Why ThermalRite Dominates Commercial Cold Storage

ThermalRite represents more than 80 years of cold-storage innovation, delivering modular walk-in coolers and freezers engineered for demanding commercial applications. As an Everidge brand founded in California in 1988, ThermalRite has built an outstanding reputation for product quality and custom engineering solutions.

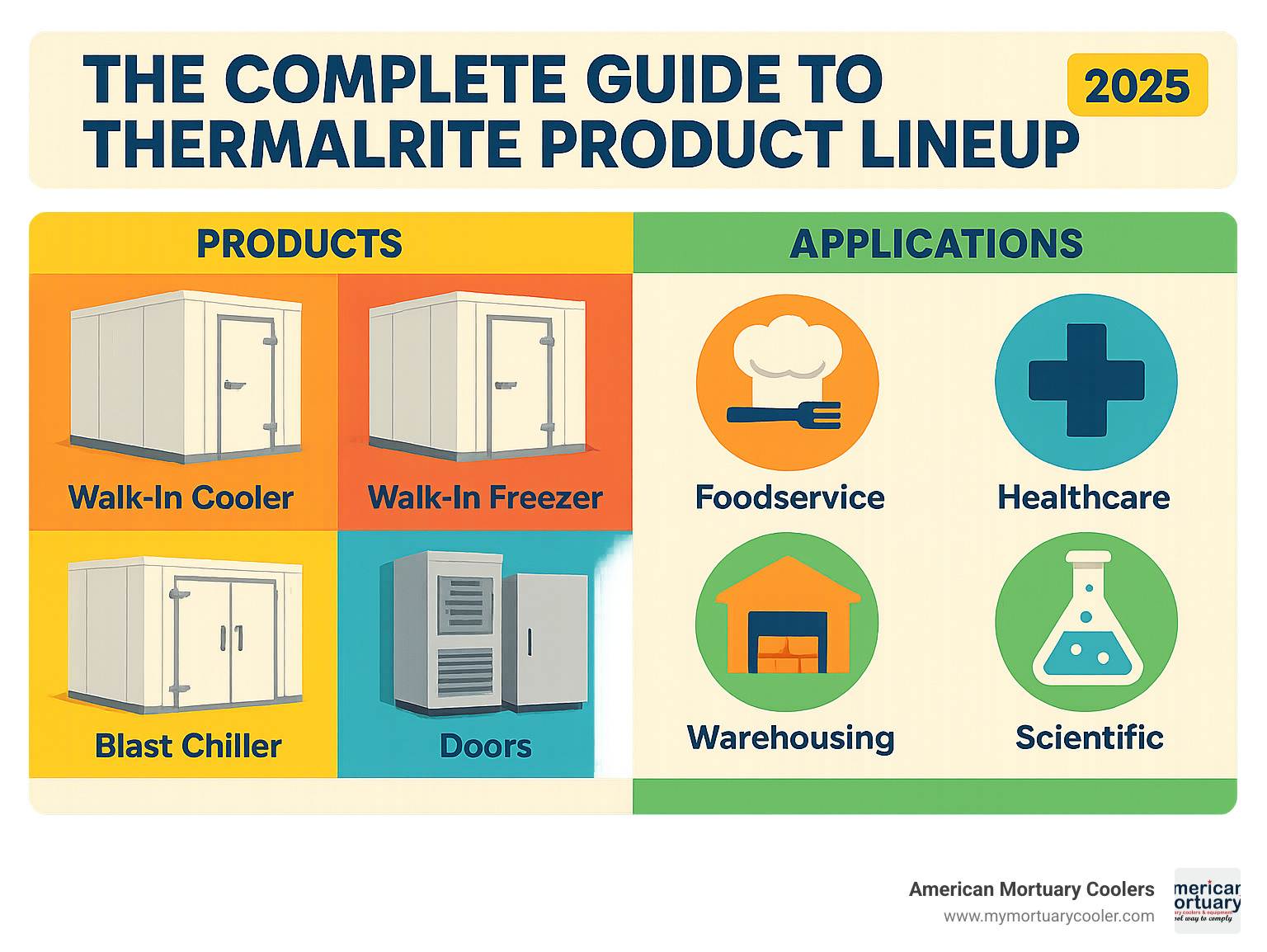

Quick ThermalRite Overview:

