Why Exterior Walk In Coolers Are Essential for Modern Operations

An exterior walk in cooler is a weatherproof refrigeration unit designed specifically for outdoor installation, offering businesses a space-saving solution that moves temperature-controlled storage outside the main facility. Unlike indoor units, exterior walk-in coolers feature improved insulation, weatherproof roofing, and specialized materials to withstand environmental conditions.

Key Benefits of Exterior Walk In Coolers:

- Space Optimization - Frees up valuable interior square footage for operations

- Weather Resistance - Built with thicker insulation and protective roofing systems

- Energy Efficiency - Cold climates actually improve performance by reducing heat absorption

- Regulatory Compliance - NSF-approved components meet strict industry standards

- Durability - Seamless construction prevents moisture damage and bacterial growth

For mortuary and forensic facilities, exterior units provide critical advantages. Moving refrigeration outdoors creates more workspace indoors while maintaining OSHA compliance through specialized construction features like NSF-approved flooring and proper insulation systems.

The research shows that outdoor walk-in coolers require specific engineering considerations that indoor units simply cannot provide. Conventional indoor units lack weatherproofing and proper insulation thickness, making outdoor use inadvisable and potentially damaging to both equipment and stored materials.

Modern exterior coolers use advanced materials like urethane insulation with industry-leading R-values, while fiberglass construction offers superior thermal properties compared to traditional metal exteriors that conduct heat.

Why Choose an Outdoor Unit Over an Indoor One?

The benefits of an exterior walk in cooler go far beyond another refrigeration option, especially when every square foot in your mortuary or forensic facility is precious.

Space optimization is the game-changer here. Moving your temperature-controlled storage outdoors immediately frees up valuable interior square footage that you can put to better use. That space can become preparation areas, equipment storage, or give staff more room to work. In sensitive operations, that extra breathing room makes a difference.

But the benefits don't stop at space savings. An outdoor unit creates an independent structure that operates completely separately from your main building. This means when it's time for maintenance or repairs, your indoor operations keep running smoothly. No technicians disrupting your workflow or temporary shutdowns affecting your daily schedule.

Here's something many people don't consider: reduced indoor noise and heat load. Refrigeration systems work hard and generate both sound and heat as byproducts. By moving this equipment outside, you create a quieter, more comfortable indoor environment while potentially reducing your building's air conditioning costs.

For mortuary professionals, outdoor coolers offer another advantage - independent access. Staff can retrieve what they need without entering the main facility, which can be particularly useful during off-hours or when managing workflow around sensitive procedures.

To understand the full scope of these benefits, consider how outdoor walk-in coolers maximize storage and efficiency. You can learn more about maximizing storage and efficiency with outdoor walk-in coolers in our detailed guide.

The engineering differences between indoor and outdoor units are significant. Indoor coolers typically rely on your building's roof and foundation, use standard insulation thickness, and need minimal weatherproofing. Exterior walk in coolers, on the other hand, require specialized membrane or standing seam roofs, thicker insulation for superior thermal resistance, NSF-approved reinforced flooring rated for pallet jacks, and comprehensive weatherproofing to handle everything from UV exposure to snow loads.

These aren't just nice-to-have features - they're essential for reliable outdoor performance. The improved seals, weather-resistant panels, and engineered structural support ensure your investment performs reliably regardless of climate conditions, while maintaining the OSHA compliance standards your facility requires.

Key Design Factors for Your Exterior Walk In Cooler

When investing in an exterior walk in cooler, you're building a fortress to protect your inventory from the elements. Whether it's sun, rain, snow, or salt air, your cooler must maintain perfect internal conditions while standing strong.

The secret lies in getting four critical factors right: structural integrity, weather resistance, longevity, and performance. Missing any of these can lead to costly repairs, energy waste, or spoiled inventory. For a comprehensive look at how these factors work together, check out our Comprehensive Guide to Walk-in Cooler Options.

