect of modern life. Home refrigerators and freezers use the cycle to preserve food, preventing spoilage and reducing waste. Air conditioners make hot climates livable and protect sensitive equipment from overheating.

In industrial applications, process cooling maintains product quality in manufacturing. Cold storage warehouses use large refrigeration systems to preserve food from farm to table. Data centers rely on precision cooling to prevent server failures that could disrupt internet services.

At American Mortuary Coolers, we've specialized in applying the cycle of refrigerant to mortuary applications. Our custom units serve funeral homes across the contiguous 48 states, from our Tennessee base to installations in major metropolitan areas. Each application requires careful attention to the refrigeration cycle design.

Cold chain logistics depends entirely on reliable refrigeration cycles. Vaccines, medicines, and temperature-sensitive foods all require unbroken refrigeration from production to consumption. A single cycle failure can result in thousands of dollars in lost product and potential health risks.

Diagnosing Common Cycle Failures

Understanding the cycle of refrigerant helps diagnose common problems that affect system performance. Low refrigerant charge is perhaps the most common issue, causing reduced capacity, longer run times, and potential compressor damage from overheating or liquid slugging.

High head pressure can result from dirty condenser coils, inadequate airflow, or overcharge. This forces the compressor to work harder, increasing energy consumption and potentially causing premature failure. Regular maintenance prevents most high head pressure problems.

Iced evaporator coils indicate problems with defrost systems, low airflow, or refrigerant flow issues. More info about fixing iced evaporator provides detailed troubleshooting steps for this common problem.

Oil return problems can starve the compressor of lubrication, leading to catastrophic failure. Proper system design ensures oil circulates with refrigerant and returns to the compressor. Low refrigerant velocity, improper piping, or wrong oil type can all cause oil return issues.

Frequently Asked Questions about the Cycle of Refrigerant

When you're working with refrigeration systems day in and day out, certain questions come up again and again. Whether you're troubleshooting a walk-in cooler or trying to understand why your mortuary unit isn't performing optimally, these are the cycle of refrigerant questions that matter most.

What causes pressure differences in the cycle of refrigerant?

The magic behind the cycle of refrigerant starts with the compressor - it's literally the engine that creates the pressure differences that make everything work. Think of it like your heart pumping blood through your body, except the compressor is pumping refrigerant through the system.

When the compressor runs, it mechanically squeezes refrigerant vapor, creating what we call a compression ratio. Most systems operate with compression ratios between 3:1 and 8:1, meaning the high-side pressure is three to eight times higher than the low-side pressure. This isn't just a random number - it's carefully engineered to create the right temperature differences for heat transfer.

The expansion device then acts like a controlled bottleneck, creating a flow restriction that maintains the pressure difference. Without this restriction, pressures would equalize and no cooling would occur. It's a delicate balance - too much restriction and the evaporator starves for refrigerant, too little and the compressor can't build adequate pressure.

How often does refrigerant complete a full cycle?

Here's something that might surprise you - in a typical residential HVAC system, the same refrigerant molecules complete their journey through all four components about 3-5 cycles per hour. That means every 12-20 minutes, refrigerant travels from the compressor through the condenser, expansion device, and evaporator, then back to start over again.

Commercial systems often cycle more frequently, especially during peak load conditions. In our mortuary cooler applications, cycling frequency depends on factors like ambient temperature, door openings, and the thermal load from bodies being stored. A busy funeral home might see more frequent cycling than one with steady, predictable loads.

The cycling frequency actually tells you a lot about system health. Systems that cycle too frequently might be oversized or have control issues, while systems that run continuously might be undersized or have refrigerant problems.

Why are superheat and subcool critical?

Superheat and subcooling are like the safety guards and performance boosters of the cycle of refrigerant. Get these wrong, and you're looking at either equipment damage or poor performance - sometimes both.

Liquid slugging is every compressor's worst nightmare. When liquid refrigerant enters a compressor designed for vapor, it's like trying to compress water - something's got to give, and it's usually expensive internal components. Proper superheat ensures only vapor reaches the compressor, preventing this catastrophic damage to valves, pistons, or scroll elements.

On the flip side, subcooling ensures capacity boost by delivering solid liquid refrigerant to the expansion device. Vapor bubbles in the liquid line cause erratic operation and reduce system capacity. Every degree of subcooling typically increases system capacity by about half a percent - that might not sound like much, but it adds up to significant energy savings and better performance.

At American Mortuary Coolers, we've seen how critical these measurements are in our custom units. Proper superheat and subcooling mean the difference between a system that maintains precise temperatures reliably and one that struggles to keep up with demand.

Conclusion

The cycle of refrigerant has quietly revolutionized how we live and work, making possible everything from your morning coffee's fresh cream to the servers hosting this very webpage. When you understand how refrigerant dances through its four-stage performance - compression, condensation, expansion, and evaporation - you gain insight into one of humanity's most practical scientific achievements.

This knowledge becomes especially meaningful in our work at American Mortuary Coolers. Our custom units don't just rely on textbook theory - they depend on perfectly tuned refrigeration cycles that funeral directors can count on day after day. Whether we're installing a system in the humid climate of Tennessee or the desert heat of Arizona, the same fundamental principles ensure families receive the dignity and care they deserve during difficult times.

The beauty of the cycle of refrigerant lies in its neat simplicity. Four components, four stages, endless applications. Yet this simplicity shouldn't fool anyone - achieving reliable performance requires careful attention to superheat, subcooling, proper sizing, and maintenance. When everything works together harmoniously, the system operates so smoothly you hardly notice it's there.

Looking ahead, refrigeration technology continues advancing with more efficient compressors, environmentally friendly refrigerants, and smarter controls. But the core science remains unchanged - we're still manipulating pressure and temperature to move heat exactly where we want it. This timeless foundation gives us confidence that the systems we design today will serve funeral homes reliably for decades to come.

For funeral professionals investing in cooling equipment, understanding these principles helps you make smarter decisions about equipment selection, maintenance schedules, and troubleshooting. A system that's properly designed around sound refrigeration cycle principles will reward you with consistent temperatures, lower energy bills, and fewer emergency service calls. More info about Refrigeration System basics dives deeper into these essential concepts that keep your most important equipment running smoothly.