- Product Range: Walk-in coolers, freezers, combo units, blast chillers, doors, and parts

- Key Industries: Restaurants, healthcare facilities, cafeterias, warehouses, scientific labs

- Insulation Performance: R-32 rating for freezers (exceeds the R-25 requirement)

- Construction: Modular design with foamed-in-place polyurethane panels

- Customization: Flexible sizing for indoor or outdoor installations

ThermalRite’s modular construction techniques allow precise customization for diverse kitchen environments, from cramped restaurant spaces to expansive institutional facilities. Their cam-lock panel system and superior insulation deliver both energy efficiency and long-term durability — critical factors for operations where temperature control directly impacts product quality and regulatory compliance.

Whether you manage a busy hospital cafeteria or plan cold storage for a new restaurant, understanding ThermalRite’s capabilities helps you make informed equipment decisions that protect your investment and operational efficiency.

I’m American Mortuary Coolers, a national-level commercial refrigeration supplier specializing in ThermalRite systems. With extensive experience helping funeral homes and commercial operators select optimal cold-storage equipment, we’ve seen how the right walk-in cooler choice impacts daily operations and long-term costs.

Key thermalrite applications:

Why This Guide Matters

In temperature-critical operations, equipment failure isn’t just inconvenient — it’s catastrophic. We’ve witnessed restaurants lose thousands of dollars in spoiled inventory and funeral homes face regulatory violations due to inadequate cold storage. Understanding ThermalRite’s engineering advantages helps you avoid these costly scenarios while optimizing energy costs that can represent 15-20% of your facility’s utility expenses.

This comprehensive guide covers everything from ThermalRite’s 80-year heritage to the specific insulation technologies that give the brand its superior performance. Whether you’re replacing aging equipment or planning new construction, we’ll show you why ThermalRite consistently outperforms competitors in both reliability and operational efficiency.

Meet ThermalRite: History, Products & Brand Strengths

Picture this: It's the 1940s, and American businesses are just beginning to understand the power of commercial refrigeration. That's when ThermalRite's story began, growing from those early days into what would become one of the most trusted names in cold storage.

The modern ThermalRite company took shape in California back in 1988, but it carries the DNA of nearly 80 years of refrigeration innovation. As part of the Everidge brand family, they've built something special - a company that truly understands what happens when temperature control goes wrong.

We've seen it firsthand. A restaurant loses $10,000 worth of inventory overnight. A funeral home faces regulatory issues because their cooling system couldn't maintain proper temperatures. These aren't just business problems - they're the kind of crises that keep owners awake at night.

That's exactly why ThermalRite has spent decades perfecting their craft. They don't just make walk-in coolers and freezers - they engineer complete cold storage ecosystems. From the smallest replacement door gasket to massive combo units that serve entire institutional kitchens, they've got every piece of the puzzle covered.

What really sets them apart is their approach to custom work. While other manufacturers might say "pick from these five standard sizes," ThermalRite asks "what do you actually need?" Their modular design philosophy means they can build solutions for the tightest urban restaurant space or the most sprawling warehouse operation.

View fullsize | Visit the ThermalRite website

ThermalRite Walk-In Coolers & Freezers Portfolio

ThermalRite's product lineup reads like a cold storage wish list. Their indoor models start small - think 6x6 units perfect for cozy restaurants - and scale up to warehouse giants that stretch 40x40 feet or more. Each one built with the same attention to detail, whether you're storing a few cases of beer or managing inventory for a major food distributor.