Essential Structural Features

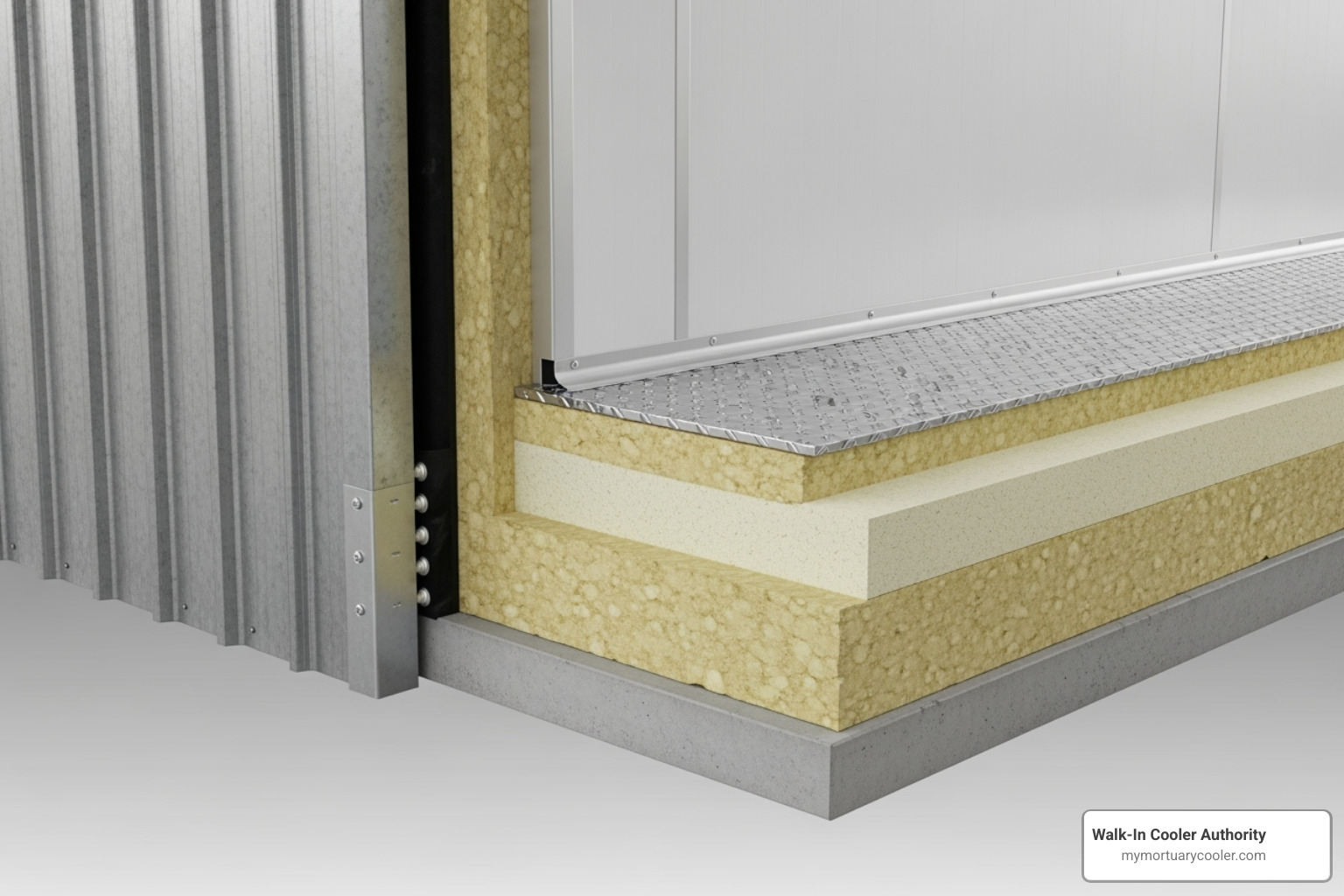

The backbone of any reliable exterior walk in cooler starts with superior insulation. Urethane insulation delivers the highest R-value in the industry, and for outdoor units, this matters more than you might think. While indoor units might get by with standard thickness, outdoor coolers typically need beefier protection – often 4 inches or more of foamed-in-place urethane insulation that can achieve R-values around R-29 for coolers and R-32 for freezers.

Think of your panel thickness as your first line of defense against heat infiltration. When the summer sun is beating down relentlessly, that extra insulation is what keeps your refrigeration system from working overtime and your energy bills from skyrocketing.