The outdoor models are where things get interesting. These units face whatever Mother Nature throws at them - blazing summer heat, freezing winter cold, driving rain - while keeping your products at exactly the right temperature inside. The weather-resistant construction and improved insulation make them incredibly reliable, even in challenging climates.

Beer caves have become a specialty of theirs, especially with craft breweries popping up everywhere. These aren't just cold boxes - they're designed to showcase products while maintaining the precise temperatures that keep beer at its absolute best.

But perhaps the most ingenious solution is their combo units. Picture a funeral home with limited space that needs both refrigerated and frozen storage. A combo unit delivers both temperature zones in a single footprint, maximizing versatility without eating up precious square footage.

Why ThermalRite Stands Out

When you peek inside a ThermalRite panel, you'll find 4-inch polyurethane insulation that puts most competitors to shame. This isn't just about meeting minimum standards - it's about exceeding them by such a wide margin that your energy bills will thank you for years to come.

Their cam-lock system is pure engineering genius. Panels connect with precision, creating airtight seals that don't require specialized tools or a PhD in refrigeration to install. We've watched installation crews put these systems together, and it's almost satisfying how perfectly everything fits.

Quality certifications matter in this business, and ThermalRite doesn't mess around. UL and NSF approvals across their product line mean you're not just getting a cold box - you're getting equipment that meets the highest safety and sanitation standards.

Here's where the numbers get impressive: their coolers deliver R-25 or better insulation performance, while freezers hit R-32 ratings. That's significantly higher than many competitors, and it translates directly into lower energy costs and rock-solid temperature stability.

Where ThermalRite Fits: Industries, Applications & Case Studies

When you're in the business of keeping things cold, you quickly learn that every industry has its own unique challenges. ThermalRite has spent decades mastering these different needs, and frankly, they've gotten pretty good at it.

Foodservice operations form the backbone of ThermalRite's business. Walk into any busy restaurant kitchen, and you'll likely find their equipment quietly doing its job. From corner bistros storing fresh produce to massive institutional catering facilities preparing thousands of meals daily, ThermalRite units handle the temperature-critical work that keeps food safe and businesses running.

Healthcare facilities present some of the most demanding applications we encounter. Hospitals and clinics need pharmaceutical storage that never fails, meal preparation areas that meet strict health codes, and specialized laboratory spaces where a few degrees can make the difference between successful research and ruined samples.

Warehousing and distribution operations appreciate ThermalRite's ability to think big. These facilities need custom configurations that maximize every cubic foot of storage while keeping products easily accessible for busy inventory teams. Scientific laboratories add another layer of complexity, requiring sample storage solutions that maintain precise conditions for months or even years.

The beer cave market has exploded in recent years, and ThermalRite has responded beautifully. Craft breweries, distributors, and retail stores need systems that not only keep beer at perfect temperatures but also create attractive displays that make customers want to buy.

We've also seen growing interest from the mortuary industry, where ThermalRite's rock-solid reliability meets the sensitive nature of funeral home operations. These applications demand both technical excellence and respect for the special circumstances that funeral directors steer every day.

The Ultimate Guide to Walk-In Coolers: Options & Features

Real-World Success Stories

We recently worked with a central kitchen operation for a major university system that needed to completely rethink how they fed students across multiple campuses. The challenge was massive: prepare thousands of meals in one location, then distribute them while maintaining both quality and food safety standards. The ThermalRite solution included multiple combo units and specialized blast chillers that let the kitchen team cook, chill, and ship meals with confidence.

University cafeterias face their own unique pressures. High volume, tight budgets, and students who definitely notice when something goes wrong. One campus we worked with needed storage that could handle everything from fresh salad ingredients to frozen desserts, all within a kitchen space that hadn't been updated since the 1980s. ThermalRite's modular design let us create a custom solution that tripled their storage capacity without major construction.

Healthcare facilities push equipment to its limits. A regional hospital came to us needing pharmaceutical storage that could maintain temperatures within incredibly narrow ranges while giving nursing staff quick access during emergencies. The custom ThermalRite solution included specialized door configurations and internal organization systems that satisfied both regulatory inspectors and the medical teams who use the equipment daily.

Application-Specific Advantages

Temperature precision separates the professionals from the pretenders in commercial refrigeration. ThermalRite's advanced insulation and tight construction tolerances create remarkably stable internal environments. This means compressors don't have to work as hard, equipment lasts longer, and your energy bills stay reasonable.

Space optimization becomes crucial when every square foot costs money. Urban restaurants and healthcare facilities often work with spaces that were never designed for modern refrigeration needs. ThermalRite's modular design maximizes storage capacity within whatever space you have while maintaining workflow patterns that actually make sense for daily operations.

Combo boxes solve one of the most common problems we encounter: needing both refrigerated and frozen storage but not having room for separate units. Instead of cramming two units into inadequate space, a single ThermalRite combo provides both temperature zones with shared infrastructure.

Inside a ThermalRite Walk-In: Features, Insulation & Modular Engineering

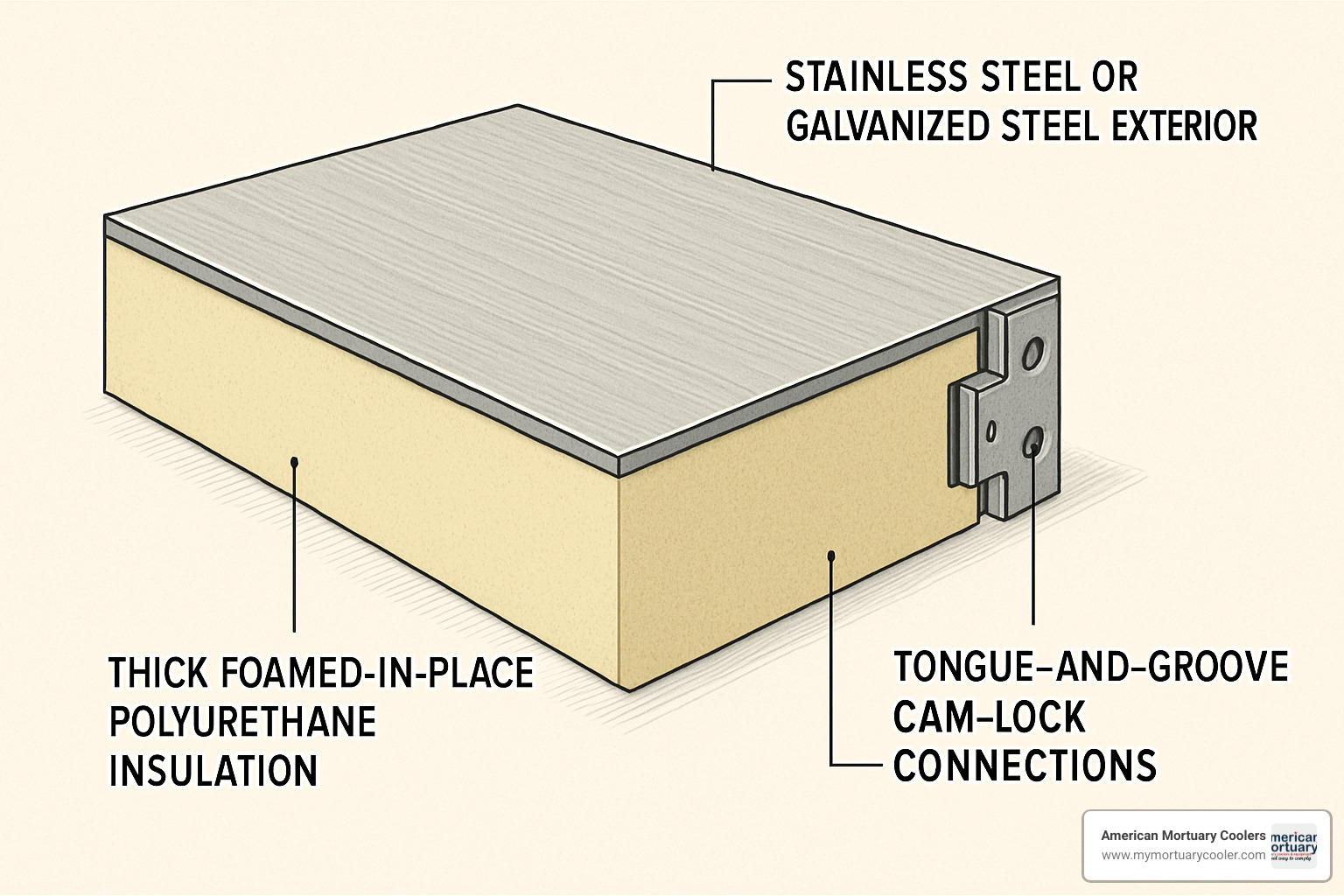

When you step inside a ThermalRite walk-in, you're experiencing the result of decades of cold storage engineering. What you can't see - the foamed-in-place polyurethane insulation - makes all the difference in performance and energy costs.

Unlike cheaper alternatives that piece together pre-formed panels, ThermalRite creates each unit with continuous insulation that eliminates gaps and weak spots. This process delivers their impressive R-32 performance for freezers while easily exceeding the R-25 requirement for coolers that federal energy standards demand.

The magic happens in their cam-lock tongue-and-groove connection system. Each panel edge features precision-machined profiles that lock together like a perfect puzzle. No gaskets needed, no messy sealants - just clean, airtight connections that stay tight even when panels expand and contract with temperature changes.