Roofing is where outdoor units really differ from their indoor cousins. Your exterior walk in cooler absolutely needs a robust roof system – there's no building overhead to protect it. Membrane roofs and standing seam roofs are the gold standards here, engineered to handle specific snow loads based on your geographic location while providing bulletproof protection against rain and UV radiation.

The flooring situation gets interesting with outdoor units. NSF-approved flooring isn't just a nice-to-have – it's essential for meeting health codes and ensuring safety. Look for non-slip floors that can handle the specific demands of your operation. Need to roll hand trucks around? You'll want flooring rated for 1000 PSF. Planning to use pallet jacks? Go for pallet jack rated floors at 2500 PSF. Some applications even require reinforced floors capable of handling 5000 PSF for heavy-duty operations.

Door selection deserves special attention in outdoor applications. Your doors need heavy-duty hinges, magnetic seals that actually seal, interior safety releases for emergencies, and diamond kick plates to handle the inevitable bumps and scrapes. Don't forget rain hoods – they're not optional for outdoor doors. For detailed guidance on making the right choice, our Beginners Guide to Choosing the Right Cooler Doors covers everything you need to know.

Choosing the Right Materials for an Exterior Walk In Cooler

Here's where material science meets practical reality. Fiberglass exteriors are game-changers for outdoor coolers, and the reason is simple physics. Fiberglass has terrible thermal conductivity – and that's exactly what you want. While metal exteriors act like heat sponges, absorbing and storing solar energy that your refrigeration system then has to fight against, fiberglass just shrugs off the heat.

Seamless construction takes this advantage even further. A 100% seamless fiberglass design creates an unbroken thermal barrier that keeps your insulation completely intact. No gaps, no thermal bridges, no moisture infiltration points where bacteria can take hold. This matters especially when you're dealing with sun exposure, driving rain, heavy snow loads, or corrosive salt air.

Metal exteriors aren't necessarily bad, but they come with challenges. Steel and aluminum are natural heat conductors, which means they're constantly absorbing solar energy and transferring it toward your cooled space. If you go with metal, choose coated options to prevent oxidation and stick with light, natural colors to minimize heat absorption. Just understand that your refrigeration system will work harder than it would with fiberglass.

The concept of thermal conductivity is crucial here – materials that conduct heat well are your enemy in refrigeration applications. You can learn more about thermal conductivity and how it affects your cooling costs.

Refrigeration Systems and Energy Efficiency

The heart of your exterior walk in cooler is its refrigeration system, and choosing wisely here can save you thousands in operating costs over the unit's lifetime. Top-mounted systems offer the advantage of being self-contained, pre-charged units that install quickly on your cooler's roof. They're straightforward and reliable, though they do put all the mechanical components right on top of your unit.

Remote refrigeration systems take a different approach, separating the heat-rejecting condensing unit from the cooling evaporator. This gives you flexibility in placement – you can put the noisy, heat-generating condenser somewhere more convenient while keeping the evaporator where it needs to be. In many setups, this arrangement actually improves energy efficiency.

Energy consumption varies based on size and application, but most systems fall in the 1½-3 horsepower range, typically requiring 15-30 amps at 208-230 volts, 3-phase power. The key is ensuring DOE compliance – modern units must meet strict Department of Energy guidelines for efficiency.

Here's something fascinating: climate impact on efficiency works differently than most people expect. Cold weather actually helps your exterior walk in cooler run more efficiently, since there's less heat load to fight against. Hot climates demand thicker insulation and specialized roof options, while cold regions need low ambient controls to keep the refrigeration system operating properly when outdoor temperatures drop.

The high temperature differential (TD) that outdoor units face – the big difference between internal and external temperatures – requires robust, well-engineered systems that can handle the constant thermal stress. For help selecting the right refrigeration setup for your specific needs, our Quick Start Guide to Finding a Walk-in Refrigeration Unit breaks down all the key considerations.

Types, Sizing, and Customization

Finding the right exterior walk in cooler for your facility means understanding your options. The good news? There's incredible flexibility in both standard and custom solutions. Whether you need something off-the-shelf or completely custom to your unique requirements, modern exterior coolers can adapt to virtually any situation.