You'll notice the quality in the finishes too. Stainless steel surfaces provide superior corrosion resistance and easy cleaning for busy kitchens, while galvanized finishes offer excellent durability at lower cost when appearance isn't the primary concern.

The gasketed seams between panels create an additional barrier against air infiltration. Combined with ThermalRite's precision manufacturing, these seams help maintain stable internal temperatures while reducing the workload on your refrigeration system.

Flooring choices range from standard insulated panels to heavy-duty systems designed for high-traffic areas or wash-down applications. The floor system integrates seamlessly with wall panels, eliminating thermal bridges that waste energy and create condensation problems.

Everything You Need to Know About Walk-In Cooler Panels

Energy Efficiency Technologies

Modern ThermalRite units pack impressive energy-saving technology that translates directly into lower utility bills. The EC fans (electronically commutated) automatically adjust their speed based on actual cooling demand. Instead of running full blast constantly, they dial up or down as needed, saving energy while improving temperature consistency.

High-efficiency compressors use advanced refrigerants like R-448A that provide better cooling performance while reducing environmental impact. These systems often qualify for utility rebates that help offset initial equipment costs while delivering ongoing energy savings month after month.

Smart controls allow remote monitoring and adjustment of operating parameters. You can spot potential problems before they cause equipment failure or temperature excursions, and optimize energy consumption based on actual usage patterns.

Quality & Compliance

ThermalRite doesn't cut corners on quality control. Their ISO procedures ensure consistent manufacturing from panel fabrication through final assembly and testing. Every unit undergoes factory test-assembly to verify proper fit and finish before shipping - eliminating costly surprises during installation.

UL certification confirms that electrical components and overall system design meet rigorous safety standards for commercial refrigeration equipment. NSF7 certification verifies that food contact surfaces and overall design meet sanitation requirements for food service applications.

EISA compliance ensures insulation performance meets federal energy efficiency requirements, though ThermalRite units typically exceed these minimums. This provides additional energy savings and future-proofs your investment against potential regulation changes.

Custom Options, Installation & Lifetime Support

One of the most impressive aspects of working with ThermalRite is their genuine commitment to making each unit fit your exact needs. Their modular construction isn't just a marketing buzzword - it's an engineering approach that opens up possibilities other manufacturers simply can't match.

We've worked with customers who needed everything from tiny 6x6 coolers squeezed into cramped restaurant basements to sprawling warehouse installations that seem to go on forever. The beauty of ThermalRite's system is that size becomes almost irrelevant. Need an oddly-shaped unit to fit around existing plumbing? No problem. Want a door positioned in what seems like an impossible location? They'll make it work.

Door placement flexibility really shines when you're dealing with challenging spaces. We recently helped a funeral home that needed access from three different directions due to their unique layout. ThermalRite positioned doors exactly where they needed them without compromising the unit's structural integrity or thermal performance.

Glass display fronts transform ordinary cold storage into something special. These aren't just functional - they're genuinely attractive. We've seen restaurants use them to showcase premium ingredients and breweries create stunning beer displays that customers love to photograph.

Floor systems deserve special attention because they're often overlooked until installation day. ThermalRite offers everything from flush-mounted systems that blend seamlessly with existing floors to raised configurations that make cleaning underneath much easier.

When it comes to refrigeration, you've got real choices. Remote systems keep noisy compressors away from customer areas, which is particularly important in funeral homes where quiet operation matters. Self-contained units work beautifully when you need everything in one compact package or when running refrigeration lines isn't practical.

The Definitive Guide to Custom Walk-In Cooler Options

Modular Construction Benefits

The modular approach pays dividends long after installation. We've seen too many businesses outgrow their cold storage and face the painful choice between cramped operations or expensive replacement. With ThermalRite, expansion often means adding panels rather than starting over.

One of our restaurant clients started with a modest cooler and has expanded it twice as their business grew. Each expansion took just a few days and cost a fraction of what new equipment would have required. That's the kind of flexibility that helps businesses adapt and thrive.

Installation downtime gets minimized because everything fits together predictably. ThermalRite's factory test-assembly process means our installation crews know exactly what to expect. No surprises, no delays, no frustrated customers waiting to get back to business.

Warranty & After-Sale Care

ThermalRite stands behind their work with warranties that reflect real confidence in their manufacturing quality. Twenty-year panel coverage isn't just impressive - it's reassuring when you're making a significant investment in your operation. Five-year refrigeration warranties cover both parts and labor, which matters when service calls can be expensive.

Nationwide parts availability means you're not stuck waiting weeks for components, regardless of where your business operates. ThermalRite maintains distribution networks that understand the urgency of cold storage repairs. When your cooler goes down, every hour counts.

At American Mortuary Coolers, we add another layer of support through our regional presence across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania. When ThermalRite customers need service or support, our proximity means faster response times and better understanding of local conditions that might affect equipment performance.