The beauty of today's market is that you're not locked into cookie-cutter solutions. Standard sizes work perfectly for many operations, while custom dimensions ensure you maximize every square foot of available space. For a comprehensive look at what's available, explore our Chill Out with These Walk-in Cooler Solutions guide.

Standard Models: Coolers, Freezers, and Combos

When it comes to temperature requirements, walk-in coolers maintain that sweet spot between 35°F and 55°F, making them perfect for fresh storage needs. These units handle everything from produce to pharmaceuticals with consistent, reliable cooling.

Walk-in freezers take things to the next level with sub-zero temperatures designed for long-term frozen storage. The engineering behind these units is impressive - they're built to maintain consistent freezing temperatures even when fighting against outdoor heat.

Here's where things get really interesting: dual-temperature combo units combine both cooling and freezing in one exterior structure. Each section operates independently with its own door and controls. It's like getting two units for the space of one, which is brilliant for operations with limited outdoor space.

For urgent needs, Quick Ship models can be a lifesaver. These pre-designed units in standard sizes like 8'x10' or 8'x12' ship in as little as 10 days. They arrive fully assembled and ready to connect - just add power and you're operational.

The modular panel approach used in most standard units offers surprising flexibility. These precision-formed panels snap together for rapid assembly, but they also mean you can expand later if your needs grow.

The Advantages of a Custom-Built Unit

Sometimes standard just doesn't cut it, and that's where custom-built exterior walk in cooler solutions shine. The level of customization available today is remarkable.

Specific dimensions mean you can maximize awkward spaces or fit exact requirements. Custom widths from 6' to 16' and lengths extending up to 60' or more ensure your unit fits your space, not the other way around.

Door placement becomes crucial in custom designs. You control exactly where doors go, how they open, and even their size. This isn't just about convenience - proper door placement can dramatically improve workflow efficiency and reduce energy loss.

Custom finishes let your exterior cooler blend seamlessly with existing architecture. Beyond standard metal or fiberglass, you can specify brick facades, stone finishes, or specific paint colors. Your cooler doesn't have to look like industrial equipment if that doesn't fit your facility's aesthetic.

For larger installations, internal steel support provides additional structural integrity. This becomes especially important in areas with high wind loads or seismic activity.

The real advantage of custom units is meeting specific operational needs. Whether you need specialized shelving systems, unique entry configurations, or specific internal layouts, custom manufacturing ensures your unit works exactly how you need it to.

Many manufacturers now offer design tools to help visualize your ideal setup. You can actually design your own unit to explore possibilities and get accurate pricing before making final decisions.

The scalability factor shouldn't be overlooked either. Both standard and custom units can often be expanded later as your needs grow, making them a smart long-term investment for growing operations.

Installation, Maintenance, and Long-Term Value

Properly installing your exterior walk in cooler is like laying the foundation for years of reliable service. It's an investment that pays dividends through improved operations and durability, but success depends on doing things right from day one.

The beauty of outdoor units lies in their longevity when properly maintained. Well-cared-for exterior coolers can serve businesses faithfully for decades, delivering consistent performance while freeing up valuable indoor space.

Site Preparation and Installation Checklist

Before your exterior walk in cooler arrives, proper groundwork makes all the difference between a smooth installation and costly headaches down the road.

The concrete pad is your unit's foundation - literally. This level, stable surface needs to support not just the cooler itself, but everything you'll store inside. A properly poured pad also ensures good drainage, preventing water from pooling around your investment.

Electrical connections require professional attention. Most units need anywhere from 115 volts to 208/230 volts, depending on size and refrigeration requirements. Having a licensed electrician handle this work isn't just smart - it's often required by local codes and necessary for warranty coverage.

Don't forget about local building codes and permits. Outdoor structures face unique challenges that indoor units never encounter. Your area might have specific requirements for wind resistance, snow loads, or seismic considerations. Some states require engineering stamps or wet-stamped documents, especially for larger custom units.

Site accessibility often gets overlooked until delivery day arrives. Make sure trucks can reach your installation site, especially if you've chosen a fully assembled unit. Nothing's more frustrating than finding your new cooler can't actually get where it needs to go.