ThermalRite vs Competing Brands & FAQs

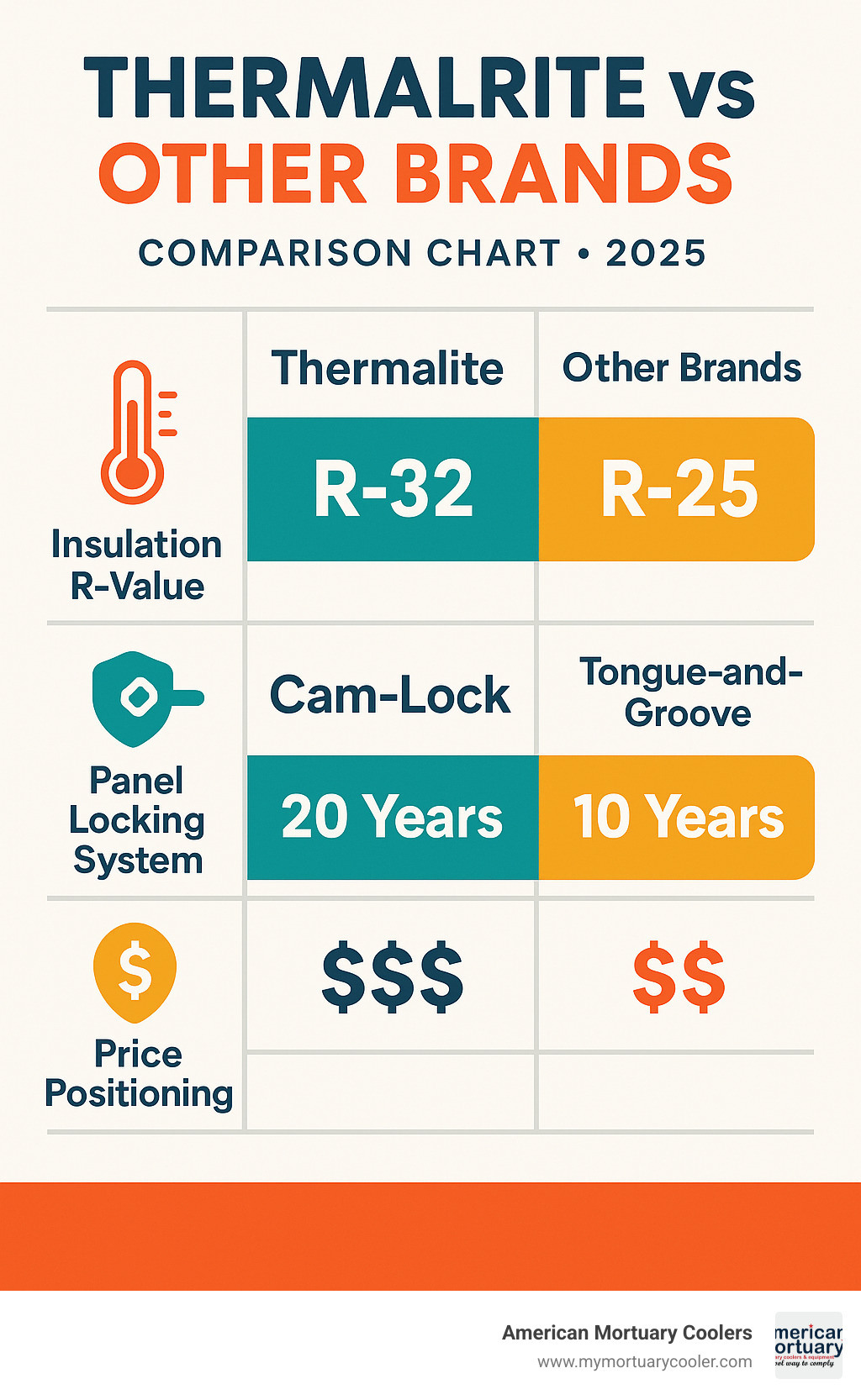

After working with hundreds of commercial refrigeration installations, I've learned that choosing between ThermalRite, Norlake, and U.S. Cooler often comes down to understanding what you're really paying for. The differences aren't always obvious at first glance, but they become crystal clear once you dig into the details.

ThermalRite's R-32 freezer insulation and R-25+ cooler performance consistently outperform most competitors by 15-20%. That might not sound like much on paper, but it translates into real money saved every month on your electric bill. When we installed a ThermalRite system for a busy restaurant chain, they noticed the difference in their utility costs within the first billing cycle.

The cam-lock panel system sets ThermalRite apart from simpler tongue-and-groove designs you'll find elsewhere. I've watched installation crews work with both systems, and the difference is night and day. ThermalRite panels snap together with precision, creating airtight seals that last for decades.

Warranty coverage tells you everything about a manufacturer's confidence in their product. ThermalRite's 20-year panel warranty beats most competitors by a wide margin, while their 5-year refrigeration coverage protects your entire investment.

Yes, ThermalRite typically costs 10-15% more upfront than economy alternatives. But here's what I tell customers: you're not just buying a cooler, you're buying decades of reliable operation. The superior insulation and build quality often pay for themselves within 2-3 years through energy savings alone.

How Does ThermalRite Compare on Energy Use?

The energy savings with ThermalRite are impressive, and they start showing up immediately. That higher R-value insulation means your compressor doesn't work as hard to maintain temperature. Instead of constantly cycling on and off, the system runs more efficiently with longer, gentler cycles.

We installed a ThermalRite freezer for a funeral home that replaced a 15-year-old unit from another manufacturer. Their energy usage dropped by nearly 30% overnight. The owner called me three months later, amazed at how much his electric bill had decreased.

Shorter compressor cycles don't just save energy - they extend equipment life. When refrigeration components aren't constantly starting and stopping, they last longer and need fewer repairs. I've seen ThermalRite units run for 15+ years with minimal maintenance, while some competitors need major service every few years.

What Customization Lead Times Should I Expect?

Most ThermalRite custom orders take 4-6 weeks from confirmation to delivery. That includes engineering review, manufacturing, and their factory test-assembly process that ensures everything fits perfectly before shipping. It's not the fastest turnaround in the industry, but the quality control is worth the wait.

Rush options are available when you're facing an emergency situation. We've gotten expedited delivery for customers dealing with equipment failures, though it typically costs extra and depends on current production schedules.

Are ThermalRite Units Easy to Maintain?

The modular construction makes ThermalRite units surprisingly easy to maintain. Individual panels can be removed for deep cleaning or replacement without tearing apart the entire system. I've watched maintenance crews work on both modular and traditional walk-ins, and the difference in time and effort is remarkable.

Gasket replacement is the most common maintenance task you'll face. ThermalRite uses standardized gasket profiles that are readily available and easy to install. Most facility maintenance staff can handle gasket replacement with basic tools, saving the cost of service calls for routine maintenance.

The Complete Guide to Walk-In Cooler Features and Prices

Conclusion & Next Steps

After eight decades of innovation, ThermalRite has earned its reputation as the gold standard in commercial walk-in refrigeration. Their combination of superior engineering, energy efficiency, and rock-solid reliability makes them the smart choice when your operation can't afford temperature failures.

We've seen how the right cold storage equipment transforms businesses. The difference between a struggling restaurant constantly battling spoiled inventory and a thriving operation often comes down to choosing reliable refrigeration that just works, day after day.

ThermalRite's modular design philosophy means you're not just buying equipment - you're investing in flexibility. Need to expand next year? Add more panels. Moving locations? Take your investment with you. This adaptability has saved our clients thousands of dollars over the years.

Why American Mortuary Coolers Partners with ThermalRite

At American Mortuary Coolers, we've built lasting relationships by delivering solutions that exceed expectations. Our experience spans from intimate funeral homes in small Tennessee towns to major institutional facilities across the country. ThermalRite consistently delivers the performance our clients demand.

The energy savings alone often justify the investment. We've helped clients reduce their refrigeration costs by 20-30% simply by upgrading to ThermalRite's superior insulation technology. When you factor in reduced maintenance and extended equipment life, the total cost of ownership typically favors ThermalRite over cheaper alternatives.

Our nationwide service network means you're never alone with your investment. With regional presence spanning Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, we provide the local support that keeps your operation running smoothly.

Making Your Decision

Whether you're planning new construction, replacing aging equipment, or expanding your operation, ThermalRite offers proven solutions. Their track record speaks for itself - reliable performance in demanding applications where failure isn't an option.

Ready to explore how ThermalRite can transform your cold storage operations? Our team understands the unique challenges you face and can design solutions that fit your space, budget, and operational requirements.

A Comprehensive Guide to Custom Cooling Solutions

Choose ThermalRite, and choose a partner committed to your long-term success. Because when it comes to protecting what matters most to your business, you deserve equipment that works as hard as you do.