For a complete breakdown of what to expect financially, check out our detailed guide on walk-in cooler installation costs.

Understanding Costs and Warranty Coverage

Let's talk numbers, because understanding the full cost picture helps you make the smartest decision for your business.

Initial purchase prices for standard exterior units typically range from around $8,000 to over $24,000, but that's just the starting point. Installation costs, operational expenses, and site preparation all factor into your total investment.

Several key factors influence your final price. Size and dimensions obviously matter - larger units need more materials and bigger refrigeration systems. Insulation thickness affects both upfront costs and long-term energy savings. Material choices between fiberglass and metal exteriors can impact pricing, though fiberglass often pays for itself through energy efficiency.

Refrigeration system type also plays a role. Top-mounted units versus remote systems each have different cost structures. Flooring options from basic to heavy-duty pallet jack rated floors add varying amounts to your total. Custom features like unique dimensions, special finishes, or additional doors naturally increase costs but deliver exactly what your operation needs.

Here's where smart buying pays off: Quick Ship models often cost less than custom builds due to standardization, while still delivering professional-grade performance.

Warranty coverage protects your investment in ways that matter most. Panel warranties often stretch 10 to 20 years, reflecting manufacturers' confidence in their construction. Compressor warranties typically cover 5 years on this critical component. Labor and parts warranties usually provide 1-year coverage on refrigeration components and installation work.

Always clarify what's covered and what isn't. Accidents, improper installation, or neglected maintenance can void coverage. Many manufacturers provide warranty lookup tools to help you track your protection.

For pricing insights specific to different unit types, our walk-in freezer price guide offers valuable perspective.

Maintenance Needs for an Exterior Walk In Cooler

Here's the truth about exterior walk in cooler maintenance: a little attention goes a long way toward protecting your investment and ensuring peak performance.

Routine cleaning keeps your unit looking professional and operating efficiently. Seamless fiberglass exteriors make this job surprisingly easy - often just requiring a good hose-down to look like new. Interior cleaning follows standard food safety protocols, maintaining the hygienic environment your business demands.

Door gaskets deserve special attention because they're your first line of defense against energy loss. Check them regularly for wear, tears, or compression damage. A damaged gasket might seem minor, but it can significantly impact operating costs by forcing your refrigeration system to work overtime.

Panel seals and joints need periodic inspection too. Look for any cracks or deterioration that could allow moisture or air infiltration. Catching these issues early prevents bigger problems later.

Professional refrigeration system service isn't optional - it's essential. This includes cleaning condenser coils, checking refrigerant levels, and inspecting electrical components. Think of it like regular oil changes for your car - small investments that prevent major breakdowns.

Roof maintenance is unique to outdoor units but straightforward. Clear leaves, snow, and debris regularly to prevent damage and ensure proper drainage. Your membrane or standing seam roof is engineered to handle weather, but it needs clear pathways to do its job.

The average lifespan of your outdoor walk-in depends heavily on how well you maintain it. Environmental factors play a role, but proactive care consistently extends equipment life far beyond neglected units.

When you need professional help, finding the right service provider matters. Our guide to walk-in cooler service and repair helps you locate reliable professionals who understand outdoor units' unique requirements.

Frequently Asked Questions about Exterior Walk-In Coolers

When considering an exterior walk in cooler for your facility, you probably have questions about what works, what doesn't, and what factors really matter. Let's explore the most common concerns we hear from professionals in the field.

Can an indoor walk-in cooler be used outdoors?

The short answer is absolutely not, and here's why this matters more than you might think. While indoor and outdoor units might look similar at first glance, they're built for completely different environments - kind of like comparing a house cat to a mountain lion.

Indoor units simply aren't built for the great outdoors. They lack weatherproofing systems that protect against rain, snow, and UV exposure. Without these protections, you're looking at panel degradation, water infiltration, and structural damage that can happen surprisingly quickly.

The insulation story is even more telling. Indoor units typically use thinner insulation because they're designed for stable indoor temperatures. Put them outside, and they'll struggle against direct sunlight and extreme temperature swings. This leads to massive energy waste and potential system failure - not exactly what you want when storing temperature-sensitive materials.

Structural risks are another major concern. Outdoor units are specifically engineered to handle wind loads, snow loads, and seismic activity. Indoor units lack this reinforcement, which creates genuine safety risks for your facility and staff.

Perhaps most importantly, using an indoor unit outdoors will void its warranty completely. That means you're on your own for any resulting damage - and trust us, there will be damage.

How does climate affect the design of an outdoor cooler?

Climate plays a huge role in how your exterior walk in cooler should be designed, and understanding these factors can save you both money and headaches down the road.

Hot climates demand thicker wall insulation to combat intense heat absorption. Think of it as putting on a heavier coat - you need more protection when the outside temperature is working against you. Light, natural exterior colors work best here because they reflect sunlight rather than absorbing it. Specialized roof options, like highly reflective membrane roofs, can also make a significant difference in performance.

Cold climates actually offer some advantages. Outdoor walk-ins can be more energy-efficient in colder environments because the refrigeration system doesn't have to work as hard to remove heat. However, they need specialized components like low ambient controls to ensure proper operation in freezing temperatures. Snow load ratings become critical for roof design too.

Coastal areas present their own unique challenges due to salt air corrosion. In these regions, materials like fiberglass or specially coated metals become essential for preventing oxidation and ensuring long-term durability.

The key is working with professionals who understand your specific climate conditions and can recommend the right combination of features for your location.

What are the main differences between fiberglass and metal exteriors?

The exterior material choice significantly impacts both performance and longevity of your exterior walk in cooler, and the differences are more dramatic than most people realize.

Fiberglass exteriors are natural insulators that absorb very little heat due to their properties against thermal conductivity. This is a game-changer for energy efficiency. Metal and steel exteriors, on the other hand, are actual heat conductors that absorb and store heat from direct sunlight. This forces your refrigeration system to work overtime, leading to increased electricity consumption and reduced equipment lifespan.

Durability tells an interesting story too. Fiberglass resists rust, dents, and corrosion naturally, making it ideal for harsh outdoor environments. This includes areas with high moisture or salt exposure where metal might struggle. Metal exteriors, especially untreated steel, are more susceptible to rust and impact damage, though coated metal options can help prevent oxidation.

Seamless construction is where fiberglass really shines. Many fiberglass units feature completely seamless designs that create a continuous surface. This keeps the insulated structure intact and prevents moisture damage and bacteria formation. While panelized metal units are well-sealed, they naturally have more joints where moisture could potentially intrude over time without proper maintenance.

The choice often comes down to your specific environment and long-term operational goals, but understanding these fundamental differences helps you make the right decision for your facility.

Conclusion

Choosing an exterior walk in cooler represents far more than simply adding storage space to your facility—it's a smart business decision that can transform how you operate. Throughout this guide, we've explored how these specialized units free up precious interior square footage while delivering reliable, weather-resistant cold storage that actually performs better in many climates than you might expect.

The key takeaways are clear: proper design matters immensely. From the superior thermal resistance of urethane insulation to the weatherproof protection of membrane roofing systems, every component works together to create a storage solution that stands strong against the elements. The choice between fiberglass and metal exteriors isn't just about appearance—it directly impacts your energy costs and long-term durability.

Space maximization becomes reality when you move refrigeration outdoors. That freed-up interior space can be transformed into additional work areas, dry storage, or expanded operations. Meanwhile, you're reducing indoor noise and heat load, creating a more comfortable environment for your team.

Operational efficiency improves through thoughtful planning. Whether you choose a quick-ship standard model or invest in a custom-built unit custom to your exact specifications, the result is a refrigeration system designed to handle your specific needs while meeting all regulatory requirements.

At Walk-In Cooler Authority, we understand that reliable refrigeration isn't just about keeping things cold—it's about maintaining the highest standards of professionalism and compliance in critical situations. Our expertise in OSHA-compliant solutions ensures you get equipment that meets the unique demands of mortuary and funeral service operations.

For a complete overview of mortuary-specific refrigeration solutions, explore our Complete Authority Guide to Walk-In Mortuary Coolers in 2025.